TRACER PRODUCTS Marksman II Series User manual

1

OPERATOR’S MANUAL

What You Can't Hear Is What

You Need To Hear!

10/19 AM16056ML-4

PRINTED IN U.S.A.

ENG - 1 FR - 23 DE - 67ES - 45

TP-9367L

2

EU DECLARATION OF CONFORMITY

This declaration is issued under the sole responsibility of the manufacturer

Tracer Products. The object of the declaration is to certify that this equipment,

designed and manufactured by Tracer Products, is in conformity with the

relevant Community harmonization legislation. It has been constructed in

accordance with good engineering practice in safety matters in force in the

Community and does not endanger the safety of persons, domestic animals

or property when properly installed and maintained and used in applications

for which it was made.

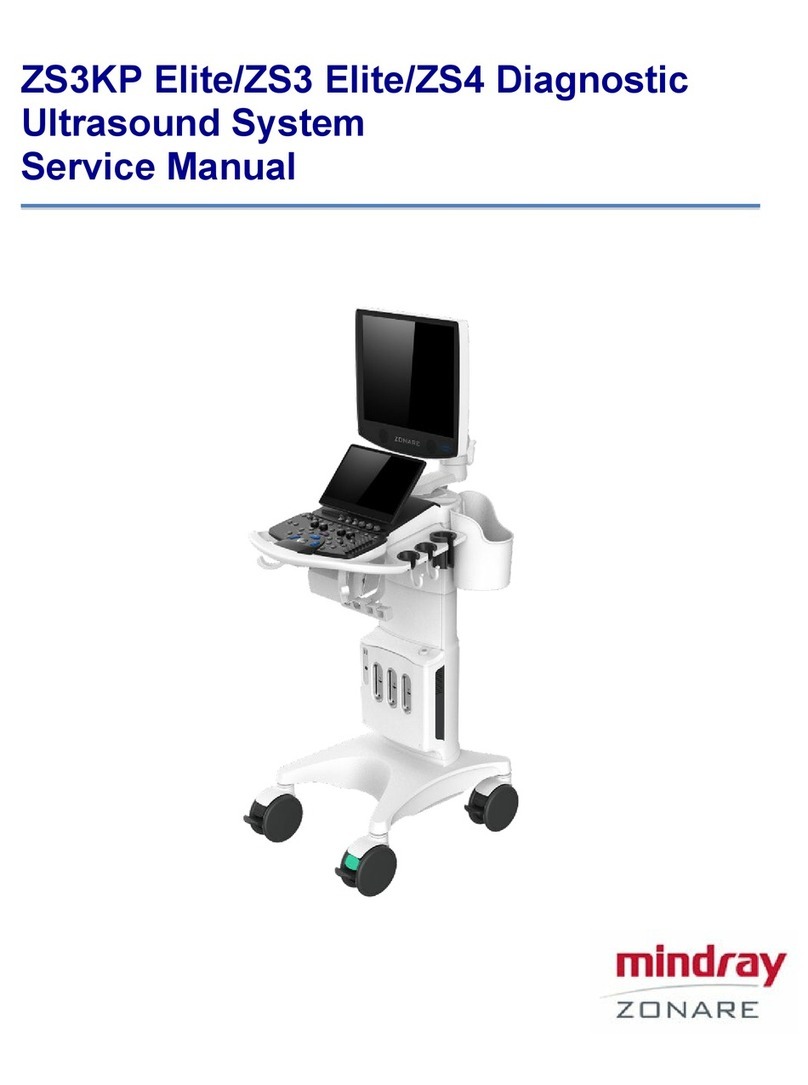

Equipment Description: Ultrasonic Leak Detector (with integrated laser

pointer)

Model Number: TP-9367L

Applicable Directives:

• 2014/30/EU General EMC

• 2011/65/EU RoHS

Applicable Standards:

Safety:

• EN 61010-1:2010 Safety requirements for electrical equipment for

measurement, control, and laboratory use. General requirements.

• IEC 60825-1:2014 Safety of Laser Products - Part 1: Equipment

Emissions:

• CISPR 11/EN 55011:2009 (+A1 :2010) Emission standard for

Immunity:

• EN 61326-1:2013 Edition 2.0 (EMC - Measurement, Control &

Laboratory Equipment) Immunity per Table A.1 - Portable Test and

Measurement Equipment.

RoHS:

• EN 50581:2013 Technical documentation for the assessment of

electrical and electronic products with respect to the restriction of

hazardous substances.

CE Implementation Date:

• April 26, 2016

3

CONTENTS

Declaration of Conformity............................................................2

Contents ......................................................................................3

......................................................................................4

Introduction/General Information............................................. 5-6

Kit Configuration and Components.......................................... 6-7

....................................7

Important Tips.......................................................................... 7-8

Integrated Laser........................................................................8-9

Safety Precautions ....................................................................10

Operating Instructions ..........................................................10-11

...................................................................12

Ultrasonic Emitter ......................................................................13

High Noise Environments..........................................................14

Typical Scanning Methods/Tips........................................... 14-16

Applications ......................................................................... 17-20

Care and Maintenance .............................................................20

Warranty and Liability ................................................................21

Technical Specifications ...................................................... 21-22

Replacement Parts....................................................................22

Marksman™ II is a trademark of Tracer Products.

DURACELL®is a registered trademark of Duracell Inc.

4

FEATURES

The Marksman II Ultrasonic Diagnostic Tool converts and amplifies

inaudible ultrasonic sound into audible “natural” sound by

employing technologically advanced circuitry. It operates on the

principle of detecting high frequency ultrasonic waves, which are

created by friction from all moving parts, whether solid, liquid or

gaseous. These “sounds” reside far above the range of the human

ear and tend to be highly directional.

This directional aspect of ultrasonic waves allows one to isolate a

suspect signature sound from other background noises and detect its

exact location. This sound analysis can be used for efficiently

investigating the following areas of repair and preventive mainte-

nance in the following transportation and industrial applications:

1. Air leaks

packet or wave front which can result in an ultrasonic

emission with a differential of 5 psi from a 12 inch (30.5 cm)

distance, and/or a hole down to 0.004 inches (0.1 mm) in

diameter.

2. A/C refrigerant leaks (for most types of refrigerant)

3. Gas and liquid turbulence

Turbulence associated with steam trap and internal valve

leaks, cavitation, and blockages in liquid and air/gas lines.

4. Electrical discharge

Electrical discharge associated with insulation breakdown,

tracking, corona and arcing.

5. Diagnosing solenoid operations

6. Mechanical wear

State of mechanical wear in bearing and race assemblies,

shafts and gears (also indicating the state of lubrication).

INTRODUCTION

pneumatic devices, as well as in container-type objects, start as

small defects or leaks. The physical size of these defects is so

5

relatively small that the sounds they produce are above the range

of human hearing. Most commonly, these faults generate sounds

in the 38,000 to 43,000 cycles per second range, generally

referred to as being in the ultrasonic range.

To employ the ultrasound methodology in a usable manner, it is

imperative that the listener have access to an audible sound that

bears a resemblance to the natural sound of the defect.

A mechanical bearing with a defective ball should sound like such.

Likewise, converting the ultrasound frequencies to audible

frequencies is not sufficient with regard to rendering a usable

signal. For this reason, the Marksman II incorporates a

process whereby the audible signal bears a close likeness to

the natural incoming sample. We call this process “Sound

Signature Technology,” whereby a gas leak sounds like a gas leak

and a defective bearing sounds like one.

GENERAL INFORMATION

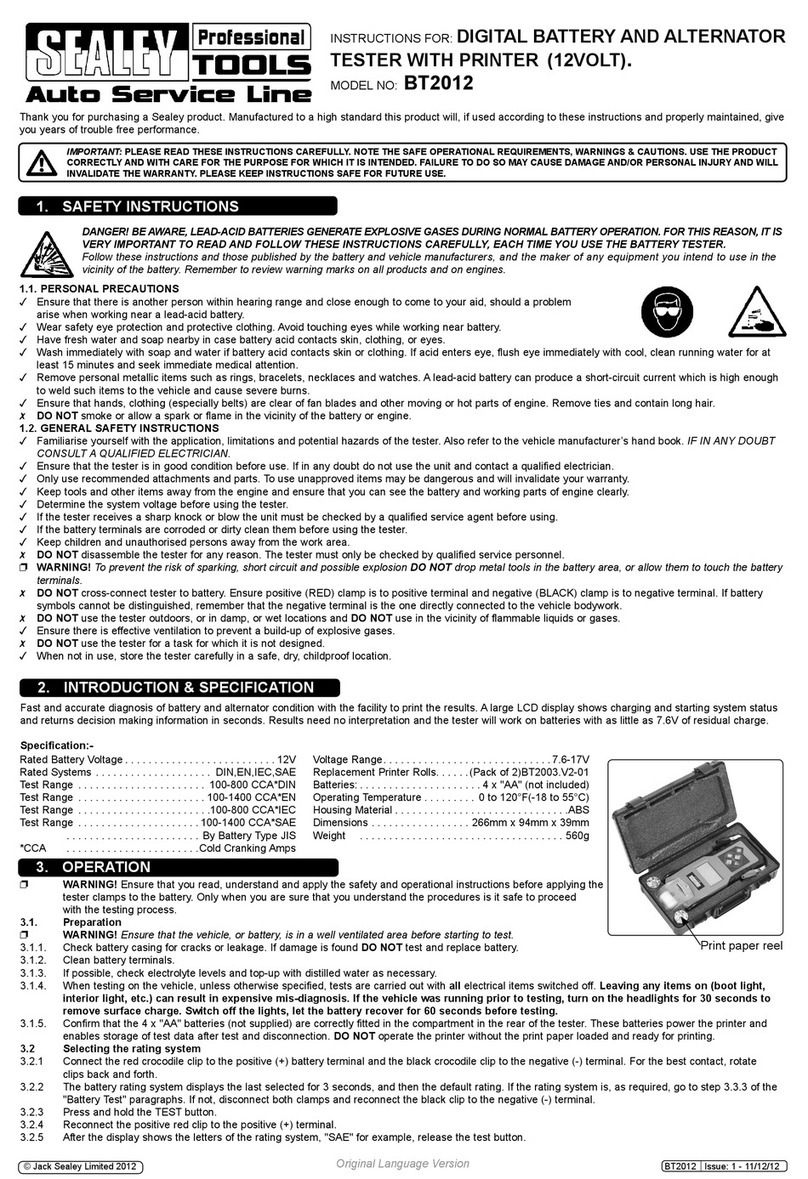

The Marksman II is sensitive only to ultrasound (40.5 kHz) and is

unaffected by audible noise. Internal Noise Control (I.N.C.) allows

the use of this instrument in extremely noisy environments such as

mechanical rooms, around operational chillers, etc. Drag your

finger upwards on the sensitivity touch pad to increase sensitivity

when experiencing little or no environmental noise. Drag your

finger downwards on the sensitivity touch pad to reduce sensitivity

in response to an increase in environmental noise. The I.N.C.

works much like a two-way radio squelch allowing only the

strongest and closest signals to penetrate the electronic wall built

by the I.N.C. circuitry.

Many variables can affect the amount of ultrasound generated by

the leakage of gas through an orifice. Such factors include the

pressure/vacuum versus the surrounding environment, how

smooth the edges of the orifice are, the diameter of the orifice, the

leak detector’s distance from the orifice and the presence of air-

flow, which may dissipate the ultrasound. As you use the

Marksman II, keep in mind that these factors may affect your abil-

ity to detect ultrasonic leaks.

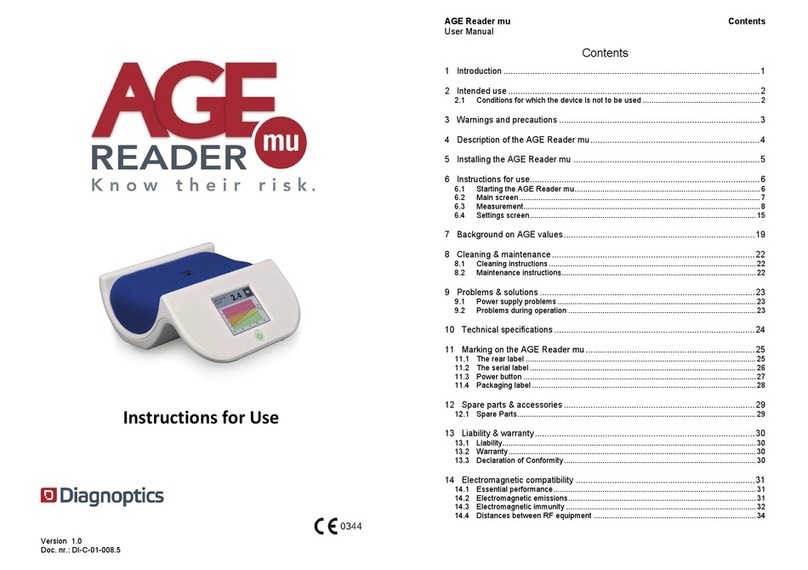

This manual suits for next models

1

Table of contents

Languages: