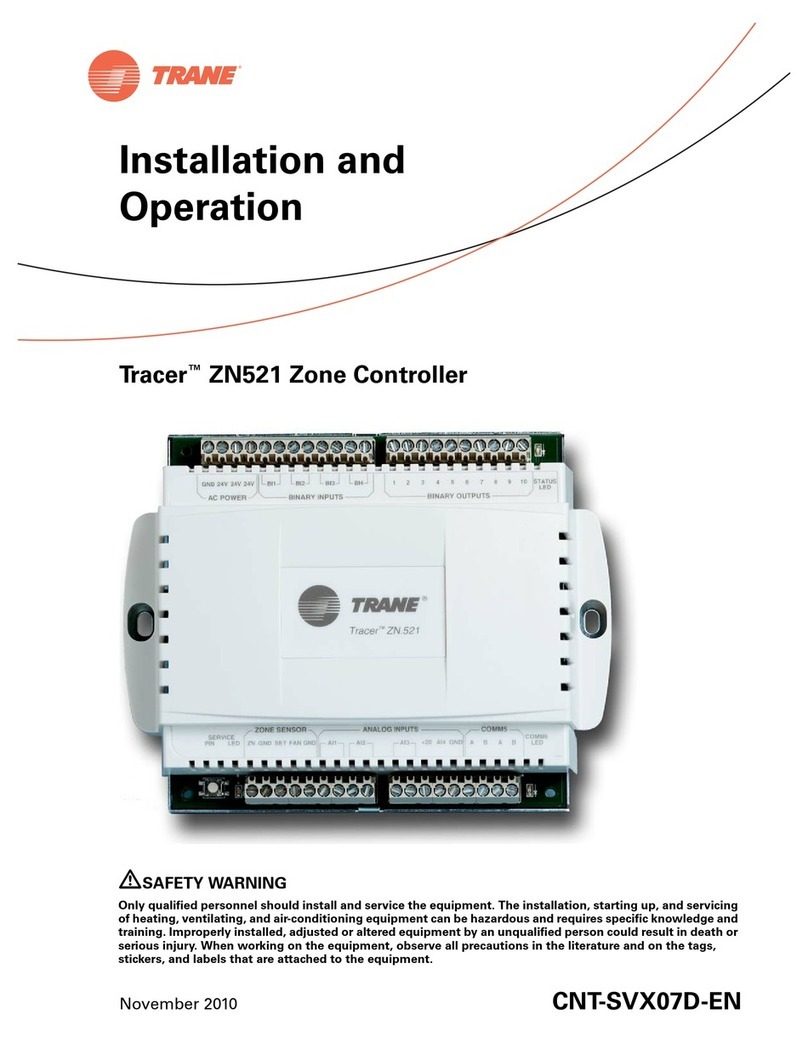

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation,

starting up, and servicing of heating, ventilating, and air-conditioning equipment can

be hazardous and requires specific knowledge and training. Improperly installed,

adjusted or altered equipment by an unqualified person could result in death or

serious injury. When working on the equipment, observe all precautions in the

literature and on the tags, stickers, and labels that are attached to the equipment.

132

© 2020 Trane

45

Installation Instructions

Tracer® UC400 Pre-programmed for

RTU or Heat Pumps

Order Numbers: BMUC400ABA0100011

X39641254-01

Warnings, Cautions, and Notices

Read this manual thoroughly before operating or servicing this unit. Safety

advisories appear throughout this manual as required. Your personal safety

and the proper operation of this machine depend upon the strict

observance of these precautions.

The three types of advisories are defined as follows:

WARNING Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious

injury.

CAUTION Indicates a potentially hazardous situation which,

if not avoided, could result in minor or moderate

injury. It could also be used to alert against unsafe

NOTICE Indicates a situation that could result in

equipment or property-damage only accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made chemicals can affect

the earth’s naturally occurring stratospheric ozone layer when released to

the atmosphere. In particular, several of the identified chemicals that may

affect the ozone layer are refrigerants that contain Chlorine, Fluorine and

Carbon (CFCs) and those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these compounds have the

same potential impact to the environment. Trane advocates the responsible

handling of all refrigerants-including industry replacements for CFCs such

as HCFCs and HFCs.

Important Responsible Refrigerant Practices

Trane believes that responsible refrigerant practices are important to the

environment, our customers, and the air conditioning industry. All

technicians who handle refrigerants must be certified according to local

rules. For the USA, the Federal Clean Air Act (Section 608) sets forth the

requirements for handling, reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these service procedures. In

addition, some states or municipalities may have additional requirements

that must also be adhered to for responsible management of refrigerants.

Know the applicable laws and follow them.

WARNING

Proper Field Wiring and Grounding Required!

Failure to follow code could result in death or serious injury. All field wiring

MUST be performed by qualified personnel. Improperly installed and grounded

field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards,

you MUST follow requirements for field wiring installation and grounding as

described in NEC and your local/state electrical codes.

WARNING

Personal Protective Equipment Required!

Installing/servicing this unit could result in exposure to electrical, mechanical

and chemical hazards. Before installing/servicing this unit, technicians MUST

put on all Personal Protective Equipment (PPE) recommended for the work

being undertaken. ALWAYS refer to appropriate SDS sheets and OSHA

guidelines for proper PPE. When working with or around hazardous chemicals,

ALWAYS refer to the appropriate SDS sheets and OSHA guidelines for

information on allowable personal exposure levels, proper respiratory

protection and handling recommendations. If there is a risk of arc or flash,

technicians MUST put on all necessary Personal Protective Equipment (PPE) in

accordance with NFPA70E for arc/flash protection PRIOR to servicing the unit.

Failure to follow recommendations could result in death or serious injury.

WARNING

Follow EHS Policies!

Failure to follow instructions below could result in death or serious injury.

• All Trane personnel must follow the company’s Environmental, Health and

Safety (EHS) policies when performing work such as hot work, electrical, fall

protection, lockout/tagout, refrigerant handling, etc. Where local

regulations are more stringent than these policies, those regulations

supersede these policies.

• Non-Trane personnel should always follow local regulations.

June 2020 BAS-SVN099E-EN

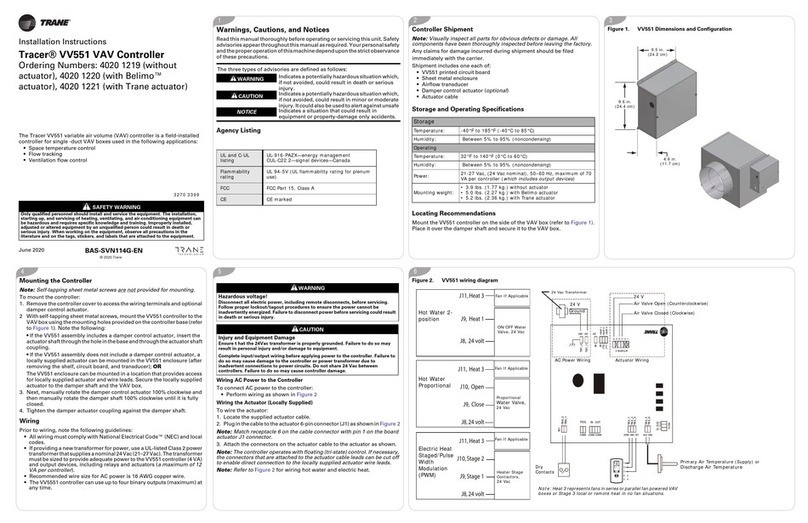

Storage/Operating Specifications

Storage

Temperature: -48°F to 203°F (-44°C to 95°C)

Relative

Humidity: Between 5% to 95% (non-condensing)

Operating

Temperature: -40°F to 158°F (-40°C to 70°C)

Humidity: Between 5% to 95% (non-condensing)

Power: 20.4–27.6 Vac (24 Vac, ±15% nominal) 50–60 Hz, 24 VA

(24 VA plus binary output loads for a maximum of 12 VA for each binary output)

Mounting Weight

of Controller: Mounting surface must support 0.80 lb. (0.364 kg)

Environmental

Rating

(Enclosure): NEMA 1

Altitude,

Installation,

Pollution: 9,842 ft (3,000 m), U.L. 840; Category 3, U.L. 840; Degree 2

5.65 in. (143.5 mm)

*(8 units)

2.37 in.

(60.1 mm)

1.89 in.

(48 mm)

4.00 in.

(101.6 mm)

End View

Front View

1.79 in.

(45.4 mm)

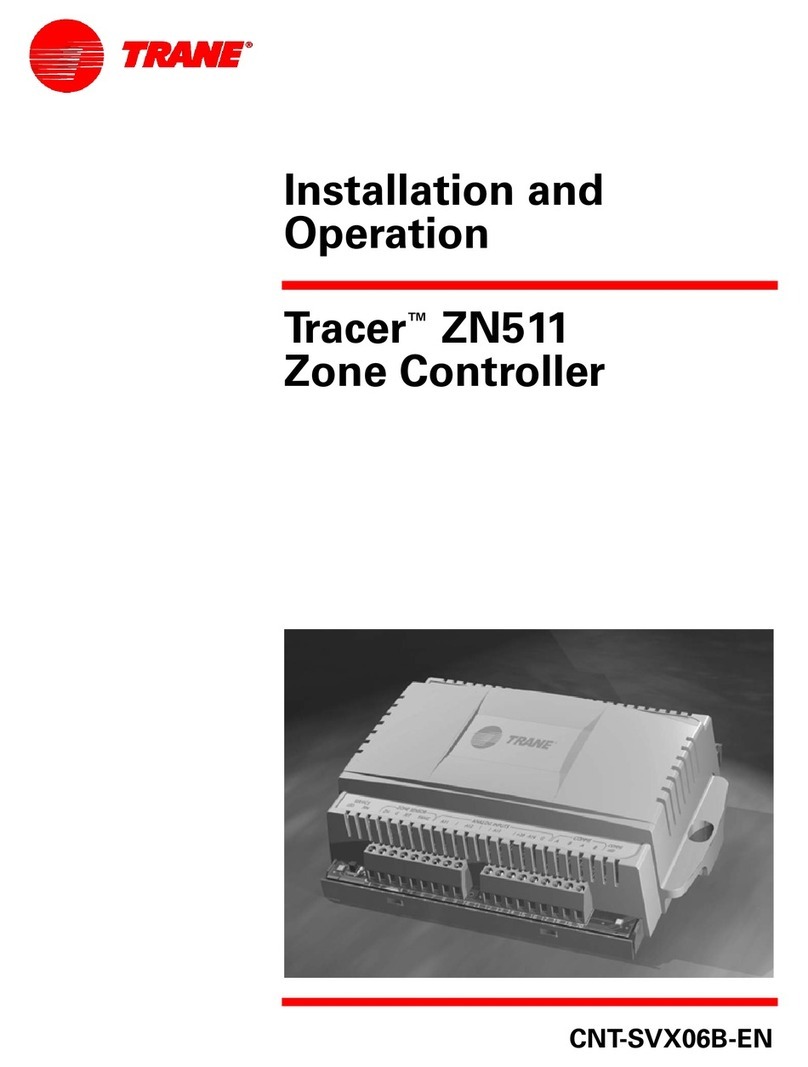

To mount device:

1. Hook device

over top of DIN

rail.

2. Gently push

on lower half

of device in the

direction of

arrow until the

release clip

clicks into

place.

To remove/reposition device:

1. Disconnect all connectors before

removing or repositioning.

2. Insert screwdriver into slotted release

clip and gently pry upward with the

screwdriver to disengage the clip.

3. While holding tension on the clip, lift

device upward to remove or reposition.

4. If repositioned, push on the device until

the release clip clicks back into place to

secure the device on the DIN rail.

Slotted release clip

shown from back side

NOTICE

Equipment Damage!

Do not use excessive force to install the controller on the DIN rail. Excessive force could result

in damage to the plastic enclosure. If using another manufacturer’s DIN rail, follow their

recommended installation.

WARNING

Equipment Damage!

Disconnect all electric power, including remote disconnects, before servicing. Follow proper

lockout/tag out procedures to ensure the power cannot be inadvertently energized. Failure to

disconnect power before servicing could result in serious injury or death.

CAUTION

Personal Injury and Equipment Damage!

After installation, ensure to check that the 24 Vac transformer is grounded through the

controller. Failure to check could result in personal injury and/or damage to equipment.

Measure the voltage between chassis ground and any ground terminal on the UC400. Expected

result: Vac <4.0 volt.

Dimensions/Mounting/Removing the UC400 Communication Link Wiring

The TracerUC400 controller communicates with the building automation

system (BAS) and with other controller over a BACnet® MS\TP

communication link.

For instructions on BACnet MS\TP communication wiring, refer to the Unit

Controller Wiring For the Tracer SC System Controller Wiring Guide (BAS-

SVN03).Transformer Recommendations

A/C Power Wiring

Prior to connecting AC power to the controller:

• All wiring must comply with National Electrical Code™ (NEC) and local codes.

• The recommended wire for AC power is 16 AWG copper wire, minimum.

• Refer to the section for Transformer Recommendations.

NOTICE

Equipment Damage!

Do not use excessive force to install the controller on the DIN rail. Excessive force could result

in damage to the plastic enclosure. If using another manufacturer’s DIN rail, follow their

recommended installation.

WARNING

Equipment Damage!

Disconnect all electric power, including remote disconnects, before servicing. Follow proper

lockout/tag out procedures to ensure the power cannot be inadvertently energized. Failure to

disconnect power before servicing could result in serious injury or death.

CAUTION

Personal Injury and Equipment Damage!

After installation, ensure to check that the 24 Vac transformer is grounded through the

controller. Failure to check could result in personal injury and/or damage to equipment.

Measure the voltage between chassis ground and any ground terminal on the UC400. Expected

result: Vac <4.0 volt.

Wiring Requirements

To ensure proper operation of the UC400, install the power supply circuit in accordance

with the following guidelines:

• The UC400 must receive AC power from a dedicated power circuit; failure to comply may cause the

controller to malfunction.

• A dedicated power circuit disconnect switch must be near the controller, easily accessible by the

operator, and marked as the disconnecting device for the controller.

•DONOT run AC power wires in the same wire bundle with input/output wires; failure to comply may

cause the controller to malfunction due to electrical noise.

18 AWG copper wire is recommended for the circuit between the transformer and the UC400.

Transformer Recommendations

The UC400 can be powered with 24 Vac. Use of a 24 Vac power supply is recommended

in order to use the spare 24 Vac outputs for powering relays and TRIACs.

• AC transformer requirements: UL listed, Class 2 power transformer, 24 Vac ±15%, device max load

24 VA, BCI application 6 VA. The transformer must be sized to provide adequate power to the UC400

controller (12 VA) and outputs (maximum 12 VA per binary output).

• CE-compliant installations: The transformer must be CE marked and SELV compliant per IEC

standards.

A separate transformer is recommended for each UC400. The line input to the transformer

must be equipped with a circuit breaker sized to handle the maximum transformer line

current. If a single transformer is shared by multiple UC400s:

• The transformer must have sufficient capacity

• Polarity must be maintained for every UC400 powered by the transformer

Important: If a technician inadvertently reverses polarity between controllers powered by the

same transformer, a difference of 24 Vac will occur between the grounds of each

controller. The following symptoms could result:

•Partial or full loss of communication on the entire BACnet MS/TP link

•Improper function of UC400 outputs

•Damage to the transformer or a blown transformer fuse

NOTICE

Equipment Damage!

Sharing 24 Vac power between controllers could result in equipment damage.

The Tracer UC400 controller is a field-installed device that provides direct

digital zone temperature control. It can operate as a stand-alone device or

as part of a building automation system (BAS) and control:

• 0/1/2-heat plus 0/1/2-cool rooftop unit

• heat pump; 0/1/2 compressor plus auxiliary heat (optional)

Visually inspect contents for obvious defects or damage. All components

have been thoroughly inspected before leaving the factory. Any claims for

damage incurred during shipment should be filed immediately with the

carrier.