Warning and Safety use Instruction

● To avoid damage of the balance , please read the operation manual carefully before use .

☆Please do not use it in dangerous environment .

☆Please cut off the electricity without use for more than one week .

☆Please power off the balance when it connects with external device or before cut off the connection .

☆Magnet or static interference will affect the accuracy of balance, when these interference removed,

balance will recover to normal use .

Spare Parts

※The spare parts we used are the most compatible with the balance .

Any revision to the balance or use the third party’s cable and other device , it’s end user’s responsibility

to check and correct the power and voltage .

※Please do not open the out case. If the safety label is damaged, no warranty will be offered .

Overview

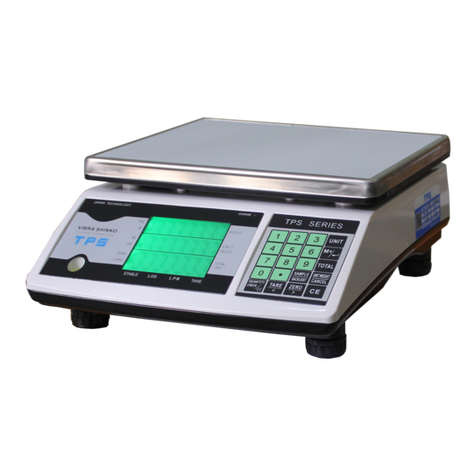

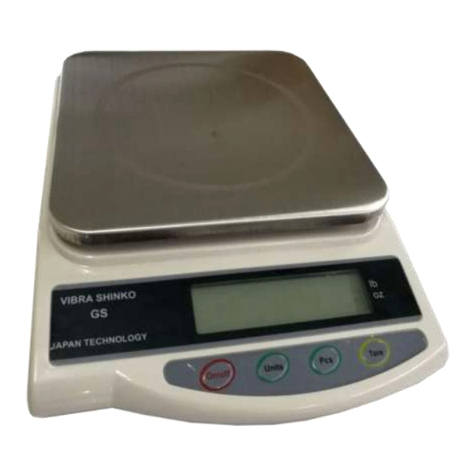

These series electronic balance are designed and developed by our company. Utilized the advanced

microcomputer controlled technology and high precision sensor technology (magnetic balance), it is the

ideal device for fast accurate weighing , widely used in medical research institute, schools, enterprise, road

construction and defense department etc.

▶LCD backlight display, easy and clear;

▶Operator-

▶Highly smart, tare and back to zero within the whole weighing scope, overload display .

▶Multi-mode choice : counting, percentage weigh, density weigh .

▶With RS-232C interface, easy to connect with printer, computer and other output device.

Part I: Open the package

☆Once open the package, please check any visible damage on the balance.

☆Please keep all the packing material until successful installation, to avoid any balance return. When pack

the balance, please remove all the cables to avoid any unnecessary damage.

Part II、Packing list

----balance

----operation manual

----scale

----power adapter

----weights(≤500g)

----Conformity certificate

----warranty card

Part III Remarks

Forbid to get wet in the rain or washed by water

Forbid to put balance in the place where is too hot or too wet, with vibration, corrosion, strong magnet

or with the risk of explosion;

Cockroach and other little creature are forbidden to live inside balance;