Totem Basic cam User manual

INSTRUCTIONS FOR USE

WARNING

• This product is for rock climbing and mountaineering. These

activities are inherently dangerous and entail a risk of SERIOUS

INJURY and/or DEATH.

• It is your decision to practice rock climbing and mountaineering,

so you are responsible for your own actions and decisions. Value

your safety at all times, and weigh up your capacities and the

risks involved.

• It is imperative before using this product to read carefully and

understand the following instructions and warnings, and familiarise

yourself with its proper use.

• Any person using this equipment undertakes all risks and full

responsibility for any damages or injuries that may arise from its

utilisation. If you do not accept this responsibility, do not use the

Basic Cam.

• The manufacturer and retailers of the Basic Cam explicitly

disclaim any and all responsibility and liability (direct, indirect,

incidental or other) for any death, injury ordamage to any person

or property that may arise in relation to the use of this product.

USING BASIC CAMS

• Practice placing Basic Cams when you are still on the ground.

• It is not possible to cover all usage

situations in these instructions. We strongly

recommend to get qualified instruction.

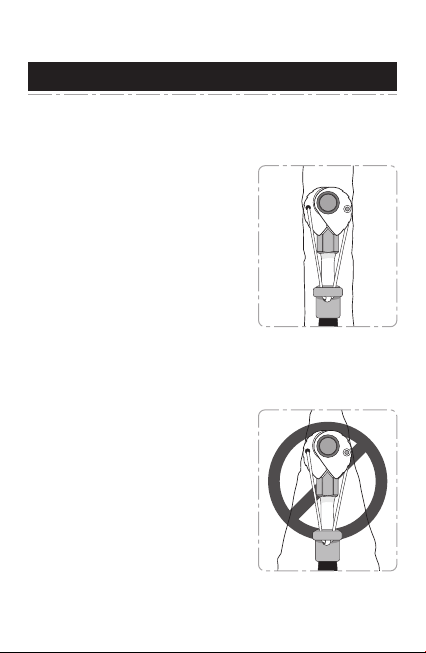

• Pull the trigger to close the cam lobes

and insert the Basic Cam in the crack,

lobes first. Release the trigger to allow the

cam lobes to make contact with the rock

face. It is best for the cam lobes to work

at less than half their expansion range, i.e.

whenthey are between 50% and 90%

closed (see figure 1). Try to avoid closing them completely, as you will find

it difficult to get them out afterwards.

• Ensure that all the cam lobes make good

contact against the rock face, and that the

crack beneath the contact point does not

open (see figure 2).

• Give a tug in the expected loading

direction to check the Basic Cam

placement stability.

Figure 1

Figure 2

• Rope drag could lead the Basic Cam

unit to walk out of its placed position. The

use of long runners helps to avoid this.

• The Basic Cam works on friction between

the rock face and the cam lobes, and any

loose shale, dirt, ice or moisture can reduce

friction and cause the Basic Cam to slip

out the crack.

• Do not use the Basic Cam with the cam

lobes near to fully open. Any movement

in the rope can change the position of the

Basic Cam and it could fail. Use another

larger Basic Cam.

• Align the Basic Cam with the expected loading force (see figure 3).

• Basic 0.70HY and Basic

0.85HY references have a small

sized two cam lobes and another

bigger sized two cam lobes, and

are special for flared cracks. The

small cam lobes must be placed

in the thinner portion of the crack

(see figure 4).

Figure 3

Figure 4

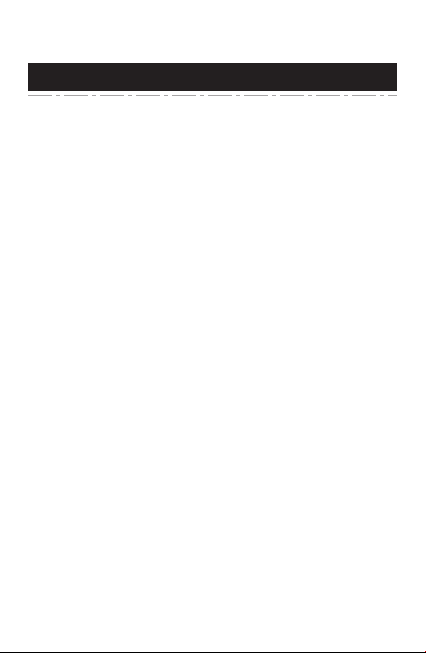

• Do not use the Basic

Cam in shallow cracks,

where the Basic Cam

body can not be

properly aligned with the

expected load (see

figure 5). The strength

is lower in this situation,

and also the device

could slip out.

• Basic Cam cannot function as passive protection, and must not be used

as shown in figure 6.

• Use a carabiner to attach the rope

to the Basic Cam, as shown in

figure

7or figure 8.

• Exercise caution with cracks created

by loose rocks. The Totem Cam

multiplies its pulling force against the

walls of the crack. This can lead the

device to fail or make the rock fall or

break.

• Do not position the Basic Cam at the edge of the crack, especially on

Figure 6

Figure 5

weaker rocks.

• The Basic Cam main wire rope or sling

can be damaged if they are loaded

across sharp edges of rock. Sharp edges

should be avoided if possible. If the main

wire rope is kinked or frayed the Basic

Cam must be replaced. If the sling is

damaged replace it.

• A heavy fall can damage the plastic

cover at the sling attachment point.

Ensure that the inner wire rope is not

exposed. If this is the case, the Basic

Cam must be replaced.

• Do not rely your life on only one piece

of protection. If failure of the piece of

protection would entail a dangerous fall,

double the pro.

• A climbing fall situation can lead to

forces greater than the Basic Cam’s

strength. To reduce this risk, use dynamic belay, shock absorbers and avoid

excessive friction between rope and rock. Caution should be exercised

specially at the beginning of the pitch and with the smallest Basic Cams.

Figure 7

Figure 8

MAINTENANCE AND CARE

• Always check the main wire rope for damage before and after each use.

Slightly bent wire rope is still safe, and you can straighten them manually.

If the wire rope is kinked or frayed, you must replace the Basic Cam

immediately.

• If the webbing or stitching is frayed, melted or torn, the sling must be

replaced. We offer a resling service for Basic Cams.

• If your Basic Cam has sticky action, make a solution of warm water with

mild detergent at appropriate solution (pH range 5,5-8,5), swish the cam

lobes in this solution while working the trigger, and dry completely avoiding

direct sunlight and heat sources. Use a watery wax lube solution to lubricate

the axle and springs after washing, and wipe away excess.

• Trigger wire ropes can be replaced with thin tennis cord. However, we

recommend you use our trigger wire rope replacement service.

• We recommend you carry Basic Cams at the top of your bag, to prevent

any undesirable bending of wire ropes and cam lobes.

• Basic Cams should only be stored while completely dry, in a dark ventilated

clean, chemically neutral environment, well away from heat sources, high

humidity and any type of corrosive agent.

REPLACE A BASIC CAM IF:

• The main wire rope is kinked or frayed.

• The cam lobes have been damaged in a fall.

• The plastic at the sling attachment point is damaged, so the inner wire

rope is exposed.

• The axle or stem is bent.

• The cam lobes are so worn, that trigger wire rope supporting hole is

damaged.

• Replace frayed, melted or torn slings.

• Replace kinked or frayed trigger wire ropes.

• The Basic Cam’s estimated lifespan is 5 years from its first usage.

QUALITY & CERTIFICATION

• Basic Cam is CE-certified, and meets the EN 12276 standard.

• Each Basic Cam is tensile-tested to 60% of its rated strength.

• Each Basic Cam has an exclusive serial number on the upper trigger plate.

The first two digits show the year of manufacture. We use this code to

ensure the traceability of all Basic Cam parts so we know the material batch

used for each part in your Basic Cam and the related test results.

WARRANTY

• Totem products are warranted to the original retail purchaser as free from

material and workmanship flaws for a period of one year from purchase.

The product will be replaced without charge if, following our inspection, no

misuse or alteration isdetected. Totem offers no other warranty either

expressed or implied.

MARKING

• Logo and trademark.

• TOTEM: Company name.

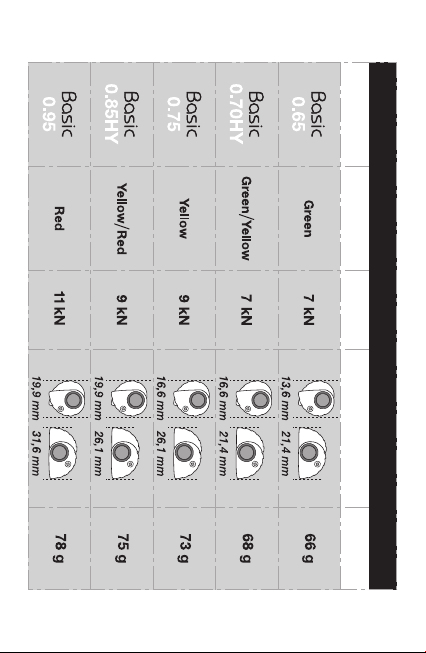

• Basic 0.65: Reference.

The number means the approximate covered crack width in

inches at 33% of expansion range (0.65 given as an example).

• CE 0082: notified body number delivered the CE certificate and for the

CE quality control system for the final product.

Basic Cam is CE certified by:

APAVE SUDEUROPE SAS

BP 3 - 33370 ARTIGUES près BORDEAUX - France

Notified body number 0082.

• 7kN: rated strength (7kN given as an example).

• Serial number: there is a 7-digit serial number on the upper trigger plate.

The first two digits show the year of manufacture.

SPECS CHART

Reference Color Strength Width Weight

TOTEM MT, Koop. E.

Florida, 56 - 24b

20120 Hernani (Gipuzkoa)

Phone: +34 943 555 465

e-mail: [email protected]

Table of contents

Popular Safety Equipment manuals by other brands

Lanex

Lanex PB-20 instruction manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use

Besto

Besto Buoyancy Aid 50N Instructions for use

TEUFELBERGER

TEUFELBERGER NODUS Manufacturer's information and instructions for use

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Salewa

Salewa MTN SPIKE user manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual