Page 3

Contents

1. Introduction ..............................................................................................4

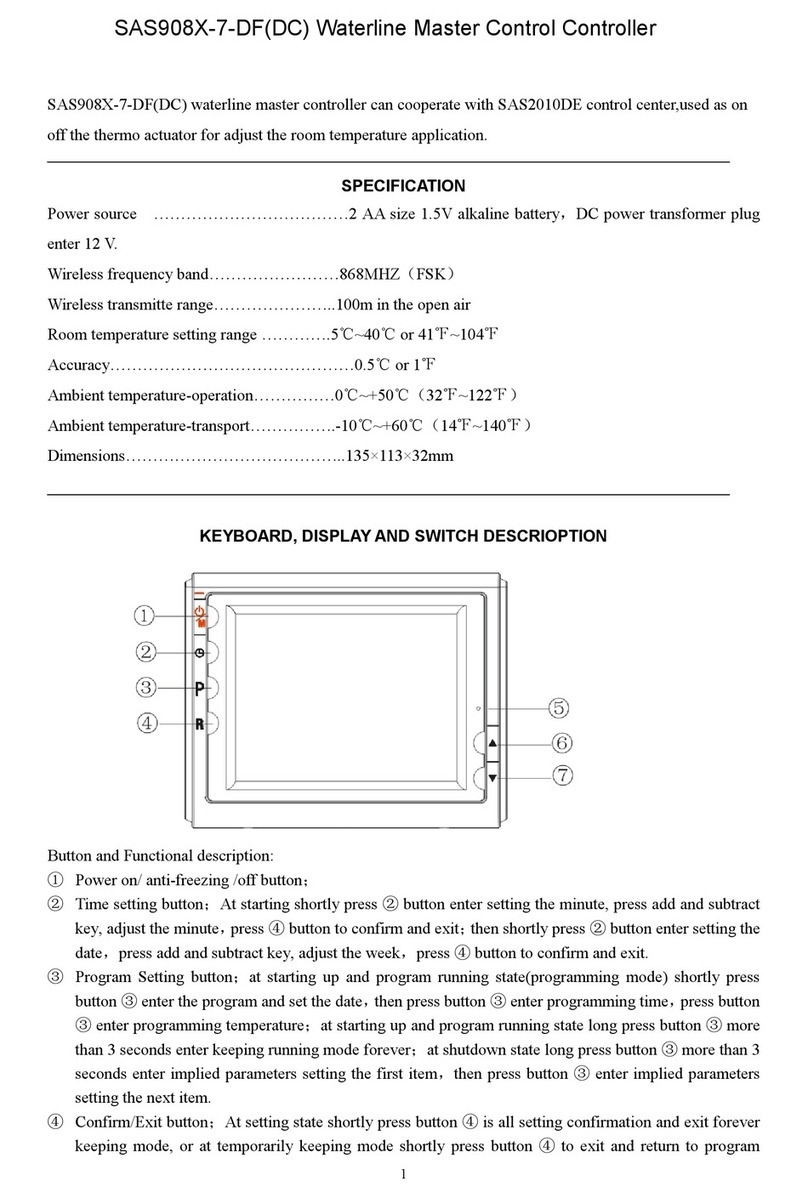

1.1 proCHEM-C Illustration .......................................................................4

1.2 Unpacking Information ........................................................................6

1.3 Specifications......................................................................................7

2. Operating Modes ......................................................................................8

3. Installation and Set-up.............................................................................9

3.1 Connection and Configuration Diagram...............................................9

3.2 Mounting the Enclosure.....................................................................10

3.3 Mounting the Sensor .........................................................................11

3.4 Terminal Connections .......................................................................12

3.5 Setting the Control Limit....................................................................15

3.6 Selecting Current or Voltage Output..................................................18

3.7 Calibrating the 4 to 20mA Output ......................................................19

4. Calibration...............................................................................................21

4.1 Calibration Procedure........................................................................21

4.2 Calibration Notes...............................................................................22

5. Process Monitoring................................................................................23

6. Automatic Control ..................................................................................23

7. Fuse Replacement..................................................................................23

8. Troubleshooting.....................................................................................25

8.1 Instrument Function Troubleshooting.................................................25

8.2 Conductivity Troubleshooting............................................................26

9. Warranty..................................................................................................28

10. Appendices .........................................................................................30

10.1 Re-setting the Display Range............................................................30

10.2 Care, Cleaning and Maintenance of Conductivity Electrodes.............32

10.3 Power Terminal connections when 12V DC option is fitted ................34

10.4 Relay Output Wiring Examples for mains powered units ...................35

10.5 Relay Output Wiring Examples for 12V DC powered units.................36