Transfer Flow TRAX3 User manual

Fuel Monitoring System For Your

Transfer Flow, Inc. Auxiliary Fuel Tank

Important Safety Information.........................................................................1

TRAX 3™Fuel Management System ..............................................................2

Fuel System Overview ...............................................................................2

Liquid Crystal Display (LCD) Overview ................................................2

Fuel Transfer Operation ............................................................................3

Computer Module Overview....................................................................4

Frequently Asked Questions ...........................................................................5

Maintenance and Troubleshooting ................................................................7

TRAX 3™Troubleshooting Table....................................................................8

Transfer Flow Replacement Parts...................................................................9

Table of Contents

1

Important Safety Information

Manual operation of the TRAX 3™ Liquid Crystal Display (LCD)

while driving could lead to unsafe driving conditions which can

cause an accident or a serious injury. Observing the screen should

only be done when it is safe to do so. Mounting the TRAX 3™ LCD and routing

the wire harness should be done where the driver’s view or operation of the

vehicle cannot be obstructed.

Filling e Fuel Tank:

•Never ll a fuel tank near a ame or ignition source which might ignite

the fuel vapors.

•Never ll the OEM or Transfer Flow auxiliary fuel tank with the engine or

ignition turned on.

•Avoid breathing fuel vapors or allowing fuel to contact the skin.

•Always ll fuel tanks while the vehicle is on a at level surface.

•Always open the fuel cap slowly to allow any pressure to escape.

•Never overll or “top-o ” any fuel tank. Overlling the fuel tank may

cause damage to the emissions system, cause dangerous spills and possibly

result in a re. e Transfer Flow TRAX 3™ system may also shut down in

the event of a “top-o ” condition.

•Never siphon fuel using the mouth, as this practice is dangerous and

potentially fatal. Use an appropriate pump.

•Never allow fuel to contaminate soil or waterways. Properly contain and

dispose of spilled fuels and cleanup materials.

Other Important Safety Information:

•Use only Transfer Flow, Inc. replacement parts. Many parts of our fuel

system appear common, but are actually special parts which are critical for

safe operation. See page 9 for more information.

•Disconnect the battery before working on Transfer Flow fuel systems.

•Never modify or over-pressurize a fuel tank.

•Do not grind, torch, weld, cut, or modify a fuel tank.

•Do not sleep, or let pets stay in a pickup with a camper shell that contains

an in-bed fuel tank system.

•NEVER connect a TRAX 3™ system to a previously modied fuel system.

•Do not smoke near a fuel tank.

•TRAX 3™ is designed to work only with Transfer Flow auxiliary fuel

tanks. Under no circumstance should TRAX 3™ be used in conjunction

with a modied fuel tank system, or other aermarket fuel tank systems.

2

TRAX 3™ is a computer controlled, self-diagnosing auxiliary fuel system that

automatically transfers fuel from the auxiliary tank to the main tank. e

TRAX 3™ system also monitors the vehicle’s fuel system status and the fuel

levels of each tank. TRAX 3™ transfers fuel as needed with an electric fuel

pump at a rate of one gallon every three minutes.

Fuel System Overview:

Based on the individual vehicle fuel system calibration and size of the Transfer

Flow auxiliary fuel tank, the TRAX 3™ system will transfer fuel at predetermined

fuel levels while the vehicle is in use. e fuel level in the main tank and

auxiliary tank will decrease at similar rates and the LCD will display the fuel

level percentages in each tank and the operational status of the fuel system.

When the system is not transferring fuel and all is normal, the message, “SYS OK”

will be displayed. When the fuel system is transferring fuel, the message, “PUMP

ON” will be displayed on the right side of the LCD. If there is an issue with the

fuel system, the LCD will display a Diagnostic Trouble Code (DTC). e TRAX

3™ computer module does all the work independent of the LCD. If the LCD is

disconnected, the computer module will still monitor and transfer fuel normally.

TRAX 3™Fuel Management System

Liquid Crystal Display (LCD) Overview:

= Each black bar on the LCD display is equivalent to 10%. As

fuel is consumed, the number of bars illuminated will decrease.

3

Aer both tanks are at 85%, the system will maintain

the same fuel level percentage until the AUX tank

reaches 25%. For example, when the MAIN tank is at

55%, the AUX tank will also be at 55%.

When both tanks reach 25%, fuel in the AUX tank will

be transfered to the MAIN tank, keeping the MAIN

tank at 25% until the AUX tank reaches 0%.

When both fuel tanks are full, the LCD will display

100% for both tanks.

When the MAIN is at 85%, the pump will go through

several transfer cycles until both tanks are at 85%.

Fuel Transfer Operation:

e AUX tank is now empty. e only fuel le is in the

MAIN tank.

4

Computer Module Overview:

5

How accurate is my main tank fuel gauge after installing TRAX 3™?

e accuracy of the main fuel gauge will not change. e TRAX 3™ computer

module is wired into the truck’s main wire harness, in between the main fuel

tank and the fuel gauge. e TRAX 3™ module monitors the level of fuel in the

main tank, and then sends that same information to the fuel gauge on the dash.

e stock in-dash fuel gauge displays the level of fuel in the main tank as it did

before installing the TRAX 3™ auxiliary fuel system.

How do I adjust the contrast and brightness of my screen?

e two buttons on the front of the TRAX 3™ LCD module can be used to

adjust the contrast and backlight of the LCD display.

Steps to adjust the contrast or backlight setting:

1. With the ignition in the ON position the TRAX 3™ module should be

operational. Press the RIGHT button on the front of the display until you

reach “LCD Adjust” screen. Select with the LEFT button.

2. Press the LEFT or RIGHT buttons to adjust the contrast or backlight

respectively.

3. To exit the “LCD Adjust” mode and save your settings, do not press any

more buttons; e display will automatically default back to the fuel level

screen in approximately 3 - 4 seconds.

I typically keep trucks for one or two years and then get a new

one. Do I need a new Transfer Flow auxiliary fuel system?

It depends on the truck you are buying. You may need to purchase a re-

installation kit.

Why do I see my fuel level percentage uctuate ± 10% in the rst

two minutes of operation?

e module is rapidly calculating the fuel level in each tank to determine the

accurate value.

Frequently Asked Questions

6

The fuel levels displayed on the LCD change when cornering hard

or during other rapid motions. Is this normal?

Yes, your Transfer Flow fuel tank system has been designed to keep fuel

sloshing to a minimum. However, it is not possible to completely eliminate all

fuel sloshing. Many times, you will nd that fuel sloshing will be greater in the

main tank compared to the Transfer Flow tank. is is because the Transfer

Flow tank is fully baed while most main tanks are not. In either case, you

should not see a fuel level change of more than ± 10%, except under periods

of high cornering, braking, or acceleration loads. If your main tank is close to

empty you may see the low fuel light turn ON and OFF.

If the TRAX 3™ system develops a problem, what do I do?

If a problem develops with the TRAX 3™ system, you can use the

troubleshooting table on page 8, or you can deactivate the system by

disconnecting the power to the computer module, located on the top or side

of the auxiliary tank. Reference the “TRAX 3™ Computer Module Overview”

diagram on page 4; disconnect the three pin connector with the red and

black wire that goes to the TFI wire harness. e LCD will display, “TRAX 3™

Connecting.....” when the power is disconnected and the ignition is cycled. e

vehicle will now operate from the main tank only and the main tank gauge will

read the fuel level in the main tank just as though the Transfer Flow system was

never installed.

Why is the TRAX 3™ LCD displaying “CHK FLTR” when my system

is brand new or the lter is clean?

is may be due to an individual’s driving habits or driving conditions because

of fuel sloshing in the main or auxiliary tank. e “Check Filter” condition will

reset aer 20 minutes or by cycling the ignition (turning it o then on).

7

Filter Maintenance

To replace the auxiliary fuel tank lter, remove the cover box to access the

in-line lter and fuel hoses. Be certain that the lter is in the right direction.

Replace the lter with one listed in Filter Replacement Options.

Replacement aer initial installation:

e fuel lter should be replaced within 3 - 6 months. Transfer Flow includes

an extra lter with your initial purchase.

Routine lter replacement:

Transfer Flow recommends the lter be replaced every 12 months on vehicles

that see normal use. If the vehicle is operated in dusty conditions or driven

more than 20,000 miles per year, the lter should be changed every 6 months.

Vehicles traveling outside the United States and Canada may be exposed to

lling stations containing elevated levels of contaminants. It may be wise to

carry spare lters when traveling outside of the country.

Filter Replacement Options:

FRAM G3, WIX 3303, NAPA 23003, TFI 070-FL-32861

NAPA 3270 for cold weather and biodiesel up to B-20

“Critical Failure/Disconnect Power”

If the LCD displays, “CRITICAL FAILURE/DISCONNECT POWER” the user

should deactivate the system by disconnecting the power to the computer

module, located on the top or side of the auxiliary tank. Reference the “TRAX

3™ Computer Module Overview” diagram on page 4; disconnect the three pin

connector with the red and black wire that goes to the TFI wire harness. e

LCD will display, “TRAX 3™ Connecting.....” when the power is disconnected

and the ignition is cycled. e vehicle will now operate from the main tank

only and the main tank gauge will read the fuel level in the main tank just

as though the Transfer Flow system was never installed.

Maintenance andTroubleshooting

8

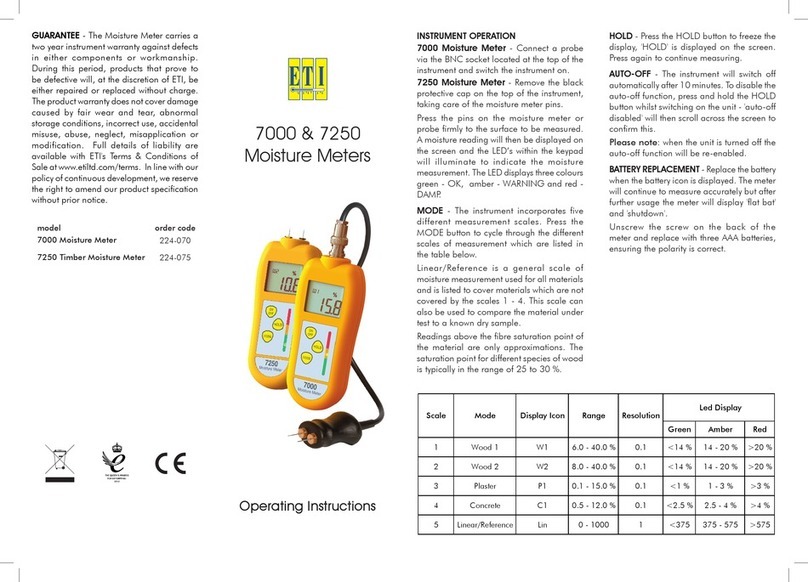

TRAX 3™Troubleshooting Table

TRAX 3

Display Symptom DTC Denition/Possible Cause

Possible

Remedy/

Repair

OEM fuel

gauge

uctuates

Aux pump on, outside of transfer range

Disconnect main

power at module

MSL (MAIN

& AUX fuel

level at 0%)

OEM fuel

gauge at

empty

Main sender low/sending unit bad or a

wire shorted to ground

Call original

installer

MSH (MAIN

& AUX fuel

level at 0%)

OEM fuel

gauge at

empty

Main sender high/malfunctioning sender Call original

installer

MSO (MAIN

& AUX fuel

level at 0%)

OEM fuel

gauge at

empty

Main sender open/severed main

sender wire, defective sender, improper

electrical connection

Call original

installer

ASL & AUX

fuel level at 0%

Pump not

transferring

Aux sender low/sending unit bad or a

wire shored to ground

Call original

installer

ASH & AUX

fuel level at 0%

Pump not

transferring Aux sender high/malfunctioning sender Call original

installer

ASO & AUX

fuel level at 0%

Pump not

transferring

Aux sender open/severed auxiliary

sender wire, defective sender, improper

electrical connection

Call original

installer

CHK FLTR Pump not

staying on

Filter clogged/ow rate not adequate,

kinked line, broken electrical

connection, or excessive fuel sloshing

Replace lter/call

original installer

Blank Display not

turning on Display not getting power

Check for 12V @

TRAX 3™ LCD,

check fuse/call

original installer

9

Transfer Flow, Inc. fuel systems are designed to work only with specic

components which have been selected for their unique properties. Years of

design work have produced the nest auxiliary fuel system available that relies

on relatively few, but critical parts. e components used in Transfer Flow fuel

systems are not generic or “o-the-shelf”parts and cannot be replaced with

parts that appear to be similar.

For example, the in-line fuel pump used with our TRAX 3™ system appears to

be a normal fuel pump, but it is actually a high quality solenoid pump with a

critical forward and reverse check feature. Under no condition should any

other pump be substituted for the provided pump.

is auxiliary fuel system has been outtted with a replaceable fuel lter

that requires periodic service. e lter is available though automotive parts

retailers and is not covered by Transfer Flow’s warranty. e lter should be

inspected/replaced every 3 - 6 months depending on the conditions that the

vehicle is operated in and the quality of fuel purchased. Transfer Flow will not

honor warranty claims from diagnosis or replacement of obstructed lters.

Transfer Flow Replacement Parts

Table of contents

Other Transfer Flow Measuring Instrument manuals