Tractel Griphoist Skybeam User manual

1

© 2013 Tractel Ltd. All Rights Reserved.

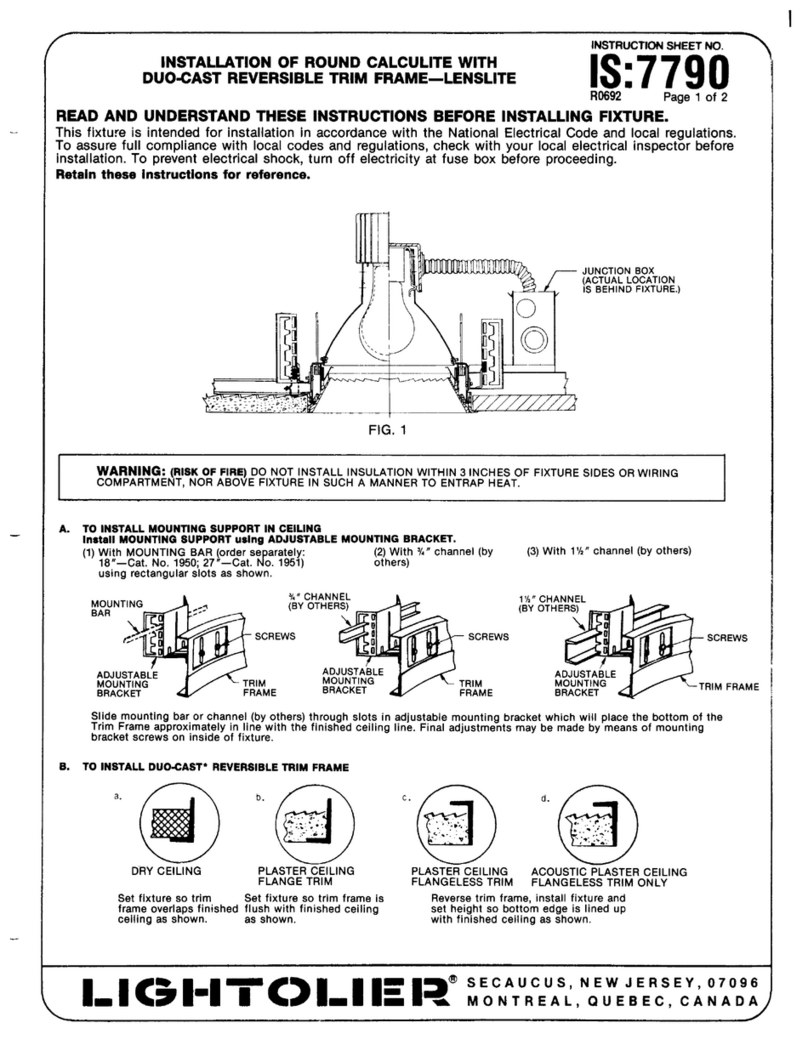

4’ reach light skybeam® 1,000 lb. (454kg) capacity

United States: Boston: 1 800 421-0246 • Los Angeles: 1 800 675-6727 • [email protected]

Canada: Montreal: 1 800 561-3229 • Toronto: 1 800 561-3229 • [email protected]

temporary outrigger beam for suspended platforms

assembly manual for

ractel, Griphoist®Division

4’ orizontal Beam

4’ Inclined Beam

Tieback

Required

Tieback

Required

Tieback

Required

Tieback

Required

© 2013 Tractel Ltd. All Rights Reserved.

2

CONTENTS

PAGE

1. GENERAL WARNING 4

2. TRANSPORT AND ANDLING 5

3. TEC NICAL SPECIFICATIONS OF T E 4’ SKYBEAM 6-9

3.1 Horizontal Version

3.2 Inclined Version

4. ASSEMBLY INSTRUCTIONS OF T E 4’ SKYBEAM 9-15

5. ASSEMBLY INSTRUCTIONS OT ER 16-19

5.1 Installation of Tieback

5.2 Calculation of Counterweights skybeams (reference)

5.3 Set up of Primary Wire Ropes

5.4 Set up of Outriggers and Counterweights

6. C ECKS BEFORE USING T E SKYBEAM 20

6.1 Suspension Points and Support Equipment

6.2 Tieback

6.3 Platforms

6.4 Wire Ropes

6.5 Hoists

7. USE AND OPERATION OF T E SKYBEAM 21

8. INFORMATION FOR MAINTENANCE 21

9. SKYBEAM LABELS AND MARKINGS 22-23

4’ reach light skybeam® 1,000 lb. (454kg) capacity

temporary outrigger beam for suspended platforms

assembly and operating instructions

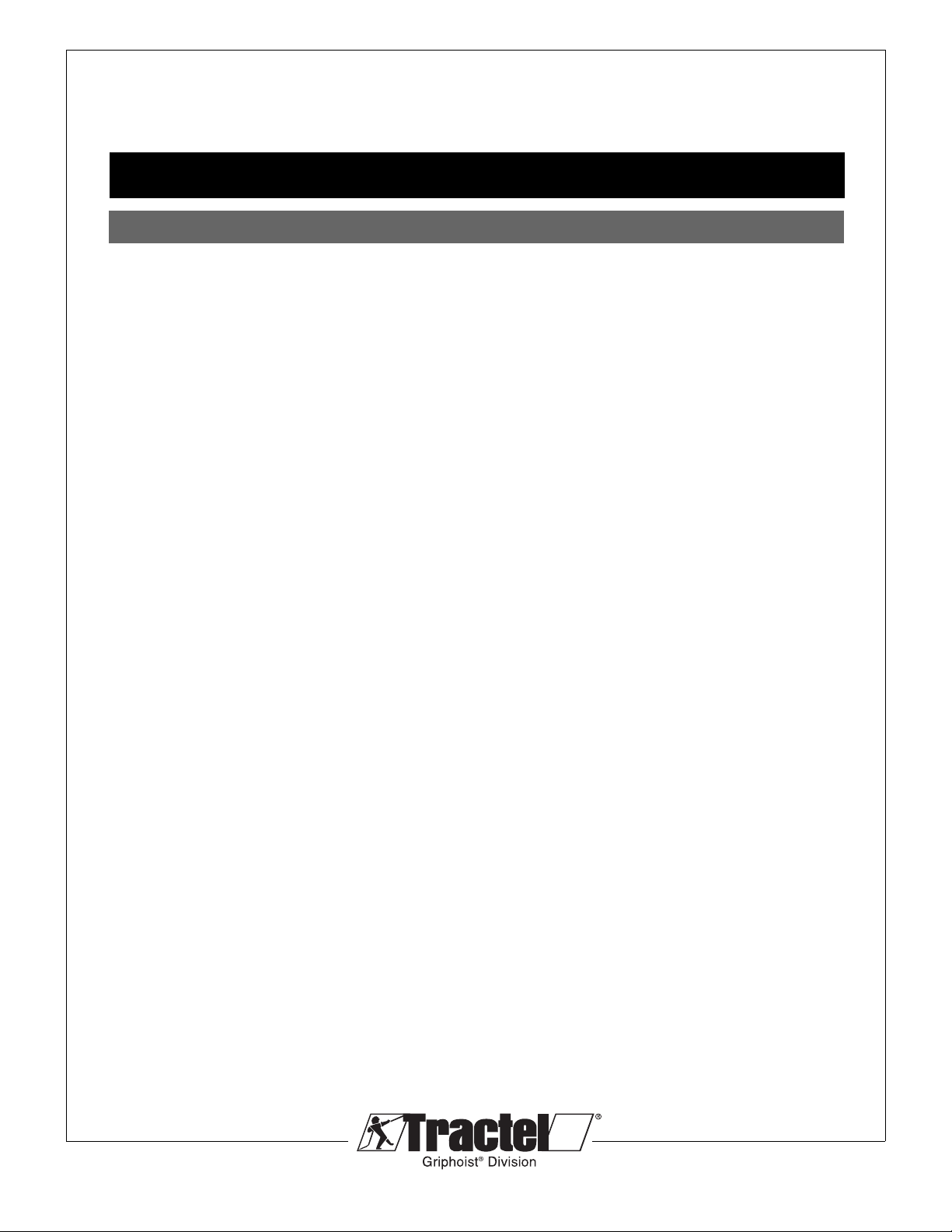

Explanation of Symbols used in this manual

Safety advice

Possible consequence

Symbol Code word Meanin of non-compliance

IMMEDIATE or

WARNING possibly imminent Fatal or serious injuries!

dan er:

CAUTION possibly dan erous Minor injuries to persons!

situation:

Other Advice

Statement of

NOTE Policy Related Dama e to equipment

to Safety: or its surroundin s

Instruction for

(none) documentation in writin (none)

(i.e. record keepin ):

© 2013 Tractel Ltd. All Rights Reserved.

3

The 4' reach light skybeam®is designed for a Maximum load of 1,000lbs (454kg).

Do not use this system with a hoist of a greater capacity then 1,000lbs (454kg).

© 2013 Tractel Ltd. All Rights Reserved.

4

GENERAL WARNING

Read this general warning first.

In suspended platform operations, safety is a matter of life or death for riggers,

operators and by-standers. This warning is your share of duties for achieving safety.

YOUR DUTY TO UNDERSTAND AND COMPLY.

1. It is the responsibility of the riggers and operators, and their

employer’s responsibility, if they operate under an

employer’s control, to strictly conform to the following

warnings.

2. It is imperative for safety and efficiency of operations

that this manual be read and fully understood by the

rigger and the operator before rigging or operating the

platform. All instructions contained herein must be

carefully and strictly followed, including applicable SAIA

code of safe practices.

3. Should you hand over a skybeam under any conditions, to

any party operating out of your control, you must attach a

clean copy of this manual and draw to other party’s attention

that strictly following all the instructions therein is a matter of

life or death.

4. Before using the skybeam, the rigger and the operator must

become aware of all the requirements of federal, state,

provincial and local safety regulations not only applicable to

the skybeam, but also to the entire suspended scaffold

system or any component of it.

5. Never use the skybeam for any job other than lifting

personnel on suspended scaffold according to the

instructions of this manual.

6. Never load the skybeam above its rated load.

YOUR DUTY TO INSPECT AND MAINTAIN.

7. Keep this manual available at all times for easy reference

whenever required. Extra copies are available through the

equipment supplier.

8. Carefully take notice of all the labels and markings affixed to

the skybeam. Never rig or operate the skybeam if any label,

normally fixed on it, is obscured or missing. Replacement

labels are available through the equipment supplier.

9. Every time the skybeam is to be rigged or used, check that

the skybeam, platform, hoists, wire ropes and other

components of the suspended scaffold system are complete

and in good working condition, prior to proceeding.

10. A careful and regular inspection of the platform hoists, wire

ropes and other components of the installation is part of the

safety requirements. If you have a question, call the

equipment supplier.

11. Before rigging, re-rigging and after, the skybeam must be

inspected by a Competent Person familiar with the skybeam

and professionally trained for the purpose.

12. Inspection by persons authorized by riphoist is to be

carried out once every six months, to spot check the

condition of the beam and its components and that

rigging is being done correctly. A signed and dated

report card should be maintained for these purposes.

13. The manufacturer declines any responsibility for

consequences of repairs or modifications brought out of

its control to the product, specially by replacement of

original parts or repairs by another manufacturer.

YOUR DUTY TO TRAIN AND CONTROL PEOPLE.

Compliance with safety rules extends to rigging

operations which must be carried out only after securing

safe conditions of operation as per safety regulations and

requirements.

14. An operator must not be assigned to a suspended job or

to rigging for a suspended job, or to de-rigging after the

job, if that person is not:

a) mentally and physically fit for the purpose, especially

at heights.

b) competent for the job to be performed.

c) familiar with the scaffold equipment as rigged.

d) professionally trained for working under the above

requirements.

Except for the operations described in this manual, the

maintenance of the skybeam, as well as repairs, must be

exclusively done by repairers authorized by riphoist.

Spare parts used for all equipment must be in

accordance with the product, no substitutions are

allowed.

15. Never let the skybeam or other components of a

suspended scaffold system be managed or operated by

any person other than authorized and assigned to the

job. Keep the equipment, either rigged or unrigged, out of

reach of unauthorized persons, while out of operation.

16. Training operators and riggers includes setting up rescue

procedure should a scaffold be brought to a standstill

during a job. Such procedure must be set up by a

Competent Person or its technical consultant, according

to the working conditions, prior to putting the equipment

into operation.

17. Every suspended job must be placed under the control of

a person having the required competence and authority

for checking that all the instructions prescribed by this

manual be regularly and efficiently carried out.

Draft #2 June 19, 2013

© 2013 Tractel Ltd. All Rights Reserved.

5

YOUR DUTY TO SAFETY BEYOND T E ROOFBEAM

As being only one piece of a scaffold system, the skybeam

can contribute to the required safety only if:

18. Compatibility of other brands has been verified & approved

by Tractel® griphoist engineering department.

19. It is fitted on compatible equipment.

20. Other components meet the requirements of the applicable

safety regulations and requirements, are of the proper

quality, assembled to form a safe and efficient suspended

scaffold system, and are approved by riphoist engineering

department.

21. Every upper support of the scaffold is stable, sufficiently

strong and properly tied back to the structure, according to

the load either static or dynamic.

22. The supporting structure and tie-backs are required to

withstand every load to be applied, either static or dynamic,

during rigging or operating the scaffold equipment.

23. All the requirements in strength and resistance are obtained

with the necessary safety coefficients (see regulations and

professional standards).

24. All the calculations, design and subsequent work necessary

to meet the above requirements have been made by a

Competent Person on the basis of proper technical

information regarding the site.

YOUR DUTY TO AVOID TAKING C ANCES.

25. Once the suspended platform has been lifted off its initial

support (ground or any other level), it is imperative not to

release, remove, alter or obstruct any part of the equipment

under load.

26. NEVER allow any condition which would result in a

suspension wire rope becoming SLACK during the

operation unless:

a) the suspended platform is safely supported on a safe

surface giving a safe access to the operator in compliance

with safety regulations.

b) another suspension wire rope has been safely rigged to

the suspension platform.

27. Never operate a platform and its accessories, especially

electric ones, in a potentially explosive atmosphere.

28. For any job to be performed on the suspended equipment,

consider and control the specific risks related to the nature

of the job.

29. Should you decide that this skybeam is no longer to be

used, take precautions in disposing of it so that it cannot be

used any more.

30. The manufacturer declines any responsibility for any

special rigging or structural combinations beyond the

descriptions of this manual.

31. The manufacturer declines any responsibility for any

other use of the skybeam, than described in this

manual.

32. Do not mix and match the 4' reach light skybeam and

the 11’ skybeam components. Only use configurations

as shown in this manual.

AN ULTIMATE RECOMMENDATION

Never neglect means to improve safety. Due to the risks

inherent in the use of suspended scaffolding, it is strongly

recommended that every installation be equipped with

secondary wire rope(s) fitted with a separate fall arrest

system, anchored to a safe separate point of the building

structure.

This manual is neither a regulations compliance

manual nor a general training guide on a suspended

scaffold operations. You must refer to proper

instructions delivered by manufacturers of the other

pieces of equipment included in your suspended

scaffold installation. Whenever calculations and

specific rigging and handling are involved, the operator

should be professionally trained to that end and secure

relevant information prior to commencing such work.

2. TRANSPORT AND ANDLING

andle equipment with care, do not drop equipment

during loading or unloading. Impose loads on the

skybeam gently and without impact.

© 2013 Tractel Ltd. All Rights Reserved.

6

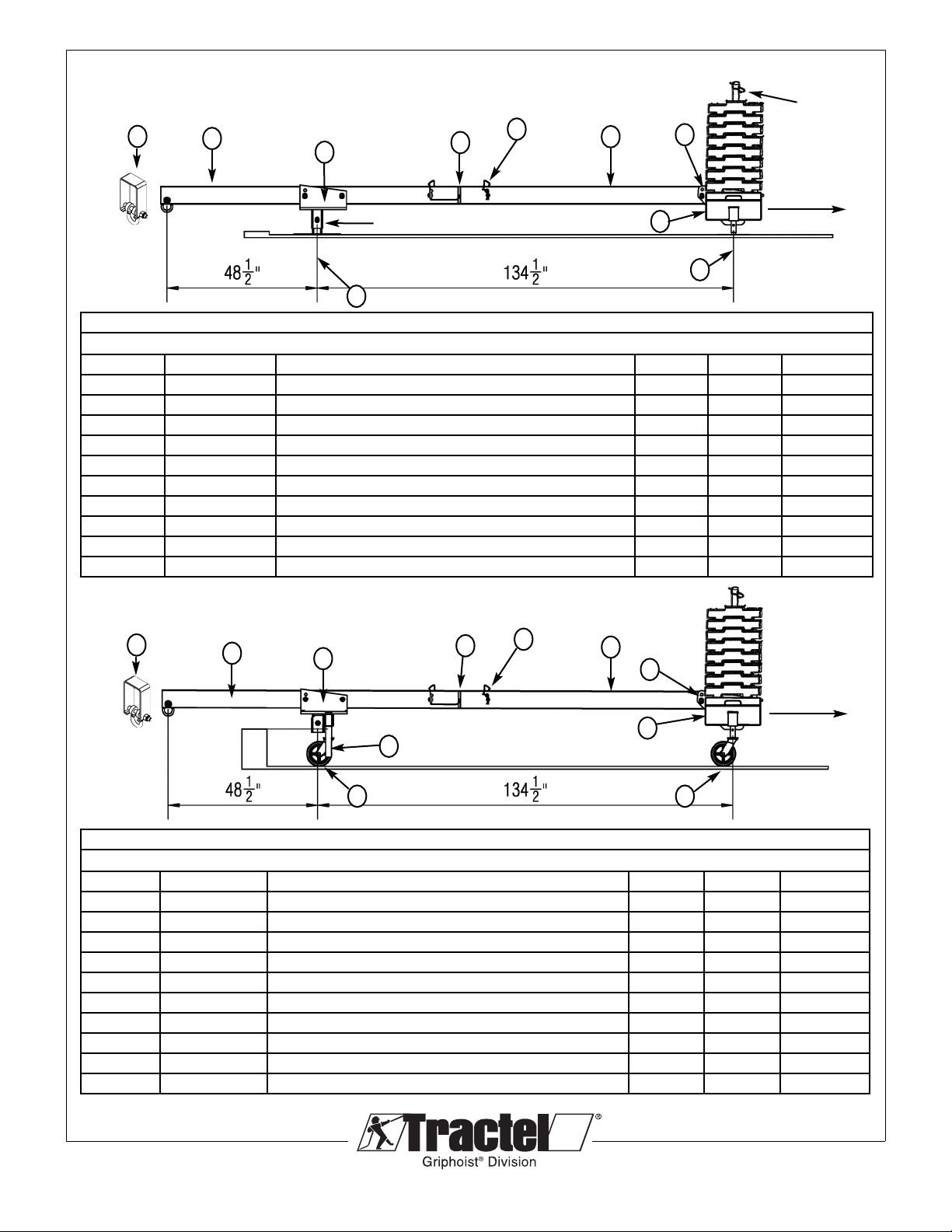

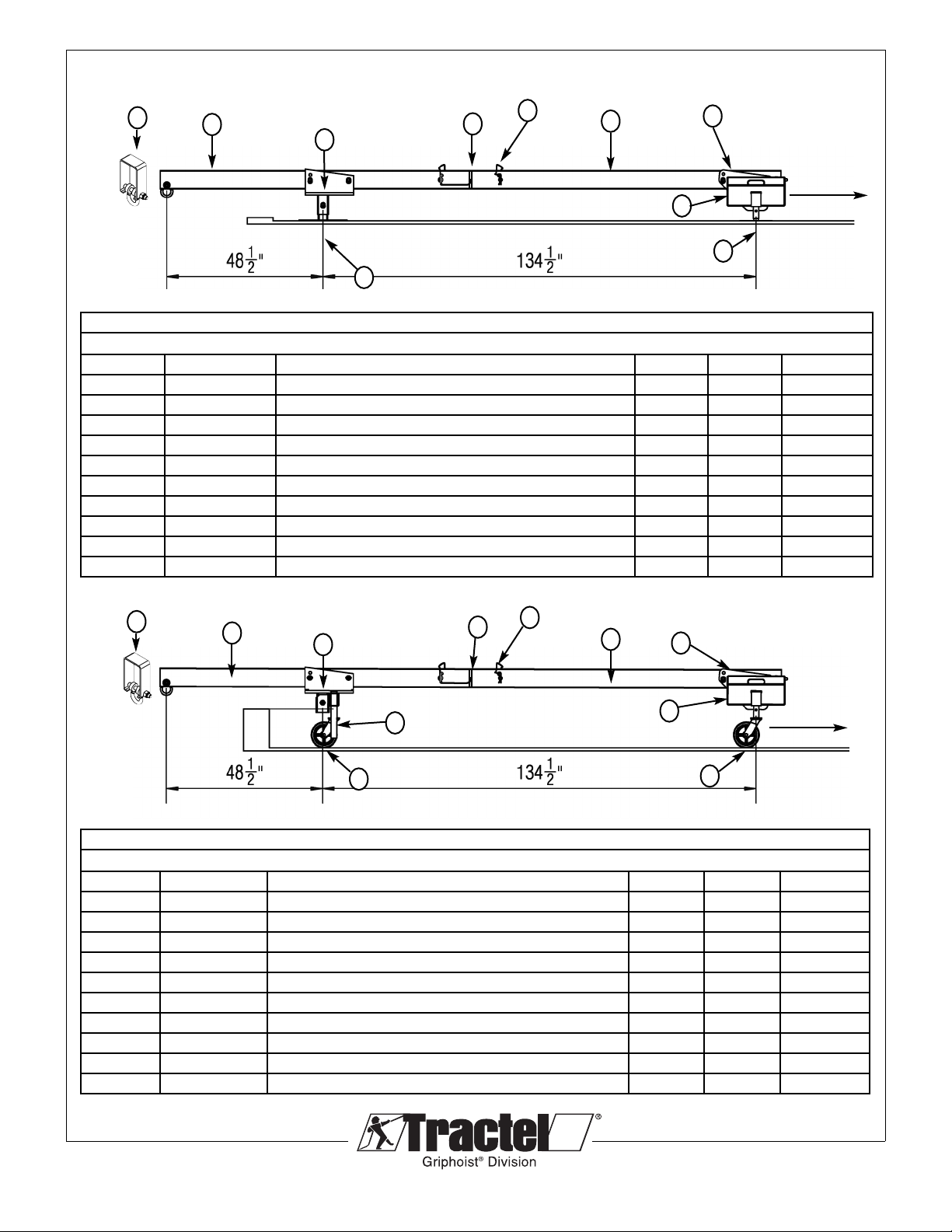

3.1 TEC NICAL SPECIFICATIONS AND COMPONENTS OF T E 4’ REAC LIG T ORIZONTAL SKYBEAM

ORIZONTAL 4' SKYBEAM - 4' REAC -1,000lb. (454 kg) CAPACITY - RBL0042

TWO 4' SECTION BEAMS WIT SINGLE COUNTERWEIG T FRAME ON PLATE STAND

ITEM PART # DESCRIPTION LB K QTY

1 RBC1010B FRONT SUPPORT SADDLE c/w 3 LOCK PINS 35 16 1

2 RBC2010 REAR SIN LE CWT FRAME c/w 2 LOCK PINS 60 28 1

3 RBH1080B REAR SUPPORT BASE PLATE c/w 2 MT BOLTS 84 2

4 RBC2070B FRONT SUPPORT BASE PLATE 29 13 1

5 RBLO210 FRONT 4 FOOT BEAM c/w SHACKLE 34.4 15.6 1

6 RBL0230 REAR 4 FOOT BEAM c/w SHACKLE 34.9 15.9 1

7 RBL0200 CONNECTION BEAM c/w 2 PINS 11.9 5.4 1

8 3378 COUNTERWEI HT - RIPHOIST (55 LB/25 K EACH) 55 25.0

28 by riphoist

9 RBL0910 OPTIONAL SLIDIN COLLAR 3.6 1.6 PARTS

10 RBC3080A LOCK PIN ASSEMBLY 3/4" DIA. c/w LANYARDS 10.5 PARTS

ORIZONTAL 4' SKYBEAM - 4' REAC -1,000lb. (454 kg) CAPACITY - RBL0040

TWO 4' SECTION BEAMS WIT SINGLE COUNTERWEIG T FRAME ON CASTORS

ITEM PART # DESCRIPTION LB K QTY

1 RBC1010B FRONT SUPPORT SADDLE c/w 3 LOCK PINS 35 16 1

2 RBC2010 REAR SIN LE CWT FRAME c/w 2 LOCK PINS 60 28 1

3 RBH1050B FRONT FRAME WITH SIDE HOLDER 24 11 1

4 RBL0210 FRONT 4 FOOT BEAM c/w SHACKLE 34.4 15.6 1

5 RBL0230 REAR 4 FOOT BEAM c/w SHACKLE 34.9 15.9 1

6 RBL0200 CONNECTION BEAM c/w 2 PINS 11.9 5.4 1

7 3378 COUNTERWEI HT - RIPHOIST (55 LB/25 K EACH) 55 25

28 by riphoist

8 HAC17W99 CASTER ASSEMBLY - RIPHOIST 13 6 4 by riphoist

9 RBL0910 OPTIONAL SLIDIN COLLAR 3.6 1.6 PARTS

10 RBC3080A LOCK PIN ASSEMBLY 3/4" DIA. c/w LANYARDS 10.5 PARTS

1

95

8

4

3

762

10

1

94

7

3

65

2

10

8

8

Tieback

Required

Tieback

Required

(Stacking weight version)

RBC2070B

RBC2010

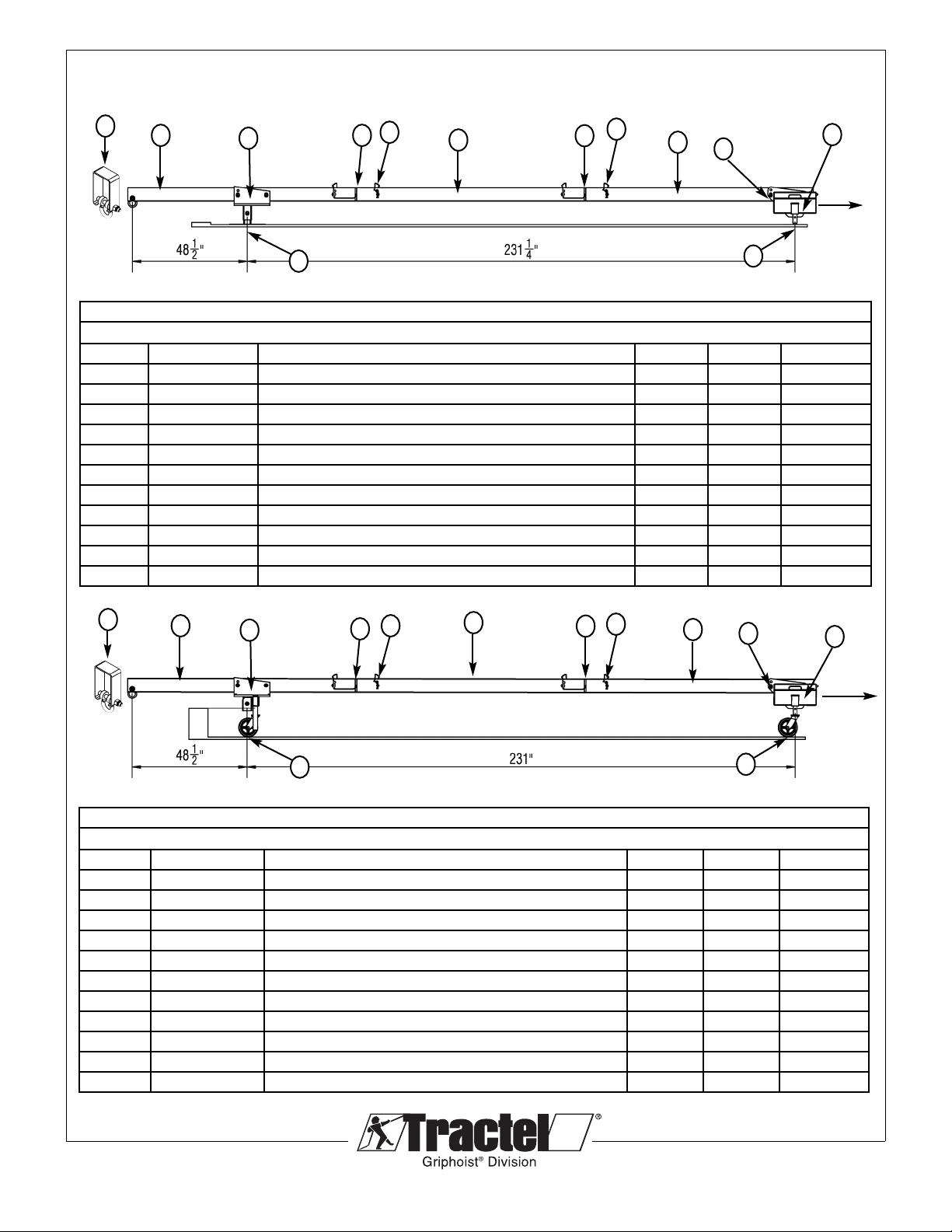

ORIZONTAL 4' SKYBEAM - 4' REAC -1,000lb. (454 kg) CAPACITY - RBL0043

T REE 4' SECTION BEAMS WIT SINGLE COUNTERWEIG T FRAME ON PLATE STAND

ITEM PART # DESCRIPTION LB K QTY

1 RBC1010B FRONT SUPPORT SADDLE c/w 3 LOCK PINS 35 16 1

2 RBC2010B REAR SIN LE CWT FRAME c/w 2 LOCK PINS 60 28 1

3 RBH1080B REAR SUPPORT BASE PLATE c/w 2 MT BOLTS 84 2

4 RBC2070B FRONT SUPPORT BASE PLATE 29 13 1

5 RBL0210 FRONT 4 FOOT BEAM c/w SHACKLE 34.4 15.6 1

6 RBL0230 REAR 4 FOOT BEAM c/w SHACKLE 34.9 15.9 1

7 RBL0220 MIDDLE 4 FOOT BEAM 32.2 14.6 1

8 RBL0200 CONNECTION BEAM c/w 2 PINS 11.9 5.4 2

9 3378 COUNTERWEI HT - RIPHOIST (55 LB/25 K EACH) 55 25.0

16 by riphoist

10 RBL0910 OPTIONAL SLIDIN COLLAR 3.6 1.6 PARTS

11 RBC3064A LOCK PIN ASSEMBLY 3/4" DIA. c/w LANYARDS 10.5 PARTS

© 2013 Tractel Ltd. All Rights Reserved.

7

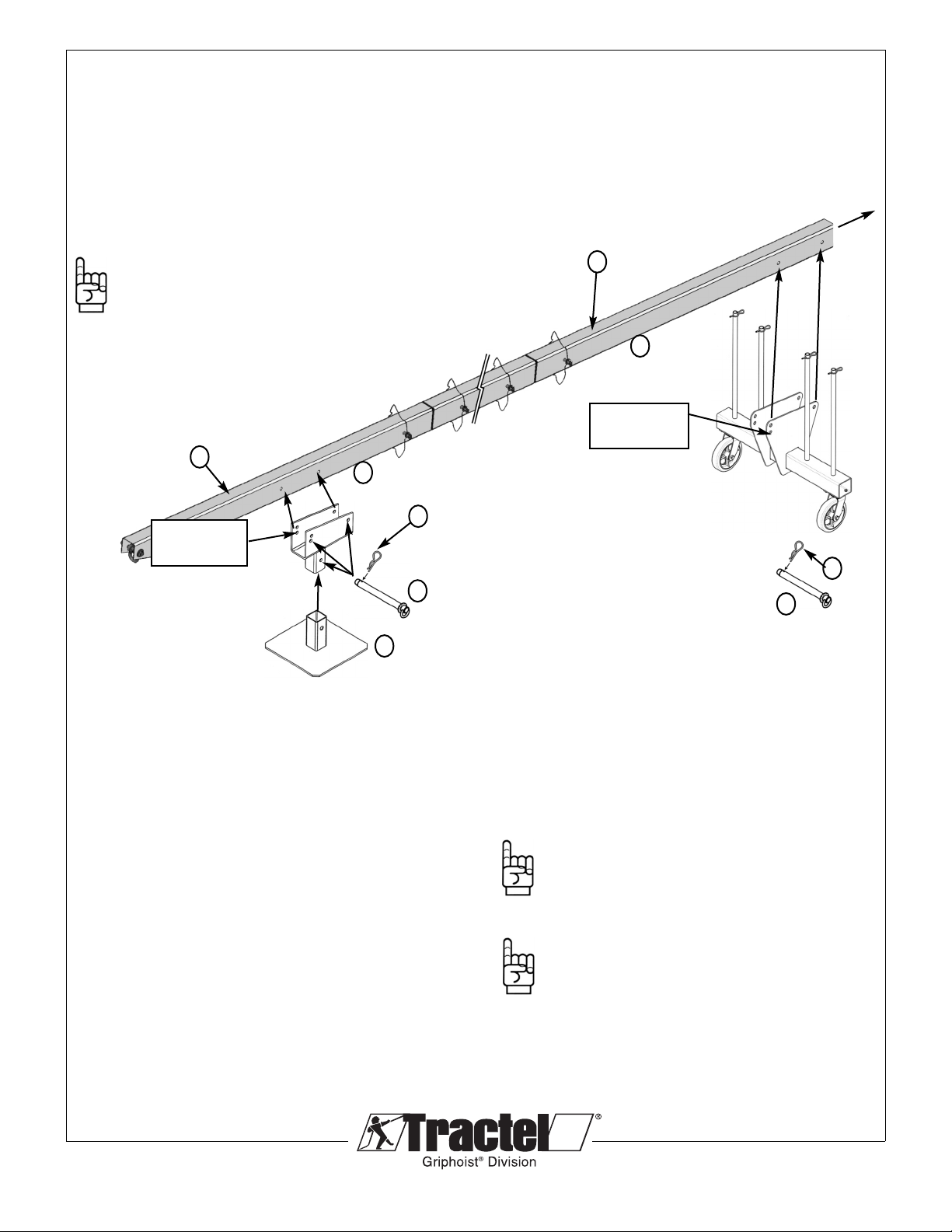

3.1 TEC NICAL SPECIFICATIONS AND COMPONENTS OF T E 4’ REAC LIG T ORIZONTAL SKYBEAM

ORIZONTAL 4' SKYBEAM - 4' REAC -1,000lb. (454 kg) CAPACITY - RBL0041

T REE 4' SECTION BEAMS WIT SINGLE COUNTERWEIG T FRAME ON CASTORS

ITEM PART # DESCRIPTION LB K QTY

1 RBC1010B FRONT SUPPORT SADDLE c/w 3 LOCK PINS 35 16 1

2 RBC2010B REAR SIN LE CWT FRAME c/w 2 LOCK PINS 60 28 1

3 RBH1050B FRONT FRAME WITH SIDE HOLDER 24 11 1

4 RBL0210 FRONT 4 FOOT BEAM c/w SHACKLE 34.4 15.6 1

5 RBL0230 REAR 4 FOOT BEAM c/w SHACKLE 34.9 15.9 1

6 RBL0220 MIDDLE 4 FOOT BEAM 32.2 14.6 1

7 RBL0200 CONNECTION BEAM c/w 2 PINS 11.9 5.4 2

8 3378 COUNTERWEI HT - RIPHOIST (55 LB/25 K EACH) 55 25

16 by riphoist

9 HAC17W99 CASTER ASSEMBLY - RIPHOIST 13 6 4 by riphoist

10 RBL0910 OPTIONAL SLIDIN COLLAR 3.6 1.6 PARTS

11 RBC3080A LOCK PIN ASSEMBLY 3/4" DIA. c/w LANYARDS 10.5 PARTS

1

47

99

652

10 78

11

11

(Stacking weight version)

RBC2070B

1

58

43

762

10 89

11

11

Tieback

Required

Tieback

Required

© 2013 Tractel Ltd. All Rights Reserved.

8

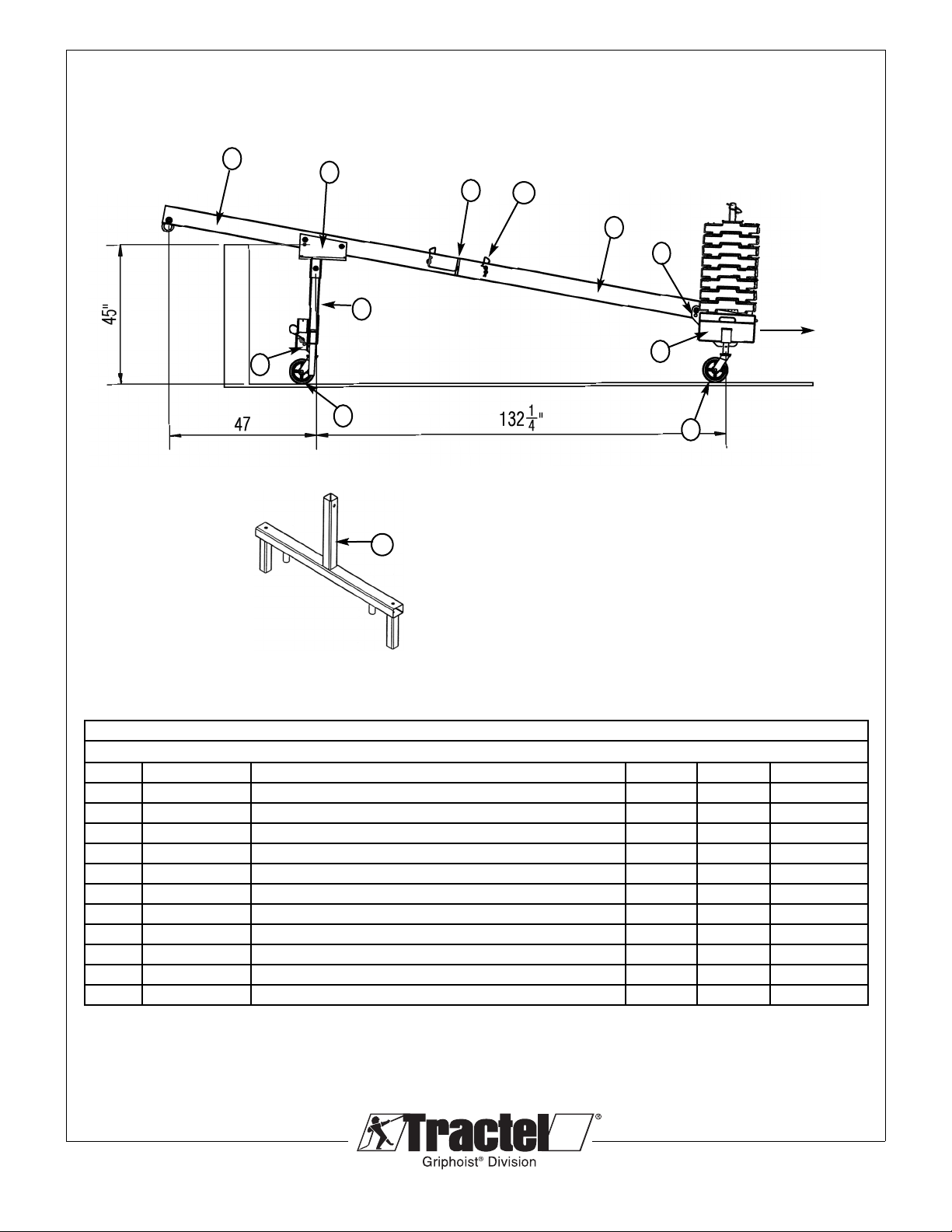

3.2

TEC NICAL SPECIFICATIONS AND COMPONENTS OF T E 4’ REAC LIG T ORIZONTAL SKYBEAM

6

2

1

4

3

7

5

INCLINED 4' SKYBEAM - 4' REAC -1,000lb. (454 kg) - RBL0030

TWO 4' SECTION BEAMS WIT SINGLE COUNTERWEIG T FRAME ON CASTORS

ITEM PART # DESCRIPTION LB K QTY

1 RBC1010B FRONT SUPPORT SADDLE c/w 3 LOCK PINS 35 16 1

2 RBC2010B REAR SIN LE CWT FRAME c/w 2 LOCK PINS 60 28 1

3 RBI1016A FRONT VERTICAL TUBE c/w 1 LOCK PIN 22 10 1

4 RBH1050B FRONT FRAME WITH SIDE HOLDER 24 11 1

5 RBL0210 FRONT 4 FOOT BEAM c/w SHACKLE 34.4 15.6 1

6 RBL0230 REAR 4 FOOT BEAM c/w SHACKLE 34.9 15.9 1

7 RBL0200 CONNECTION BEAM c/w 2 PINS 11.9 5.4 1

8 3378 COUNTERWEI HT - RIPHOIST (55 LB/25 K EACH) 55 25 28 by riphoist

9 HAC17W99 CASTER ASSEMBLY - RIPHOIST 13 6 4 by riphoist

10 RBI1070B FRONT FRAME 100 45 OPTION

11 RBC3080A LOCK PIN ASSEMBLY 3/4" DIA. c/w LANYARDS 10.5 PARTS

11

10

9

9

8Tieback

Required

© 2013 Tractel Ltd. All Rights Reserved.

9

3.2

TEC NICAL SPECIFICATIONS AND COMPONENTS OF T E 4’ REAC LIG T ORIZONTAL SKYBEAM

INCLINED 4' SKYBEAM - 4' REAC -1,000lb. (454 kg) - RBL0031

T REE 4' SECTION BEAMS WIT SINGLE COUNTERWEIG T FRAME ON CASTORS

ITEM PART # DESCRIPTION LB K QTY

1 RBC1010B FRONT SUPPORT SADDLE c/w 3 LOCK PINS 35 16 1

2 RBC2010B REAR SIN LE CWT FRAME c/w 2 LOCK PINS 60 28 1

3 RBI1016A FRONT VERTICAL TUBE c/w 1 LOCK PIN 22 10 1

4 RBH1050B FRONT FRAME WITH SIDE HOLDER 24 11 1

5 RBL0210 FRONT 4 FOOT BEAM c/w SHACKLE 34.4 15.6 1

6 RBL0230 REAR 4 FOOT BEAM c/w SHACKLE 34.9 15.9 1

7 RBL0220 MIDDLE 4 FOOT BEAM 32.2 14.6 1

8 RBL0200 CONNECTION BEAM c/w 2 PINS 11.9 5.4 2

9 3378 COUNTERWEI HT - RIPHOIST (55 LB/25 K EACH) 55 25 16 by riphoist

10 HAC17W99 CASTER ASSEMBLY - RIPHOIST 13 6 4 by riphoist

11 RBI1070B FRONT FRAME 100 45 OPTION

12 RBC3080A LOCK PIN ASSEMBLY 3/4" DIA. c/w LANYARDS 10.5 PARTS

6

2

1

4

3

7

5

12

11

9

8

8

12

10

11

Tieback

Required

© 2013 Tractel Ltd. All Rights Reserved.

10

3.3 TEC NICAL SPECIFICATIONS AND COMPONENTS OF T E 4’ REAC LIG T ORIZONTAL SKYBEAM

ORIZONTAL 4' SKYBEAM - 4' REAC -1,000lb. (454 kg) CAPACITY - RBL0022

TWO 4' SECTION BEAMS WIT SINGLE COUNTERWEIG T FRAME ON PLATE STAND

ITEM PART # DESCRIPTION LB K QTY

1 RBC1010B FRONT SUPPORT SADDLE c/w 3 LOCK PINS 35 16 1

2 RBC2010 REAR SIN LE CWT FRAME c/w 2 LOCK PINS 60 28 1

3 RBH1080B REAR SUPPORT BASE PLATE c/w 2 MT BOLTS 84 2

4 RBC2070B FRONT SUPPORT BASE PLATE 29 13 1

5 RBLO210 FRONT 4 FOOT BEAM c/w SHACKLE 34.4 15.6 1

6 RBL0230 REAR 4 FOOT BEAM c/w SHACKLE 34.9 15.9 1

7 RBL0200 CONNECTION BEAM c/w 2 PINS 11.9 5.4 1

8 3378 COUNTERWEI HT - RIPHOIST (55 LB/25 K EACH) 55 25.0

28 by riphoist

9 RBL0910 OPTIONAL SLIDIN COLLAR 3.6 1.6 PARTS

10 RBC3080A LOCK PIN ASSEMBLY 3/4" DIA. c/w LANYARDS 10.5 PARTS

ORIZONTAL 4' SKYBEAM - 4' REAC -1,000lb. (454 kg) CAPACITY - RBL0020

TWO 4' SECTION BEAMS WIT SINGLE COUNTERWEIG T FRAME ON CASTORS

ITEM PART # DESCRIPTION LB K QTY

1 RBC1010B FRONT SUPPORT SADDLE c/w 3 LOCK PINS 35 16 1

2 RBC2010 REAR SIN LE CWT FRAME c/w 2 LOCK PINS 60 28 1

3 RBH1050B FRONT FRAME WITH SIDE HOLDER 24 11 1

4 RBL0210 FRONT 4 FOOT BEAM c/w SHACKLE 34.4 15.6 1

5 RBL0230 REAR 4 FOOT BEAM c/w SHACKLE 34.9 15.9 1

6 RBL0200 CONNECTION BEAM c/w 2 PINS 11.9 5.4 1

7 3378 COUNTERWEI HT - RIPHOIST (55 LB/25 K EACH) 55 25

28 by riphoist

8 HAC17W99 CASTER ASSEMBLY - RIPHOIST 13 6 4 by riphoist

9 RBL0910 OPTIONAL SLIDIN COLLAR 3.6 1.6 PARTS

10 RBC3080A LOCK PIN ASSEMBLY 3/4" DIA. c/w LANYARDS 10.5 PARTS

1

95

8

4

3

762

10

1

94

7

3

652

10

8

8

Tieback

Required

Tieback

Required

(Sliding weight version)

© 2013 Tractel Ltd. All Rights Reserved.

11

ORIZONTAL 4' SKYBEAM - 4' REAC -1,000lb. (454 kg) CAPACITY - RBL0023

T REE 4' SECTION BEAMS WIT SINGLE COUNTERWEIG T FRAME ON PLATE STAND

ITEM PART # DESCRIPTION LB K QTY

1 RBC1010B FRONT SUPPORT SADDLE c/w 3 LOCK PINS 35 16 1

2 RBC2010B REAR SIN LE CWT FRAME c/w 2 LOCK PINS 60 28 1

3 RBH1080B REAR SUPPORT BASE PLATE c/w 2 MT BOLTS 84 2

4 RBC2070B FRONT SUPPORT BASE PLATE 29 13 1

5 RBL0210 FRONT 4 FOOT BEAM c/w SHACKLE 34.4 15.6 1

6 RBL0230 REAR 4 FOOT BEAM c/w SHACKLE 34.9 15.9 1

7 RBL0220 MIDDLE 4 FOOT BEAM 32.2 14.6 1

8 RBL0200 CONNECTION BEAM c/w 2 PINS 11.9 5.4 2

9 3378 COUNTERWEI HT - RIPHOIST (55 LB/25 K EACH) 55 25.0

16 by riphoist

10 RBL0910 OPTIONAL SLIDIN COLLAR 3.6 1.6 PARTS

11 RBC3064A LOCK PIN ASSEMBLY 3/4" DIA. c/w LANYARDS 10.5 PARTS

3.3 TEC NICAL SPECIFICATIONS AND COMPONENTS OF T E 4’ REAC LIG T ORIZONTAL SKYBEAM

ORIZONTAL 4' SKYBEAM - 4' REAC -1,000lb. (454 kg) CAPACITY - RBL0021

T REE 4' SECTION BEAMS WIT SINGLE COUNTERWEIG T FRAME ON CASTORS

ITEM PART # DESCRIPTION LB K QTY

1 RBC1010B FRONT SUPPORT SADDLE c/w 3 LOCK PINS 35 16 1

2 RBC2010B REAR SIN LE CWT FRAME c/w 2 LOCK PINS 60 28 1

3 RBH1050B FRONT FRAME WITH SIDE HOLDER 24 11 1

4 RBL0210 FRONT 4 FOOT BEAM c/w SHACKLE 34.4 15.6 1

5 RBL0230 REAR 4 FOOT BEAM c/w SHACKLE 34.9 15.9 1

6 RBL0220 MIDDLE 4 FOOT BEAM 32.2 14.6 1

7 RBL0200 CONNECTION BEAM c/w 2 PINS 11.9 5.4 2

8 3378 COUNTERWEI HT - RIPHOIST (55 LB/25 K EACH) 55 25

16 by riphoist

9 HAC17W99 CASTER ASSEMBLY - RIPHOIST 13 6 4 by riphoist

10 RBL0910 OPTIONAL SLIDIN COLLAR 3.6 1.6 PARTS

11 RBC3080A LOCK PIN ASSEMBLY 3/4" DIA. c/w LANYARDS 10.5 PARTS

1

47

99

652

10 78

11

11

(Sliding weight version)

1

5 8

43

762

10 89

11

11

Tieback

Required

Tieback

Required

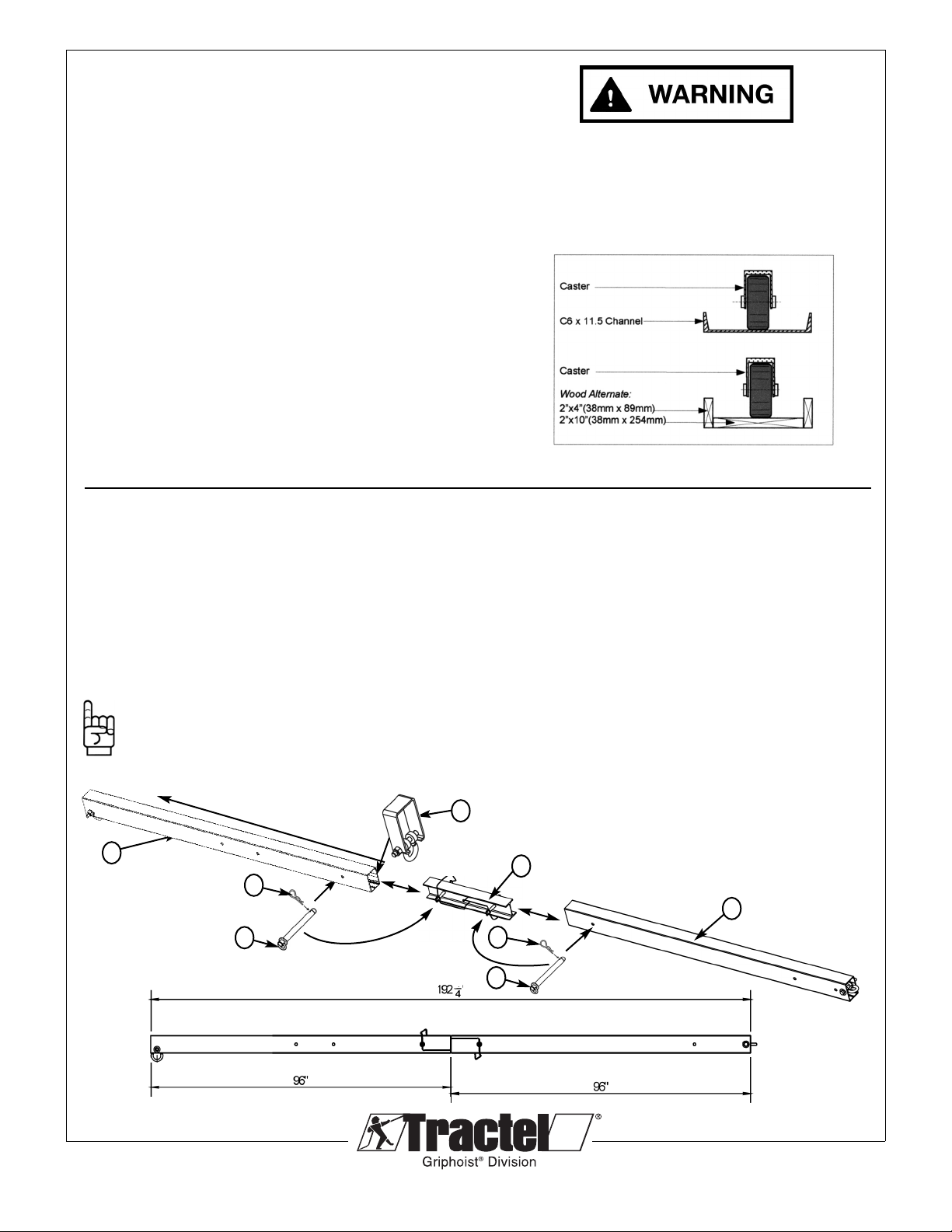

4.1 ASSEMBLY OF T E 4’ SKYBEAM®

The SKYBEAM must be pre-assembled in accordance with

these instructions. The counterweights are assembled on the

counterweight Frame and all roof loads must be confirmed in

accordance with this manual.

When using casters, install guide channels on structure to guide

the casters. Two channels are required, one for the front

support and one for the rear counterweight Frame. See Fig. 1.

• Block the end of guide channels with end stops.

• Always use a guide channel on roofs to distribute bearing

load.

• uide channels to run parallel to building face.

• Rigidly secure both ends of guide channels to the structure

Determine if you are using the two or three beam version of the

4’ Skybeam. Both have a 4’ reach and a 1,000lb (454 kg)

capacity, the advantage of the three piece beam is less

counterweights are required (16) versus (28) required for the

two beam variation.

4.2 TWO PIECE SKYBEAM ASSEMBLY. (MRB2P)

Ensure you have the correct components for assembly

1 – MRBL0200 Connection Beam (1)

1 – MRBL0210 4’ Front Beam (2)

1 – MRBL0230 4’ Rear Beam (3)

Lie the components on the ground in the following sequence:

Front beam (2) – Connection Beam (1) – Rear Beam (3)

Note: If Using the Optional Sliding Collar (for Horizontal

applications only) (4), slide the collar onto the bottom of

the Front Beam (2) before connecting the unit together.

Then slide the collar behind the front shackle.

© 2012 Tractel Ltd. All Rights Reserved.

12

Fig. 1

3

When using casters, channel guides or

roofjacks must be used.

1) Slide the connection beam (1) into the back of the front

beam (2) to so the first hole aligns with the back hole of

the front beam as shown in Fig 2. Connect the beams

together with the provided 3/4" locking pin (5) and secure

the locking pin with the hair pin (6) provided.

2) The rear beam (3) is then slide over the remaining

section of the connection beam and joined at the front

hole of the rear beam as shown Fig. 2. Connect the

beams together with the provided 3/4" locking pin (5) and

secure the locking pin with the hair pin (6) provided.

For Assembly in the horizontal position go to section 4.4,

for the inclined position go to section 4.5.

1

2

5

5

6

6

4

Fig. 2

Fig. 3

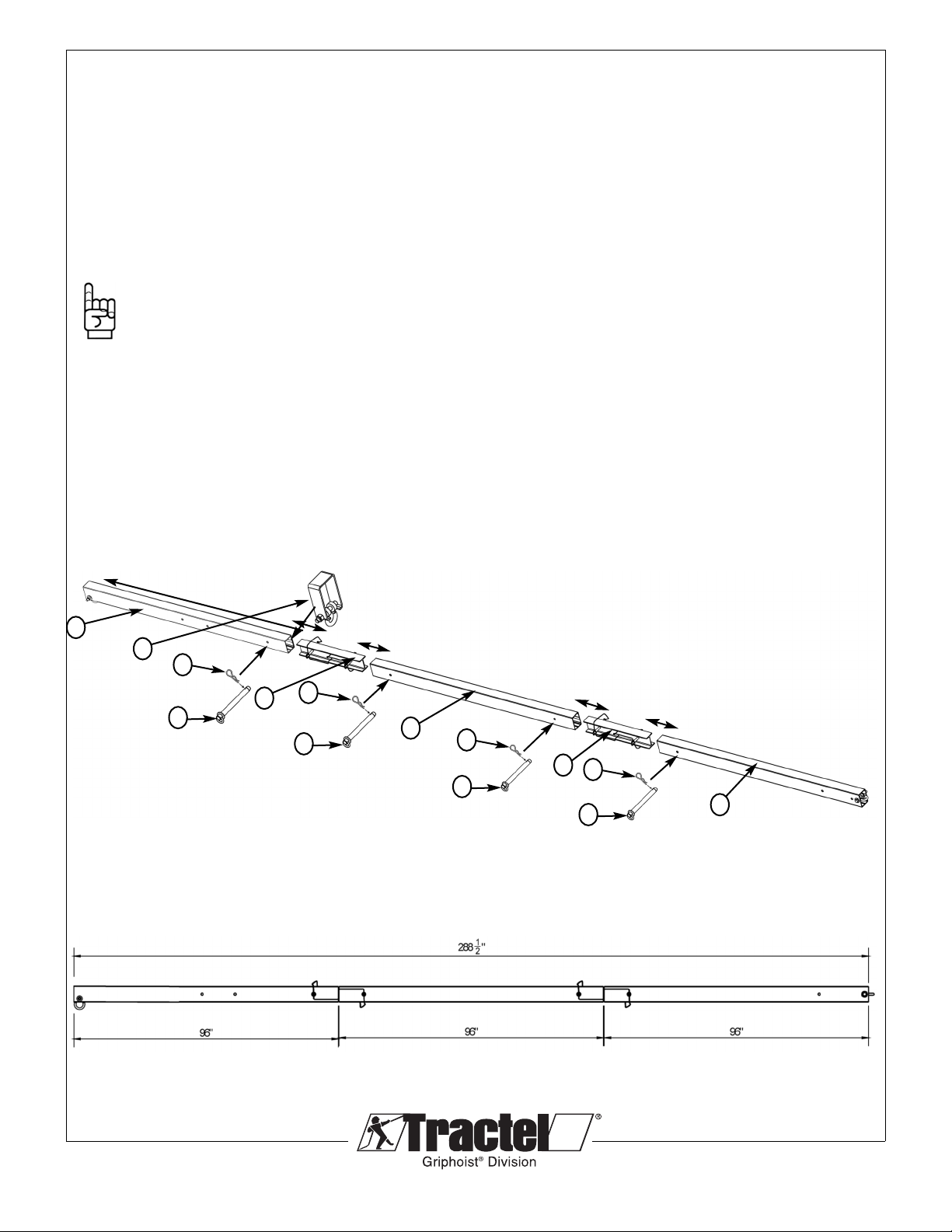

4.3 T REE PIECE SKYBEAM ASSEMBLY. (MRB3P)

Ensure you have the correct components for assembly

2 – MRBL0200 Connection Beam (1)

1 – MRBL0210 4’ Front Beam (2)

1 – MRBL0220 4’ Middle Beam (3)

1 – MRBL0230 4’ Rear Beam (4)

Lie the components on the ground in the following sequence:

Front beam (2) – Connection Beam (1) – Middle Beam (3) -

Connection Beam (1) – Rear Beam (4)

Note: If Using the Optional Sliding Collar (for Horizontal

applications only) (7), slide the collar onto the bottom of

the Front Beam (2) before connecting the unit together.

Then slide the collar behind the front shackle.

1) Slide the connection beam (1) into the back of the front beam

(2) to so the first hole aligns with the back hole of the front

beam as shown in Fig 3. Connect the beams together with the

provided 3/4" locking pin (5) and secure the locking pin with the

hair pin (6) provided.

© 2013 Tractel Ltd. All Rights Reserved.

13

2) The middle beam (3) then slides over the remaining

section of the connection beam and joined at the front

hole of the middle beam as shown Fig. 4. Connect the

beams together with the provided 3/4" locking pin (5) and

secure the locking pin with the hair pin (6) provided.

3) Slide the connection beam (1) into the back of the

middle beam (3) to so the first hole aligns with the back

hole of the middle beam as shown in Fig 5. Connect the

beams together with the provided 3/4" locking pin (5) and

secure the locking pin with the hair pin (6) provided.

4) The rear beam (4) is then slides over the remaining

section of the connection beam and joined at the front

hole of the rear beam as shown Fig. 6. Connect the

beams together with the provided 3/4" locking pin (5) and

secure the locking pin with the hair pin (6) provided.

For Assembly in the horizontal position go to section 4.4,

for the inclined position go to section 4.5.

3

1

2

5

6

7

1

4

5

6

5

6

5

6

Fig. 4

Fig. 5

4.4 CONTINUED - ASSEMBLY OF 4’ ROOF BEAM -

INCLINED VERSION (Two or three piece beam)

FRONT FRAME

Set the reach and connect the front support (1) to the front

beam (2) with two 3/4" dia. locking pins (3) onto the ‘U’ shaped

Top Ledger of the front support, through aligned holes* on the

frame and beam. Be sure to lock the pins with the hair pins (4)

provided. When attaching the front support (1) ensure you do

not exceed the maximum extension of the front beam (2)

based on your load weight calculations.

*Note: The front support (1) has three holes in total,

always face the side with two holes toward the front of

the beam. These two holes are dependent on the

configuration being used. The top is used when

the beam configuration is for inclined position

and the bottom used for the

horizontal position.

INCLINED BEAM

Attach casters (5) to the front leg (6) by aligning holes in the

leg with those of the casters and connect with the 0.375" bolt

(7), washer (8) and nut (9). Then slip the front leg into the front

support and align the holes and connect using a 3/4” locking

pin (3) and secure with the hair pin (4).

For bigger loads/reaches than 1000lbs. /5 Ft. use wood

plates under the two vertical extensions (10) of the

inclined front support, to unload the wheels.

ORIZONTAL BEAM

Attach the front support (1) to the front leg (11) by slipping the

Leg into the front support and aligning the holes and connect

using the 3/4” locking pin (3) and secure with the hair pin (4).

COUNTERWEIG T BEAM

The counterweight beam (12) is secured with two 3/4" dia.

locking pins (13) into the ‘U’ shaped center ledge of the rear

beam (14), through aligned holes** on the frame and the tail

end of the beam. Be sure to lock the pins with the hair pins

provided (15). See Fig. 5

Note: The casters are already attached to the

counterweight beam.

**Note: The counterweight beam (12) has three holes

in total, always face the side with two holes toward the

front of the beam.These two holes are dependent on

the configuration being used. The top is used when

the beam configuration is for inclined position and the

bottom used for the horizontal position.

© 2012 Tractel Ltd. All Rights Reserved.

14

6

2

8

5

1

7

14

12

3

9

Fig. 6

Tieback

Required

11

4

10

13

15

Use the top hole for

the reclined position

Use the top hole for

the reclined position

4.4 CONTINUED - ASSEMBLY OF ROOF BEAM -

ORIZONTAL VERSION (TWO OR T REE PIECE

BEAM)

FRONT SUPPORT

Connect the Front Support (1) to the Front Beam (2) with two

3/4" dia. Locking Pins (3) using the ‘U’ shaped form of the Front

Support, through aligned holes* on the support and beam. Be

sure to lock the pins with the hair Pins (4) provided.

*Note: The Front Support (1) has three sets of holes in

total. Always face the side with two holes toward the front

of the beam. These two holes are dependent on the

configuration being used. The top is used when the

beam configuration is for inclined position and the bottom

used for the horizontal position.

Installing the orizontal Front Support Base Plate

Attach the Front Support (1) to the Support Base Plate (11) by

slipping the leg into the Front Support and aligning the holes

and connect using the 3/4” Locking Pin (3) and secure with the

Hair Pin (4).

© 2012 Tractel Ltd. All Rights Reserved.

15

COUNTERWEIG T BEAM

The counterweight beam (12) is secured with two 3/4" dia.

locking pins (13) into the ‘U’ shaped center ledge of the rear

beam (14), through aligned holes** on the frame and the tail

end of the beam. Be sure to lock the pins with the hair pins

provided (15). See Fig. 5

Note: The casters are already attached to the

counterweight beam.

**Note: The counterweight beam (12) has three holes

in total, always face the side with two holes toward

the front of the beam.These two holes are dependent

on the configuration being used. The top is used

when the beam configuration is for inclined position

and the bottom used for the horizontal position.

2

1

14

4

11

3

12

Fig. 7

Use the bottom

hole for the

horizontal position

Use the bottom

hole for the

horizontal position

Tieback

Required

13

15

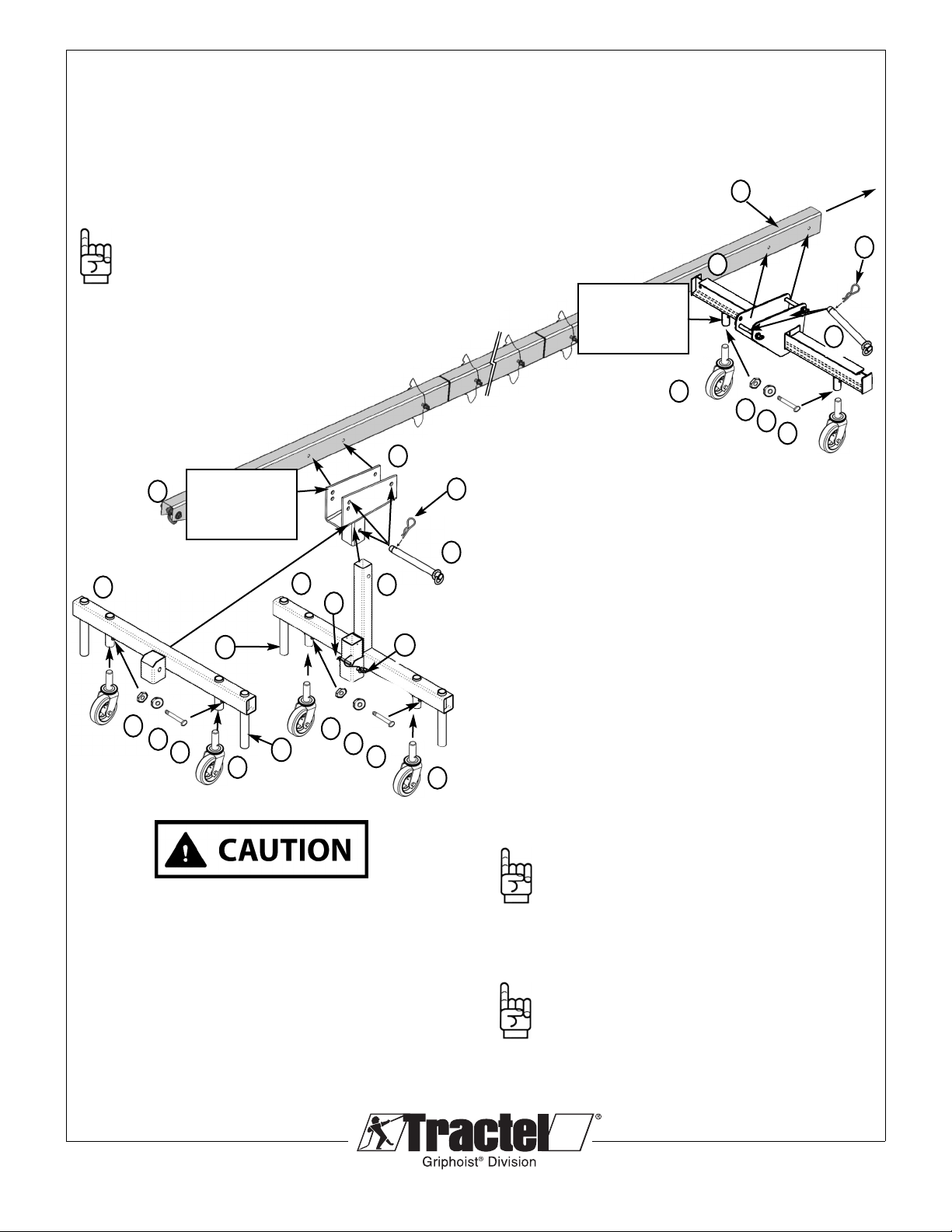

4.4 CONTINUED - ASSEMBLY OF 4 ROOF BEAM -

ADJUSTABLE STAND (RBI101016A & RB 1050B)

FRONT SUPPORT

Connect the front support (1) to the Front Beam (2) with two

3/4" dia. Locking Pins (3) using the ‘U’ shaped form of the front

support, through aligned holes* on the support and beam. Be

sure to lock the pins with the Hair Pins (4) provided.

*Note: The Front Support (1) has three sets of holes in

total. Always face the side with two holes toward the

front of the beam. These two holes are dependent on

the configuration being used. The top is used when the

beam configuration is for inclined position and the

bottom used for the horizontal position.

It is recommended to use wood plates or roofjacks

with the two vertical extensions (11) of the inclined

high support to unload the casters.

Installing Adjustable Stand for orizontal or Inclined

positioning of the Roofbeam

Attach casters (5) to the Front Frame (7) by aligning holes in the

legs with those of the casters and connect with the 3/8" bolt (8),

washer (9) and nut (10). For the Horizontal position the front

support (1) into the front frame (7) in the center post support and

align the holes and connect using a 3/4” locking pin (3) and secure

with the hair pin (4).

SINGLE COUNTERWEIG T FRAMES

Single Counterweight Frame (13) is secured with two 3/4"

dia. Locking Pins (3) into the back of the Rear Beam (14),

through aligned holes** on the Counterweight Frame and the

tail end of the beam. Be sure to lock the pins with the hair

pins provided (4).

See Fig. 8.

**Note: The Counterweight Frames (13) have three sets of

holes in total. Always face the side with two holes

toward the front of the beam. These two holes are

dependent on the configuration being used. The top

is used when the beam configuration is for inclined

position and the bottom is used for the horizontal

position.

Note: Installation of casters if not already in place. Attach

casters (5) to the Single Counterweight Frame (13) by

aligning holes in the bottom posts on the

Counterweight Frame with those of the casters and

connect with the 3/8" bolt (8), washer (9) and nut (10).

Two casters are required for the Single Counterweight

Frame.

© 2012 Tractel Ltd. All Rights Reserved.

16

2

9

5

1

8

7

14

4

3

10

13

3

4

Fig. 8.

10 98

Use the top hole for

the inclined position

and the bottom hole

for the horizontal

position.

Use the top hole for

the inclined position

and the bottom hole

for the horizontal

position.

5

98

10

11

11

76

5

3

4

For the inclined position install the inclined extension (6) into the

front frame (7) as shown and connect using a 3/4” locking pin

(3) and secure with the hair pin (4). The inclined extension is

then inserted into the front support (1) and connected using the

3/4” locking pin (3) and secured with the hair pin (4).

Tieback

Required

© 2012 Tractel Ltd. All Rights Reserved.

17

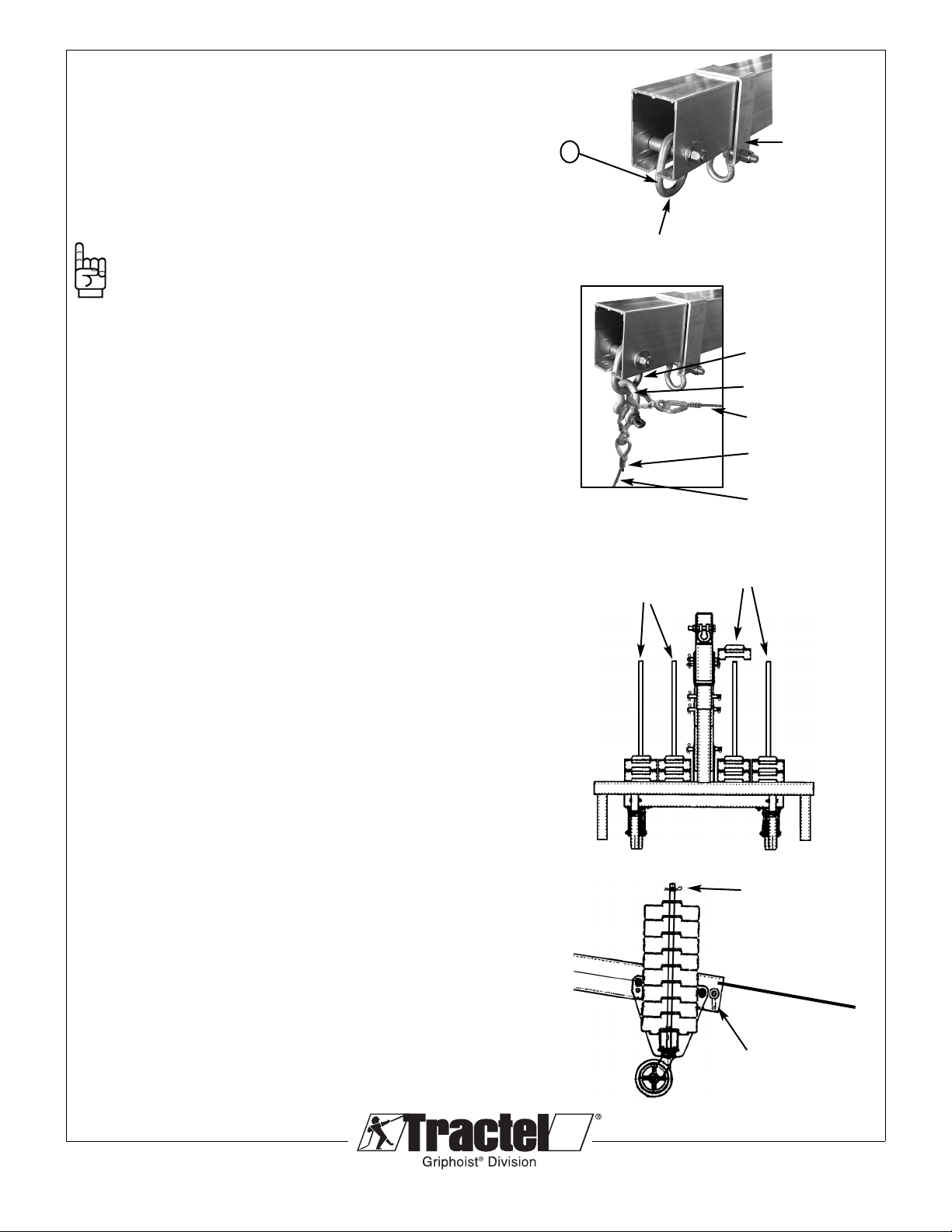

4.4 CONTINUED - ASSEMBLY OF ROOF BEAM

Level the outrigger beam and support assembly. Attach the

thimble end of the suspension wire rope to beam using a 5/8",

3-1/4 ton shackle (1). See Fig 10. Once the rope is attached,

set the assembly into working position. For beams with casters,

apply the brakes on all of the casters. Once in position install

taut tieback to the rear shackle (Fig. 13) as shown on Page 16

& 17 Fig. 14 & 15.

Note: The optional sliding collar shown in Fig. 10 is

for suspension only in the horizontal position. It is

not recommended for the inclined suspension beam.

If you are using the two beam version of the 4’

skybeam 28 counterweights are required. The three

beam version requires 16 counterweights. Both

beams have a 4’ reach and a 1,000lb. (454 kg)

maximum capacity.

Add the counterweights (#3348) (up to 32 max.) to the

counterweight beam (See fig 8). Check once again the

maximum admissible load (see Section 4.4 page 17 –

Calculation of counterweight) related to the reach and the

number of counterweights on the counterweight beam. Install all

required counterweights on the counterweight beam by lowering

them over the extension pole, starting with the two inside poles.

Distribute the weight as equally as possible on each side of the

frame. See Fig.12.

When all weights are in place install the locking pin to prevent

removal. See Fig. 13.

Attach the tieback wire rope at the back of the rear beam,

to the rear shackle inside. Always insure the tieback has

equivalent strength to the hoisting rope and they must be

installed without slack. See Fig 13. See Section 4.4 Fig. 11

& 12 for proper tie back instructions.

1

Primary wire rope is attached

here (see details below)

Beam Shackle

5/8” Shackle

Tieback Line

Wire Rope Thimble

Primary Wire Rope

Optional

sliding collar

Locking Pin

Rear shackle and

safety tieback as

required

Insert weights over the post,

starting on the inside and

evenly distributing from side

to side.

Fig. 10

Fig. 11

Fig. 12

Fig. 13

5.0 ASSEMBLY INSTRUCTIONS OT ER

5.1 INSTALLATION OF OUTRIGGER TIEBACKS

Installation of outrigger tiebacks is mandatory!

Fig. 14

Secure tieback to rear shackle on the roof beam, and to the tieback anchor on the roof.

Tieback wire ropes must have the equivalent strength to the hoisting ropes and must be

installed without slack.

NOTE: 1) Tieback may also be installed from the tip of the roof beam.

2) When using the two tiebacks, one must be on each side of the beam.

© 2013 Tractel Ltd. All Rights Reserved.

18

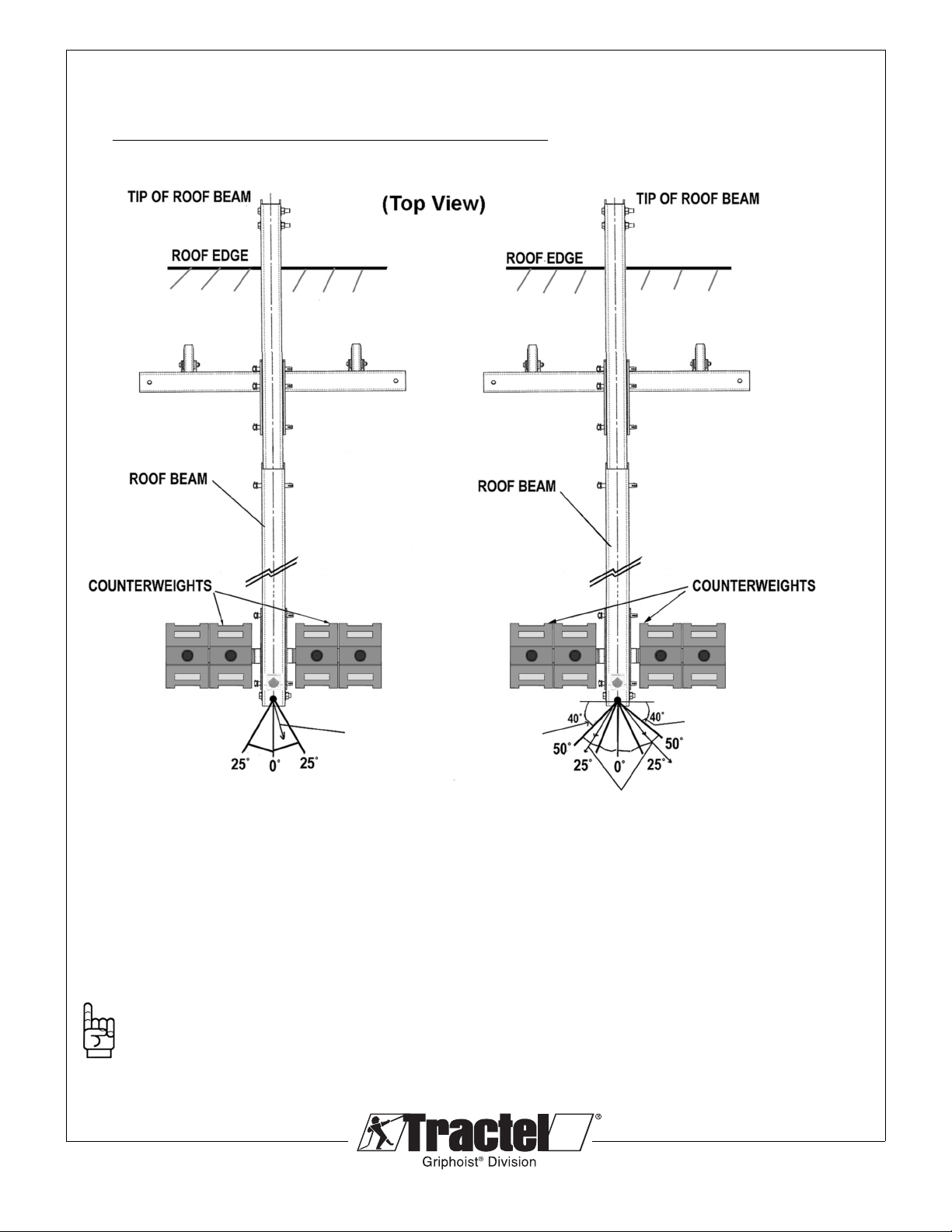

TWO TIEBACKS ARE REQUIRED IF

BETWEEN 25° TO 50° OF CENTERLINE.

ONE MUST BE ON EACH SIDE OF THE

CENTERLINE.

SKYBEAM

SKYBEAM

ONE TIEBACK IS REQUIRED WITHIN

25° OF THE CENTERLINE.

TIEBACK

REQUIRED

TIEBACKS NOT ALLOWED

IN THIS AREA

TIEBACKS NOT

ALLOWED IN

THIS AREA

© 2013 Tractel Ltd. All Rights Reserved.

19

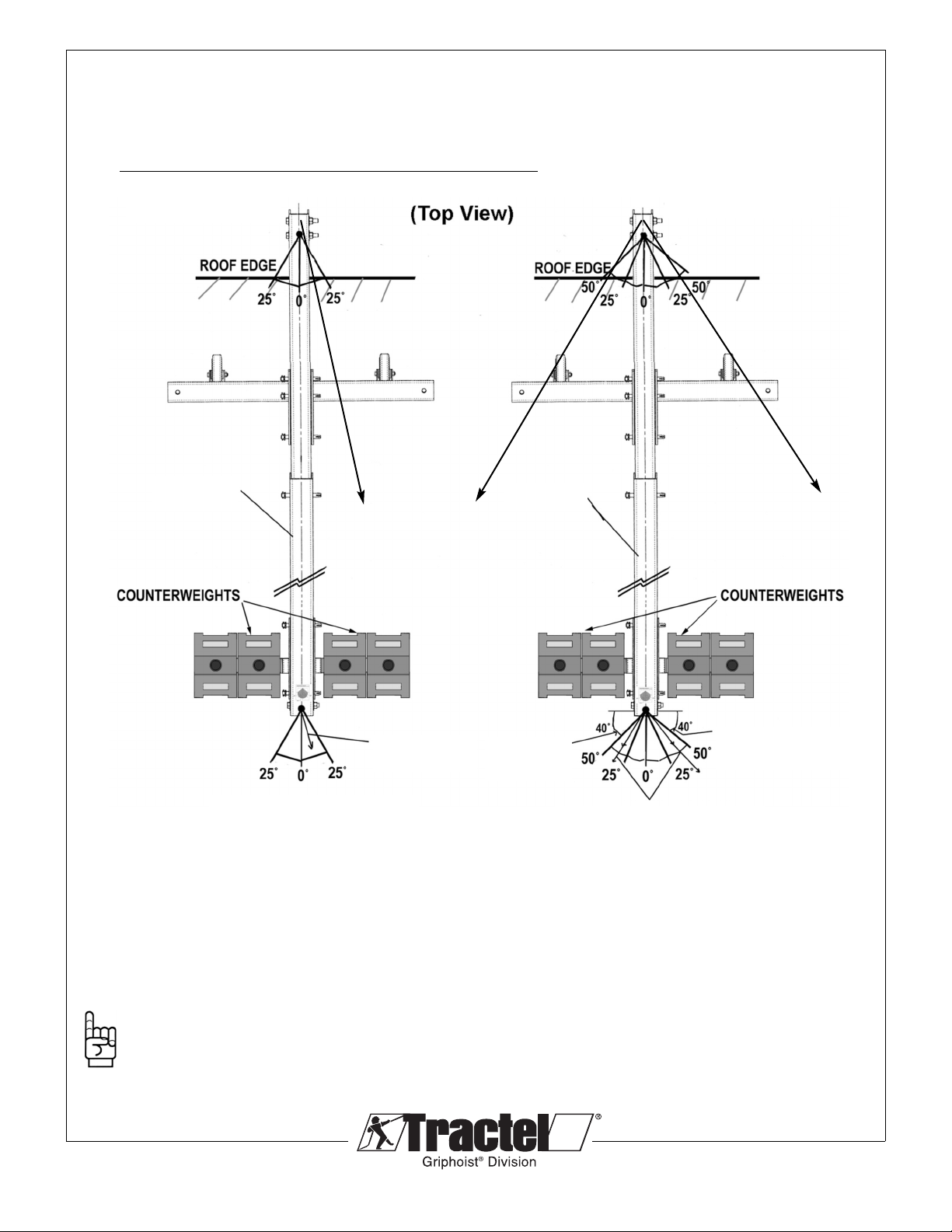

5.1 INSTALLATION OF OUTRIGGER TIEBACKS - CONTINUED

Tieback instructions for the secondary wire rope if installed.

Installation of outrigger tiebacks is mandatory!

Fig. 15

Secure tieback to rear shackle on the roof beam, and to the tieback anchor on the roof.

Tieback wire ropes must have the equivalent strength to the hoisting ropes and must be

installed without slack.

NOTE: 1) Tieback may also be installed from the tip of the roof beam.

2) When using the two tiebacks, one must be on each side of the beam.

Secondary wire rope tieback. Note: only

one required within 25°. Two are

required if between 25° and 50° of the

beam. Tiebacks are not permitted

beyond 50°.

TIEBACK

REQUIRED

TIEBACKS NOT ALLOWED

IN THIS AREA

TIEBACKS NOT

ALLOWED IN

THIS AREA

TWO TIEBACKS ARE REQUIRED IF

BETWEEN 25° TO 50° OF CENTERLINE.

ONE MUST BE ON EACH SIDE OF THE

CENTERLINE.

ONE TIEBACK IS REQUIRED WITHIN

25° OF THE CENTERLINE.

FRONT OF SKYBEAM

SKYBEAM

FRONT OF SKYBEAM

SKYBEAM

Formula for calculating COUNTERWEI HT & LEN TH of

back beam,

(La) 4 (La) 4

W = or b =

b W

W = L x a x 4 ÷ b or b = L x a x 4 ÷ W

W = Counterweight in Pounds

L = Load in Pounds (Rated capacity of oist)

a = Reach (from center front frame to the suspension wire

rope in feet)

b = Back Span - (Distance between front frame and

back frame in feet center to center)

4 = Safety Factor

Severe injury or death can result from improper use or

assembly. Assemble in accordance to this manual. Check

and recheck counterweight chart and formula. Minor

changes could cause complete system failure. Consult your

GRIP OIST dealer for additional information.

Counterweights must be a nonflowable material, and they

must be attached to the outrigger beam.

Always use tieback wire ropes capable of holding the full

load.

© 2013 Tractel Ltd. All Rights Reserved.

20

5.2 CALCULATION OF COUNTERWEIG TS

COUNTERWEIG T FORMULA CALCULATIONS

Provided only as a reference. If you are using the two beam version of the 4’ Skybeam 28 counterweights

are required. The three beam version requires 16 counterweights. Both beams have a 4’ reach and a

1,000lb. (454 kg) Maximum capacity.

Example Calculations:

W= ? L = 1000 lbs.

a = 4 foot b = 11’ 6"

(1000x4) x4

W =

11.5

W = 1391 lbs of Counterweights

(26 pcs.) or more, must be added.

Only have 990 lbs. in Counterweights

then

W= 990 L = 1000 lbs.

a = 4 foot b = ?

(1000x4) x4

b =

990

b = 16’ 2" Therefore the distance

between A and B must be 16 foot and

2 inches or greater.

Table of contents

Other Tractel Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

ADJ

ADJ ALLEGRO Z6 User instructions

Manaras Opera

Manaras Opera Lightcurtain 003 Specification and installation instructions

EuroLite

EuroLite LED D-40 TCL 2X9W user manual

involight

involight SlimPAR766 user manual

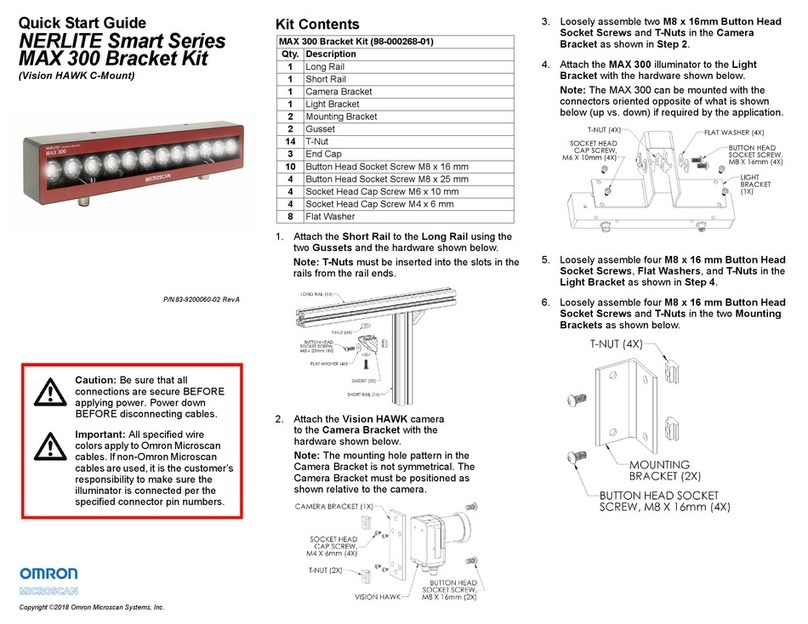

Omron Microscan

Omron Microscan NERLITE Smart Series quick start guide

V-TAC

V-TAC VT-8061 Installation instruction