CONCRETE MOISTURE ENCOUNTER X5 USER GUIDE

2

TABLE OF CONTENTS

Introduction......................................................................................3-4

How it works.....................................................................................5-8

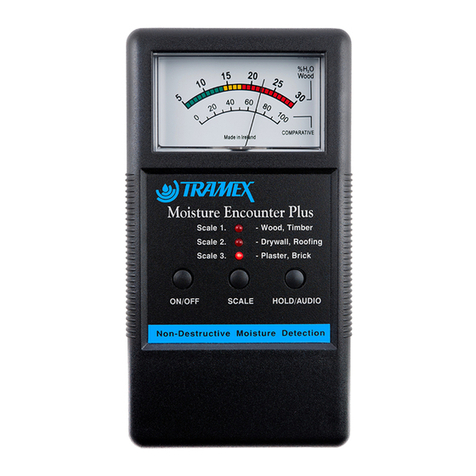

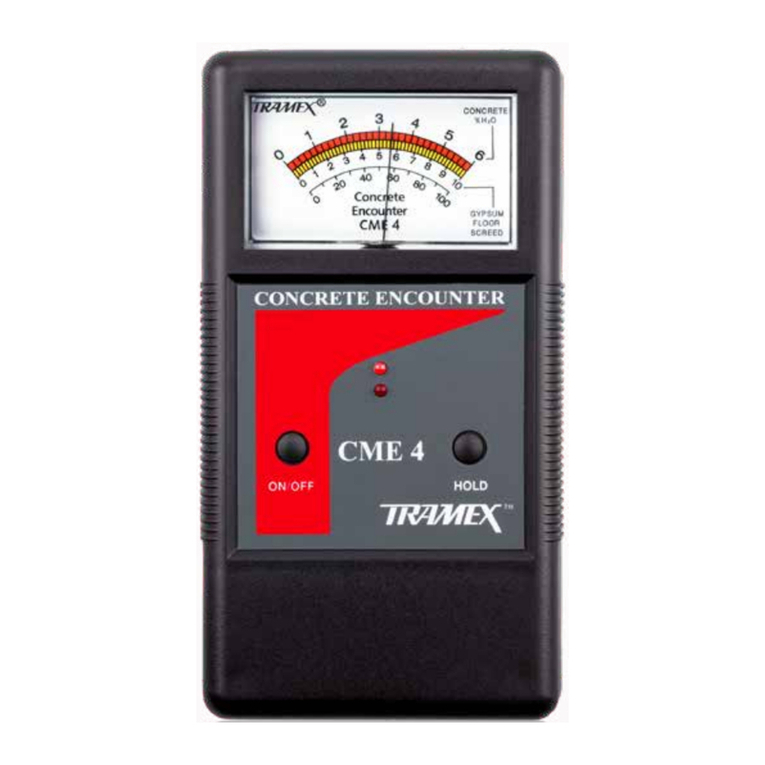

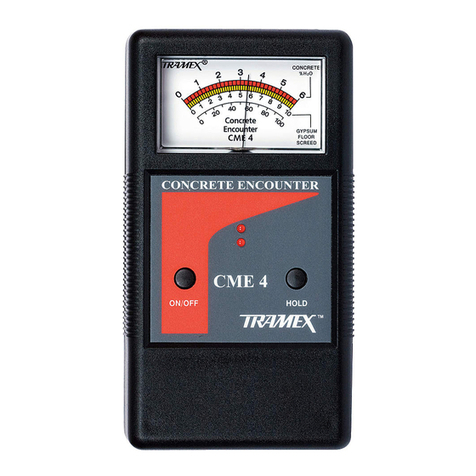

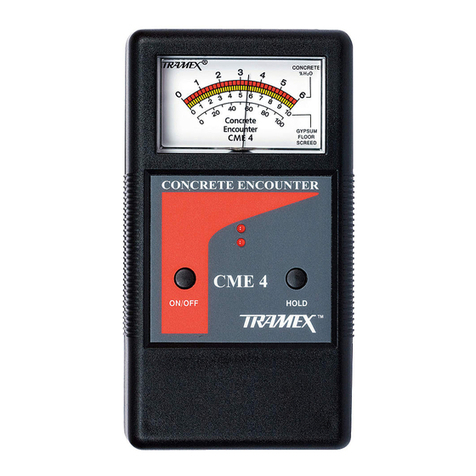

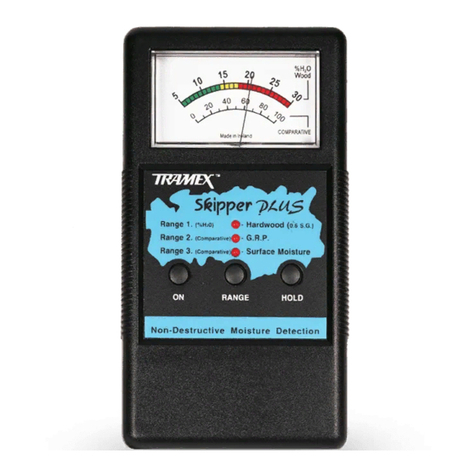

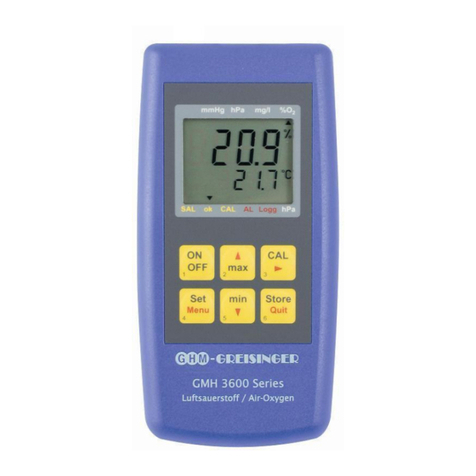

Instrument Features..................................................................9-10

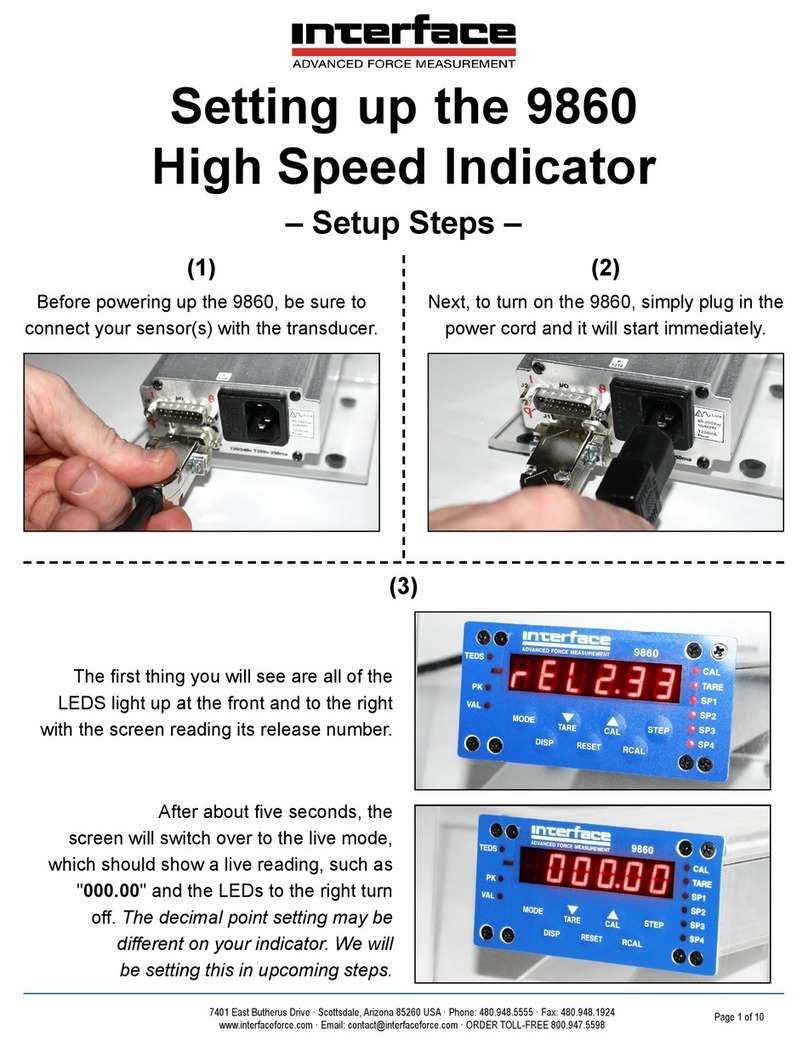

OperatingInstructions....................................................................11

Non-Destructive Measurement Mode .........................12-18

ConcreteMCScale......................................................................12

CM (Carbide Method) Scale ..................................................13

CMAnhydrite/GypsumScale................................................13

Gypsum Ref 0-12 Scale...........................................................13

ReferenceScale...........................................................................13

Calibration ....................................................................................14

Typical Concrete Moisture Encounter X5 Displays..15

Drying time for concrete floors and screeds...............16

Testing moisture content in a floor slab.........................17

Pre-testing guidelines..............................................................17

Guideline non-destructive test procedures as per

International Standards........................................................18

Hygrometer Mode & Ambient RH ...................................19-29

Equilibrium / Ambient Relative Humidity Mode ......19-20

Relative Humidity Measurement........................................21

MoistureTestingGuidelines..........................................22-23

Hole Liner/Hood Instructions.....................................24-27

Calibration Check Salts...................................................28-29

Pin Probe Mode.........................................................................30-42

Pin Probe Menu Selections...................................................31

Factors Affecting Moisture Readings.....................32-33

Wood Flooring .....................................................................34-36

Temperature Adjustment Chart..........................................37

Humidity and Moisture Content Relationship.............38

Species Correction Charts.............................................39-50

Limitations .............................................................................................51

Calibration ...........................................................................................51

Warranty ...................................................................................................52

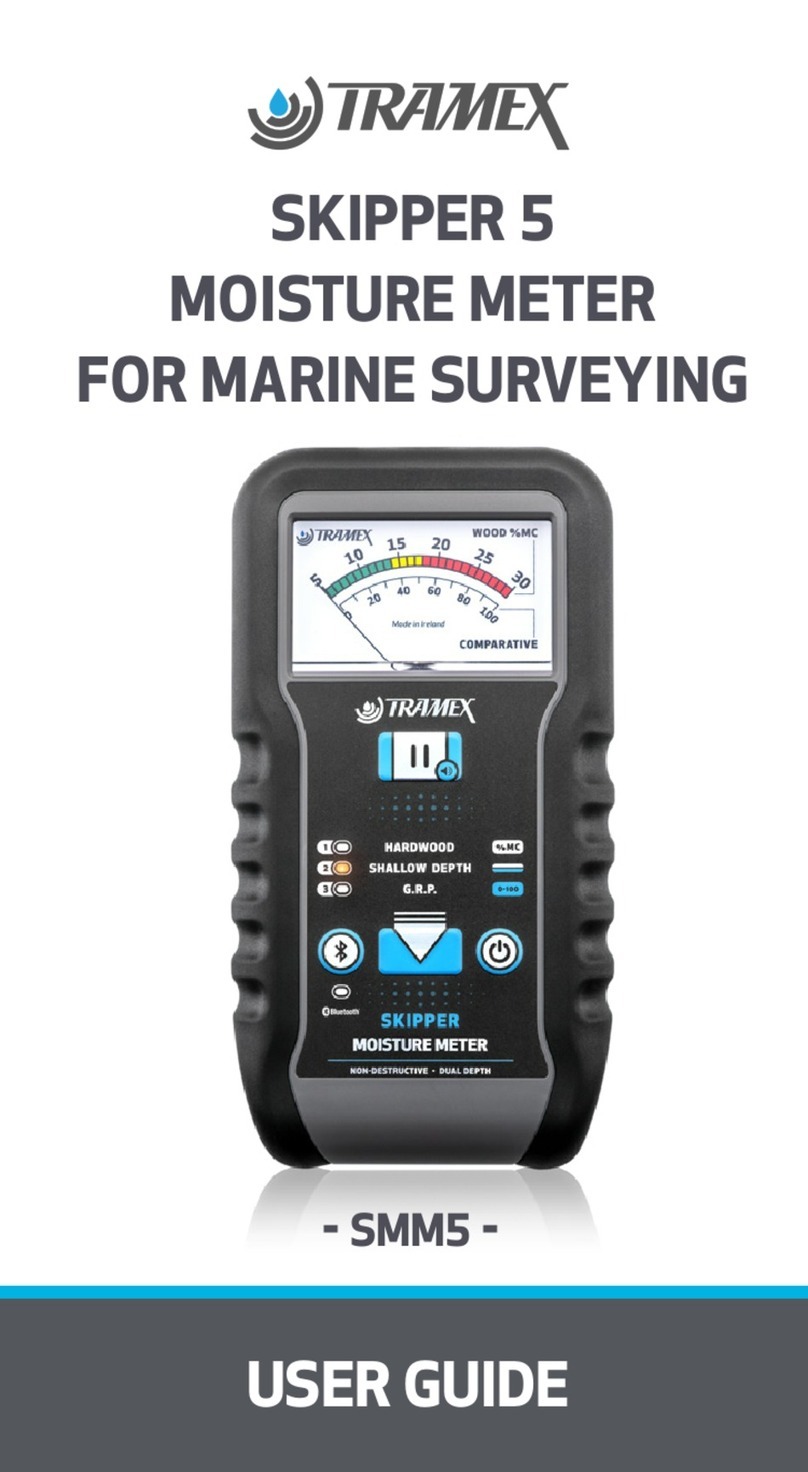

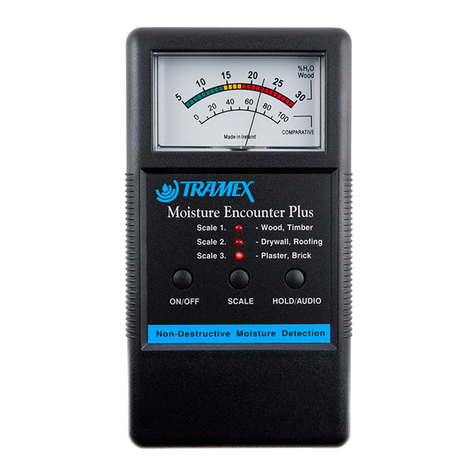

Product Development....................................................................53

Safety...........................................................................................53