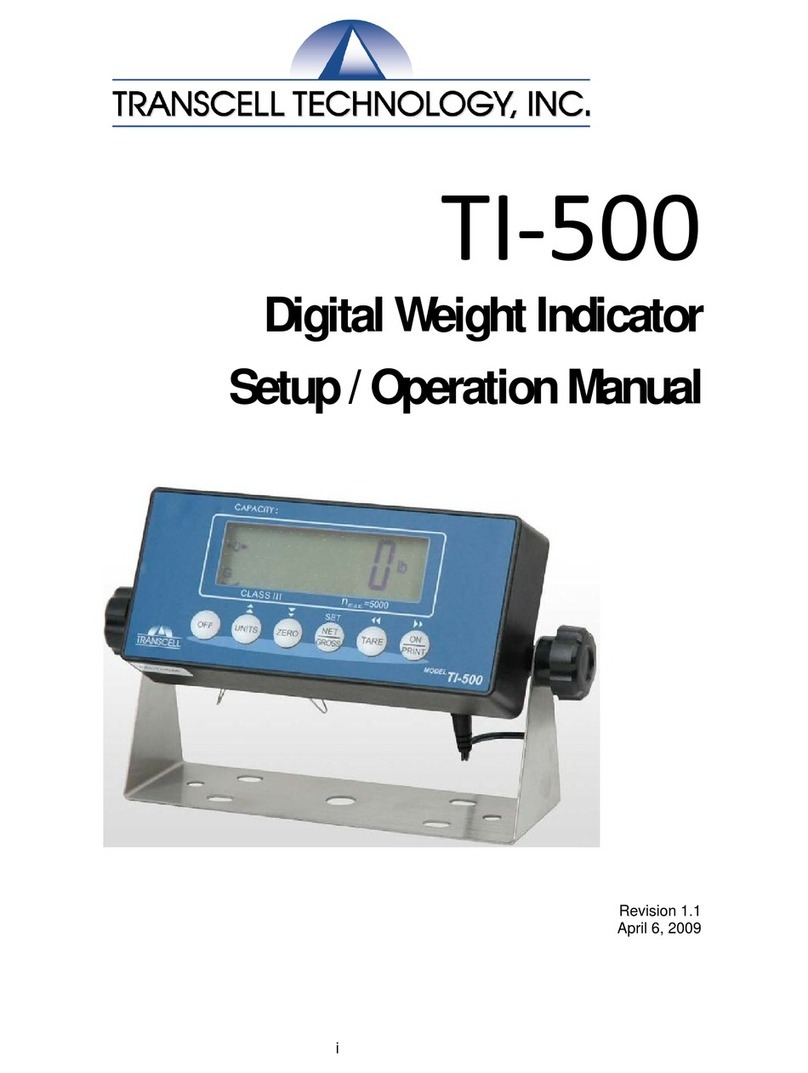

Transcell Technology TI-1680 User manual

MODEL

TI-1680

Digital Weight Indicator

Manual

Revision 3.7 December 12, 2022

1

Table of Contents

BASIC OPERATION............................................................................................................... 3

Getting Started........................................................................................................................... 3

Operation –TI-1680................................................................................................................... 3

DISPLAY & KEYPAD DETAILS ............................................................................................. 4

INSTALLATION & OVERVIEW.............................................................................................. 7

Installation of TI-1680 digital indicator....................................................................................... 7

RS-232 Connections (COM1).................................................................................................... 9

RS-232 Connections (COM2).................................................................................................... 9

Digital I/O Connections............................................................................................................10

Power Connections.................................................................................................................. 11

INDICATOR CONFIGURATION........................................................................................... 12

Configuration Menus................................................................................................................ 12

Entering the Setup (“F”) Configuration Menu ..........................................................................12

Setup (“F”) Menu Descriptions................................................................................................. 13

Entering the User (“A”) Menu................................................................................................... 16

User (“A”) Menu Descriptions ..................................................................................................16

Setting system time (A6).......................................................................................................... 18

Setting system date (A7) ......................................................................................................... 18

Diagnostics (A12) .................................................................................................................... 19

Editing the output string (A14).................................................................................................19

Entering the Batching (“B”) Menu ............................................................................................ 20

Batching (“B”) Menu Descriptions............................................................................................ 21

INDICATOR CALIBRATION................................................................................................. 22

Calibration Overview................................................................................................................ 22

Zero Calibration Instructions (F16).......................................................................................... 22

Span Calibration Instructions (F17)......................................................................................... 22

ADVANCED OPERATION.................................................................................................... 24

Entering an ID Number............................................................................................................24

Application Summary (F30) .....................................................................................................24

Programming Set Points (SP1-SP4) ....................................................................................... 25

Programming Over/Under Weights.......................................................................................... 25

Gross/Net/Tare (F30 = 0)......................................................................................................... 26

Standard Digital Outputs..........................................................................................................26

Accumulation (F30 = 1)............................................................................................................ 27

Piece Counting (F30 = 3).........................................................................................................27

Weight Hold (F30 = 5)..............................................................................................................28

Peak Hold ................................................................................................................................ 28

Static Checkweigher (F30 = 6) ................................................................................................ 29

2

Batching (F30 = 7)...................................................................................................................29

Weigh-In/Weigh-Out (F30 = 8) ................................................................................................ 30

SERIAL (COM) PORT INFORMATION................................................................................ 33

SERIAL PORT MODES...........................................................................................................33

OUTPUT STRINGS................................................................................................................. 34

ERROR MESSAGES............................................................................................................ 36

SPECIFICATIONS................................................................................................................ 36

TROUBLESHOOTING.......................................................................................................... 37

©Transcell Technology, Inc. 2010-2022. All rights reserved.

The information contained herein is the property of Transcell Technology and is supplied without liability for errors or

omissions. No part may be reproduced or used except as authorized by contract or other written permission. The copy-

right and the foregoing restriction on reproduction and use extend to all media in which the information may be embod-

ied.

Contents subject to change without notice.

THIS EQUIPMENT CONTAINS NO USER SERVICEABLE COMPONENTS.

- Servicing of the equipment must only be carried out by trained and authorized

personnel.

- Use only the internal AC adapter supplied with the indicator. Other power sup-

plies may cause damage.

Routine maintenance

- Harsh abrasives, solvents, scouring cleaners and alkaline cleaning solutions

should not be used, especially on the display window.

- The outside of the product may be sprayed with water as needed.

This manual covers the following product:

Model

Display

Enclosure

Power Source

TI-1680

LED

St. Steel

100-240 VAC, 50-60 Hz 0.8A

3

BASIC OPERATION

Getting Started

Simply plug the unit into a suitable AC wall outlet (100 –240 VAC). After a brief initialization pe-

riod, the scale will revert to a zero (“0”) weight display.

Your scale is now ready for operation!

Operation –TI-1680

Before weighing it is necessary to check if the scale is unloaded and indicating zero weight in

the desired unit of measure, for example lb for pounds.

If the indicator is not displaying the desired unit of measure, press the UNITS key a few times

until it is indicated, e.g., lb for pounds, kg for kilograms, etc.

The indicator features an automatic zero correction meaning that small deviations will be zeroed

automatically. If the indicator does not automatically determine the zero point, press the ZERO

key once briefly.

4

DISPLAY & KEYPAD DETAILS

This model utilizes a 6-digit LED (Light Emitting Diode) display, an LED bar graph and eight (8)

annunciators.

Annunciator

Display Indication

GROSS

The indicator is in Gross Weight mode.

NET

The indicator is in Net Weight mode.

TARE

A tare weight has been established in the system.

ZERO

Displays when the reading is at “Center of Zero”.

lb

The displayed weight reading is in pounds (lb).

kg

The displayed weight reading is in kilograms (kg).

The displayed reading is in pieces (piece counting). Also used to indicate that weight hold

/ peak hold mode is active.

STABLE

Displays whenever the indicator reading is not in motion.

UNDER

The weight of the item on the platform is below the target weight. (Checkweigher)

ACCEPT

The weight of the item on the platform is within the target weight range. (Checkweigher)

OVER

The weight of the item on the platform is above the target weight. (Checkweigher)

When not in Checkweigher mode, the LED bar graph shows the status of each one of the four

digital outputs (O1 –O4):

5

The keypad comprises a total of twenty-four (24) keys: twelve (12) function keys and twelve (12)

numeric keypad keys.

“Function Keys”

Key

Keypad Function

UNITS

Cycles the displayed weight indication among pounds (lb), kilograms (kg), and a selectable

third unit. This key can be disabled.

ZERO

Zeroes the weight display reading, provided certain conditions are met.

MODE

Cycles the displayed weight indication among Gross weight, Net Weight, and Tare Weight.

TARE

Establishes a system Tare, provided certain conditions are met.

PRINT

Sends the displayed weight reading to the serial communication port, provided certain con-

ditions are met.

C/CE

Exits current function. Can also be used as a backspace key during numeric entry.

F1

Main function key for a specification application, e.g., piece counting or peak hold

SETPOINT

Used to enter the set points (target weights) into the system.

UNDER

Used to enter the minimum target weight for Checkweigher mode.

OVER

Used to enter the maximum target weight for Checkweigher mode.

ID

Used to enter an ID number into the system.

ENTER

Used to enter numeric data into the system.

Certain keys may be password protected. See Advanced Operation section for more details.

6

Conditional keypad functions:

TARE (Push button tare only)

Indicator reading must not be in motion or displaying an error message. Gross weight must be greater than

zero.

ZERO

Indicator reading must not be in motion or displaying an error message. Operation may be restricted by the

Zero Reset Range setting (see F4 menu parameter).

PRINT

Indicator reading must not be in motion or displaying an error message.

“Numeric Keys”

Key

Keypad Function

0 –9

Self-explanatory … used when numeric data entry is required.

*

Temporarily display system information for a specific application.

.

Inserts a decimal point during numeric entry.

7

INSTALLATION & OVERVIEW

Remember that the installer is ultimately responsible to assure that an installa-

tion will be and remain safe and operable under the specific conditions encoun-

tered.

The indicator must be properly configured and calibrated prior to use.

Installation of TI-1680 digital indicator

Find a suitable location for the indicator and use this handy guide to mount the included bracket

to a wall or table:

CONNECTIONS

The rear cover must be removed to make the appropriate connections to the weighing platform

and peripheral devices.

Caution! Disconnect the indicator from its power source prior to removing rear cover.

To remove the rear cover, simply remove the six (6) acorn nuts that secure it to the enclosure

and set it aside.

Caution! The rear cover contains components which are wired to the main board.

Route all cables through the PGA9 cord grips (cable entry glands). All terminal blocks are spring

loaded and are located on the main circuit board.

At each terminal, first strip away some insulation, and then push down on the orange release

tab with a small screwdriver. Insert the wire into the terminal and then allow the orange release

tab to spring back into its original position. For stranded wires, you may find that crimping on a

ferrule will improve connection integrity, as will tinning it with solder.

8

When all connections have been made, tighten the cord grips, re-install the rear cover, and then

tighten the acorn nuts.

Load Cell Connections

Connect your shielded load cell cable to the load cell terminal block using the table below.

Load Cell Terminal Block (J1)

Marking

Function

Marking

Function

SH

Shield

E-

- Excitation

S-

- Signal

SEN+

+ Sense

S+

+ Signal

E+

+ Excitation

SEN-

- Sense

Load Cell Terminal Block

From the Factory, the indicator is configured for 4-wire load cells. If you wish to utilize Sense

wires, then you must remove the jumper blocks from R47 and R48, which are located adjacent

to the Load Cell Terminal Block (J1), circled in red below:

9

RS-232 Connections (COM1)

Connect your RS-232 serial cable to the COM1 / RS-232 terminal block using the table below.

COM1 / RS-232 Terminal Block (J10)

Markings

Function

GND

Signal Ground

RTS

Request to Send

CTS

Clear to Send

TxD1

Transmit Data

RxD1

Receive Data

COM1 / RS-232 Terminal Block

RS-232 Connections (COM2)

Connect your RS-232 serial cable to the COM2 / RS-232 terminal block using the table below.

COM1 / RS-232 Terminal Block (J9)

Markings

Function

GND

Signal Ground

RTS

Request to Send

CTS

Clear to Send

TxD2

Transmit Data

RxD2

Receive Data

COM2 / RS-232 Terminal Block

10

Digital I/O Connections

Connect your control cables to the Digital I/O terminal block (J4) using the diagrams below.

Digital I/O Terminal Block

The outputs (OUT1 –OUT 4) can be wired to external relays (not included) to switch inductive

loads on and off. The single remote input (INPUT) is triggered by simple contact closure.

There are two ways to drive the external relay(s):

1. Using the internal power supply from the indicator

2. Using an external power supply (not included)

Internal Power Supply

Use the +5V terminal to drive the external relay. This terminal can supply up to 500 mA of cur-

rent. The CATCHDIODE connection is not required when using solid-state relays.

J4

OUTx

+5V

Indicator

External Relay

LOAD

Ctrl

VR = 5V

CATCH

DIODE

11

External Power Supply

The CATCHDIODE connection is not required when using solid state relays.

Power Connections

The TI-1680 indicator ships with a pre-installed AC line cord. It has been pre-wired to Terminal

Block J7 at the factory. Simply plug the unit into a standard wall outlet.

J4

OUTx

GND

Indicator

External Relay

LOAD

Ctrl

External Power Vp(*)

(*) External power source must be:

5V <Vp≤ 24V

V-

V+

CATCH

DIODE

12

INDICATOR CONFIGURATION

Configuration Menus

The TI-1680 contains three (3) menus to configure the indicator:

Setup (“F”) Menu –Configures all scale-related parameters including calibration procedures.

User (“A”) Menu –Configures the serial communication ports and enables some user options

Batching (“B”) Menu –Configures the I/O for process control and checkweigher functions.

The configuration menus are laid out in the following vertical arrangement:

•Parameter level

•Selection level (or function level, e.g., span calibration)

Please review the following chart to get a feel for how to navigate among the various menus and

parameters.

Parameter

F1

F2

Etc.

A1

A1-2

Etc.

Level

Graduations

Sampling Rate

Baud Rate

Data, Parity, Stop Bits

Selection

Key-in

100 to 50000

10, 80

600, 1200, 2400,

4800, 9600, 19200,

38400

8n, 7o, 7E, 7n

Level

Use the directional keys shown below to move around in the Configuration Menus.

Entering the Setup (“F”) Configuration Menu

To access this menu, please follow these directions:

1. Unplug the indicator from the AC wall outlet.

2. Locate the slide switch on the rear cover and move it to the opposite position.

NOTE: A metal plate conceals the slide switch; remove the two drilled-head fasteners and

cover plate to access the slide switch:

13

3. Plug in the indicator to the AC wall outlet. The display shows “PASS_”.

4. Key-in the password (1397) and then press Enter key. The display shows “F 1”.

5. Move from one “F” menu parameter to the next by using the TARE (left) or PRINT (right) keys.

For example, to go from F1 to F2, press the PRINT key. To go from F2 back to F1, press the

TARE key.

6. Once you have arrived at the proper “F” menu parameter, e.g., “F1”, press the

ZERO (down) key once to arrive at the selection level. The scale displays the current param-

eter setting.

7. If there is a selection list, scroll thru the available parameter settings, use the TARE (left) or

PRINT (right) keys. Otherwise, use the front panel numeric keys to key-in the new value.

8. Once the setting you want is displayed on the screen, press the MODE (set) key to save this

value and revert up to the parameter level, e.g.,” F1”.

Setup (“F”) Menu Descriptions

This section provides more detailed descriptions of the selections found in the Setup Menu Chart.

Factory-set defaults are shown in bold with a checkmark; (√).

CODE/NAME

DESCRIPTION

SELECTION LIST

F1

Graduations

Sets the number of full-scale graduations, i.e., max capacity ÷ display

division (d). Pressing the ZERO key to scroll down one level begins

the sequence.

Key-in

100 - 100000

10000

F2

Sampling Rate

Sets the sampling rate in Hertz (measurements per second).

Use 10 Hz for most applications or use 80 Hz for extra fast response

time.

10 80

F3

Zero Track

Band

Selects the range within which the scale will automatically zero. Selec-

tions are in display divisions per second (d/s).

0 (Off) 0.5

1 3

5

F4

Zero Range

Selects the range within which the scale may be zeroed. Selections

are expressed as a percentage of full-scale capacity.

100 1.9

2 20

F5

Motion Band

Sets the level at which motion is detected. If motion is not detected,

the scale can process a Print orZero command. Maximum value varies

depending on local regulations. Expressed as scale divisions per sec-

ond (d/s). Pressing the ZERO key to scroll down one level begins the

sequence.

Key-in

0.0 –32.0

1.0

F6

Digital Filter

Averages weight readings to produce higher stability. Choose the

speed that works best for your application.

“FASt” = Fast “nnEd” = Medium “SLo” = Slow

FASt

neEd

SLo

F7

Overload Limit

Selects the desired formula which determines the point at which the

indicator shows the overload message. All selections are based on

the primary unit selected in F8.

"FS" = Full scale capacity.

FS

FS + 2%

FS + 5%

FS + 1d

FS + 9d

14

CODE/NAME

DESCRIPTION

SELECTION LIST

F8

Calib. Unit

Selects the primary base unit to used in the calibration process and

the default unit for normal operation.

"1" = primary unit is lb "2" = primary unit is in kg

1 2

F9

Display

Divisions

Sets the interval value. Use together with F10.

1

2

5

F10

Decimal Point

Sets the decimal point value. Use together with F9.

0 00

0.0000 0.000

0.00 0.0

F11

Custom Unit

Multiplier

Sets the multiplier for the custom unit, or the conversion factor thatyou

would divide the calibration unit by to obtain the custom unit of weight.

Pressing the ZERO key to scroll down one level begins the sequence.

Key-in

0.0001 - 1000

1.0

F12

Power On Zero

(IZSM)

Allows you to enable or disable power-on zero (IZSM). The maximum

range is 20% of FS.

"0" = Disable IZSM "1" = Enable IZSM

0

1

F13

Analog Output

Function

Selects the function of the optional active analog output in Tare mode.

"0" = Output NET weight "1" = Output GROSS weight

0

1

F14

Units Key

Selects function of the Units key.

"0" = Disabled "1" = Enabled

0

1

F15

Third unit se-

lection

Allows you to select a third unit of measure

0" = No Third Unit, "1" = Grams, "2" = oz, “3” = custom unit

0 1

2 3

F16

Zero Calibra-

tion

Places indicator into live zero-calibration mode. Scrolling down with

the ZERO key one level begins the procedure.

Press ZERO key

to begin sequence

F17

Span Calibra-

tion

Places indicator into live span calibration mode. Scrolling down with

the ZERO key one level begins the procedure.

Press ZERO key

to begin sequence

F18

View Calibra-

tion

Actuates the function that allows you to view both the zero and span

calibration value. Scrolling down with the ZERO key one level begins

the procedure.

Press ZERO key

to begin sequence

F19

Key-in Zero

Allows you to key-in known zero calibration value. Scrolling down with

the ZERO key one level begins the procedure.

Press ZERO key

to begin sequence

F20

Key-in Span

Allows you to key-in a known span calibration value. Scrolling down

with the ZERO key one level begins the procedure.

Press ZERO key

to begin sequence

F21

Factory Reset

(pounds)

This sub-menu will reset all parameters in the “F” and “A” menu to the

default settings. It will not overwrite any previously saved calibration

data. USE WITH CAUTION!

Press the ZERO

key twice to exe-

cute

15

CODE/NAME

DESCRIPTION

SELECTION LIST

F22

Factory Reset

(kilos)

This sub-menu will reset all parameters in the “F” and “A” menu to the

default settings. It will not overwrite any previously saved calibration

data. USE WITH CAUTION!

Press the ZERO

key twice to exe-

cute

F23

Fine Tune

4-20 mA

Fine-tune the optional analog output board. Pressing the ZERO key to

scroll down one level begins the sequence.

Press the ZERO

key to begin se-

quence

F24

Analog Output

Function

Selects the function of the optional active analog output.

"0" = 4-20 mA "1" = 0–10V

0

1

F30

Special Appli-

cation

Enable a special application function.

“0” = None (Gross/Net), “1” = Accumulation, “2” = Remote Display,

“3” = Piece Count, “5” = Hold, “6” = Checkweigher, “7” = Batching, “

8” Weigh-In/Weigh-Out

0 1

2 3

5 6

7 8

F31

Gross Zero

Band

Selects the range within which the scale will automatically clear the

tare and switch to Gross mode. Note that the scale must be in stand-

still. Selections are in display divisions (d). Scrolling down with the

ZERO key one level begins the procedure.

“0” = Disabled

Key-in

0 - 10

0

F32

Center of Zero

Band

Selects the range around gross zero within which the scale will display

the Center of Zero annunciator. Selections are in display divisions (d).

0.25

0.5

F34

Auto Print Min.

Weight

Selects the minimum weight at which the auto print function will work

if enabled. Selections are in display divisions (d). Scrolling down with

the ZERO key one level begins the procedure.

“0” = Disabled

Key-in

0 - 100

1

F35

Hold Mode

Selects the specific Hold Mode. F30 must be set to “5”.

"1" = Automatic Hold, "2" = Manual Hold, "3" = Peak Hold

1

2

3

F36

Percentage

Hold Weight

Selects the percentage (of the displayed held value) of weight change

before the scale automatically unlocks the held weight and relocks

onto the new weight. Use together with F35.

Key-in

0 –100 %

10

F37

Min. Hold

Weight

Sets the minimum weight that can be captured and held; expressed

in display divisions (d). Use together with F35.

1, 2, 5 , 10, 20,

50, 100, 200, 500,

1000

F38

Permanent

Tare

Allows a TARE to be stored with an ID number. Used for the Truck

Weigh In/Weigh Out application.

"0" = Disable "1" = Enable

0

1

16

Entering the User (“A”) Menu

To access this menu, please follow these directions:

1. Unplug the indicator from the AC wall outlet.

2. Locate the slide switch on the rear cover and move it to the opposite position.

NOTE: A metal plate conceals the slide switch; remove the two drilled-head fasteners and

cover plate to access the slide switch:

3. Plug in the indicator to the AC wall outlet. The display shows “PASS_”.

4. Key-in the password (1793) and then press Enter key. The display shows “A 1”.

5. Move from one “A” menu parameter to the next by using the TARE (left) or PRINT (right) keys.

For example, to go from A1 to A2, press the PRINT key. To go from A2 back to A1, press the

TARE key.

6. Once you have arrived at the proper “A” menu parameter, e.g., “A1”, press the

ZERO (down) key once to arrive at the selection level. The scale displays the current param-

eter setting.

7. If there is a selection list, scroll thru the available parameter settings, use the TARE (left) or

PRINT (right) keys. Otherwise, use the front panel numeric keys to key-in the new value.

8. Once the setting you want is displayed on the screen, press the MODE (set) key to save this

value and revert up to the parameter level, e.g.,” A1”.

User (“A”) Menu Descriptions

This section provides more detailed descriptions of the selections found in the User Menu Chart.

Factory-set defaults are shown in bold with a checkmark; (√).

CODE/NAME

DESCRIPTION

SELECTION LIST

A1

Baud Rate

Selects the baud rate for data transmission through the serial ports.

This menu selection has two sub-menus: “A1U1” (COM1) and “A1U2”

(COM2), both with identical selections.

600, 1200, 2400,

4800, 9600 ,

19200, 38400

A2

Data Bits,

Parity and

Stop Bits

Selects the number of data bits and parity of serial transmission. This

menu selection has two sub-menus: “A2U1” (COM1) and “A2U2”

(COM2), both with identical selections.

"8 n" = 8 data bits with no parity bit and one stop bit

"7 o" = 7 data bits with odd parity bit and one stop bit

"7 E" = 7 data bits with even parity bit and one stop bit

"7 n" = 7 data bits with no parity bit and two stop bits

8 n

7 o

7 E

7 n

17

CODE/NAME

DESCRIPTION

SELECTION LIST

A3

Serial Port

Mode

Selects the mode of the serial ports: This menu selection has two sub-

menus; “A3U1” (COM1) and “A3U2” (COM2): both with identical se-

lections. Refer to Serial Port Information for more information.

"d" = Demand Duplex, "C" = Continuous Duplex

"AUto" = Auto Print

d

C

AUto

A4

Serial Port

Output String

Selects the output string of the serial ports: Refer to Serial Port Infor-

mation for more details. This menu selection has two sub-menus:

“A4U1” (COM1) and “A4U2” (COM2), both with identical selections.

"0" = Text Print Ticket Basic

"1" = Text Print Ticket Accumulator

"2" = Text Print Ticket Piece Counting

"4" = String Format 1 (Condec Demand)

"5" = String Format 2 (Condec Continuous)

“6” Truck Weigh In/Weigh Out

0

1

2

4

5

6

A5

Handshaking

Selects function of the hardware handshaking. This menu selection

has two sub-menus: “A5U1” (COM1) and “A5U2” (COM2), both with

identical selections.

"0" = Off (no handshaking)

"1" = RTS/CTS

"2" = XON/XOFF (Ctrl-Q/Ctrl-S)

0

1

2

A6

Set System

Time

Set the system time. Pressing the ZERO key to scroll down one level

begins the sequence.

Press ZERO key

to begin sequence

A7

Set System

Date

Set the system date. Pressing the ZERO key to scroll down one level

begins the sequence.

Press ZERO key

to begin sequence

A8

Print Format -

Time

Selects format of the printed time. This menu selection has two sub-

menus: “A8U1” (COM1) and “A8U2” (COM2), both with identical se-

lections.

"0" = AM/PM "1" = 24 Hr

0

1

A9

Print Format -

Date

Selects format of the printed date. This menu selection has two sub-

menus: “A9U1” (COM1) and “A9U2” (COM2), both with identical se-

lections.

"1" = mm/dd/yy "2" = mm/dd/20yy “3” = dd/mm/yy

"4" = dd/mm/20yy "5" = yy/mm/dd “6” = 20yy/mm/dd

1 2

3 4

5 6

A10

Print Format –

Decimal Point

Selects format of the printed decimal point. This menu selection has

two sub-menus: “A10U1” (COM1) and “A10U2” (COM2), both with

identical selections.

"0" = Period (‘.’) "1" = Comma (‘,’)

0

1

A12

Diagnostics

Used to access the listed test functions (one at a time). Pressing the

ZERO key begins the sequence.

"A12U1" = Display segment test, "A12U2" = A/D converter test,

“A12U3” = Input test, “A12U4” = Output test (all)

“A12U5” = Serial Port test (both), “A12U6” = Keyboard test

Press ZERO key

to begin sequence

18

CODE/NAME

DESCRIPTION

SELECTION LIST

A14

Edit Output

String

Edit the output string. This menu selection has two sub-menus:

“A14U1” (COM1) and “A14U2” (COM2), both with identical selec-

tions. Pressing the ZERO key to scroll down one level begins the se-

quence.

Press ZERO key

to begin sequence

A15

MP-20 Print

Header

Selects the header mode for the MP-20 printer. This menu selection

has two sub-menus: “A15U1” (COM1) and “A15U2” (COM2), both

with identical selections.

"0" = Do NOT Print Header "1" = Print Header

0

1

A16

MP-20 Auto

Label Feed

Selects the automatic label feed mode for the MP-20 printer. This

menu selection has two sub-menus: “A16U1” (COM1) and “A16U2”

(COM2), both with identical selections.

"0" = Disable "1" = Enable

0

1

A17

Set Point

Password

Allows you to enable or disable the password prompt when entering

new Set Point values, Over values and Under values. See B5.

"0" = Disable the prompt "1" = Enable the prompt

0

1

A18

Checkweigher

Mode

Selects the Checkweigher Mode.

"0" = Coarse "1" = Fine

0

1

Setting system time (A6)

NOTE: For versions 2.5 and higher, it is no longer necessary to enter the User Menu to set the

system time. Simply press and hold the ENTER key while powering up the unit and then follow

the directions as written below.

The system time is displayed and set in military (24-hr) format or hh.mm.ss. For example, 09.00.00

is 9:00 AM and 17.00.00 is 5:00 PM.

1. While in the User (“A”) Menu, scroll to "A6", and then scroll down once using the

ZERO (down) key. The screen displays the current system time.

2. If the indicator is displaying the correct time, simply press the C/CE key to exit.

3. Otherwise, press the MODE key to reset the display to zeroes (00.00.00).

4. Use the front panel numeric keys to key-in the new time and then press ENTER. If you make

a mistake, use the C/CE key as a backspace key. The display will revert up to "A6".

Setting system date (A7)

NOTE: For versions 2.5 and higher, it is no longer necessary to enter the User Menu to set the

system date. Simply press and hold the ENTER key while powering up the unit and then follow

the directions as written below.

The system date is displayed and set in month/day/year format or mm.dd.yy. For example,

01.07.20 is January 7, 2020, and 11.30.20 is November 30, 2020.

19

1. While in the User (“A”) Menu, scroll to "A7", and then scroll down once using the

ZERO (down) key. The screen displays the current system date.

2. If the indicator is displaying the correct date, simply press the C/CE key to exit.

3. Otherwise, press the MODE key to reset the display to zeroes (00.00.00).

4. Use the front panel numeric keys to key-in the new date and then press ENTER. If you make

a mistake, use the C/CE key as a backspace key. The display will show revert up to "A7".

Diagnostics (A12)

Here is a brief description of each diagnostic test:

A12U1 Display Test –Lights up all display segments and counts down from 666666 to

11111. Test ends automatically when complete.

A12U2 ADC Test –Shows internal A/D converter counts –useful for troubleshooting weigh-

ing issues. End test manually by pressing the MODE (set) key. The ZERO key works in this

test mode.

A12U3 Input Test –Displays the input logic of the Input terminal. “0” means input pin is

shorted to ground; “1” means input pin is open. End test manually by pressing the MODE

(Set) key.

A12U4 Output Test –Sets all four Output terminals to ‘0’for a few seconds, followed by ‘1’

for a few seconds. Test repeats until ended manually by pressing the MODE (Set) key.

A12U5 Serial Test –Transmits a data string continuously out of both serial ports: “TEST1”

on COM1 and “TEST2” on COM2. End test manually by pressing the MODE (set) key.

A12U6 Keyboard Test –Displays a keycode for each key pressed on the keypad. See Table

below. End test manually by pressing the MODE (set) key.

Key

Keycode

Key

Keycode

UNITS

UnIt5

0

0

ZERO

2Ero

1

1

TARE

tArE

2

2

PRINT

PrInt

3

3

C/CE

CE

4

4

F1

F1

5

5

Set Point

SP

6

6

Under

UndEr

7

7

Over

ovEr

8

8

ID

Id

9

9

*

StAr

Enter

EntEr

Dec. Pt.

dP

Mode

SEt

Editing the output string (A14)

The indicator contains one customizable output string. Output strings are created by assigning a

hexadecimal value to a decimal address. The addresses start at 00 and end at 94. The HEX

value can be a printable ASCII character, or a manufacturer defined print command. All output

strings must end with an End of String (EOS) character.

The programming format is AA__vv where AA is the address (00 to 94) and vv is the programming

value.

Other manuals for TI-1680

1

Table of contents

Other Transcell Technology Measuring Instrument manuals

Transcell Technology

Transcell Technology TI-500 FDI Series User guide

Transcell Technology

Transcell Technology TI-1500 Parts list manual

Transcell Technology

Transcell Technology TI-500 User manual

Transcell Technology

Transcell Technology TI-500 Parts list manual

Transcell Technology

Transcell Technology TI-500E3 Parts list manual