Transforming Technologies PTEC IN6430 User manual

Model IN6430

Static Eliminators

Instruction Manual

Ionizing Air Gun

Model IN6430

Contents

1Description

IN6430 1

Features 1

Power Requirements 2

2Operation and Use

Environmental Conditions 2

Set-up and Placement 2

Mounting 3

Power and Gas Connection 3

3Maintenance

Periodic Maintenance 4

Cleaning Emitter Points 4

Emitter Point Replacement 5

Service 6

Troubleshooting 6

4 Specifications 7

5 Assembly and

Mounting Instructions 8

6Service and Warranty 12

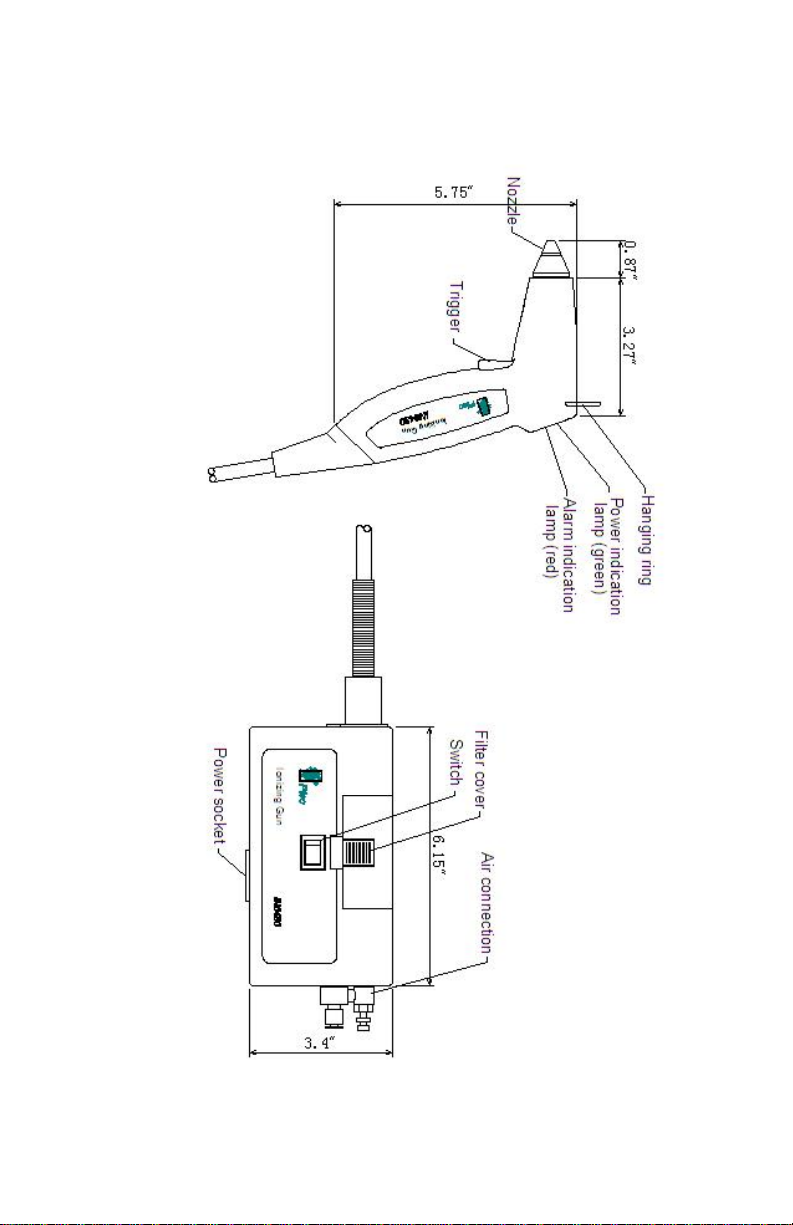

7 IN6430 Line Drawing 13

Description

Ionizing Air Gun Model IN6430

The Model IN6430 68KHz AC ionizing air gun effec-

tively removes particle contamination, even on static sen-

sitive components The IN6430 easily connects to a com-

pressed air source and is compact and lightweight. Using

AC corona technology to make the air more conductive,

Ptec™ ionizers produce a balanced stream of positive and

negative air ions that never need calibration. The control-

ler connects to a clean dry air or nitrogen source and an

integrated disposable filter collects particles. The gun and

air hose are lightweight and easy to use.

About Ptec™ Technology

A specialized piezoelectric high voltage transformer

makes Ptec™ ionizers among the most reliable products

available. Ptec™ ionizers are designed to remain in bal-

ance and to alarm when the HV output affects perform-

ance. The model IN6430 ionizing air nozzle produces a

68KHz AC output of approximately 2200V and a continu-

ous stream of balanced air ions. Ionizers that use Ptec™

technology do not require calibration and only minimal

maintenance.

Features

On the gun of the IN6430 are two LEDs. The green

LED indicates that power is applied to the Ptec™ HV

transformers The red LED illuminates when an alarm con-

dition occurs. An on-off switch is provided on the controller

as well as a 100—240vac IEC input.

1

Features cont’d.

Complete point-of-use protection.

Rapidly decays static charges. (+1000V to 100V, < 2

sec. @ 6”, typical).

Excellent ion balance, 0 +30V.

Stable AC technology.

Ionization indicator light.

HV alarm (red) lights.

No periodic adjustments.

Durable, replaceable tungsten alloy emitter points.

Up to 75 PSI output, adjustable.

Optional filter.

Power Requirements

The Model IN6430 High Frequency AC ionizing air noz-

zle is internally powered by a DC switching power supply

that operates from 100-240 VAC 50/60 Hz IEC input. The

output of the supply is +24 VDC @ .5 AMP. Note: Ionizer

must be grounded.

Operation and Use

Environmental Conditions

The IN6430 can be operated in areas where humidity

is 20-70% RH (Non-condensing). Excess humidity may af-

fect ionizer performance. The temperature range for the

IN6430 is 65-78°F (18-25°C).

Set-up and Placement

Choose a location convenient to the work area and the air

supply. Determine if you will use the product with or without

an internal filter and attach the appropriate connector to the

hose assembly.

2

Mounting

No equipment or tools are necessary, except for

permanent mounting and air line. A permanent mounting

bracket, with screws for the controller, is included. See

mounting instructions.

Power and Gas Connection

Attach the IN6430 gun assembly to the controller. Af-

ter mounting the controller, attach the gas line. The

IN6430 comes with a 1/4” interchange connector and

alternative 1/4” quick release connector. Adjust oper-

ating pressure as required to maximum 75 psi.

Connect the IEC power cord to the controller and

plug it in an AC socket.

Make certain the outlet is grounded.

Turn the unit on and depress the trigger to start the

airflow and the corona process. The ionizer creates a

Caution

!

Do not use this ionizer in an explosive environ-

ment! Corona ionizers produce a weak plasma

that can cause ignition in explosive environ-

ments.

3

Caution

!

The IN6430 operates only with clean dry air

(CDA) or nitrogen (N2). Operator must provide

clean and filtered incoming gas to adequately

remove moisture, oil and particles from the

source supply.

Caution

!

The IN6430 is not designed to withstand high

air pressure. The product should be installed

with shutoff valve upstream. The output side of

the nozzle should always be at atmospheric pre-

seure.

continuous stream of positive and negative air ions

when activated.

The ionized airflow is directed through the nozzle tip

which feature OSHA relief holes. Charged objects in

the ionization area are rapidly neutralized .

A green light will illuminates to signal the IN6430 is

operating.

The red alarm indicator light illuminates in the event

of a problem with the high voltage power output.

Turn the power switch off when not in use for ex-

tended periods.

Maintenance

Periodic Maintenance

The only regular maintenance required for the

IN6430 is the periodic cleaning of the emitter point. Emit-

ter point cleaning affects the static decay ability of the

ionizer and is important for maintaining its optimal per-

formance.

Cleaning the emitter points

Contaminants will gradually accumulate on the tip

of the emitter points, depending in part, on frequency of

use. Periodic cleaning of the emitter points is necessary

to maintain the performance of the ionizer. If the emitter

points are dirty, clean them with a polyester or cotton

swab and IPA. Do not damage or loosen the emitter

points.

Caution

!

The only serviceable parts inside the ionizer are

the replaceable emitter points. Any unauthor-

ized service will void the warranty and may

result in additional repair fees.

4

Follow these instructions to clean the emitter point:

1. Turn off power and unplug ionizer.

2.

1.

Remove the output nozzle tip and ceramic insulator.

2. Moisten a swab in the IPA solution.

3. Swab or wipe the emitter point until it is free of

particles.

4. Make certain the emitter point is straight and undam-

aged.

5. Replace the output nozzle tip and insulator.

6. Make sure the emitter points are dry before powering the

ionizer again.

Emitter Point Replacement

The IN6430 uses tungsten alloy precision etched emit-

ter needles. Contact Transforming Technologies for infor-

mation about ordering replacement emitters. The part num-

ber for emitters is listed below:

Replacement part Part Number

IN6430 tungsten replacement emitters 22-6433

Because the IN6430 high voltage output is AC, emitter

erosion from the ionization process on the electrodes is

minimal. Unless physically broken or stressed, the IN6430

emitters should last the life of the ionizer.

Follow these instructions to remove the emitter points:

1. Turn off and disconnect the unit from the AC power.

2. Remove the output nozzle.

3. Unscrew the threaded emitter point using a needle nose

pliers.

4. Replace and tighten the new emitter using the same

tool. Do not over-tighten.

5

5. Make certain the emitter point is straight and undam-

aged.

6. Replace the output nozzle.

Assembling the Ionizing Gun

1. Determine if you will use the optional integrated filter

(FL0030). Screw the FA100 bypass into the gun/hose

assembly, if not using the filter. Screw the FL0030

and then the FA200 filter adapter into the gun/hose

assembly, if using the filter option.

2. Remove the filter cover from the controller.

3. Connect the gun/hose assembly to the controller. The

FA100 or FA200 must connect securely to the air

coupling inside the controller.

4. Connect the controller to the air supply using inter-

change connector or quick release connector.

Service

Ptec™ ionizers are reliable products with a long ser-

vice life. If you feel your unit is not operating properly,

turn off the unit and disconnect the power cord. Contact

Transforming Technologies’ Technical Support for repair

assistance.

Troubleshooting

The information below provides a reference for prob-

lems that may arise with your IN6430 ionizing air nozzle.

If you have other problems not covered below, please

contact Transforming Technologies’ Technical Support

for repair assistance

6

Problem Causes

Balance outside Emitter points are dirty, damaged

specifications. or not straight. Clean or replace

Alarm light activated Low HV output, call for repair

7

Specifications

Power Input AC 100V~240V, 50/60Hz

Power Outlet un-fused, 0.5A or 1.0A max.

Ion Emission AC, 68KHz

Balance +30 volts

Decay Time 1000V—100V, < 2 seconds @

12”

Temperature 66-78°F (19-25°C)

Humidity 20-60% RH (non-condensing

Air Pressure 20—75 PSI, CDA or N2

Indicators Power: Green LED, Alarm: Red

Controls On/off switch

Mounting Mounting holes on controller

Emitter Points Tungsten Alloy

Dimensions

Hand Unit 8.5"H x 4"W x 1"D, (21.6 x

10.2 x 2.5 cm)

Console 3.5"H x 6.25"W x 1.5"D, (8.9 x

15.8 x 3.8 cm)

Filter Option .01 micron filter (replaceable)*

*Note: Unit also may be operated without filter.

Weight

Hand Unit 12 oz. (.341 kg) with 9.5’ air

hose

Console 1 lb. (.45 kg)

Gas Input & Connection 20—75 psi, CDA or N2, 1/4” male

industrial interchange quick

disconnect or 1/4” quick release

tube fitting

Warranty 1-year limited warranty

Figure 1. Gun with FA100 (no filter) Figure 2. Gun with FA200 and FL0030

2. Standard Operation (no filter):

Insert one end of the filter bypass (FA100) with rubber washer

into hose assembly and twist clockwise. Twist clockwise until

tight. Assembled hose should look like figure 3.

Figure 3. Hose with FA100 (no filter)

Assembly

1. Overview: The IN6430 can be used with or without a filter at-

tachment. The product comes standard without the filter assembly

and uses the filter bypass unit (FA100) to connect the gun to the

console. The filter (FL0030) and filter assembly (FA200) are used

together when the filter is required and is purchased separately.

3. Filter Assembly: To attach filter, insert one end of the filter

with rubber washer into hose assembly and twist clockwise.

Place the Filter Assembly (FA200) with rubber washer on re-

maining end of filter and twist clockwise until tight. Assembled

hose should look like figure 5.

8

Assembly Cont.

Figure 4. Filter Assembly Figure 5. Filter Assembly Finished

Washers

5. Connect gun hose to base console.

Insert hose until the filter bypass unit (FA100) or the filter

assembly (FA200) locks into finger release button ( Figure

5.).

Figure 6. Finger

Release Button

Finger Release

Figure 7. Assembled Gun 6. Use locking screw to firmly

secure hose to base console.

Locking Screw

9

7. Mounting the gun: A mounting back plate and 2 screws

are included with the IN6430 . Mount to the IN6430 as pic-

tured. Then mount the back plate to the desired location.

8. Air attachment: Use Teflon tape with all pressurized

connections. Both finger quick release and industrial inter-

change connectors are provided.

Converter (included)

1/8 BSPT to 1/8 NPT Thread

Gun on the left with out Converter. Gun on the right with Converter

Mounting

10

Industrial Interchange

(Included) 1/4 inlet, 1/8 NPT Thread

Option 2

Finger Quick Release

(Included) 1/4 inlet, 1/8 NPT Thread Size

Option 1

Gun with converter and quick release attachments

Air Inlet Options

11

Service and Warranty

Transforming Technologies, LLC provides a lim-

ited warranty for the Model IN6430 ionizing air noz-

zle. All new products are guaranteed to be free from

defects in material and workmanship for a period of

one (1) year from the date of shipment. Liability is

limited to servicing (after evaluating, repairing or re-

placing) any product returned to Transforming Tech-

nologies. The company does not warrant damage

due to misuse, neglect, alteration or accident. In no

event shall Transforming Technologies be liable for

collateral or consequential damages.

To receive service under warranty, please con-

tact Transforming Technologies Technical Support.

About Transforming Technologies

Since 1998, Transforming Technologies has

helped electronic manufacturing facilities to protect

their products and processes from the many serious

problems associated with static electricity.

Transforming Technologies offers a wide range

of unique and outstanding products to detect, pro-

tect, eliminate and monitor electrostatic charges.

Our products are integral components of an effec-

tive static control program.

12

IN6430 Line Drawing

13

3719 King Rd | Toledo, OH 43617 | P: 419-841-9552 | F: 419-841-3241 | info@transforming-technologies.com

Table of contents

Other Transforming Technologies Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

KAUP

KAUP 3T458P operating manual

ABB

ABB HT607822 Operation manual

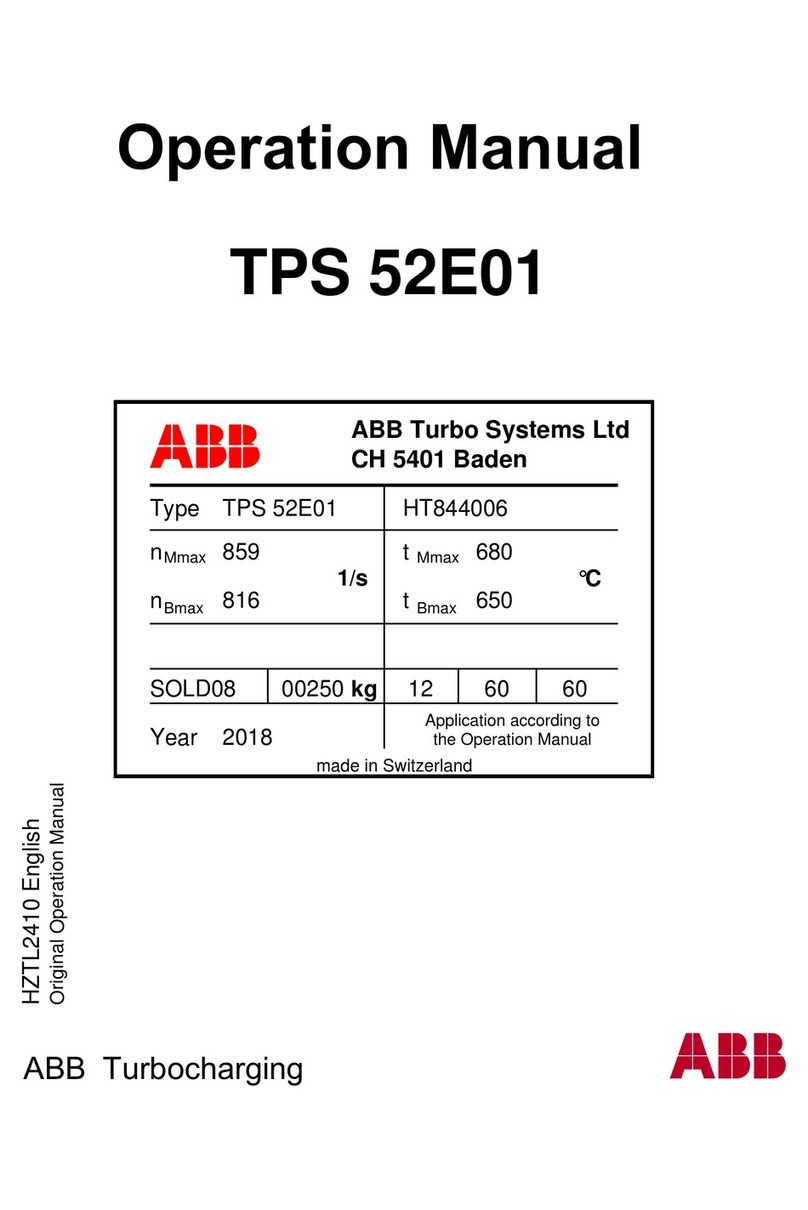

ABB

ABB HT844006 Operation manual

Alpha Technologies

Alpha Technologies Cordex 24-3.1kW Installation & operation manual

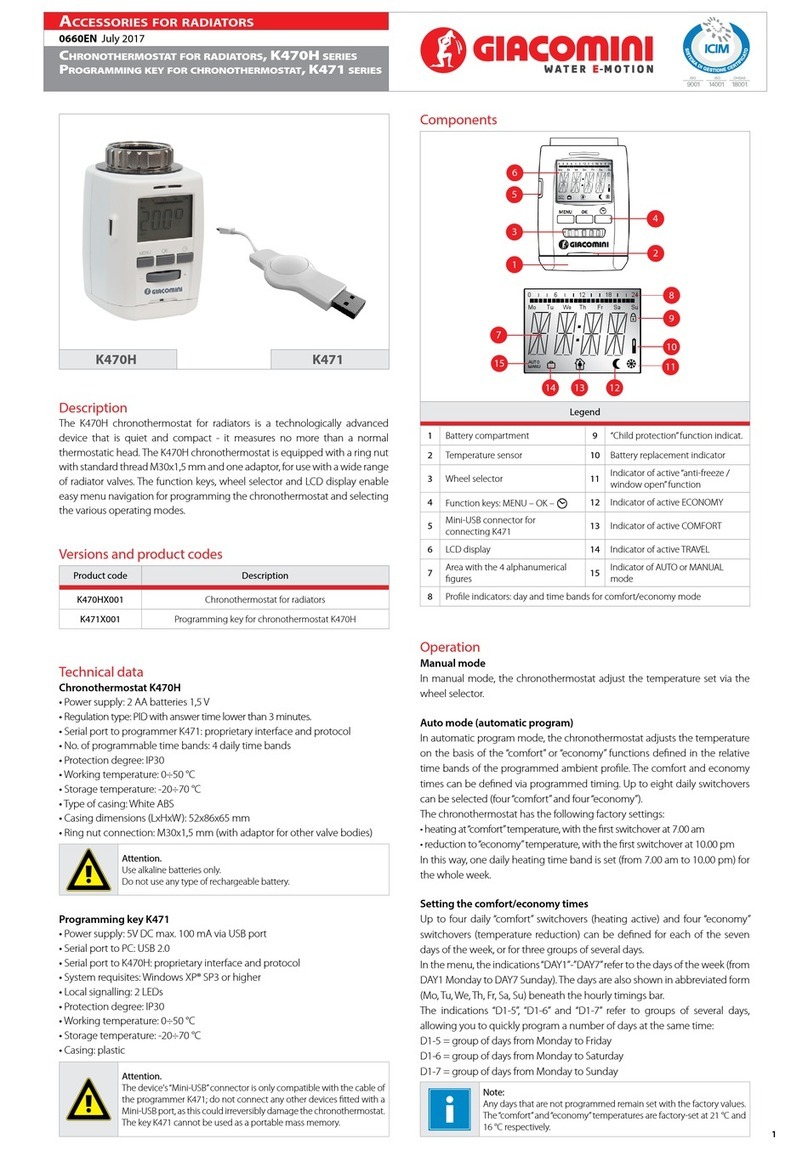

Giacomini

Giacomini K470H Series quick start guide

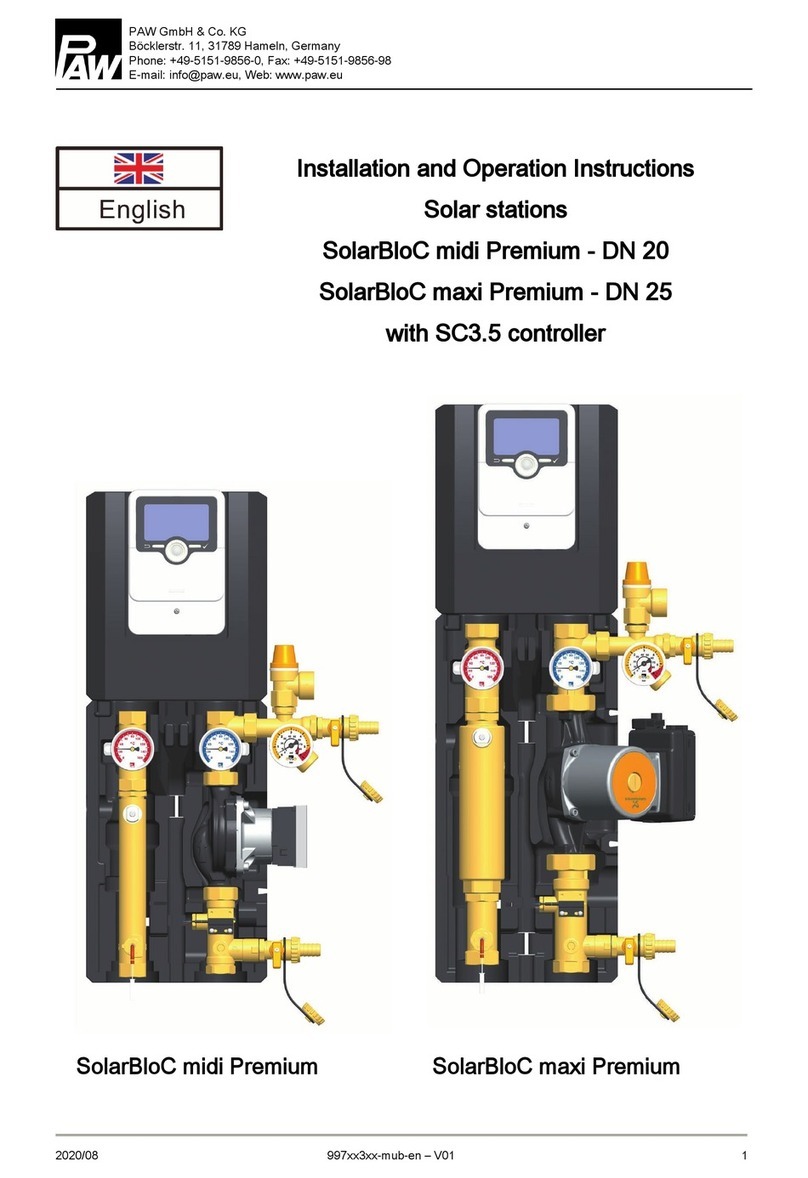

PAW

PAW SolarBloC midi Premium Assembly, installation and operation instructions