TQC LD8100 User manual

1

TQC LOW VOLTAGE

PINHOLE DETECTOR®

LD8100 - LD8105

User Guide

V1.4 1117

2

This product is RoHs compliant (Directive 2002/95/EC)

DANGER

People with for instance a pacemaker or heart problems should completely avoid

the use of this device.

WARNING: Risk of electric shock

The TQC Low Voltage Pinhole Detector (possibly) uses tensions that may cause a

mild electric shock. The earth clamp

detection will switch o the voltage

of the device once it is removed from

the substrate, yet the risk of electric

shock remains, particularly if the

device isn’t used properly. It is

strongly recommended at all times

to hold the device UNDER the button

and avoid. each contact with the top

plate (the live part) The use of gloves

is also recommended.

EN

3

WARRANTY

TQC will grant a warranty for a period of 12 months for TQC Pinhole Detector and 12 months for

all related equipment from the date of delivery in respect of any evidence of faulty workmanship

and materials. TQC will extend the warranty for TQC Pinhole Detector to a period of 24 months

from the date of delivery if TQC Pinhole Detector is licensed via the TQC Ideal Finish Analysis

software. Should a delivered consignment prove to be contrary to contract upon inspection, the

customer shall grant TQC the opportunity hereunder of removing the fault, or else the customer

may demand replacement? Should the supply or delivery of any improvement or replacement

not prove possible, the customer may choose between having the purchase price reduced or

in demanding the contract of sale to be rescinded (conversion). Damage resulting from natu-

ral wear and tear, mechanical or chemical damage, an act of God or non-compliance with the

operating instructions shall be excluded from the warranty as well as mechanical interference by

the customer or by third parties with TQC Pinhole Detector and related equipment without TQC’s

written permission. No liability will be accepted for defects, damage or injury caused due to use

not carried out in accordance with the manufacturer’s user instructions.

To claim warranty, the rejected product has to be sent to TQC together with the original invoice,

any exchange before the product has been returned to TQC is not possible. TQC reserve the right

to repair, exchange or supply an equivalent substitute. TQC is not liable for handling or transport

costs. Warranty on the purchase price is limited, all liability for consequential damages or chan-

ges in technology is expelled

lijkheid voor gevolgschade of technologische veranderingen zijn uitgesloten.

SCOPE OF SUPPLY

The TQC Low Voltage Pinhole Detector-Basic

(LD8100) comes in a hardboard box with the

following items:

t 52$-PX7PMUBHF1JOIPMF%FUFDUPS

t 4QPOHFXBOE

t (SPVOEJOHDBCMFXJUIDMBNQ

t $BMJCSBUJPODFSUJöDBUF

t 6TFSNBOVBM

The TQC Low Voltage Pinhole Detector-Advanced

(LD8105) comes in a hard plastic box with the

following items:

t 52$-PX7PMUBHF1JOIPMF%FUFDUPS

t 4QPOHFXBOE

t 3PMMFS4QPOHF8BOE

t 5FMFTDPQJDIBOEMFFYUFOETUPDN

44.1 inch

t 4QBSFXBOEXJUICFMU

t &YUFOTJPOQJFDFNNJODI

t (SPVOEJOHDBCMFXJUIDMBNQ

t $BMJCSBUJPODFSUJöDBUF

t 6TFSNBOVBM

EN

4

TABLE OF CONTENTS

1. GENERAL

*NQPSUBODFPGPQFSBUJOHNBOVBM

6TFSSFTQPOTJCJMJUZ

3FTQPOTJCJMJUZPGQFSTPOOFM

%BOHFST

%FTJHOBUFEQVSQPTF

$PQZSJHIU

.BOVGBDUVSFST4VQQMJFSTBEESFTT

2. SAFETY INSTRUCTIONS 8

.FBOJOHPG4ZNCPMT

2.2 Availability of Safety Information 8

5SBJOJOHPG1FSTPOOFM

2.4 Dangers from Electrical Energy 9

53"/41035"/%4503"(&

1BDLJOH

6TFS$IFDLPO3FDFJQU

3FQPSUJOH5SBOTQPSU%BNBHFBOE%PDVNFOUBUJPO

4UPSBHFBOE1SPUFDUJWF.FBTVSFTXIFOOPUJOVTF

4. DEVICE 10

4.1 Ground connection detection 10

5. GE TTING STARTED WITH THE LOW VOLTAGE PINHOLE DETECTOR 12

5.1 Assembly 12

0UIFSQSFQBSBUJPOT

5IFPQFSBUJOHCVUUPO

1PXFSJOHVQUIF1JOIPMF%FUFDUPS

0QFSBUJOHCVUUPOGVODUJPOT

5.4 How to operate the Pinhole Detector? 15

.BJONFOV

4FUUJOHT

1PXFSPOPò

EN

5

(&/&3"-."*/5&/"/$&

$BSF.BJOUFOBODF3FQBJST

%JTQMBZNBJOUFOBODF

$BCMFTBOEDPOOFDUPST

)FBUNPJTUVSFBOEEVTU

.PEJöDBUJPOTUPUIF&RVJQNFOU

$BMJCSBUJPO

#BUUFSJFT

41&$*'*$"5*0/452$1*/)0-&%&5&$503

ANNEX A | LOW VOLTAGE PINHOLE DETECTOR EXPANSION KIT 21

EN

6

1. GENERAL

1.1 Importance of operating manual

This manual is written in order to become familiar with all the functions and possible applicati-

ons of the instrument. It contains important instructions about how to use the instrument safely

and economically; according to the purpose designated. Following these instructions is not only

essential to avoid risks. It also reduces repair costs and down-time and increases the products

reliability and service-life.

Anyone who works with the instrument should follow the instructions in this manual, particularly

the safety related instructions. Additionally local rules and regulations relating to environmental

safety and accident prevention should be observed.

1.2 User-responsibility

The user should

a) only allow persons to work with the instrument who are familiar with the general instructions

on how to work safely and to prevent accidents. The use of the instrument should have been

instructed duly The safety chapter and the warnings in this manual should have been read and

understood; acknowledged as evidenced by their signature.

b) regularly check the safety-awareness of personnel at work.

1.3 Responsibility of personnel

Before commencing work anyone appointed to work with the instrument should pay attention

to the general regulations relating to working safety and accident prevention. The safety chapter

and the warnings in this manual should have been read and understood; acknowledged as

evidenced by their signature.

1.4 Dangers

This instrument has been designed and constructed in accordance with state-of-the-art techno-

logy and the acknowledged safety regulations. Nevertheless, working with the instrument may

cause danger to the life and health of the operator or to others, or damage to the instrument or

other property. Therefore the instrument should only be used for its designated purpose, and in

a perfect technical condition. Any defect that could have a negative eect on safety should be

repaired immediately.

1.5 Designated purpose

The TQC Low Voltage Pinhole Detector is exclusively designed to The TQC Low Voltage Pinhole

detector enables you to inspect various coatings on conductive substrates for small defects such

as holidays and pinholes using the‘wet sponge technique’. Other applications constitute impro-

per use.

EN

7

TQC will not be held liable for damage resulting from improper use. Designated purpose

also includes properly observing all instructions in the operation manual, and adherence to

inspection and maintenance schedules.

1.6 Copyright

The copyright of this operating manual remains with TQC.

This operating manual is intended solely for the user and his personnel. Its instructions and

guidelines may not be duplicated, circulated or otherwise passed on to others, neither fully, nor

partly. Infringement of these restrictions may lead to legal action may be taken if this restrictions

are infringed upon.

1.7 Manufacturer’s/Supplier’s address

52$.PMFOCBBO--$BQFMMFBBOEFO*+TTFM5IF/FUIFSMBOET

5'

EN

8

2. SAFETY INSTRUCTIONS

2.1 Meaning of Symbols

The following symbols for dangers are used in this instruction manual.

DANGER

Possible immediate danger to the life or health of personnel If this guideline is not noted it can

lead to severe danger to health, up to fatal injury

WARNING

A dangerous situation could be caused. Non observance of this guideline can lead to injury or to

damage to equipment.

TIPS! / NOTE!

Special tips and particular information. Guidelines to make optimal use of the instrument.

2.2 Availability of Safety Information

The instruction manual should be kept at the place where the instrument operates.

In addition to the information contained in the instruction manual, general and local regulations

for accident prevention and environmental protection shall be kept available and observed.

Always ensure all guidelines in respect of safety and dangers on the instrument are in readable

condition.

2.3 Training of Personnel

t "OZPOFXIPPQFSBUFTUIFJOTUSVNFOUTIPVMECFUSBJOFEQSPQFSMZ

t *UIBTUPCFDMFBSXIPIBTXIJDISFTQPOTJCJMJUZSFHBSEJOHDPNNJTTJPOJOHTFUVQPG

maintenance and repairs, installation, and operation.

t "OZPOFXIPIBTOUöOJTIFEUSBJOJOHTIPVMECFTVQFSWJTFECZBOFYQFSJFODFEQFSTPOXIJMF

working with the instrument.

EN

9

2.4 Dangers from Electrical Energy

DANGER People with for instance a pacemaker or heart problems should

completely avoid the use of this device.

WARNING: Risk of electric shock

The TQC Low Voltage Pinhole Detector (possibly) uses tensions that may cause a

mild electric shock. The earth clamp

detection will switch o the voltage of

the device once it is removed from the

substrate, yet the risk of electric shock

remains, particularly if the device isn’t

used properly. It is strongly

recommended at all times to hold the

device UNDER the button and avoid

each contact with the top plate (the live

part) The use of gloves is also

recommended.

t 5IFFMFDUSJDBMFRVJQNFOUPGUIFJOTUSVNFOUNVTUCFDIFDLFESFHVMBSMZ-PPTFDPOOFDUJPOTBOE

DBCMFEBNBHFECZIFBUNVTUCFDPSSFDUFEJNNFEJBUFMZ5IJTNBZPOMZCFEPOFCZBRVBMJöFE

electrician.

t "MXBZTNBLFTVSFUIFJOTUSVNFOUTQPXFSJTUVSOFEPòXIJMFBEKVTUJOHBOZFMFDUSJDBM

component.

3.TRANSPORT AND STORAGE

3.1 Packing

Please take note of pictorial symbols on the packing.

3.2 User: Check on Receipt

t $IFDLQBDLJOHGPSEBNBHF

t "GUFSVOQBDLJOHDIFDLDPNQMFUFTVQQMZ

3.3 Reporting Transport Damage and Documentation

Any damage should be documented as accurately as possible (possibly photographed) and

reported to the relevant insurers or, in the case of sales “delivered to customers works”, to the

supplier.

EN

10

3.4 Storage and Protective Measures when not in use

t 5IFJOTUSVNFOUNVTUCFTUPSFEJOBESZQMBDFBUBUFNQFSBUVSFCFUXFFO¡$

t 5IFTUPSBHFQFSJPETIPVMEOPUCFMPOHFSUIBONPOUIT

t 4UPSFJOTUSVNFOUJOUIFPSJHJOBMQBDLJOHJGQPTTJCMF

t 5PQSFWFOUCBUUFSZMFBLBHFSFNPWFCBUUFSJFTXIFOUIFEFWJDFJTVOVTFEGPSBMPOHFSQFSJPE

of time.

4. DEVICE

The TQC Low Voltage Pinhole detector enables you to inspect various coatings on conductive

substrates for small defects such as holidays and pinholes using the‘wet sponge technique’

The grounding clamp shall be connected to an untreated piece of the substrate(which is electri-

cally connected with the measurement area), where the wet sponge will be used to probe the

entirety of the coating with the selected voltage applied. When current ows from the sponge

XBOEUPUIFHSPVOEJOHDMBNQUIJTJOEJDBUFTBEFGFDUJOUIFDPBUJOHBOEUIFVTFSXJMMCFOPUJöFE

using the selected feedback method(s). (Buzzer, vibration, headphones and/or display)

3FMJBCMFBOEWBMJEEFUFDUJPOJTPOMZQPTTJCMFPODMFBODPBUJOHT.FBTVSFNFOUTPOEJSUZFYDFTTJ-

vely wet or otherwise contaminated surfaces are unreliable.

The TQC Pinhole Detector is available in two models:

"SUJDMF/P .PEFM 7PMUBHFT%$

LD8100 TQC Pinhole Detector Basic 9 VDC - 90 VDC

-% 52$1JOIPMF%FUFDUPS"EWBODFE 7%$7%$7%$7%$

The number of detected pinholes is stored in memory, and remains available after power down,

even when replacing batteries. This memory can be cleared by the user.

4.1 Ground connection detection

The TQC Low Voltage Pinhole Detector uses a high frequency earth clamp

detection. This provides the user feedback if the earth clamp is connected

properly. It also prolongs the battery life because the power is turned o

when there is no earth detected, thus reducing the risk of electric shock.

As a side note to this technique it should be mentioned that the reliability of this detection

depends on the circumstances in which the TQC Low Voltage Pinhole Detector is used.

EN

11

A few examples will be given to illustrate whether or not detection is reliable.

Example 1: A small treated object placed on an insulating table, and connected to the

ground terminal by a short cable. Once the sponge makes contact with the

object, the earth will be detected. Once the sponge disconnects, nothing will be

detected. In this case, the earth detection will work exactly as intended.

Example 2: The earth clamp is connected to a (large) chassis of a vehicle which is isolated

from the oor . The ground cable is (partially) on sheet metal of the chassis.

Once the sponge makes contact with the object earth will be detected. If the

clamp comes loose, a signal might still be detected through the cable, and the

detection is not 100% reliable.

Example 3: The earth clamp is connected to an object that is embedded in a concrete oor

and the long cable is on this oor. In this case, it may be that the earth

detection already detects earth after switching on the device. In this case, the

earth detection is NOT reliable, and extra attention should be paid whether or

not the earth clamp is still connected properly.

WARNING: Risk of electric shock

The TQC Low Voltage Pinhole Detector

(possibly) uses tensions that may cause

a mild electric shock. The earth clamp

detection will switch o the voltage of the

device once it is removed from the

substrate, yet the risk of electric shock

remains, particularly if the device isn’t

used properly. It is strongly recommended

at all times to hold the device UNDER the

button and avoid each contact with the

top plate (the live part) The use of gloves is also recommended.

DANGER

People with for instance a pacemaker or heart problems should completely avoid the

use of this device.

EN

12

5.GETTING STARTED WITH THE LOW VOLTAGE PINHOLE DETECTOR

The Low Voltage Pinhole Detector is ready for use as soon as you

VOQBDLJU"MMZPVIBWFUPEPJTJOTFSUCBUUFSJFTTFFNPVOUUIF

sponge wand and connect the ground cable and crocodile clamp to the

device and the substrate to be tested.

5.1 Assembly

Upon delivery the device (A) and sponge wand (B) will be

delivered separately. Before use, they should be connected

by means of the screw connection. The‘Advanced’ model

also has the opportunity to use an extension cable, which

oers the possibility to connect the unit to your belt

strap. The advanced model comes with dierent additional

accessories that can be used instead of the sponge wand.

A Device

B Sponge wand

C Grounding cable

D Crocodile clamp

I Grounding cable connection

II Battery compartment

III Headphone connection

EN

13

The grounding cable (C) must be inserted into the black bus (I)

be on the bottom of the device. (near the battery compartment)

The other side of the earth cable is plugged into the supplied

crocodile clip (D). This crocodile clip must be connected. When

used on an untreated piece of the substrate

The bottom of the unit also houses the battery compartment (II)

and the headphone jack (III)

5.2 Other preparations

To get proper conductivity, it is important that you work with a wet sponge. You can use tap

water containing a small amount (drop per liter) detergent. This detergent reduces the surface

tension of the water. It is important that the surface remains wet during the measurement.

5.3 The operating button

The device is operated by a single button:

The button is located directly under the display, slightly

elevated and‘clicks’ when pressed.

EN

14

Because of the safety it’s very important to hold the

device UNDER the operating button and avoid each

contact with the top plate.

5.3.1 Powering up the Pinhole Detector

Hold the button until the TQC logo shows on the display. As soon as the logo disappears the

device is ready for use. Below the start-up screen and the main screen:

TIP!

To test if the device detects an electronic contact briey hold the crocodile clamp against

the wet sponge. When functioning properly feedback is immediately given (audio / tactile),

depending on the settings.

Connect the grounding clamp to an untreated piece of the substrate (which is electrically con-

nected with the measurement area)

Place the wet sponge, on the substrate. The left side of the screen indicates that the ground cable

is connected properly. If the coating in the selected position is in good condition, the right half of

the screen will indicate this.

When current ows from the sponge wand to the grounding clamp, this indicates a defect in the

DPBUJOHBOEUIFVTFSXJMMCFOPUJöFEVTJOHUIFTFMFDUFEGFFECBDLNFUIPETBVEJPUBDUJMF

->

EN

15

Grounding clamp detected, Grounding clamp detected,

Coating without defect Coating with defect

NOTE The device will power itself down after 5 minutes of inactivity to preserve battery

QPXFS5IFEFMBZCFGPSFQPXFSEPXOJTVTFSDPOöHVSBCMFTFF

5.3.2 Operating button functions

The button can be pressed several dierent ways to eectively be able to use it as three separate

buttons. A slight buzz will indicate roll-over to the next button function.

‘Click’ A short press of the button up to half a second

‘Press’ A press of the button from half a second to one second

‘Hold’ Holding the button for at least 1 ½ seconds

5.4 How to operate the Pinhole Detector?

This section will describe how to operate the Pinhole Detector, as well as describing the hierarchy

of the available menus and settings.

Conguring the device

After powering on (main screen) the menu can be opened using a ‘click’. Navigating the available

TFUUJOHTJTEPOFXJUITVCTFRVFOUADMJDLTBGUFSUIFMBTUJUFNUIFNFOVMPPQTCBDLUPUIFöSTUJUFN

"AQSFTTDPOöSNTPSPQFOTUIFTFMFDUFEJUFNA)PMEJOHUIFCVUUPOXJMMFYJUUIFDVSSFOUNFOV

"AIPMESFUVSOJTOPUBQQMJDBCMFJOUIFWPMUBHFTFMFDUJPONFOVJUFNT"TTPPOBTUIFCVUUPOJT

held for more than half a second (‘press’event), the selected voltage is immediately applied while

returning to the main screen. To leave the menu nonetheless, navigate past the voltage items

and then ‘hold’ the button.

EN

16

5.4.1 Main menu

# Description ‘Press’ event

1 Pinhole counter: shows Resets the counter to zero

the current number of

pinholes detected

2 Voltage: 9 VDC The selected voltage

will be applied

7PMUBHF7%$

7PMUBHF7%$

5 Voltage: 90 VDC

4FUUJOHT 5IFTFUUJOHTTVCNFOVXJMM

be opened

7PMUBHFT7%$FO7%$BSFPOMZBWBJMBCMFPOUIF"EWBODFENPEFM-%

EN

17

5.4.2 Settings

# Description ‘Press’ event

1 Buzzer (Enable /

Disable)

Buzzer enabled Buzzer disabled

2 Vibration (Enable /

Disable)

Vibration enabled Vibration disabled

4DSFFOEJNNJOH

(Enable / Disable)

Screen dimming enabled Screen dimming disabled

4 Toggle option

This function selects whether the device automatically

UVSOTPGBGUFSPSNJOVUFTPGJOBDUJWJUZ*UJTOPU

possible to disable the automatic power down function.

Automatic power down

5 Shows device information

In this menu, the device model- and serial number will

be displayed. After‘pressing’ the button device details

such as calibration date and distributor location will be

Device information displayed.

Settings: automatic power down

5IJTGVODUJPOTFMFDUTXIFUIFSUIFEFWJDFBVUPNBUJDBMMZUVSOTPGBGUFSPSNJOVUFTPG

inactivity. It is not possible to disable the automatic power down function.

Setting: Product information

On this menu, the device model- and serial number will be displayed. After ‘pressing’the button

device

EN

18

5.4.3 Power on / o

Using this menu option the device can be powered down.

1. Navigate to the main menu

2. ‘hold’ the button until this screen appears:

8IFOZPVSFMFBTFUIFCVUUPOUIFEFWJDFUVSOTPòBOEUIFTDSFFOXJMMUVSOCMBDL

6. GENERAL MAINTENANCE

6.1.1 Care, Maintenance, Repairs

t %POPUPQFOUIFEFWJDF*ODBTFPGNBMGVODUJPOBMXBZTDPOTVMUUIFNBOVGBDUVSFS

t .BJOUFOBODFBOEJOTQFDUJPOTIPVMECFDBSSJFEPVUBUUIFDPSSFDUJOUFSWBMT

t "MXBZTNBLFTVSFUIFEFWJDFTQPXFSJTUVSOFEPòXIJMFBEKVTUJOHBOZFMFDUSJDBMDPNQPOFOU

whenever maintenance, inspection or repair work is done.

t "MXBZTTUPSFUIF52$-PX7PMUBHF1JOIPMF%FUFDUPSJOJUTPSJHJOBMQBDLJOHXIFOOPUJOVTF

Never use compressed air to clean the device

6.1.2. Cleaning the device

We advise to clean te instrument with a soft dry cloth. Don’s use any solvents. In case of hard to

remove stains a small amount of Isopropyl Alcohol may be used.

6.1.3 Cables and connectors

*UJTQPTTJCMFUPDPOOFDUUIFEFWJDFUPBDPNQVUFSGPSöSNXBSFVQEBUFT6OEFSOPSNBMDPOEJUJPOT

this will not be required, end users will be informed if updates are available. Please make sure

connectors and cables are undamaged before making a connection.

6.1.4 Heat, moisture and dust

Protect the device from extreme heat. Do not leave the device on the dashboard of a car, near

heaters or furnaces, or use direct heat to dry a wet device. When drying is required use a moisture

absorbing cloth. Exposing the device to extreme temperatures may damage the screen, the plas-

tic parts as well as the internal components. Do not leave the device in extremely dusty or wet

places. Excessive dust and moisture exposure might damage the device and cause malfunctions

or defects.

EN

19

6.2 Modications to the Equipment

t "OZNPEJöDBUJPOTPSBEEJUJPOTPSBMUFSBUJPOTUPUIFEFWJDFNBZTPMFMZCFNBEFXJUI

permission from the manufacturer.

t "MMNFBTVSFTJOWPMWJOHNPEJöDBUJPOTSFRVJSFXSJUUFODPOöSNBUJPOPGBQQSPWBMGSPN52$

t %FWJDFTXIJDIBSFOPUJOGBVMUGSFFDPOEJUJPONVTUJNNFEJBUFMZCFTXJUDIFEPò

t 0OMZVTFSFQMBDFNFOUQBSUTGSPNUIFPSJHJOBMTVQQMJFS1BSUTVTFEGSPNPUIFSTPVSDFTBSFOU

guaranteed to take the loading and meet the safety requirements.

6.3 Calibration

The device will be supplied ready to use (calibrated). In the event re-calibration is required the

device will indicate this to the user.

Please send the device to:

TQC BV

.PMFOCBBO

--$BQFMMFBBOEFO*+TTFM

The Netherlands

1MFBTFDPNQMFUFBOEBEEUIF3."GPSNGSPNPVSXFCTJUF

http://www.tqc.eu/en/service/repairs-calibrations

6.4 Batteries

The battery status is displayed in the upper right corner of the display. The batteries will be

emptier as the color of the indicator shifts to red and the bars decline. The use of rechargeable

CBUUFSJFTTVDIBT/J.)PS/J$ENJHIUTIPXBWBMVFUIBUEJòFSTGSPNUIFBDUVBMWBMVF5IJT

however does not negatively impact device functionality.

#BUUFSZUZQF""7BMLBMJOFPS""/J.)/J$E5IFVTFPGIJHIRVBMJUZCBUUFSJFTJTBEWJTFE

to prevent battery leakage which may damage your device. The batteries should be inserted with

the positive pole facing inwards.

To prevent battery leakage remove batteries when the device is unused for a longer period

of time. Store device in the original packing if possible.

The battery compartment is located under the screw cap (II). Keep the Low Voltage Pinhole

Detector horizontal when placing the batteries. First insert the + side of the battery. When the

device is held vertically during battery placement, the batteries will‘fall’ in. This impact may cause

damage to the battery spring.

EN

20

7. SPECIFICATIONS TQC PINHOLE DETECTOR

.PEFM LD8100 LD8105

TQC Pinhole Detector: Basic Advanced

7PMUBHFT%$ 7%$7%$7%$7%$7%$7%$

.FBTVSJOHSBOHFVQUPNBYNDPBUJOHUIJDLOFTT

7PMUBHFBDDVSBDZ BU7%$7%$BOE7%$BOEBU7%$

Sensisitivity: 100 k Ω at all voltages

)FBETFUDPOOFDUPSUZQF NNKBDLQMVH

Headphone output power: max 150 mW

)FBEQIPOFPVUQVUJNQFEBODF _Ɔ

%JNFOTJPOT YYNNYYJODI

8FJHIUEFWJDF H

8FJHIUEFWJDFTQPOHFXBOE H

%JTQMBZ 'VMM$PMPS0-&%EJTQMBZJODIYQY

Operation: single button, menu-driven by a microprocessor

.FBTVSFNFOUTQFFE $POUJOVPVT

Units: Binary indication (defect/intact)

Operational relative humidity: 0-85 %rH

0QFSBUJPOBMUFNQFSBUVSF ¡$UP¡$¡'UP¡'

'BDUPSZDBMJCSBUJPO $FSUJöFEDPNQPOFOUTBOENFBTVSJOHFRVJQNFOU

3FDFSUJöDBUJPOQPTTJCMF

#BUUFSZQSFTFSWBUJPO 6TFSDPOöHVSBCMF

#BUUFSZMJGF "QQSIPVSTEFQFOEJOHPOCBUUFSZUZQF

Software: Firmware Update Tool inclusive

Standards:

This device is usable for inspections such as those stated in the following standards:

*40"*40#4"45.%"+*4,5.

EN

This manual suits for next models

1

Table of contents

Popular Security Sensor manuals by other brands

Interlogix

Interlogix DDI602AM Installation sheet

CoCo

CoCo PIR-2050 Quick installation guide

Leviton

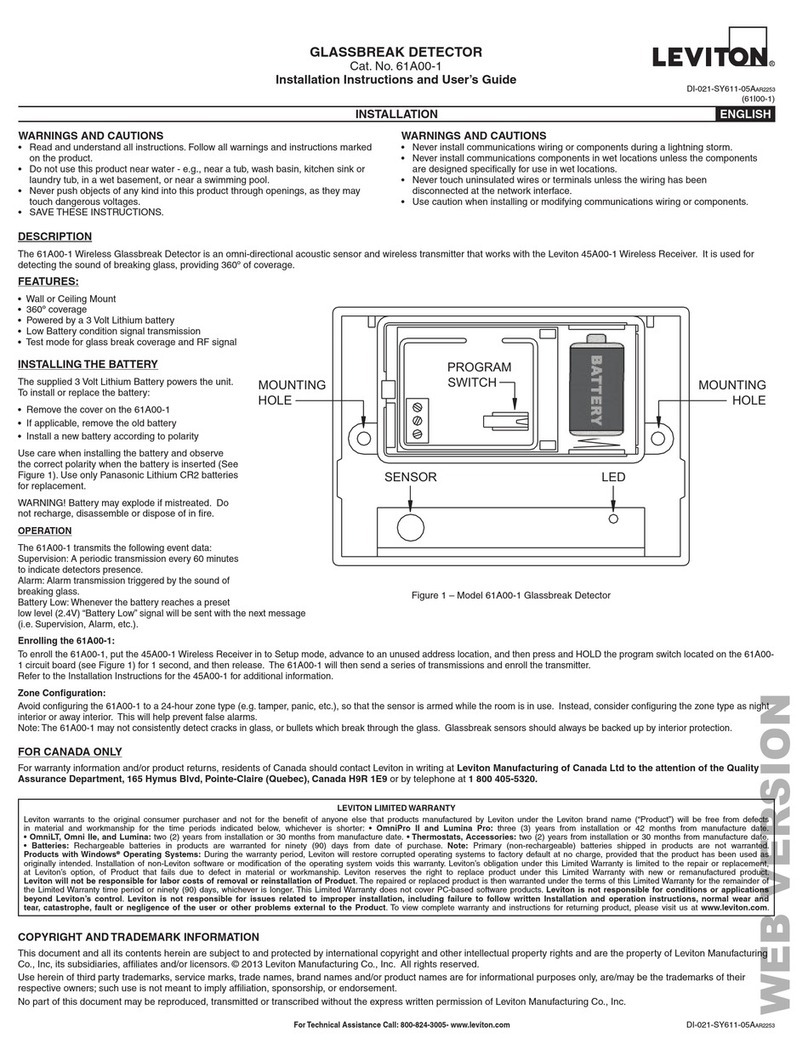

Leviton 61A00-1 Installation instructions and user guide

AFRISO

AFRISO AHD 10 operating instructions

iRay Technology

iRay Technology Mars1417XF user manual

Karagiannis-Security

Karagiannis-Security MC-335R quick start guide

LEGRAND

LEGRAND Valena quick start guide

Comelit

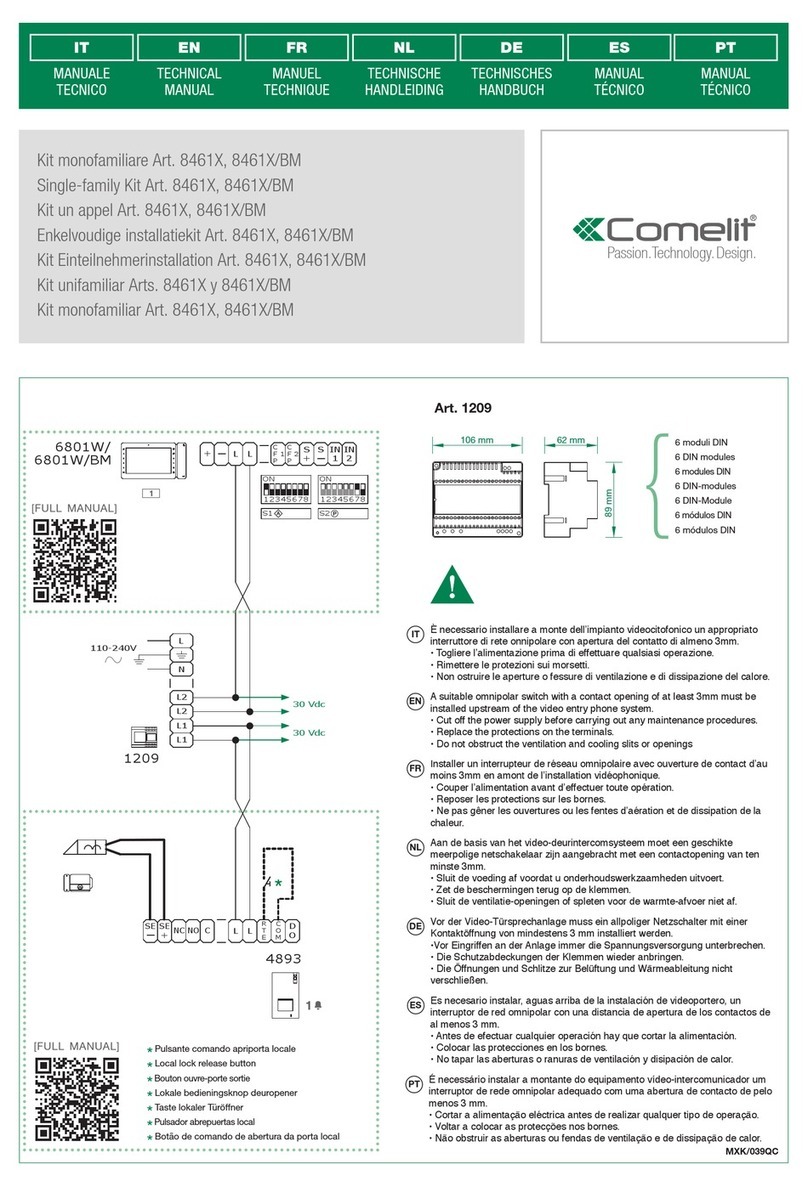

Comelit 8461 Series Technical manual

Endress+Hauser

Endress+Hauser USR30 technical information

REED

REED R9200 instruction manual

CIAS Elettronica S.r.l.

CIAS Elettronica S.r.l. MURENA PLUS 12 installation manual

Varex Imaging

Varex Imaging PaxScan 1313DXT-I manual