Tractel tirfor TU Series Manual

equipment in

accordance with

CE directives

operating and maintenance instructions

models

TU : TU-8

TU-16

TU-32

T-500D : T-508D

T-516D

T-532D

lifting and pulling machines

tirfor

1

®®

0086086.03 - 01/95

Anglia Handling Services Ltd

2

CONTENTS Page

General warning 3

Technical data 3

1. Description of equipment 4

2. Rigging arrangements 4

3. Installing the wire rope 5

4. Releasing and closing the jaws 5

5. Anchoring 7

6. Operation 8

7. Releasing the wire rope and storage 8

8. Safety devices 9

9. Replacing the shear pins 9

10. Wire rope 10

11. Maintenance instructions 10

12. Warnings against hazardous operations 11

13. Troubleshooting 11

14. Health and safety at work 11

Always concerned to improve the quality of its

products, the TRACTEL Group reserves the right

to modify the specifications of the equipment

described in this manual. The companies of the

TRACTEL Group and their agents or distributors

will supply on request descriptive documentation

onthefullrange ofTRACTEL products: liftingand

pulling machines, permanent and temporary

accessequipment,safetydevices,electronicload

indicators, accessories such as pulley blocks,

hooks, slings, ground anchors, etc...

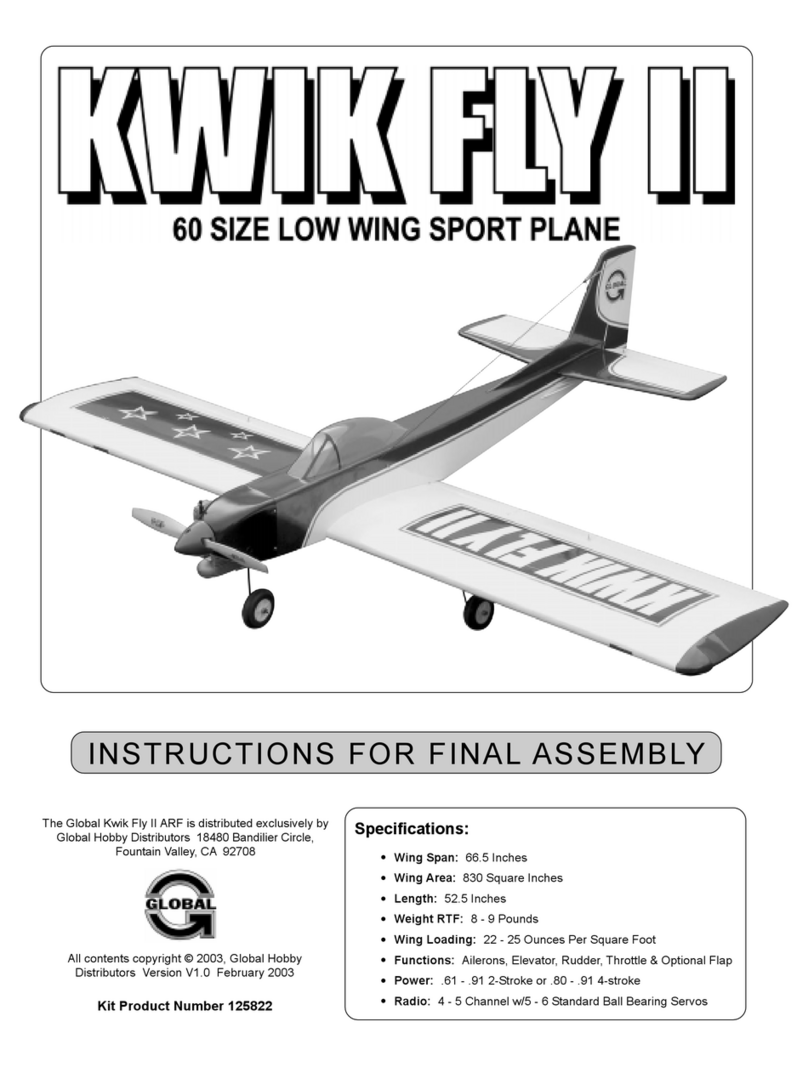

Fig. 1

TU-32

8

1

7

6

32451

8

T-508D

T-516D

T-532D

71

6

432

8

1. Hook / anchor pin

2. Forward operating lever

3. Reverse operating lever

4. Rope release lever

5. Rope release safety catch

6. Rope guide

7. Wire rope

8. Telescopic operating handle

7

4532

8

TU-8*

TU-16

5

ORIGINAL MANUAL

*without carrying handle

Wire rope on reeler

The TRACTEL network is able to supply an

after-sales and regular maintenance service.

Shouldyouhaveanyqueriesorrequiretechnical

assistance, please do not hesitate to contact

your TRACTEL dealer.

Anglia Handling Services Ltd

3

TECHNICAL DATA

MODEL TU-8 T-508D TU-16 T-516D TU-32 T-532D

Maximum working load t 0.8 1.6 3.2

Weight :

machine kg 8.4 6.6 18.0 13.5 27.0 24.0

telescopic operating handle kg 1.0 1.0 2.4 2.3 2.4 2.3

s

tandard 20 m of wire rope, complete

kg 6.1 6.1 13.1 13.1 26.6 26.6

Total weight of standard equipment kg 15.5 13.7 33.5 28.9 56.0 52.9

Machine dimensions :

length mm 527 420 660 530 676 620

length with optional hook mm – 550 – 650 860 840

height mm 265 250 330 315 330 355

width mm 108 99 140 127 156 130

telescopic handle : closed/extended

cm 51/77 40/69 68/119 65/115 68/119 65/115

TIRFOR wire rope

diameter mm 8.3 11.5 16.3

guaranteed breaking strain* kg 4000 8000 16000

weight per meter kg 0.250 0.500 1.00

Rope travel (forward/reverse)** mm 70/76 46/63 56/70 42/57 30/48 18/36

* Including end fittings of the wire rope.

** One complete cycle of the operating lever at maximum working load.

!

GENERAL WARNING

!

1- Before using the TIRFOR machine it is essential for the safe and correct operation of the

equipmentthatthismanualbereadandfullyunderstoodandthatalltheinstructionsbefollowed.

This manual should be made available to every operator. Extra copies of this manual will be

supplied on request.

2- The TIRFOR machine allows the operator to carry out work with complete safety. Ensure that this

machine is only handed over for use or rigging to an operator who is trained to operate it in a

responsible manner.

3- Neveruseamachinewhichisnotingoodworkingcondition.Replaceanywornordamagedwire

rope (See Section 10). Continuous monitoring of the condition of the machine, its wire rope and

anchor sling is an important safety consideration.

4- The manufacturer declines any responsibility for the consequences of dismantling or altering the

machine by any unauthorised person. Specially excluded is the replacement of original parts by

parts of another manufacturer.

5- The models as described in this manual must not be used for lifting people.

6- Moreover, these models are designed for manual operation and must not be motorised.

The TRACTEL Group has designed special motorised models (TU-16H and TU-32H).

7- Never attempt to overload the machine.

8- Standard TIRFOR machines are not designed for use in explosive atmospheres.

9- IMPORTANT:Iftheequipmentdescribedinthismanualissuppliedtoanemployedperson,check

thatyoumeetyourobligationswithrespecttosafetyatworkregulations(seepage11-chapter 14)

LIFTING PEOPLE AND SPECIAL APPLICATIONS

For further information on equipment for lifting people, and on any special application, please refer to

Tractel S.A.

Anglia Handling Services Ltd

4

1. DESCRIPTION OF EQUIPMENT

The TIRFOR machine is a hand-operated lifting

and pulling machine. It is versatile, portable and

multi-purpose, not only for pulling and lifting but

also for lowering, tensioning and guying.

The originality of the TIRFOR machine is the

principle of operation directly on the wire rope

which passes through the mechanism rather than

beingreeledontoadrumofahoistorconventional

winch.Thepull isappliedbymeansoftwo pairsof

self-energised jaws which exert a grip on the wire

ropeinproportiontotheloadbeingliftedorpulled.

A telescopic operating lever fitted to either the

forward or the reverse lever transmits the effort to

the jaw mechanism to give forward or reverse

movement of the wire rope.

The machine is fitted with a hook or anchor pin,

dependingonthemodel,sothatitcanbesecured

quickly to any suitable anchor point.

TIRFOR machines, intended for lifting and pulling

materials, are available in two ranges each with

three models of different capacities :

–T-500D range for light duty applications (with

safety release catch)

–TUrangeforheavydutyapplications(withsafety

release catch).

Each machine is supplied with a telescopic

operatinghandle,andusuallywitha20mstandard

length of special TIRFOR wire rope fitted with a

safetyhookandwoundontoametalreeler.Longer

or shorter lengths of wire rope are available on

request.

This manual together with a guarantee card are

supplied with each machine, as well as the CE

declaration of conformity.

IMPORTANT:TIRFORwireropehasbeenspecially

designed to meet the particular requirements of

the TIRFOR machine. The manufacturer does not

guarantee the safe operation of machines used

with wire rope other than TIRFOR wire rope.

2. RIGGING ARRANGEMENTS

VariouswaysofriggingareshowninFigs.2.1,2.2,

2.3 and 2.4. Figs. 4 and 5 show particular

arrangements (one forbidden and the other

recommended).

Themachinemaybeanchoredtoafixedpointwith

the wire rope travelling towards the machine

(Figs. 2.1, 2.2, 2.3), or travel along the wire rope,

with the load, the wire rope itself anchored to a

fixed point (Fig. 2.4).

In example 2.2, the maximum working load of the

pulley and the anchor point should be equal to or

greater than twice the load.

Fig. 2.1 Fig. 2.2

Fig. 2.3 Fig. 2.4

Fig. 3

N.B.Whatever therigging arrangement,and ifthe

machine is anchored directly to a fixed point,

ensure that there are no obstructions around the

machine which could prevent the wire rope, the

machine and anchor from operating in a straight

line. It is therefore recommended to use a sling of

anappropriatecapacitybetweentheanchorpoint

and the machine (Fig. 3).

!

WARNING

!

: Any rigging arrangement

whichrequiresthecalculationoftheforcesapplied

shouldbecheckedbyacompetentengineer,with

special attention to the appropriate strength of

fixed point used.

For work such as guiding the trunk in tree felling,

the operator should ensure that he is outside the

danger area by passing the wire rope around one

or more return pulleys.

Anglia Handling Services Ltd

5

3. INSTALLATING THE WIRE ROPE

N.B. When handling the wire rope it is

recommendedto protectthehandsby usingwork

gloves.

If the wire rope is to be anchored to a high anchor

point, the wire rope should be anchored before

fitting the wire rope in the machine.

1. Uncoil the wire rope in a straight line to prevent

loops or kinks.

2. Releasetheinternalmechanism (Seesection4:

«Releasing and engaging the jaws»).

3. Insert the wire rope through the rope guide at

the end opposite to the anchor point (hook or

anchor pin).

4. Push the wire rope through the machine, and if

necessary, helping it by operating the forward

operating lever.

5. Whenthewireropeappearsthroughtheanchor

point, pull the slack wire rope through the

machine, to the point required.

6. Engage the jaws by operating the rope release

mechanism (See section 4 : «Releasing and

engaging the jaws»).

7. Anchor the TIRFOR machine or the wire rope to

the appropriate fixed point (See section 5 :

«Anchoring») taking care to ensure that the

anchor point ( hook or pin, depending on the

model) is correctly fixed.

8. Extendthetelescopicoperatinghandleuntilthe

spring locks into position. If necessary twist the

two sections of the handle, one inside other, to

align the spring (Fig. 1).

9. Replacethetelescopic operatinghandleon the

chosenoperatinglever(forwardorreverse)and

twist the handle to ensure that it is locked in

position (about a half turn).

After this procedure, the machine is ready for

operation,providingtheloadiscorrectlyanchored

to the machine or the wire rope (See section 5 :

«Anchoring» and section 2 «Rigging

arrangements»).

4.RELEASING AND CLOSING THE JAWS

Eachmachineisfittedwithalever(Fig.1Item4)for

releasingthejawmechanismwhichshouldonlybe

operated when the machine is not under load.

There are two positions for the rope release lever

(See Fig. 7, 8 and 9) : released or engaged.

N.B.Whennotinoperation,itisrecommendedthat

the rope release lever should be in the engaged

position. The machine must therefore be released

before attempting to feed in the wire rope.

Fig. 4 Fig. 5

Fig. 6.1 - Pulling

2 2 2 2 2 2

2

2

2 2

2

13

4

1

11111

111 11111

11

11

1

1

1

1

1

1

3

1

1

1

1

1

1

1

2

1

22

2

2

4

1

1

1

1

1

2

2

1

3

4

4

Fig. 6.2 - Lifting

INCORRECT CORRECT

The capacity of the machine may be increased

considerablyforthesameeffortbytheoperatorby

using multiple sheave blocks. (See the examples

set out in Figs. 6.1 and 6.2). The increase in the

capacity shown is reduced depending on the

efficiency of the pulleys.

The diameter of the pulleys used should be equal

to at least 18 times the diameter of the wire rope.

(Refer to the applicable regulations).

For any rigging arrangement other than those

described in this manual, please consult

TRACTEL S.A. or a competent specialist

engineer before operating the machine .

Anglia Handling Services Ltd

6

4.1. TU-8 or TU-16 (Fig.7)

Releasing :

1. Completely press the rope release safety catch

(5) and lift the rope release lever (4).

2. Release the safety catch and continue to lift the

rope release lever until it locks into position. The

internal mechanism is in the released position.

Engaging :

1. Lift the rope release lever slightly.

2. Pressandmaintainpressureontheroperelease

safetycatch, allowingthereleaseleverto slowly

travel back to its original position. Release the

safety catch. The release lever locks in position

under the effect of its spring.

4.2. TU-32 (Fig.8)

Place the anchor point against a support.

Releasing :

1. Completely press rope release safety catch (5)

and push the rope release lever (4) towards the

anchor point.

2. Release the safety catch and continue to push

the rope release lever until it locks into position.

Theinternalmechanismisinthereleasedposition.

Engaging :

1. Push the rope release lever towards the anchor

point.

2. Pressandmaintainpressureontheroperelease

safetycatch, allowingthereleaseleverto slowly

travel back to its original position. Release the

safety catch. The release lever locks in position

under the effect of its spring.

4.3. T-500D range (Fig.9).

Place the anchor point against a support.

Releasing :

Turntheropereleasesafetycatch(5)andpushthe

rope release lever (4) towards the anchor pin until

it locks into position when raised slightly at its limit.

Release the safety catch.

Engaging :

1.Turn the rope release safety catch

2. Presstheropereleaseleververticallydownwards,

allowing the lever to travel back to its original

position under the effects of its spring. Release

the safety catch.

4

Fig. 7 - TU-8 and TU-16. Rope release lever.

FIG. 8 - TU-32. Rope release lever.

4

5

Fig. 9 - T500D range. Rope release lever

5

AB

RELEASED

ENGAGED

4

5

ENGAGED RELEASED

ENGAGED RELEASED

Anglia Handling Services Ltd

7

Optionalhooksare availabletofittheanchorpoint

of models T-500D and TU-32.

To anchor using the anchor pin, follow the

procedure below:

1. Open the spring clip of the anchor pin.

2. Remove the spring clip from the anchor pin.

3. Slide the anchor pin out of the side cases (Fig.

14).

4. Fit the anchoring arrangement, such as a sling,

between the side cases.

5. Refit the anchor pin through the side cases and

anchoring arrangement, such as the eyes of a

sling.

6. Refit the spring clip to the anchor pin.

7. Closethespringclip,ensuringthatitfitscorrectly

over the end of the anchor pin and cannot fall

out.

!

Warning

!

: It is essential for the safe

operation of the machine to ensure that, before

loading the machine, the anchor points, hooks or

pins, are correctly secured, (with the safety catch

correctly located on the hook - Fig. 12).

Fig. 11 - Machine anchor hook with catch in

open position Fig. 12 - Machine anchor hook with catch in

closed position.

Fig. 10 - Incorrect slinging. Fig. 10a - Correct slinging.

5.

!

ANCHORING

!

FailuretoanchortheTIRFORmachinecorrectly

runs the risk of a serious accident. The user

must always ensure before operation that the

anchor point(s) for the machine and wire-rope

are of sufficient strength to hold the load.

It is recommended that TIRFOR machines should

beanchoredtoafixedpointortotheloadusingan

appropriate capacity sling. It is forbidden to use

the machine’s wire rope as a sling by passing it

around the load and hooking it back onto itself

(Fig.10 : incorrect anchoring arrangement;

Fig.10a : correct anchoring arrangement).

The anchoring arrangement of models TU-8 and

TU-16 is a hook fitted with a safety catch (Figs. 11

and12).Inallcases when anchoringthemachine

the safety catch of the anchor hook should be

correctlyclosed,initspositionatthetipofthehook

(Fig.12). This advice for the machine anchor hook

also applies to the hook fitted to the wire rope.

TIRFORmachinesTU-32andT-500Dareanchored

bymeansof aremovableanchorpin,fittedacross

thetwoendsofthesidecases(Fig.13and14)and

locked in position by a spring clip (See Figs. 15

and 16).

INCORRECT CORRECT

Anglia Handling Services Ltd

8

7. RELEASING THE WIRE ROPE AND STORAGE

It is essential to take the load off the machine

beforeattemptingtoreleasethejaws.Todothis,

operatethereverseoperatingleveruntilthereisno

tension in the wire rope.

Remove the telescopic operating handle and

return it to the closed position.

Releasethemachineandfollowtheinstructionsfor

installing the wire rope in the reverse order.

Re-engagethejawsofthemachine beforeputting

it into storage.

Store the machine and wire rope in a dry place,

awayfromtheeffectsoftheweather.Thewirerope

should be completely removed from the machine

and rewound onto its reeler.

Beforereeling thewirerope, itis recommendedto

inspect it, clean it with a brush and then grease it.

(See section 10).

6. OPERATION

TIRFOR machines are very easy to use. Place the

telescopic operating handle on either the forward

or reverse operating lever, lock it into position by

twisting,andmovetheoperatinghandletoandfro.

Theoperatingarcisvariableforeaseofoperation.

When operation stops, both jaws automatically

grip the wire rope and hold the load which is

spread equally between the jaws.

The to-and-fro operation of the forward or reverse

lever gives continuous movement of the load.

Fig. 13 - Anchor pin in position. Fig. 14 - Anchor pin removed.

Fig. 15 - Spring clip closed. Fig. 16 - Spring clip open.

Anglia Handling Services Ltd

9

8. SAFETY DEVICES

8.1 Overload limiting safety devices

All TIRFOR machines incorporate a shear pin

system. In case of overload, one or more pins

(depending on the model), fitted to the forward

operatinglever,shear andpreventfurtherforward

or lifting operations. Reverse operation is still

possible to enable the load to be lowered or the

wire rope to be slackened.

8.2 Rope release safety device

Models TU and T-500D are fitted with a «two-

handed» rope release system which requires

deliberate operation by the user to release the

machine.Seesection4:«Releasingandengaging

the jaws».

9. REPLACING THE SHEAR PINS

Figures 17,18,19 and 20 show the position of the

shear pins for the various models. Spare shear

pins are in the stub of the operating levers for

models TU-8 and TU-16, and in the rope release

lever for the other models, behind the plastic cap.

Remove the sheared pins with a suitable punch.

For models TU-8 and TU-16, remove the forward

operating handle stub by using an extractor.

Remove the sheared pins. Refit the forward

operating handle stub on the crank and align the

grooves for the shear pins (Figs. 17 and 18).

For models T-500D and TU-32, align the holes of

the upper and lower sections of the forward

operating lever.

Positionthespare shearpin(s)anddriveit/them in

with a hammer.

!

Warning

!

: It is forbidden to replace

sheared pins by anything other than genuine

TIRFOR shear pins of the same model.

Fig. 18 - TU-16

Fig. 19 - TU-32

Fig. 20 - T-500D

Fig. 17 - TU-8

Before putting the machine back into operation,

ensure that the cause of the overload is removed.

If necessary, use multiple sheave blocks

(See Fig.6).

Rememberto re-ordersheared pinsand putthem

back in the correct place.

Anglia Handling Services Ltd

10

10. WIRE ROPE

!

To guarantee the safe operation of TIRFOR

machines,itisessentialtousethemexclusively

withTIRFORwireropewhichhasbeenspecially

designed to meet the requirements of the

TIRFOR machine.

TIRFOR wire ropes have a red strand which is

visible on new rope. One end of the wire rope has

an end fitting, such as a safety hook, fitted to a

thimble fixed by a metal ferrule (See Fig. 21). The

other end of the wire rope is fused and tapered

(See Fig. 22).

correct

method

of measuring

Fig. 24

d

Fig. 23 - Examples of damaged wire rope

IMPORTANT : It is recommended, specially for

liftingapplications,toensurethatthelengthofwire

rope is greater than actually required. Allow an

extra meter approximately.

When lifting or lowering loads over long lengths of

wire rope, steps should be taken to stop the load

fromrotatingtopreventthewireropefromunlaying.

Never allow a tensioned wire rope to rub over

sharpedges.Thewireropemustonlybeusedwith

pulleys of an appropriate diameter.

Neverexposethewireropetotemperaturesbeyond

100 degrees C.

Never use wire rope that has been subject to

damage such as fire, corrosive chemicals or

atmosphere, or exposed to electric current.

Storage : See section 7.

11. MAINTENANCE INSTRUCTIONS

The machine should be inspected, cleaned and

lubricatedatregularintervals,atleastannually,by

an approved TRACTEL S.A. repairer. Never use

grease or oil containing graphite additives or

molybdenum disulphide . To clean the machine ,

allow the machine to soak in a bath of some

proprietary cleansing fluid but not acetone and

derivativesor ethylenetrichlorideand derivatives.

Then shake the machine vigorously to loosen

foreign matter and turn it upside down to allow the

dirt to come out through the openings for the

operating levers. Allow the mechanism to drain

andbecome dry.Afterthistreatment, ensure that

the machine is well lubricated by applying a

quantity of oil (type SAE 90-120) onto the internal

mechanismthroughtheopeningsfortheoperating

levers,andforthemodelsTU-8andTU-16,through

the special lubrication holes. To carry out this

procedure, it is best for the machine to be not

under load and in the released position.

Alternatively operate the forward and reverse

!

Awireropeingoodconditionisaguarantee

of safety, to the same extent as a machine in

good condition. It is necessary to continuously

monitor the state of the wire rope, to clean and oil

it with a rag soaked with motor oil or grease.

Grease or oil containing graphite additives or

molybdenum disulphide must not be used.

Visual examination of the wire rope

The wire rope should be examined daily to detect

any signs of wear ( damage or broken wires : See

examples in Fig. 23).

In case of any apparent wear, have the wire rope

checked by a competent person. Any wire rope

with a reduction from the nominal diameter by

more than 10% should be replaced. (See Fig. 24

for the correct method of measuring the diameter

of a wire rope).

Fig. 21

dia.

max. 1.5 dia.

Fig. 22

Anglia Handling Services Ltd

11

operatingleverstoallowthe lubricanttopenetrate

all parts of the mechanism.

N.B.Excesslubricationcannotcausethemachine

or wire rope to slip.

Any machine where the side cases show signs of

dentsordamage,orofwhichthehookisdamaged

(models TU-8 and TU-16), should be returned to

an approved repairer of TRACTEL S.A.'s network.

12.

!

WARNINGS AGAINST HAZARDOUS

OPERATIONS

!

TheoperationofTIRFORmachines,inaccordance

with the instructions of this manual, is a guarantee

of safety. Nevertheless, it is useful to draw the

attention of users to the following warnings :

– TIRFOR machines as described in this manual

must not be used for lifting people.

– NeverattempttomotorisethemodelsofTIRFOR

machines described in this manual.

– TIRFOR machines must not be used beyond

their maximum working load.

– TIRFOR machines must not be used for

applications other than those for which they are

intended.

– Never attempt to operate the rope release

mechanism whilst the machine is under load.

– Never obstruct the operating levers or the rope

release lever.

– Never operate the forward and reverse

operating levers at the same time.

– Never use a handle, other than the telescopic

operating handle supplied, to operate the

TIRFOR machine.

– It is forbidden to replace sheared pins by

anythingotherthangenuine TIRFORshearpins

of the same model.

– Never anchor the machine other than by its

appropriate anchor point.

– Never obstruct the machine, which could

prevent the machine, the wire rope and the

anchor points from operating in a straight line.

– Never use the TIRFOR wire rope as a sling.

– Neverapplyaloadtotheloosewireropeexiting

from the anchor point of the TIRFOR machine.

– Never subject the controls to sharp knocks.

– Never attempt to reverse the rope completely

through the machine whilst under load.

– Do not operate the TIRFOR machine when the

ropeferrulegetstowithin10cmofthemachine.

Otherwise the ferrule is likely to foul the casing

and push the rope guide inside the machine.

13. TROUBLESHOOTING

1) The forward operating lever moves freely

and does not operate the mechanism :

the machine has been overloaded and the shear

pinshavesheared.Seesection9forreplacingthe

shear pins.

2) Pumping :

AlackoflubricantinaTIRFORmachinesometimes

brings about a condition known as «pumping»

which is not at all dangerous, but which is

inconvenient. This situation occurs when the jaw

whichis grippingtherope becomeslockedonto it

preventingtheother jawfromtakingovertheload.

Astheoperatingleverismovedinonedirectionthe

machine travels a few centimeters, but when the

operating lever travels in the other direction the

machine moves back the same distance in

sympathy with the jaw which is locked onto the

rope. The TIRFOR machine should be thoroughly

lubricatedanditwillrecommenceworkingnormally.

3. Jerkiness :

This is also a symptom of lack of lubrication. The

TIRFORmachineshouldbethoroughlylubricated.

4. Blockage :

If the wire rope becomes blocked in the machine,

generally because a damaged section of wire

ropeisstuckwithinthejaws,itisimperativetostop

operating the machine. The load should be taken

byanothermachineonaseparatewirerope,orby

another means, whilst ensuring that all safety

precautionsaretaken.Whentheblockedmachine

isnolongerunderload,thedamagedropemaybe

releasedandremoved.Shouldthisnotbepossible,

return the machine and wire rope to the

manufacturer or an approved repairer.

14. HEALTH AND SAFETY AT WORK

All lifting equipment must be supplied, operated, maintained and tested according to the provisions

of the relevent health and safety at work regulations.

It is also the responsability of every company to ensure that their employees have been fully and

properly trained in the safe operation of their equipment.

Anglia Handling Services Ltd

12

LEFT SIDE RIGHT SIDE

TU-8

TU-16

TU-32

T-508D

T-516D

T-532D

COPYRIGHT - ALL RIGHTS RESERVED

Manufactured by TRACTEL S.A.

Ensure that the labels indicated above in black are in place.

Replacement labels can be supplied on request.

Pulley blocks

and side opening blocks Slings

Hook

for TIRFOR

T-500D

and TU-32

Accessories for TIRFOR machines

Ground anchors

Anglia Handling Services Ltd

This manual suits for next models

7

Table of contents

Other Tractel Tools manuals