INSTALLATION MANUAL

SUPER MODULAR MULTI SYSTEM AIR CONDITIONER

T-shape branching joints (For R410A)

Model name: RBM-BT14UL, RBM-BT24UL

EH98605001-2

Please read and follow the "PRECAUTIONS FOR SAFETY" in the installation manual for the air conditioner.

• Make sure all the parts listed in the table are included in the package.

• Read the installation manual for the air conditioner regarding the selection of the size and material of the refrigerant pipes.

• Ask an authorized dealer or qualified installation professional to install this product.

• Installation work must be carried out by following this installation manual and using exclusive tools and pipes for the refrigerant R410A.

1English

Thank you for purchasing the “Branching

Joint” for TOSHIBA Carrier Air

Conditioner. Before starting the

installation work, please read this manual

carefully and install the product properly.

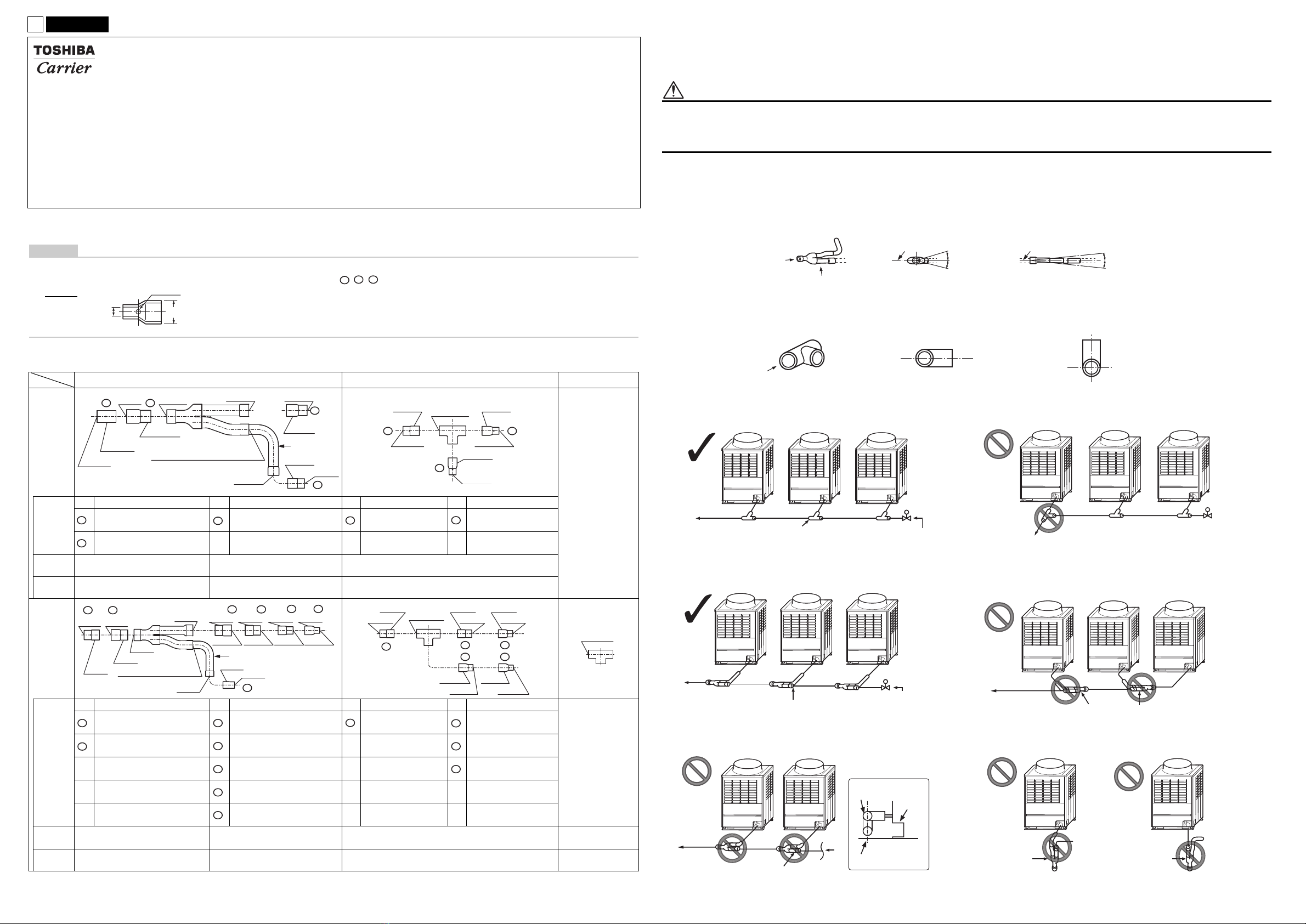

Parts Table

1 ( ): indicates outer diameter.

2 For the sockets, the side with a notch is the one to connect a pipe. ( , , : without notch)

Unit: inch

[Unit: mm]

Gas side joint Liquid side joint Balance pipe joint

RBM-

BT14UL

–

Socket

No. Specifications No. Specifications No. Specifications No. Specifications

Ø1 3/8"×(Ø1 1/4")

[Ø 34.9×(Ø31.8)] 1 pc (Ø1 1/8")×Ø7/8"

[(Ø 28.6)×Ø22.2]

2 pcs

Ø5/8"×(Ø3/4")

[Ø 15.9×(Ø19.1)]

1 pc (Ø3/4")×Ø1/2"

[(Ø19.1)×Ø12.7]

2 pcs

Ø1 1/8"×(Ø1 1/4")

[Ø 28.6×(Ø31.8)] 1 pc

Joint Joint 1 pc

L-pipe (Ø1")×Ø1 1/8"

[(Ø 25.4)×Ø28.6] 1 pc T-joint 3-Ø3/4"

[3-Ø19.1] 1 pc

Heat

insulator Heat insulator for joint 1 pc Heat insulator for L-pipe 1 pc Locally procured

RBM-

BT24UL

Socket

No. Specifications No. Specifications No. Specifications No. Specifications

–

Ø1 5/8"×(Ø1 1/2")

[Ø41.3×(Ø38.1)] 1 pc

(Ø1 1/2")×Ø1 5/8"

[(Ø38.1)×Ø41.3] 1 pc Ø3/4"×(Ø7/8")

[Ø19.1×(Ø22.2)]

1 pc (Ø7/8")×Ø3/4"

[(Ø22.2)×Ø19.1]

1 pc

Ø1 3/8"×(Ø1 1/2")

[Ø34.9×(Ø38.1)] 1 pc (Ø1 1/2")×Ø1 3/8"

[(Ø38.1)×Ø34.9] 1 pc (Ø7/8")×Ø5/8"

[(Ø22.2)×Ø15.9]

2 pcs

(Ø1 1/2")×Ø1 1/8"

[(Ø38.1)×Ø28.6] 1 pc (Ø7/8")×Ø1/2"

[(Ø22.2)×Ø12.7]

1 pc

(Ø1 1/2")×Ø7/8"

[(Ø38.1)×Ø22.2] 1 pc

(Ø1 1/8")×Ø7/8"

[(Ø28.6)×Ø22.2] 1 pc

Joint Joint 1 pc

L-pipe (Ø1 1/4")×Ø1 1/8"

[(Ø31.8)×Ø28.6] 1 pc T-joint 3-Ø7/8"

[3-Ø22.2] 1 pc

T-joint 3-Ø3/8"

[

3-Ø9.5] 1 pc

Heat

insulator Heat insulator for joint 1 pc Heat insulator for L-pipe 1 pc Locally procured Locally procured

61 62

Diameter of the

connecting pipe

External

diameter of

socket

Socket Notch

Ø1 1/8"

Ø7/8"

L-pipe

(Ø1 1/4")

(Ø1 1/8")

Ø1 1/8"

(Ø1 1/8")

Ø7/8"

(Ø1 1/4")

Ø1 3/8" Ø1 1/4" Ø1 1/8"

(Brazed locally) (Ø1")

43

(Ø3/4")

Ø1/2"

Ø1/2"

Ø5/8"

(Ø3/4") 3-Ø3/4"

(Ø3/4")

13

59 43 13

27

(Ø1 1/2")

L-pipe

Ø7/8"

(Ø1 1/8")

Ø1 1/2"

Ø1 5/8"

Ø1 1/8"

Ø1 3/8"

(Ø1 1/2")

Ø1 1/2"

(Brazed locally) (Ø1 1/8")

(Ø1 1/2")

Ø1 5/8" Ø1 3/8" Ø1 1/8" Ø7/8"

71

62

(Ø1 1/2") (Ø1 1/2") (Ø1 1/2")

Ø3/4"

Ø5/8"

Ø3/4" 3-Ø7/8"

(Ø7/8")

18

Ø1/2"

(Ø7/8")

(Ø7/8") (Ø7/8")(Ø7/8")

62 62 18

61 61

71

73

43

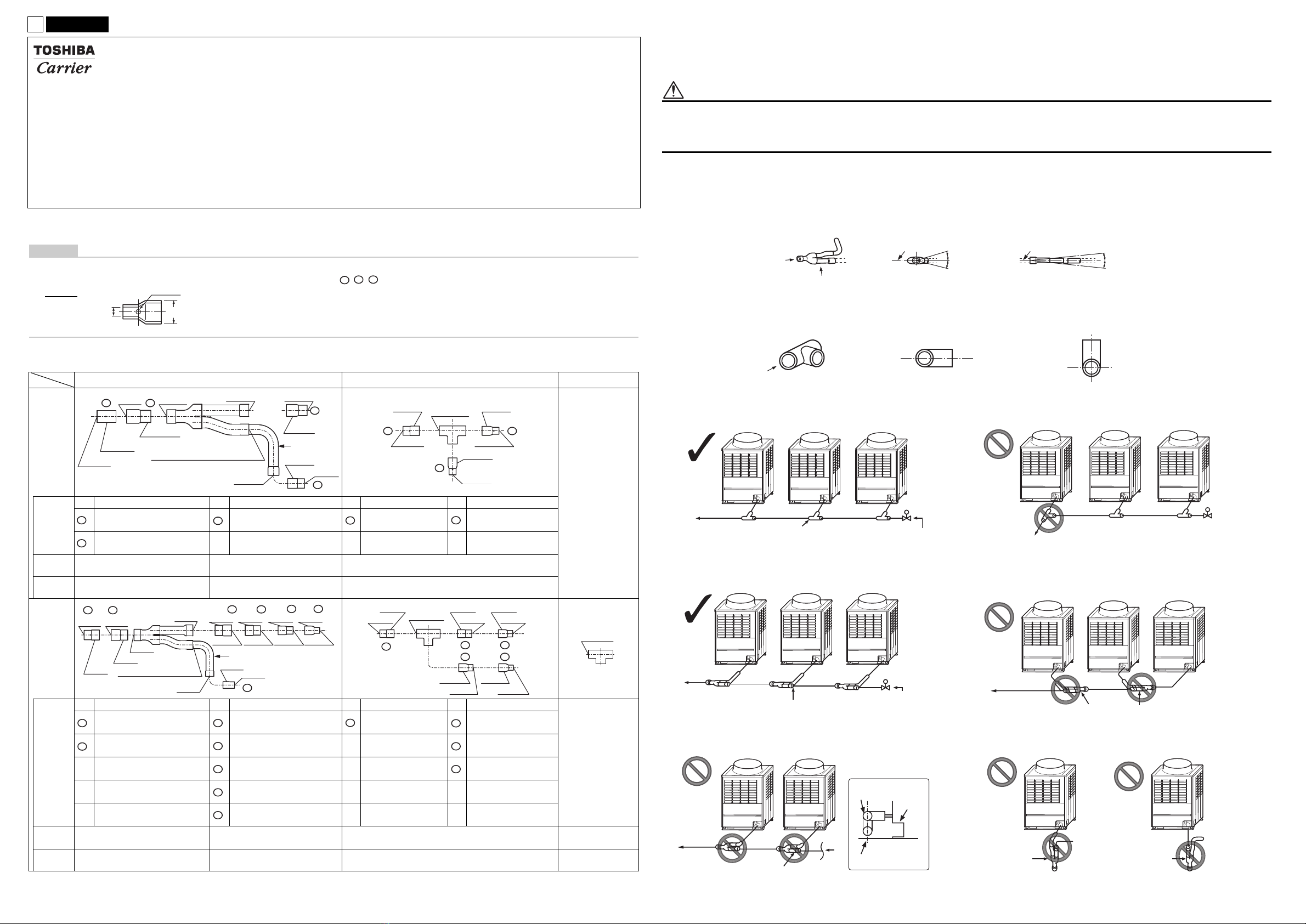

Installation and connection

Select the model and the number of outdoor unit connection piping kits that you need based on the sales catalog, design engineering, and the

data book and installation manual of outdoor unit.

• When brazing the refrigerant pipes, be sure to put the nitrogen first to prevent from oxidizing the inner pipe. If not, the oxidization scale

brings the refrigerant cycle clogging and result in malfunction.

• Use clean new pipes for the refrigerant pipes, and do not let water, moisture or dust get into the pipes during installation.

1Installation mode

<Gas joint>

Install them horizontally with a maximum gradient of ±15° for even distribution. (Do not install them perpendicularly or upright.)

(Figure 4, Figure 5, Figure 6, Figure 7)

<Liquid/balance pipe joint>

No restrictions on the installation orientation by the direction of refrigerant flow. However, on the liquid joint the installation cannot have the

refrigerant from the main pipe flow directly into the header unit. (Figure 2).

▼Liquid pipes

Figure 1 Figure 2

▼Gas pipes

Figure 3 <Gas joint reverse orientation installation>

Figure 4

<Gas joint upright orientation installation>

Figure 5

<Vertical installation>

Figure 6

<Vertical installation>

Figure 7

A

B

Horizontal line

Within ±15°

A view

Horizontal line

B view

Within ±15°

A

Horizontal line

Horizontal line

A view

A view

Header unit A Follower unit B Follower unit C

Main pipe

To indoor unit Liquid joint Extension valve installation site

(For planned system expansion)

Correct

Header unit A Follower unit B Follower unit C

To indoor unit

Main pipe

Incorrect

Header unit A Follower unit B Follower unit C

Main pipe

Gas joint

To indoor unit Extension valve installation site

(For planned system expansion)

Correct

Header unit A Follower unit B Follower unit C

Main pipe

Gas joint

To indoor unit

Incorrect

Gas joint

Header unit A Follower unit B

Main pipe

Gas joint

To indoor unit

A view

Gas joint

A

Incorrect

Unit

Vartical line

Header unit A

Gas joint

Incorrect

Header unit A

Gas joint

Incorrect