Page 2Contents

1. Introduction.....................................................................................4

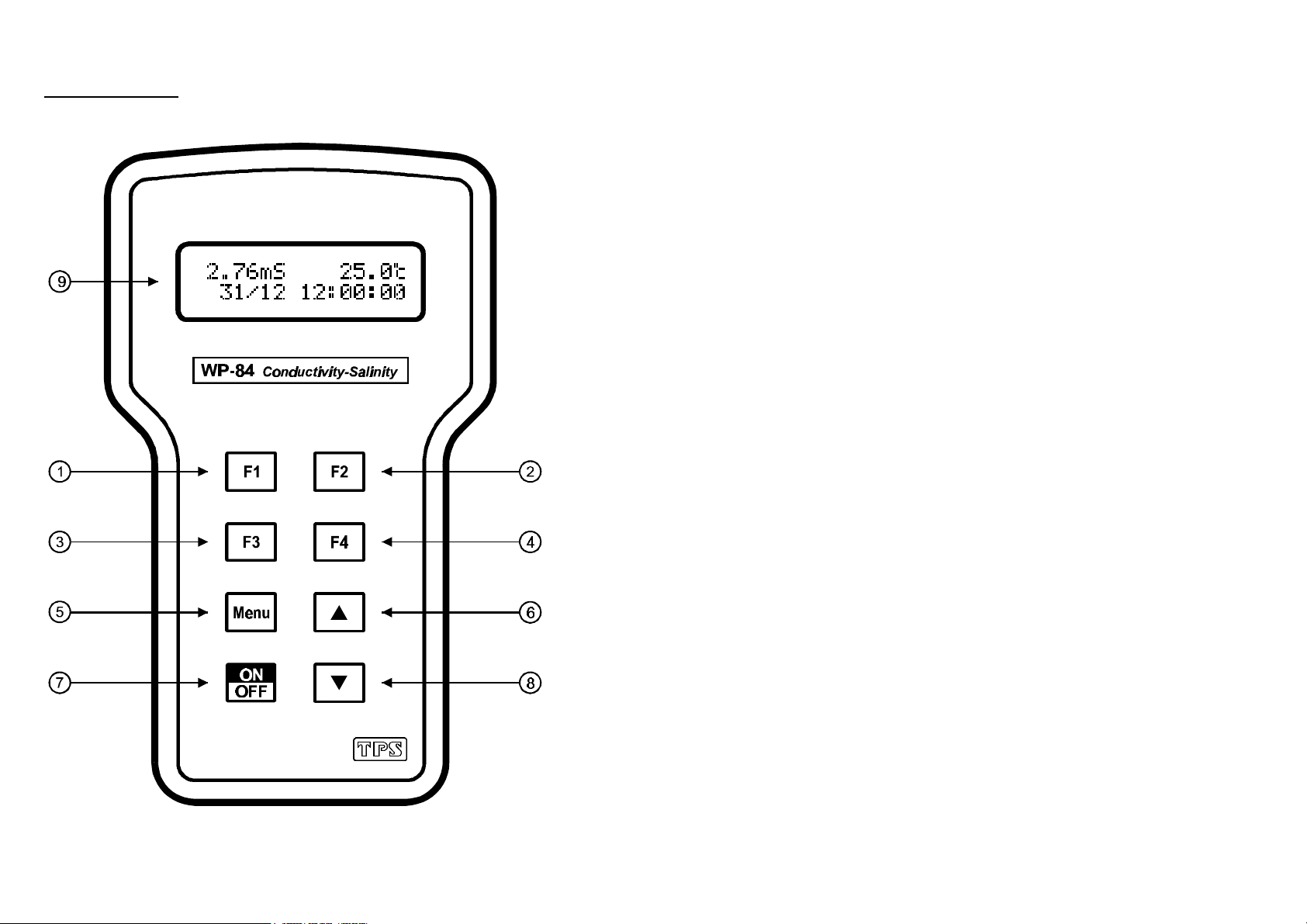

1.1 WP-84 Display and Controls.............................................................................4

1.2 Unpacking Information.....................................................................................6

1.3 Specifications....................................................................................................7

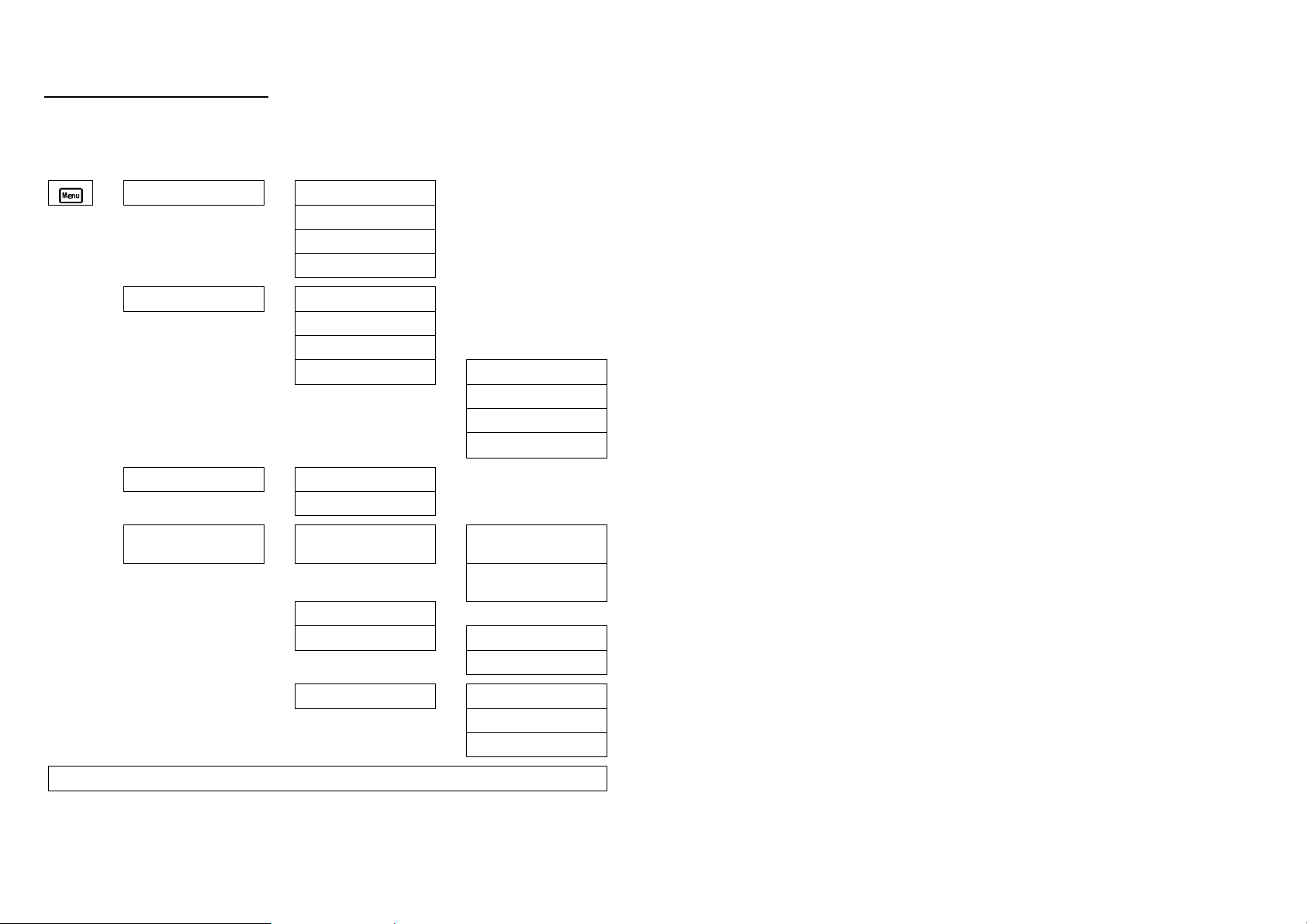

2. WP-84 Menu Structure ...................................................................9

3. Conductivity Mode........................................................................10

3.1 Selecting Conductivity Mode ..........................................................................10

3.2 Conductivity Calibration.................................................................................11

3.3 Calibration Notes............................................................................................12

3.4 Calibration Messages......................................................................................12

4. Salinity Mode................................................................................. 13

4.1 Selecting Salinity Mode ..................................................................................13

4.2 Conductivity Calibration.................................................................................14

4.3 Calibration Notes............................................................................................15

4.4 Calibration Messages......................................................................................15

5. Temperature Calibration ..............................................................16

5.1 Calibration Procedure .....................................................................................16

5.2 Calibration Notes............................................................................................16

5.3 Calibration Messages......................................................................................16

6. ATC Coefficient.............................................................................18

6.1 Setting the ATC Coefficient............................................................................18

6.2 Calculating the ATC Coefficient of a Solution ................................................19

7. Good Laboratory Practices (GLP)...............................................20

7.1 To recall GLP information on the display........................................................20

7.2 Failed Calibration...........................................................................................21

7.3 Printing GLP Information to the RS232 Port...................................................22

7.4 Instrument Serial Number...............................................................................22

7.5 Additional GLP Features.................................................................................22

8. Notepad Function.........................................................................23

8.1 Recording Readings into the Notepad..............................................................23

8.2 Recalling Records from the Notepad ...............................................................23

8.3 Erasing Records from the Notepad..................................................................23

8.4 Printing Records from the Notepad to the RS232 Port.....................................24

9. Automatic Datalogging.................................................................25