tousek Pass 838 User manual

Installation and operating manual

Barrier PASS 838

- 2 - tousek / E_PASS-838_02 / 22. 10. 2018

Important warning and safety notes for installation and operation

• These installation- and operating instructions form an integral part of this product. They have been specically written for professional installers trained and

skilled in the trade and should be carefully read in their full length before carrying out the installation. It concerns the control only, not of the overall device

“automatic gate”. After the installation this manual has to be handed over to the user.

• Installation, connection, adjustments, putting into operation, and servicing may only be carried out by trained professionals in full accordance with these

installation- and operating instructions.

• The EU Machine Directive, laws and rules concerning the prevention of accidents, and laws and standards which are in force in the EU and in the individual

countries have to be strictly followed.

• The TOUSEK Ges.m.b.H. cannot be held liable for any claims resulting from disregards of the laws and standards in force during the installation and

operation.

• The product may only be used in accordance with its original purpose, for which it has been exclusively designed, and which is described in these installation

and operating instructions. The TOUSEK Ges.m.b.H. rejects any liability if the product is used in any way not fully conforming to its original purpose as

stated herein.

• The product is not suitable for installation in explosion-hazardous areas. The existance of inammable gas and steam is of great danger !

• The packaging materials (cardboard, plastic, EPS foam parts and lling material...) have to be properly disposed of in accordance with the applying recy-

cling- and environmental procection laws. They may be hazardous to children and therefore have to be stored out of children´s reach.

• Before beginning with the installation the installer has to make sure that all mechanical components of the gate facility, like carrier prole/rail, gate frame and

panels, guiding elements etc. are sufciently supportive and resistant for the purpose of gate automation. Check also whether the product has transport

damages.

• All electrical installations have to be made in full conformity with the applying rules and laws (e.g. using a fault current circuit breaker, proper grounding...).

• An all-pole disconnecting main switch with a contact opening-gap of minimum 3 mm has to be foreseen.

• When installing the safety device (photocells, safety edges, emergency-stops etc.) please comply with the valid direcitves/standards, the criteria of practical

rules of conduct, the installation environment, the operating logic of the system and the effected force of the motorised gate.

• The safety devices must secure possible bruise, shear and general danger areas of the motorised gate.

• After installation the proper function of the gate facility and the safety devices has to be checked.

• Place warning signs and notes of the valid regulations to indicate danger areas

• With each installation the identication data of the motorised gate has to be placed in a visible place.

• The electric motor heats up during operation. Therefore the device should only be touched after it has cooled off.

• Children have to be instructed, that the gate facility as well as the belonging parts may not be used improperly, e.g. for playing. Furthermore handheld

transmitters have to be kept in safe places and other impulse emitters as buttons and switches have to be installed out of children‘s reach.

• Only original spare- and replacement parts may be used for repair of the product.

• The TOUSEK Ges.m.b.H. rejects any liability for claims resulting from usage of the product in combination with components or devices which do not fully

conform to the applying safety laws and rules.

• The installer has to inform the user about all aspects of the automatic operation of the complete gate facility, as well as about emergency operation. The

installer further has to supply to the user all instructions relating to the safe operation of the gate facility. The installation and operating instructions also

have to be handed over to the user.

• The user has to be informed that he has to turn off the main power switch in case of malfunction of the product and that he can use the facility again after

repair and adjustment works have been completed.

• Please notice that the warranty will not be applicable if the label with the engine number has been removed or

damaged.

Maintenance

• Maintenance works have to be carried out according to our maintenance plan (page12).

This manual is the sole property of the TOUSEK Ges.m.b.H. and may not be made available to competitors. All rights reserved. No part of it may be reproduced without our prior

written permission. We will not accept liability for any claims resulting from misprints or errors. This edition of the manual replaces all earlier publications of the same.

tousek / E_PASS-838_02 / 22. 10. 2018 - 3 -

PASS 838 L6

1. General Barrier PASS 838

Characterstics

• electromechanical barrier operator for barrier width 3m to 6m

• for 230 V a.c. power supply

• suitable for continuous operation (100% duty cycle)

• emergency release mechanism

• sinusoidal motion

• technology without limit switches

• speed sensor

• rednished(RAL3000)sheetsteelhousingoptionalinINOX

• integrated control board ST 80 with clear text menu

through large, illuminated LCD screen

• adjustable soft stop

• ARSAutomaticReversalSystem

• integratedsafetyedgeresistanceevaluator8,2kΩforlowerboomedge

• output for boom magnetic clamp and boom lamp with free

denablelight/blinkingfunction

•

General features

The barrier operators work electro-mechanically and are available with aluminium barrier booms (length of 3–6m depending on

type).Thebarrierboomsarepaintedwhiteandhaveredreectivestickers.Thedriveunitbasicallyconsistsofamechanical

gearing combined with a 230V electric motor, a balancing spring and a speed sensor.

Allcomponentsarebuiltintoarobustrednished(onrequestalsosilvernishedresp.inINOX),lockablesteelhousing.

Incaseofapowerfailurethebarrierboomcanbeopenedandclosedmanuallyafterlooseningtheemergencyreleasehand

wheel. Due to its particularly massive execution and the very short opening and closing times, the Tousek PASS 838 barrier

operator has been designed to handle a large number of opening/closing cycles per day.

Optional accessories: base plate for barrier operator, (barrier boom) tip rest, base plate for (barrier boom) tip rest., pluggable

radioreceiver(tousekSTN),pluggableinductionloopdetector(ISD6)andbarrierboomgrid.

Technical Data

Barrier PASS- 838V-ST 838 L3-ST80 838 L4-ST80 838 L6-ST80

max. barrier width 3m 4,5m 6m

Opening-, closing time 1,5s 7s

Motor power supply 230Va.c.

Power consumption 400W

Duty cycle (mode S1) 100%

Max. cycles/day 2000 1000 500

Ambient temperature -20°C to +40°C

Condenser 14µF

Boomconguration at - (H x B) 116mm (with rubber prole) x 30mm round - Ø 85mm

IntegratedcontrolST80 ST 80V ST 80 ST 80 ST 80

Art.No. 11530360 11530330 11530340 11530350

possible equipment:

Boom

LED boom lamp

Pendulum arm or tip rest only tip rest

Barrier boom grid

Other allbarrieroperatorsPASS838areequippedwithanemergencyoperationhandwheel

Housing colour: red

Note: The mentioned values „max. cycles per day“ require regular maintenance work according to our

specications (depending on intensity of operation between 1 and 4 times per year)

The barrier PASS 838V-ST is only for vehicle trafc !

- 4 - tousek / E_PASS-838_02 / 22. 10. 2018

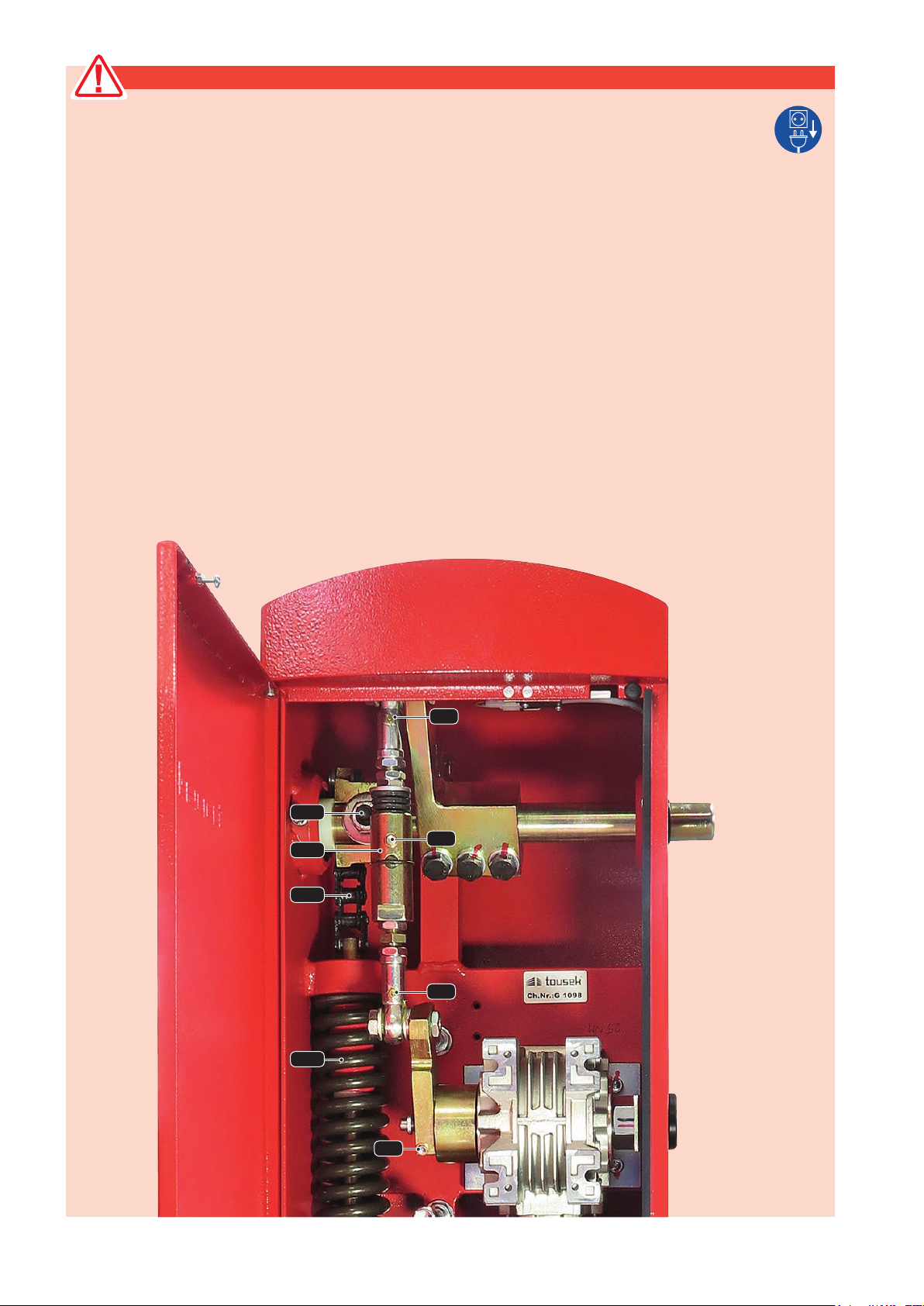

8

9

13

10

11

14

15

4

5

7

1

2

3

6

12

16

16a

2. Technical layout Barrier PASS 838

Barrier in position „OPEN“

(1) housing door

(2) gearing lever

(3) chain

(4) gearing lever

(5) balancing spring

(6) euro standard lock cylinder

(7) earthing bolt

(8) activator bolt for door switch

(9) door safety switch

(10) drive shaft

(11) Limit bolt „boom OPEN“

(12) Limit bolt „boom CLOSED“

(13) emergency release

(14) reduction gearing

(15) drive motor

(16) electronic control with LC-Display menu

programming (16a)

Barrier in position „CLOSED“

2

tousek / E_PASS-838_02 / 22. 10. 2018 - 5 -

100

800

100

100

FB

F

S

T

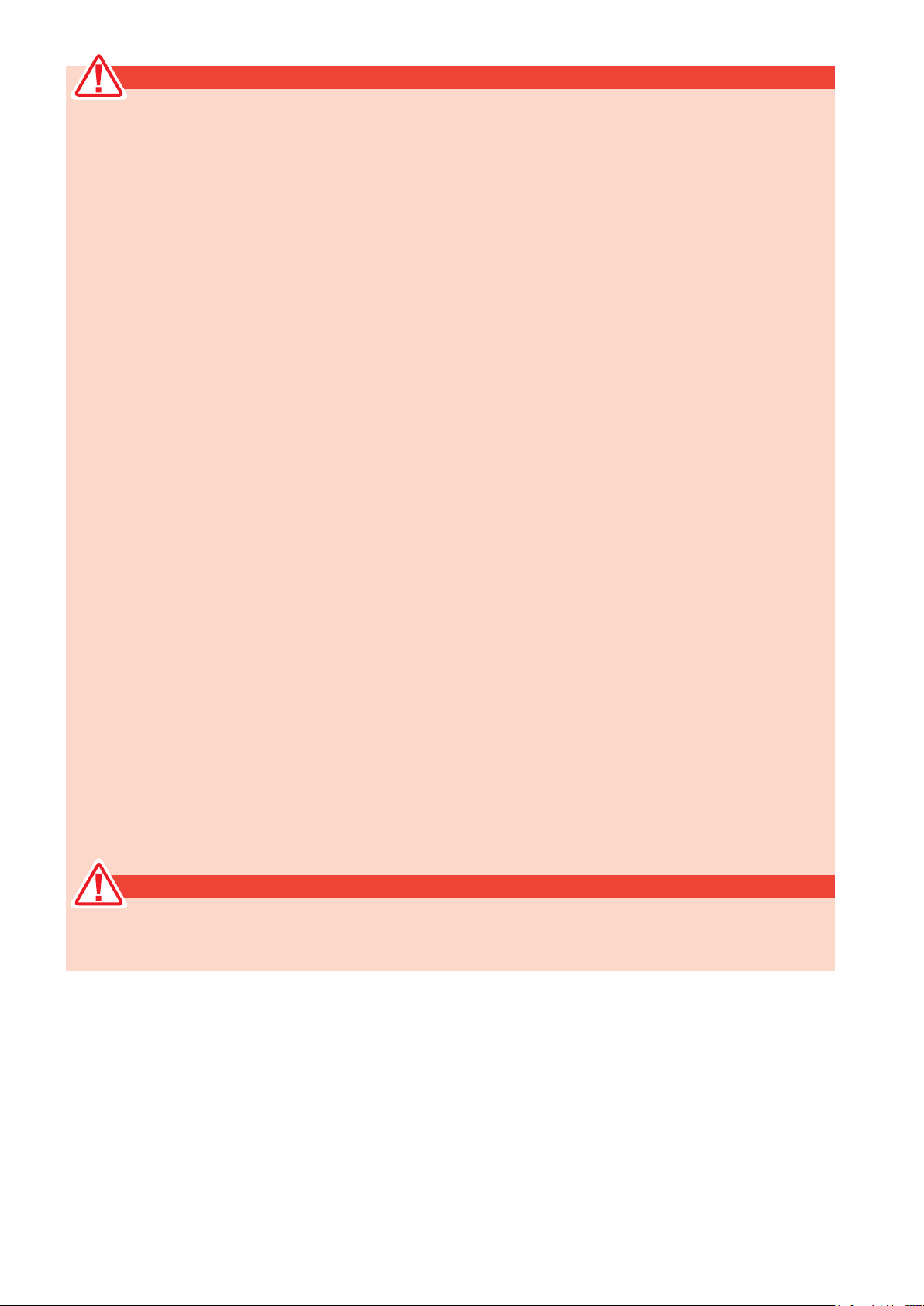

• Lead the insulating sleeves (S) for power supply and acces-

sories into the opening of the base plate.

• Embedthebaseplatermlyandhorizontallyinthefounda-

tion (F) (see „examples - Barrier installations“ page 13).

• Set the operator housing on the base plate with the door

(T) aligned to the road (FB) and secure it with the bolts.

Therefore it has to be ensured that the connecting cables

won’t be damaged.

3. Installation Barrier PASS 838

housing backside

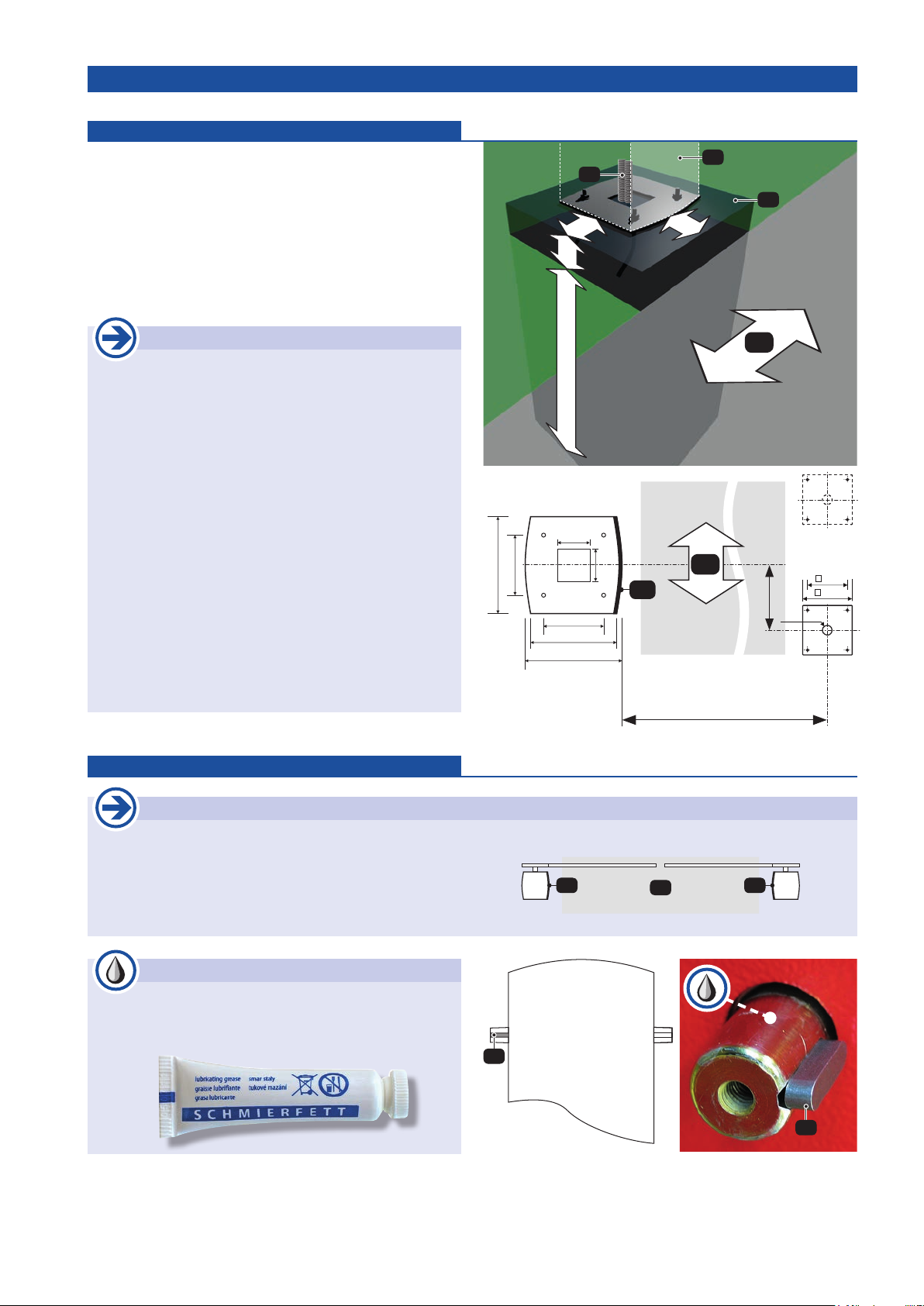

3b. Mounting the barrier boom Installation

Important

• The barrier boom can be installed either on the left

or on the right side of the operator housing.

• Please do not load additional weight (e.g. sign boards)

on the barrier boom. This could result in the damage

of the gearbox unit.

left barrier right barrier

FB

T T

• Inarststepknockinametallkey(K) into the nut of the gearing drive shaft on the side of the barrier where you wish to

mount the boom.

• Thefollowingmountingstepsdifferinaccordanceofwhetheryouwishtomounttheroundortheatbarrierboom.

Important - grease the drive shaft

• put some grease onto the external drive shaft with

provided grease!

(see picture))

Foundation

• The foundations to be made must be at least 100mm

larger around then the foundation plates concerned.

• The foundation must be raised from the ground level to

a minimum of 100mm.

• The foundation depth from ground level to should have

a minimum of 800mm (frost resistant).

• The foundation always has to be adjusted to the structure

of the ground.

It should consist ofconcrete quality C20/25 at ground

class 3. The foundation has to be horizontal and free

of cracks.

• When using a support fork/tip rest pay attention to the

offset V, which depends on the barrier used (barrier

boom):

For barriers with at boom: V = 190

For barrier type PASS 838 L6

(= barrier with round boom): V = 220

K

K

3a.

Mounting of base plate and barrier operator

Installation

= barrier width - 25mm

290

180

180

255

290

100

100

base plate

barrier operator

V

T120

150

Ø30

FB

base plate

guide in bracket

- 6 - tousek / E_PASS-838_02 / 22. 10. 2018

Push the barrier boom carrier (M) onto the drive shaft (A), so that the knocked-in metal key drives into the nut (M.N).

Now slide the slide-in module (E) as shown into the boom so that the drillings fall in line with the boom.

Then bolt 4 x (with discs) the boom carrier (M) with the slide-in module inside boom (E).

Now connect the boom (B) with cylinder head bolt (M10 x 40) and disc with drive shaft (A) (close the opening of boom

with plastic plug)

Attach the plastic covers onto the boom and drive shaft end.

Fixing the at boom (example as left barrier)

M

housing backside

(example shows boom mount for

left barrier)

left barrier right barrier

S1 S2

View S2

(Arrangement of mounting parts for left barrier)

Balkenoberseite

Important

• make sure to slide the slide in module (E) for both

mounting types (left/right) into the boom so that the

dropping (E.S) for the cylinder head bolt turns away

from barrier housing.

E

E.S

B

View S1

(boom carrier)

View S1

M.N

M

4 x

M

A

E

B

M.N

tousek / E_PASS-838_02 / 22. 10. 2018 - 7 -

Attachment of round barrier boom (example as left barrier)

Push the barrier boom carrier (M) onto the drive shaft (A), so that the knocked-in metal key drives into the nut (M.N).

Now slide the slide-in module (E) as shown into the boom so that the drillings fall in line with the boom.

Then bolt 4 x (with discs) the boom carrier (M) with the slide-in module inside boom (E).

Now connect the boom (B) with cylinder head bolt (M10 x 40) and disc with drive shaft (A)

(close the opening of boom with plastic plugs)

Attach the plastic covers onto the boom and drive shaft end.

E

S1 S2

housing back side

(example shows boom mounting

of a left barrier)

View S1

(boom carrier)

left barrier right barrier M

boom top

B

View S2

(Arrangement of mounting parts for left barrier)

M.N

M

M

E

B

A

M.N

- 8 - tousek / E_PASS-838_02 / 22. 10. 2018

SI

F

M

G

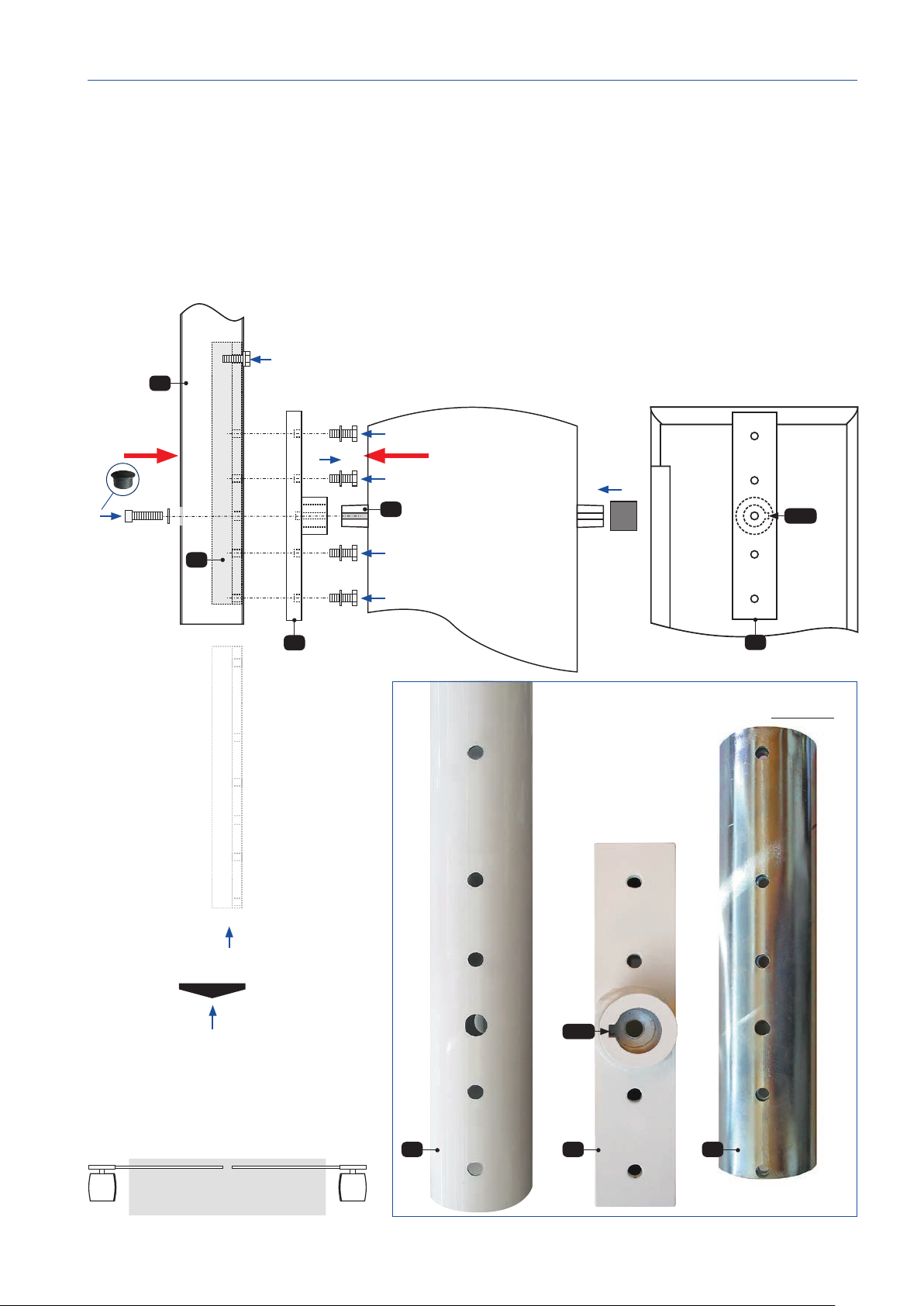

3e. Force adjusment

• The force adjustment is made by the ST80 control board.

• Due to the spring balance, the operator force is measured

in a way, that the barrier boom may be stopped with little

effort.

• As an additional safety device we recommend the connection

of a photocell.

3c. Electrical connections Installation

• Before carrying out the electrical connections, thepower

supply of the gate facility must be turned off !

• Connect the operator to the control unit according corre-

sponding control manual (mind the beside installation

notes).

• For the connection of diverse safetydevices, transmitters and

other accessories please check the corresponding manuals

(please note cable/wire plan).

Warning

• Before carrying out the electrical connections, the power supply of the gate facility must be turned off !

• The safety regulations for electric shock prevention have to be complied.

• The device should only be connected by qualied personnel

• The device should not be used in an explosive environment !

• An all-pole disconnecting mains switch with a contact opening gap of min. 3 mm has to be foreseen.

The gate facility has to be secured according to the valid safety regulations!

• IMPORTANT: The control lines (buttons, radio, photocells, etc.) have to be laid separately

from the 230V lines (supply line, motors, signal lamp). and may have a max. length of 50m.

For length > 50m decoupling steps are necessary !

Important installation notes

• Attention: The operator works with the condenser

mounted on the motor. Therefore don´t connect an

additional condenser to the control unit.

• The operator housing isequipped with asafety switch

(S) which stops the motor as soon as the housing

lid is opened. This safety switch must be connected

to the motor control unit (input for STOP switch).

3d. Adjustment of spring tension Installation

• The adjustment of spring tension is made by turning the

screw nut (M) on the spring rod.

Warning

• The safety standards and regulations regarding the

force adjustment have to be in compliance with the

effective rules !

Important

• The spring (F) has to be adjusted so that the boom

can be moved easily by hand in emergency release

state. (with pendulum arm and/or boom grid).

The boom should have a position of approx.

20–40°.

tousek / E_PASS-838_02 / 22. 10. 2018 - 9 -

3f. Adjusting the limits Montage

• Thebarrieroperatorisequippedwithtwo adjustablelimit

stop bolts, one for OPEN (AO) and one for CLOSED (AG)

position.

• The gearing lever (G)isbeingdenedinitsturningmove-

ment by these two limit stop bolts in the end positions open

and close. The integrated speed sensor registrates when it

reaches one of the limits, whereupon the control board turns

off the motor.

• The switching time and also the boom limit positions can be

denedbyboltinginoroutthelimitstopbolts.

Note

• Please note that when the limit stop bolts are being

adjusted (AO or AG) the limit positions are being

learned in.

• Choose in control board menu of ST 80 under

„DIAGNOSIS / delete position“ the value „YES“ .

T

AO

AG

G

IMPORTANT

• The end position of the barrier must take place according to the above services mentioned above description.

• Never use a support fork or pendulum support as a limit. These serve only to discharge of the bar!

• The company Tousek Ges.m.b.H. accepts no liability for damages resulting from such a misuse!

- 10 - tousek / E_PASS-838_02 / 22. 10. 2018

5. Attachment

of warning signs

• Additionaly to the safety installations of the barrier as

suggested by safety instructions in effect, some warning

signs have to be installed to warn pedestrians, bicycle

drivers etc. showing special attention and informing

of possible danger and for guidance to an alternative

route.

ATTENTION

AUTOMATIC BARRIER

RELEASE LOCKING

• Open the housing door and slide the cover of the emergency

release in direction of front part of housing.

• Insertthe10mmAllanKeyandturnit2–3timescounter

clockwise. This disengages the gear lever (G) from the

gearing transmission.

• The operator is now unlocked and the boom may be moved

manually (slowly ! - not faster than with the operator).

• To restore operation of the motor pull the emergency release

clockwiseagainrmly.

Move the boom a little so that the lever gear snaps into the

gearing.

• The lever gear (G) must rest again directly on the gearing

unit.

• After closing the housing door and turning on the power

supply, the motorised mode can be engaged again.

2–3x

Release

G

Locking

tighten

+

G

Acute risk of injury

The operator may only be emergency released if:

>>> the power supply is turned off and >>> the barrier boom is mounted

• Turn off power supply

of gate facility!

• ATTENTION: Make sure that the barrier boom is mounted!

• Ifthebarrierboomisremoved,thereisnocounterweighttothespring

tension. In this case the operator may not be emergency released

since this could lead to SERIOUS INJURIES !

4. Emergency release of the operator at power failure PASS 838

tousek / E_PASS-838_02 / 22. 10. 2018 - 11 -

14E

7

8

2x0,75 mm2

4x0,75 mm2

4S

3

5

4x0,75 mm2

min. 3x1,5 mm2

2

6

Koaxialkabel2x0,75 mm2

Warning note

Please be aware that the above picture is only a symbolic sample illustration

of a gate facility and may therefore not show all safety devices required for

your specic application.

To achieve an optimum safety level at your gate facility, please make sure

that all safety components and accessories which - according to the applying

safety rules and laws - are required in your particular case (e.g. photocells,

induction loops, sensing edges, signal lamps, trafc lights, mains- and emer-

gency power off switches etc.) are properly installed, operated, and serviced.

All possible bruise, shear and general danger areas of the motorised gate

have to be secured.

In this context please follow the EU Machine Directive, accident prevention

rules and laws, as well as applying EU- and national standards in force at the

time of installation and operation of the gate facility.

The Tousek Ges.m.b.H. cannot be held responsible for any consequences

resulting from disregard of applying standards and laws during installation

or operation of the gate facility..

Note concerning cable laying

• The electric cables have to be laid in insulating sleeves

which are suitable for underground usage. The insulating

sleeves have to be lead into the inner of the operator

housing.

• The control lines (buttons, radio, photocells, etc.) have

to be laid separately from the 230V lines (supply line,

motors,signallamp).and may have a max. length of 50m.

For length > 50m decoupling steps are necessary !

• Only double-insulated cables, which are suitable

for underground usage (e.g. E-YY-J) may be used.

In case that special regulations require another type

of cable, cables according to these regulations have

to be used.

6. Cable plan Barrier PASS 838

The 0,75mm2 control lines are shown without ground

lead. In order to facilitate connections we recommend

using exible wires and not using thicker wires for the

control lines.

1barrier operator Tousek PASS 838

2electronic logic control with optional available

radio receiver (plugable)

3main power switch

Note: An all-pole disconnecting main switch with a

contact opening-gap of minimum 3 mm has to be

foreseen

4 photocell(T:transmitter,R:receiver)

5pushbutton or key-operated momentary contact switch

6barrier housing signal lamp

7antenna (connection to radio receiver with coaxial cable)

8supply with fuse max. 13A

- 12 - tousek / E_PASS-838_02 / 22. 10. 2018

7. Maintenance plan for barrier PASS 838

Maintenance works may only be carried out by trained professionals.

ATTENTION: Before carrying out maintenance works, turn off the power supply.

According to the frequency of actuation the following works have to be carried out 1–4 times a year:

•Checkthecorrectxingofthebarrierhousing.

• Check the balancing spring, adjust if necessary.

• Grease the guiding rod of the balancing spring.

• Grease the grease nipples (N1–N4) with the grease press.

• Check and adjust the end positions opened and closed.

• Check the proper function of the emergency release.

• Check the proper function of the housing lid safety switch.

• Check the gearing on tightness.

• Check if the assembly bolts of the gearing are properly secured.

• Check barrier boom support: - proper seat of support at the main shaft

- proper seat of the 4 internal assembly bolts

• Optical inspection of ball bearings of main shaft.

• Check force adjustment of control unit.

• Check all safety devices and accessories.

• Equalising spring (W1), chain hoist device (W2) disc spring (w3) and fastening bolt M14 (W4)

have to renewed every 200.000 cycles (latest every 3 years) !

W2

W3

W1

W4

N1

N3

N2

N4

tousek / E_PASS-838_02 / 22. 10. 2018 - 13 -

V

120

150

Ø30

190

(L6: 220)

290

255

180

290

180

Foundation plate

PASS 838

Foundation plate

Tip rest/support fork

40

80

390

330

210

3000

120

150

Ø30

190

(L6: 220)

290

255

180

290

180

Foundation plate

PASS 838

Foundation plate

Tip rest/support fork

40 80

390

330

210

3000

Foundation plate

ImpulsepillarV03

Foundation plate

ImpulsecolumnV03

Distance depending

on road width

Distance depending

on road width

V

2

2

1

1

5

5

100

100

100

100

Ø70

Ø70

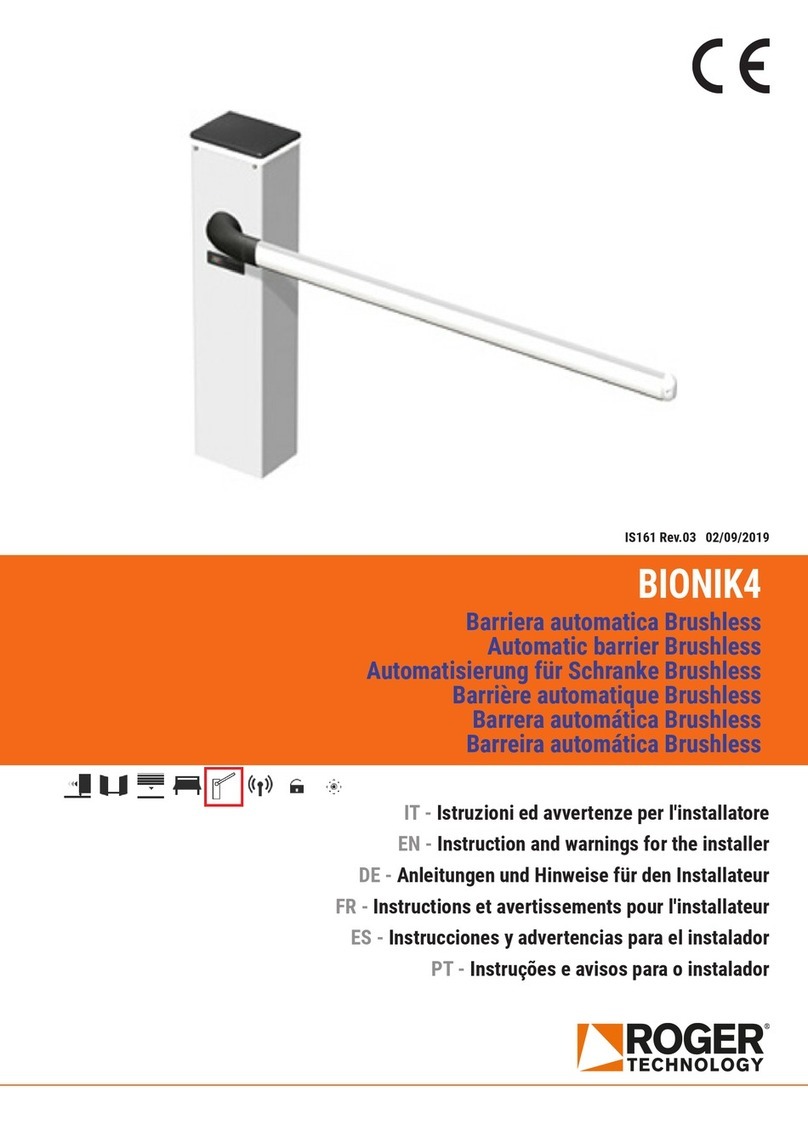

8. Barrier installations - Examples Barrier PASS 838

• Dimensions in mm

2

2

1

1

3

3

4

4

5

5

(1) Barriers PASS 838

(2)Impulsecolumns

(3) Photocells

(4)Inductionloops

(5) Tip rests/support forks

(6) Photocell pillars

Important

• The foundations to be made must be at least

100mmlarger around then the foundation plates

concerned.

• The foundation must be raised from the ground

level to a minimum of 100mm.

• The foundation depth from groundlevel to should

have a minimum of 800mm (frost resistant).

• The foundation always has to be adjusted to the

structure of the ground.

It should consist of concrete quality C20/25

at ground class 3. The foundation has to be

horizontal and free of cracks.

• When using a support fork/tip rest pay attention

to the offset V, which depends on the barrier

used (barrier boom):

For barriers with at boom: V = 190

For barrier type PASS 838 L6

(= barrier with round boom): V = 220

Single barrier with support fork and photocell pillars

Barrier system for separate entrance / exit with impulse columns V03

1

5

66

V

120

150

Ø30

190

(L6: 220)

290

255

180

290

180

Foundation plate

PASS 838

Foundation plate

Tip rest/support fork

390

Foundation plate

Photocell pillar Foundation plate

Photocell pillar

120

150

120

150

Distance depending on road width

Distance depending

on road width

Ø30Ø30

100

100

1

(F) foundation

(S) insulating sleeves

(T) housing door

(FB) road

100

800

100

100

FB

T

S

F

- 14 - tousek / E_PASS-838_02 / 22. 10. 2018

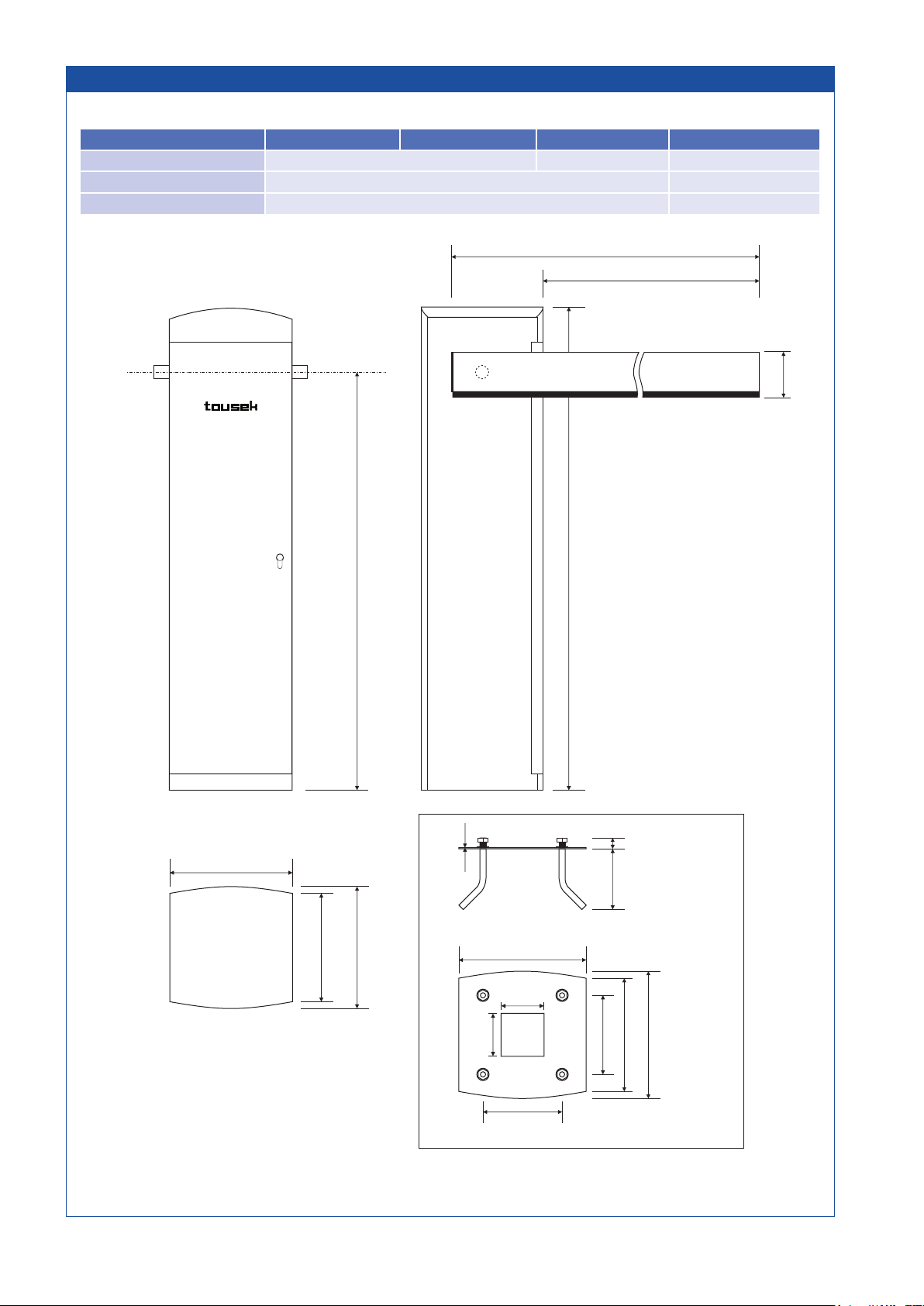

• dimensions in mm

9. Dimensioned drawing Barrier PASS 838

measuresandtechnicalmodicationssubjecttochange!

280

250

280

290

180

180

255

290

30

135

3

950

1100

116

100

100

base plate

barrier width

boom length

NOTE 838V-ST 838 L3-ST80 838 L4-ST80 838 L6-ST80

max. barrier width 3m 4,5m 6m

boom length barrier width + 220mm barrier width + 280mm

Boomconguration at - (h x w) 116mm (with rubber prole) x 30mm round - Ø 85mm

A U T O M A T I S C H E T O R A N T R I E B E

®

Einbauerklärung

im Sinne der EG-Maschinenrichtlinie 2006/42/EG,

Anhang II B für den Einbau einer unvollständigen Maschine

Hiermit erklären wir, dass das nachfolgend bezeichnete

Produkt aufgrund seiner Konzipierung und Bauart sowie

in der von uns in Verkehr gebrachten Ausführung den

grundlegenden Anforderungen der Maschinenrichtlinie

(2006/42/EG) entspricht.

Bei einer nicht mit uns abgestimmten Änderung der

Produkte verliert diese Erklärung ihre Gültigkeit.

Das Produkt:

Schiebetorantrieb PULL XR, X/o, XD/o

ist entwickelt, konstruiert und gefertigt in Übereinstimmung

mit der:

EG-Richtlinie Maschinen 2006/42/EG

EG-Richtlinie Niederspannung 2006/95/EG

EG-RichtlinieElektromagnetischeVerträglichkeit 2004/108/EG

Angewandte und herangezogene Normen und Spezifi-

kationen:

EN ISO 13849-1, PL-„c“

EN 60335-1

EN 60335-2/95

EN 61000-6-3

EN 61000-6-2

Folgende Anforderungen des Anhangs I der EG-Richlinie

2006/42/EG werden eingehalten:

1.1.2, 1.1.3, 1.1.5, 1.2.1, 1.2.2, 1.2.3, 1.2.6, 1.3.2, 1.3.4,

1.3.7, 1.5.1, 1.5.4, 1.5.6, 1.5.8, 1.7

Die speziellen technischen Unterlagen wurden gemäß

Anhang VII Teil B der EG- Maschinenrichtlinie 2006/42/EG

erstellt.

Wir verpflichten uns, diese den Marktüberwachungs-

behörden auf begründetes Verlangen innerhalb einer

angemessenen Zeit in elektronischer Form zu übermitteln.

Für die Zusammenstellung der technischen Unterlagen

ist bevollmächtigt:

TOUSEK Ges.m.b.H., A1230 Wien, Zetschegasse 1,

Österreich

Die unvollständige Maschine darf erst dann in Betrieb

genommen werden, wenn festgestellt wurde, dass die

Maschine, in die die unvollständige Maschine eingebaut

werden soll, den Bestimmungen der Maschinenrichlinie

2006/42/EG entspricht.

Eduard Tousek, Geschäftsführer Wien, 01. 01. 2013

Motornummer (Typenschild):

Sonstige Komponenten:

EG-Konformitätserklärung

im Sinne der EG-Maschinenrichtlinie 2006/42/EG,

Anhang II, Teil 1 A

Wenn die neben beschriebenenTorantriebe in Verbindung

mit einem Tor gebracht werden entsteht im Sinne der

EG-Richtlinie Maschine eine Maschine.

Einschlägige EG-Richtlinien:

Bauprodukte-Richtlinie 89/106/EWG

Maschinenrichlinie 2006/42/EG

Elektromagnetische Verträglichkeit 2004/108/EG

Niederspannungsrichtlinie 2006/95/EG

Hiermit erklären wir, dass das nachfolgend bezeichnete

Produkt aufgrund seiner Konzipierung und Bauart sowie

in der von uns in Verkehr gebrachten Ausführung den

grundlegenden Anforderungen der oben angeführten

EG-Richtlinien entspricht. Bei einer nicht mit uns abge-

stimmten Änderung der Produkte verliert diese Erklärung

ihre Gültigkeit.

Produkt:

Torbezeichnung

Antriebsbezeichnung

Die unvollständige Maschine darf erst dann in Betrieb

genommen werden, wenn festgestellt wurde, dass die

Maschine,

in die die unvollständige Maschine eingebaut

werden soll, den Bestimmungen der Maschinenrichlinie

2006/42/EG entspricht.

Ausführender Montagebetrieb

Adresse, PLZ, Ort

Datum / Unterschrift

Declaración de incorporación

enelsentidodelaDirectivaCEsobremáquinas2006/42/CE,

Anexo II B para la instalación de una máquina incompleta.

Declaramos que el producto descrito en este documento

cumple debido a su diseño y construcción y el producto

puesto en circulación por nosotros cumple con los requisi-

tos esenciales de la Directiva de Máquinas ( 2006/42/CE ).

Con cualquier modificación no autorizada del producto

esta declaración pierde su validez.

El producto:

Automatización para puerta corredera

PULL XR, X/o, XD/o

desarrollado , diseñado y fabricado de acuerdo con:

Directiva de Máquinas 2006/42/CE

CE Directiva de bajo voltaje 2006/95/EC

Directiva de compatibilidad electromagnética 2004/108/EC

Normas y especificaciones aplicadas y consultadas:

EN ISO 13849-1, PL-„c“

EN 60335-1

EN 60335-2/95

EN 61000-6-3

EN 61000-6-2

Se cumplen los requisitos del Anexo I de la Directiva

2006/42/CE:

1.1.2, 1.1.3, 1.1.5, 1.2.1, 1.2.2, 1.2.3, 1.2.6, 1.3.2, 1.3.4,

1.3.7, 1.5.1, 1.5.4, 1.5.6, 1.5.8, 1.7

Los documentos técnicos especiales fueron preparados

en conformidad con el anexo VII, parte B de la Directiva

CE sobre máquinas 2006/42/CE.

Nos comprometemos a presentar a las autoridades de

vigilancia del mercado a una razonada solicitud dentro

de un plazo razonable, en forma electrónica.

Para la preparación de la documentación técnica está

autorizada:

TOUSEK Ges.m.b.H., A1230 Viena, Zetschegasse 1,

Austria

La máquina incompleta no debe ser puesta en funcio-

namiento, si se ha constatado que la máquina en la cual

la máquina incompleta debe ser instalada no cumple

con las disposiciones de la Directiva de Máquinas

2006/42/CE en línea.

Eduard Tousek, Gerente Viena, 01. 01. 2013

Número de motor (placa de características):

Otros componentes:

Declaración de conformidad CE

enelsentidodelaDirectivaCEsobremáquinas2006/42/CE,

Anexo II, parte 1 A

Cuando los siguientes automatismos para puertas

descritos son asociados con una puerta entonces forman

en el sentido de la Directiva de máquinas CE una máquina.

Correspondientes directivas de la CE:

Productos para la Construcción de la Directiva 89/106/CEE

Directiva de Máquinas 2006/42/CE línea

Directiva de compatibilidad electromagnética 2004/108/EC

Directiva de bajo voltaje 2006/95/EC

Por la presente declaramos que el siguiente producto

designado cumple con los requisitos esenciales de las

anteriores directivas de la UE, tanto en su diseño y

construcción, como puestas en circulación por nosotros.

Con cualquier modificación no autorizada del producto

esta declaración pierde su validez.

Producto:

Denominación de la puerta

Denominación del automatismo

La máquina incompleta no debe ser puesta en funciona-

miento, si se ha constatado que la máquina en la cual la

máquina incompleta debe ser instalada no cumple con

las disposiciones de la Directiva de Máquinas 2006/42/

CE en línea.

Empresa de instalación

Dirección, código postal

Fecha / Firma

Declaration of incorporation

In compliance with EC Machine Directive 2006/42/EC,

Annex II B for the installation of an incomplete machine.

We hereby declare that the following product, as well

as its version, put by us into circulation, complies with

the essential requirements of the Machinery Directive

(2006/42/EC), due to its design and type of construction.

The validity of this declaration will cease in case of any

unauthorized modifications to the products.

The product:

Barrier operator PASS-838V, -838L3, -838L4, -838L6

is developed, designed and manufactured in accordance

with:

EG-Directive Machinery 2006/42/EG

EG-Directive Low Voltage 2014/35/EU

EG-Directive Electromagnetic compatibility 2014/30/EU

Applied and used standards and specifications:

EN ISO 13849-1, PL-„c“

EN 60335-1

EN 60335-2/95

EN 61000-6-3

EN 61000-6-2

Following requirements of Annex I of the EC Directive

2006/42/EC are met:

1.1.2, 1.1.3, 1.1.5, 1.2.1, 1.2.2, 1.2.3, 1.2.6, 1.3.2, 1.3.4,

1.3.7, 1.5.1, 1.5.4, 1.5.6, 1.5.8, 1.7

The relevant technical documentation is compiled in

accordance with Annex VII, Part B of the EC Machinery

Directive 2006/42/EC.

We undertake to submit it in electronic form and within a

reasonable time to the market surveillance authorities in

response to a duly substantiated request.

TOUSEK Ges.m.b.H., A1230 Wien, Zetschegasse 1,

Österreich

is authorized to compile the technical documentation.

The incomplete machine cannot be put into service, until it

is determined that the machine, into which the incomplete

machine has to be inserted, complies with the the Machine

Directive 2006/42/EC.

Eduard Tousek, CEO Vienna, 01. 01. 2013

Motor number (Type plate):

Other components:

EC Declaration of Conformity

In compliance with EC Machine Directive 2006/42/EC,

Annex II, Part 1 A.

When the described operators are connected to a

barrier system they form a machine in the sense of the

EC Machine Directive.

Relevant EU directives:

Construction Products Directive 89/106/EWG

Machinery Directive 2006/42/EG

Low Voltage directive 2014/35/EU

Electromagnetic compatibility 2014/30/EU

We hereby declare that the following product, in the version

put by us into circulation, complies with the essential requi-

rements of the Directives mentioned above. The validity

of this declaration will cease in case of any unauthorized

modifications to the products.

Product:

Motor description

Barrier width

The incomplete machine cannot be put into service, until it

is determined that the machine, into which the incomplete

machine has to be inserted, complies with the the Machine

Directive 2006/42/EC.

Installation company

Address, ZIP code, Place

Date/ Signature

your service partner:

Tousek Ges.m.b.H. Austria

A-1230 Vienna

Zetschegasse 1

Tel. +43/ 1/ 667 36 01

Fax +43/ 1/ 667 89 23

Tousek GmbH Germany

D-83395 Freilassing

Traunsteiner Straße 12

Tel. +49/ 8654/ 77 66-0

Fax +49/ 8654/ 57 196

Tousek Benelux NV

BE-3930 Hamont - Achel

Buitenheide 2A/ 1

Tel. +32/ 11/ 91 61 60

Fax +32/ 11/ 96 87 05

Tousek Sp. z o.o. Poland

PL 43-190 Mikołów (k/Katowic)

Gliwicka 67

Tel. +48/ 32/ 738 53 65

Fax +48/ 32/ 738 53 66

Tousek s.r.o. Czech Republic

CZ-130 00 Praha 3

Jagellonská 9

Tel. +420/ 2/ 2209 0980

Fax +420/ 2/ 2209 0989

We reserve the right to change dimensions and/or technical specications with-

out prior notice. Claims resulting from misprints or errors cannot be accepted.

tousek PRODUCTS

• sliding gate operators

• cantilever systems

• swing gate operators

• garage door operators

• folding door operators

• trac barriers

• electronic controls

• radio remote controls

• key operated switches

• access control

• safety devices

• accessories

tousek

E_PASS-838_02

22. 10. 2018

Table of contents