2 ProKiln GAC400 PROBE GAS SAMPLING SYSTEM | OI/GAC400-EN REV. A

Table of contents

1General........................................................................ 3

About these operating instructions ...................................... 3

Notifying service........................................................................ 3

2Safety..........................................................................4

General information and instructions...................................4

Warnings...................................................................................... 4

Intended use ............................................................................... 5

Improper use............................................................................... 5

Basic safety rules ....................................................................... 5

Overview of dangers ................................................................. 7

Protective installations .......................................................... 10

Requirements to be met by personnel................................ 12

Personal safety equipment.................................................... 12

Warranty provisions ................................................................ 13

Cyber security disclaimer....................................................... 13

Software downloads............................................................... 13

Manufacturer’s address ......................................................... 13

Service address ........................................................................ 13

3Design and function ................................................ 14

Overview .................................................................................... 14

Mode of functioning and operation .................................... 15

Components ............................................................................. 18

Control system .........................................................................26

User interfaces .........................................................................28

Access permissions.................................................................28

Default operation parameter settings ...............................30

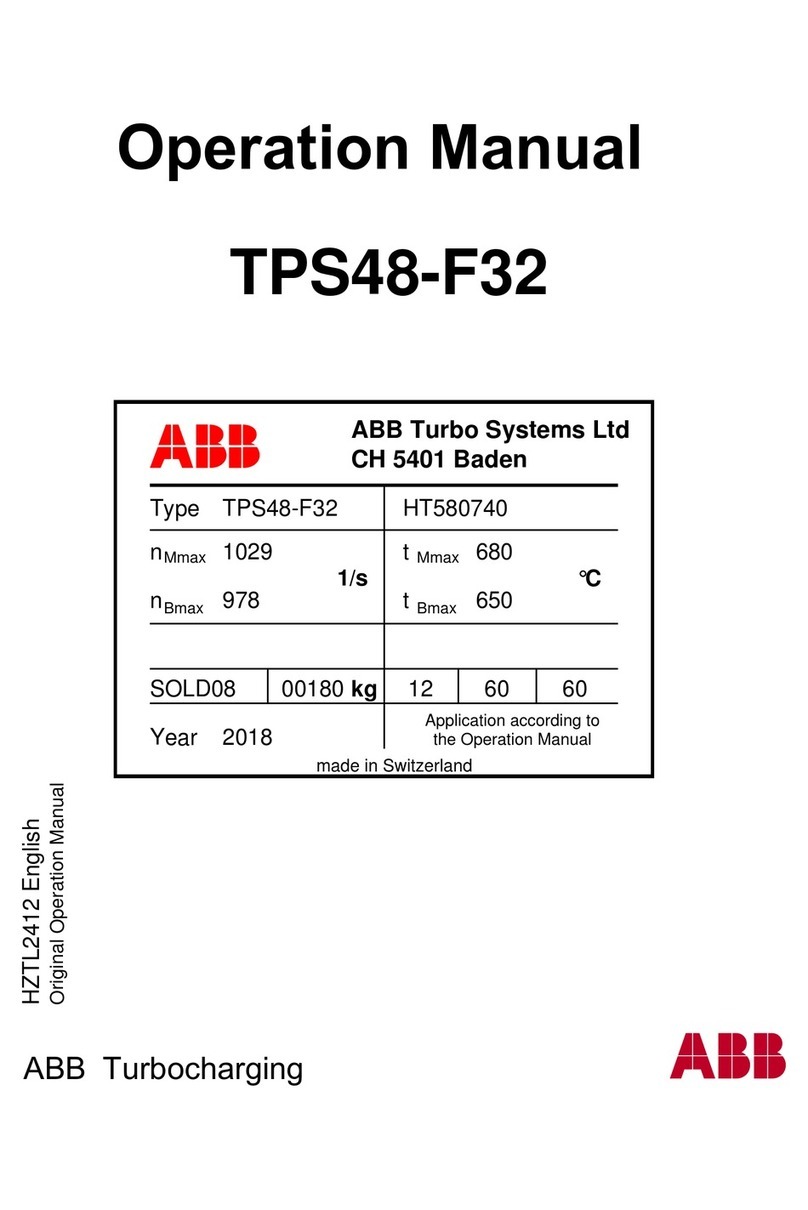

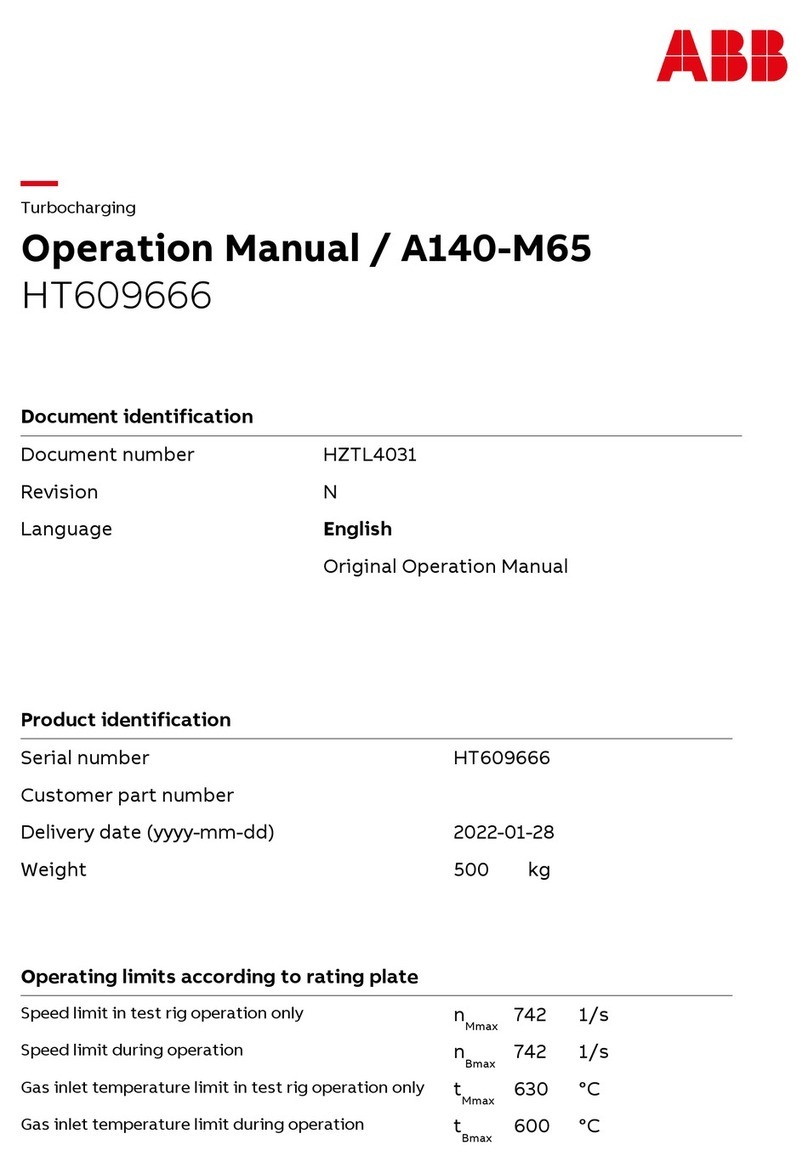

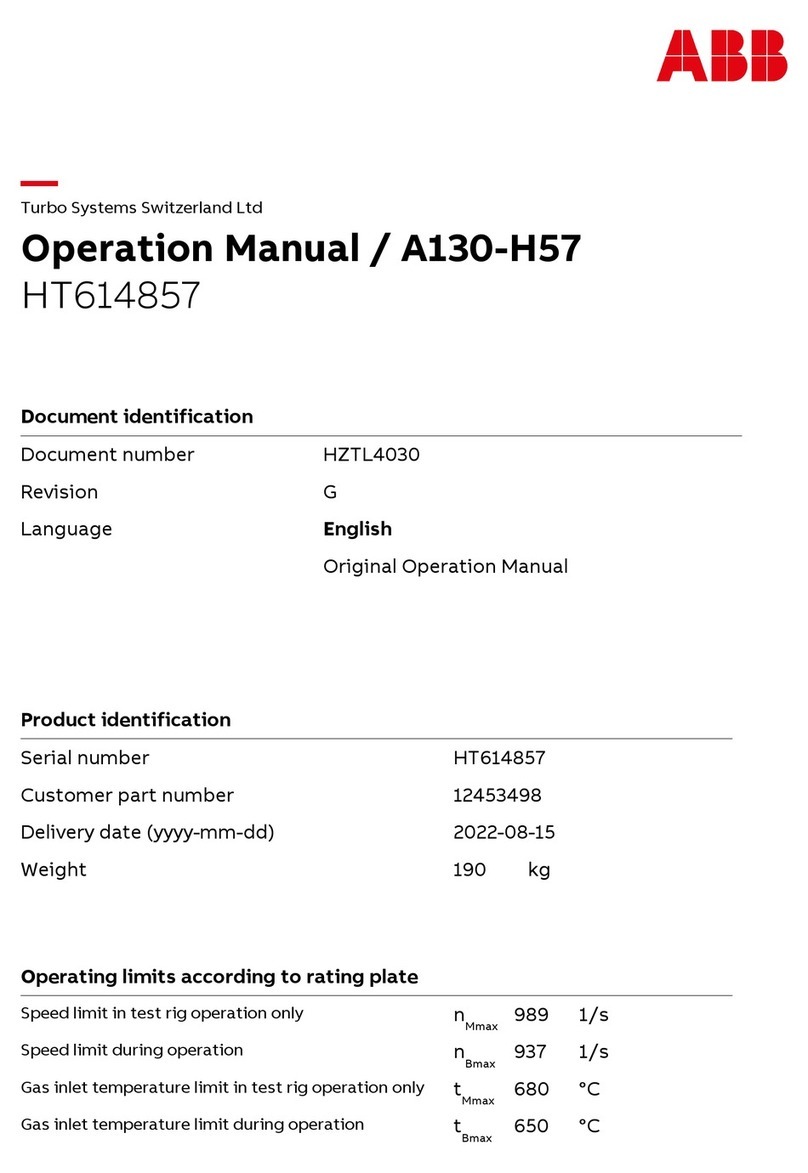

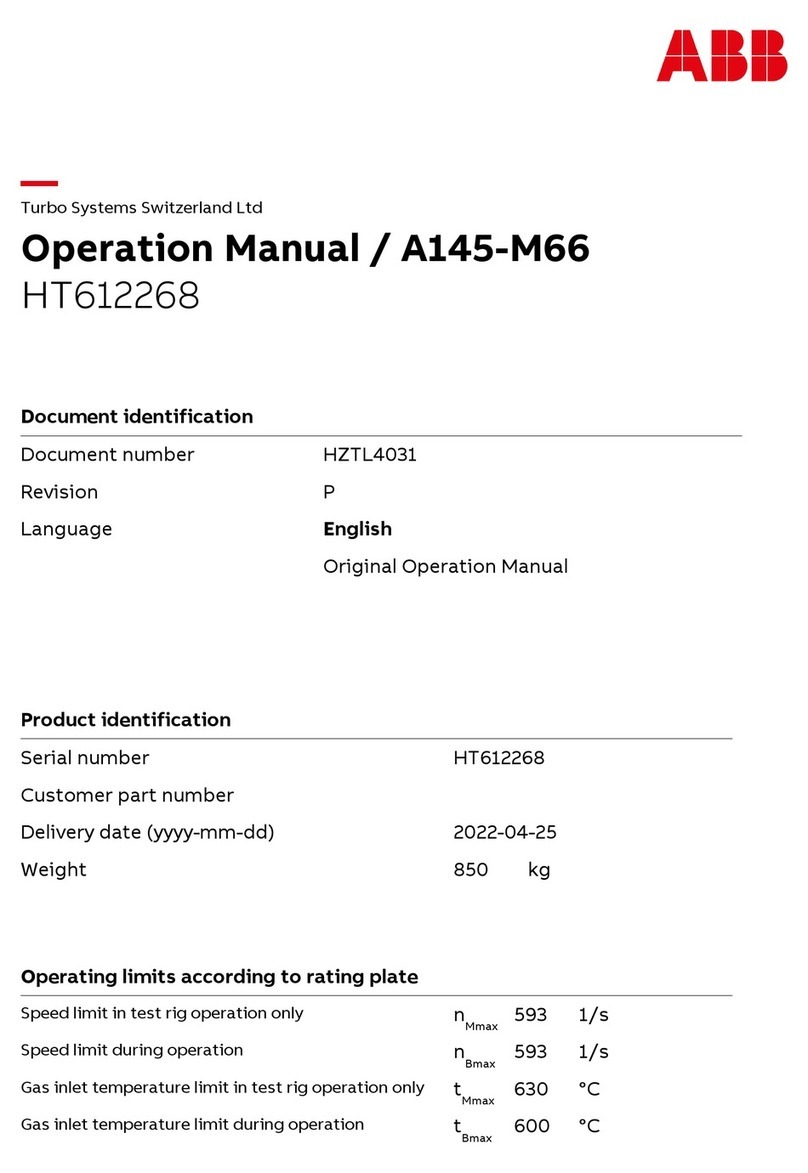

4Product identification ............................................34

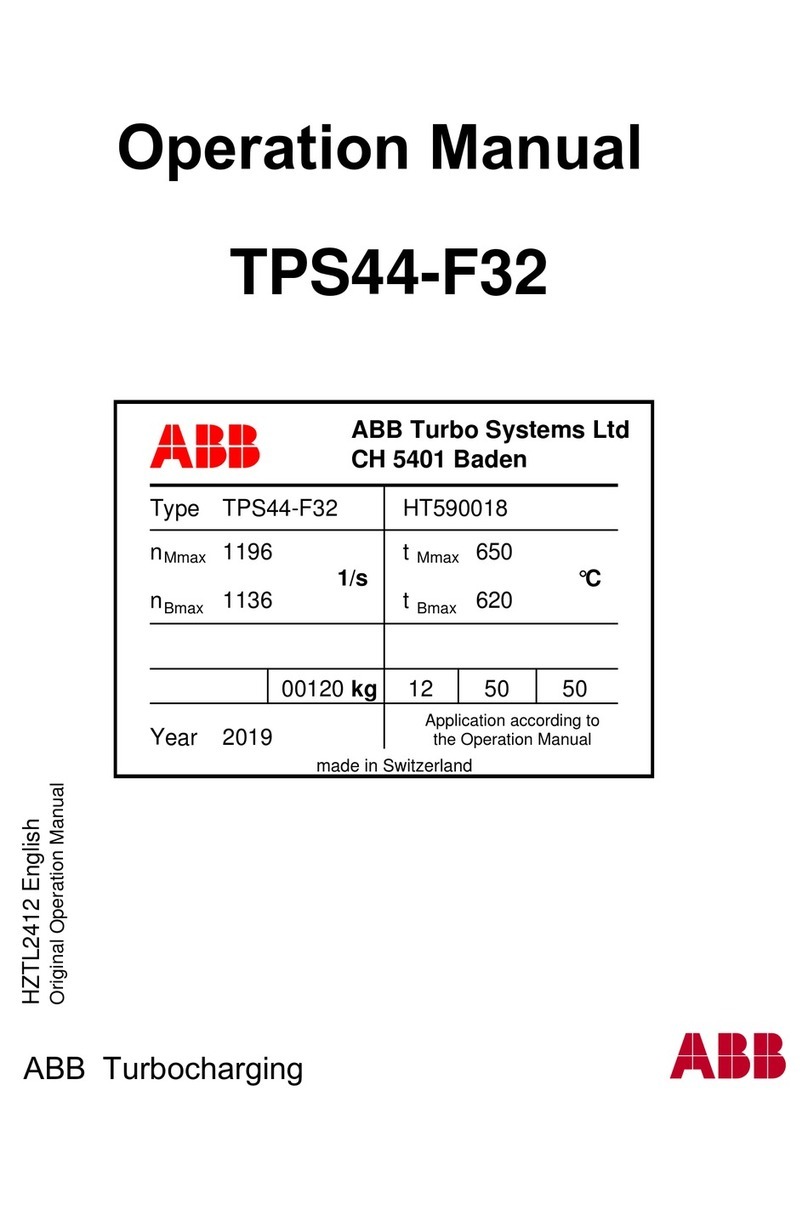

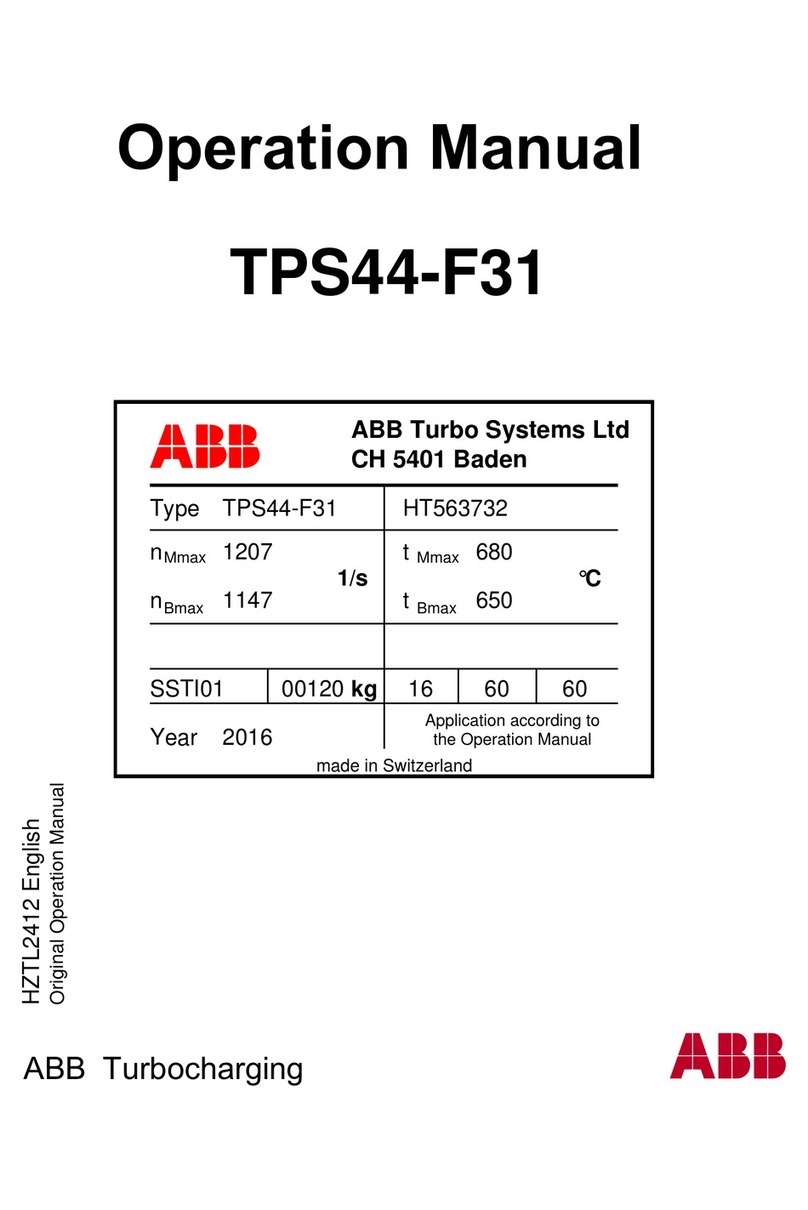

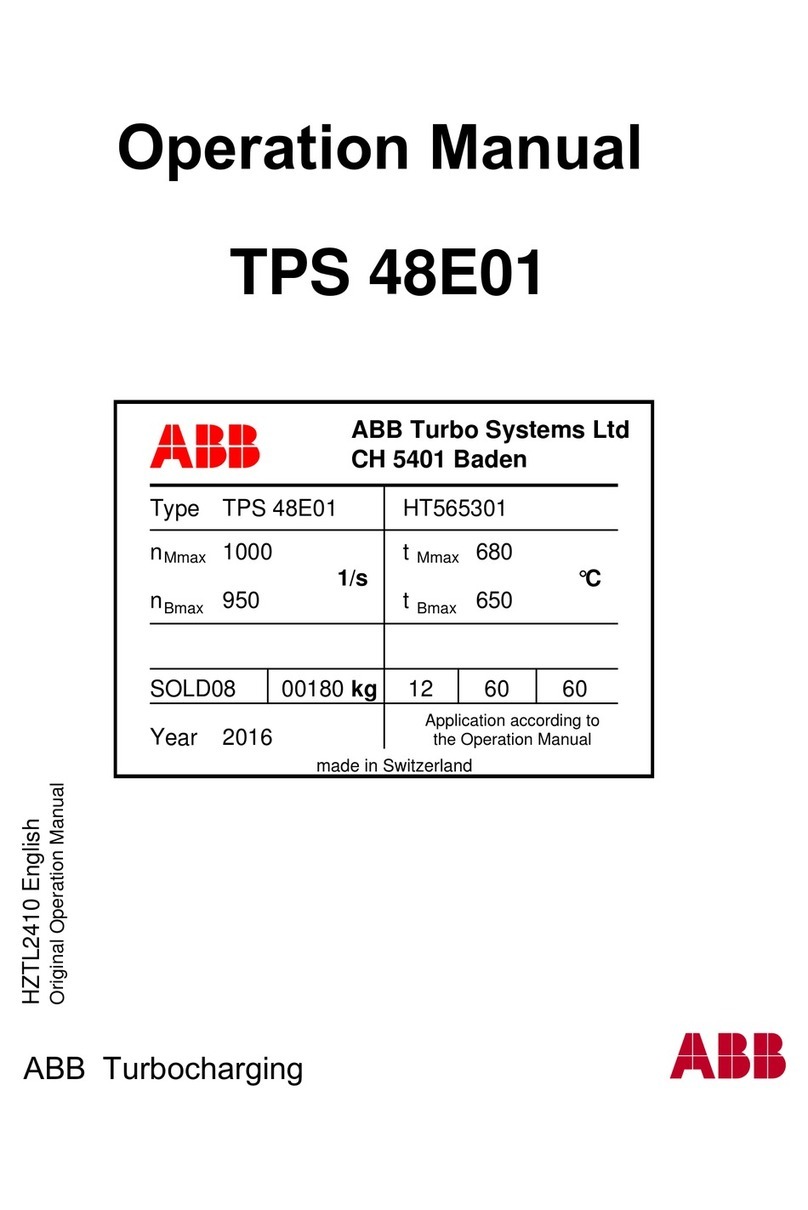

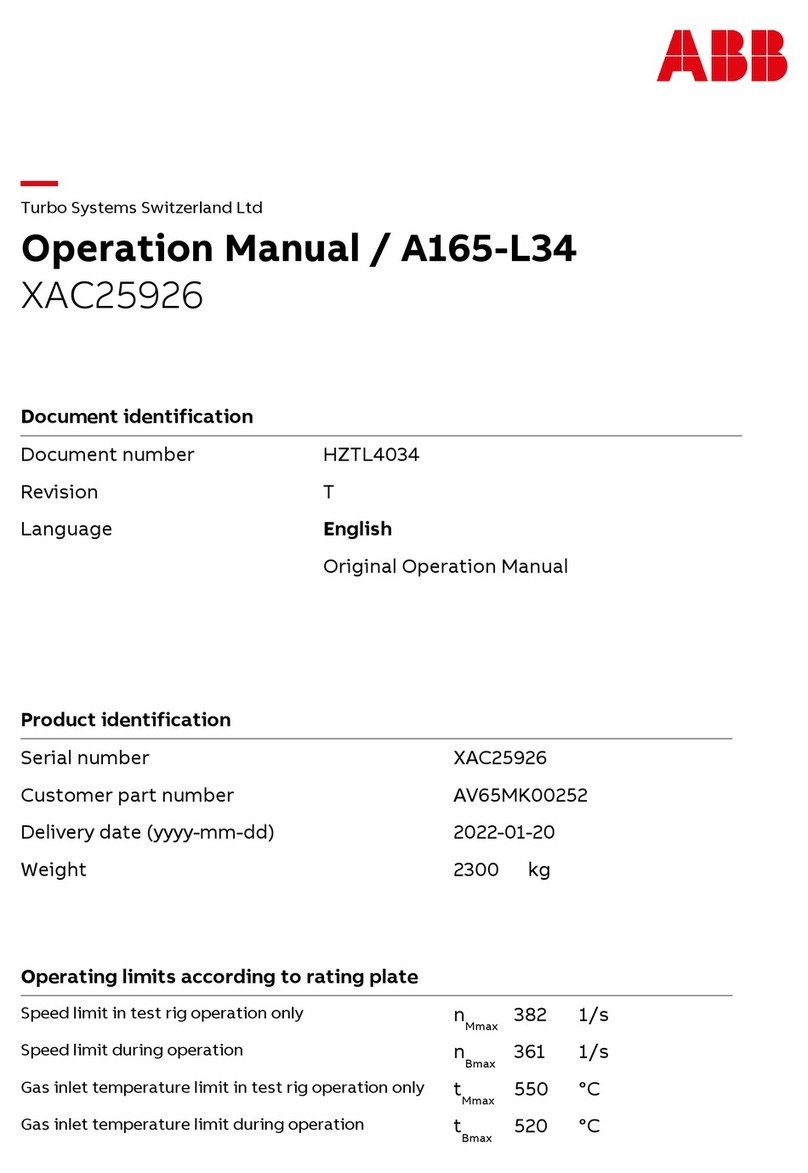

Name plates ..............................................................................34

Warning signs on the system................................................34

5Transport and storage............................................36

Safety instructions ..................................................................36

Transport...................................................................................36

Unpacking the system ............................................................38

Scope of delivery......................................................................38

Storing the system ..................................................................39

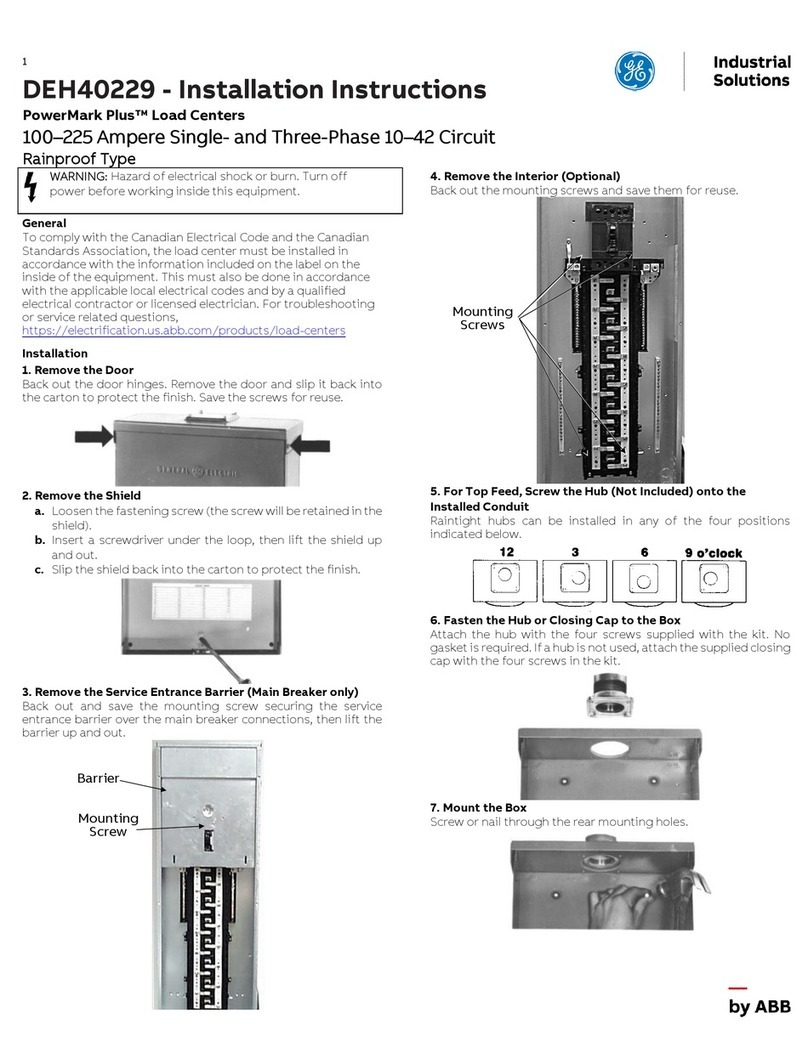

6Installation .............................................................. 40

Safety instructions ................................................................. 40

Introduction ............................................................................. 40

Overview of instruction steps.............................................. 40

Checking site conditions........................................................ 41

Installing the probe retractor/flange shutter...................42

Installing the probe .................................................................44

Installing the compressed-air supply..................................48

Installing the control cabinet ................................................48

Installing the water system and cooling panel .................48

Installing the heated sample gas line to the retractor....50

7Electrical connections............................................. 51

Safety instructions .................................................................. 51

Connecting internal electric cables ..................................... 51

Connecting external electric cables ....................................54

8Commissioning ....................................................... 56

Safety instructions.................................................................. 56

Overview of instruction steps ...............................................57

Installation check .....................................................................57

Cooling water........................................................................... 58

Air supply................................................................................... 58

Activation of the probe gas sampling system.................. 59

Working on the cooling module........................................... 62

Checking the pneumatic system ......................................... 62

Starting frequency converter and adapting control

parameters ............................................................................... 63

Checking/correcting operating parameters .................... 64

Inserting the probe and switching to automatic mode . 64

9Operation................................................................. 66

Safety instructions.................................................................. 66

Monitoring automatic mode ................................................ 67

Checking general condition .................................................. 69

Adapting the cleaning procedure of the probe................ 69

Using the EMERGENCY-STOP switch .................................. 71

Human Machine Interface (HMI)........................................... 71

10 Diagnosis / error messages ...................................73

Automatic processes...............................................................73

Irregularities and corrective action......................................73

HMI error displays................................................................... 74

Handling error messages ...................................................... 78

11 Maintenance ............................................................ 80

Introduction.............................................................................. 80

Maintenance schedule.............................................................81

Equipment layout plan ........................................................... 83

Acquiring spare parts and wear parts................................ 98

Safety instructions for maintenance work........................ 98

Maintenance work................................................................. 100

12 Decommissioning ..................................................124

Safety instructions.................................................................124

Shutting down the system...................................................124

13 Dismounting and disposal....................................126

Safety instructions.................................................................126

Disassembling the system...................................................127

Disposing of the system.......................................................127

14 Specification ..........................................................128

Dimensions and weights ......................................................128

Sound emissions ....................................................................128

15 Additional documents...........................................129

16 Appendix .................................................................130

Return form ............................................................................ 130