Thank you for purchasing the Traxxas VXL-3s™

electronic speed control. The Velineon™ VXL-3s

forward/reverse electronic speed control simplifies

brushless technology with easy, built-in profiles

and intuitive programming. Tri-mode operation

auto detects the motor type for brushed, sensored

or sensorless brushless motors. The VXL-3s uses

advanced circuit design that allows sensorless brushless motors to operate

with the smoothness and precision of the best brushed systems. The VXL-3s

comes with the peace-of-mind of the Traxxas Lifetime Electronics Warranty

and unmatched Traxxas customer support. The VXL-3s is not a toy. It is

a sophisticated electronic device capable of delivering large amounts of

current. Children under 8 years of age require adult supervision for use of the

VXL-3s. If you have questions or need assistance call us at 1-888-TRAXXAS.

Important Precautions

VXL-3s Speed Control

• Water and Electronics Do Not Mix: Do not operate the model in or

around water. Never allow water, moisture, or other foreign materials to

get inside the speed control.

• Disconnect the Batteries: Always disconnect the battery pack from the

speed control when not in use.

• Transmitter on First: Switch on your transmitter first before switching on

the speed control to prevent runaways and erratic performance.

• Don’t Get Burned: The heat sink can get extremely hot, so be careful not

to touch it until it is cool. Supply adequate airflow for cooling.

• Use Stock Connectors: If you decide to change the battery or motor

connectors, only change one battery or motor connector at a time. This

will prevent damage from accidentally mis-wiring the speed control.

Please note that modified speed controls can be subject to a rewiring fee

when returned for service. Removing the battery connector on the speed

control or using the same-gender connectors on the speed control will

void the product’s warranty.

• Insulate the Wires: Always insulate exposed or damaged wiring with heat

shrink tubing to prevent short circuits

Batteries and Battery Charging

The Velineon Power System

uses rechargeable batteries that must be

handled with care for safety and long battery life. Make sure to read and

follow all instructions and precautions that were provided with your battery

packs and your charger. It is your responsibility to charge and care for your

battery backs properly. In addition to your battery and charger instructions,

here are some more tips to keep in mind.

• Never leave batteries to charge unattended.

• Remove the batteries from the model while charging.

• Allow the battery packs to cool off between runs (before charging).

• Always unplug the battery from the electronic speed control when the

model is not in use and when it is being stored or transported.

• Do not use battery packs that have been damaged in any way.

• Do not use battery packs that have damaged wiring, exposed wiring, or a

damaged connector.

• Children should have responsible adult supervision when charging and

handling batteries.

LiPo Batteries

Lithium Polymer (LiPo) batteries are becoming popular for use in R/C

models due to their compact size, high energy density, and high-current

output. However, these types of batteries require special care and handling

procedures for long life and safe operation. Warning: LiPo batteries are

intended only for advanced users that are educated on the risks associated

with LiPo battery use. Traxxas does not recommend that anyone under

the age of 16 use or handle LiPo battery packs without the supervision of

a knowledgeable and responsible adult.

The VXL-3s electronic speed control is able to use LiPo batteries with

nominal voltage not to exceed 11.1 volts (3S packs) volts. LiPo batteries

have a minimum safe discharge voltage threshold that should not be

exceeded. The Velineon VXL-3s electronic speed control is equipped with

built-in Low-Voltage Detection that alerts the driver when LiPo batteries

have reached their minimum voltage (discharge) threshold. It is the driver’s

responsibility to stop immediately to prevent the battery pack from

being discharged below its safe minimum threshold.

Low-Voltage Detection on the speed control is just one part of a

comprehensive plan for safe LiPo battery use. It is critical for you, the user,

to follow all other instructions supplied by the battery manufacturer

and the charger manufacturer for proper charging, use, and storage of

LiPo batteries. Make sure you understand how to use your LiPo batteries.

Be aware that Traxxas shall not be liable for any special, indirect, incidental,

or consequential damages arising out of the installation and/or use of LiPo

batteries in Traxxas products.

If you have questions about LiPo battery usage, please consult with your

local hobby dealer or contact the battery manufacturer.

Installation

The VXL-3s provides two options for installation in many Traxxas models.

The most secure option is to use the mounting plate sold separately as part

#3725. It attaches to the chassis in the original speed control location.

For installations without part #3725, the VXL-3s can

be installed in the chassis with double-sided servo

tape (see illustration, Traxxas Rustler shown). The

screw bosses will need to be cut from the case with

a pair of side cutters to allow the VXL-3s to fit in the

chassis side pod. The screw bosses may need to be

removed for installation in non-Traxxas models as

well. When mounting the speed control with double-

sided servo tape, clean both application surfaces

thoroughly with alcohol. The surfaces must be

perfectly clean for maximum adhesion.

Here are some tips for choosing a location for the speed control:

• The VXL-3s does not use a conventional on/off switch. Pressing the

EZ-Set button on the speed control turns it on and off. It is not necessary

to install an on/off switch into the wiring harness.

• If you are planning to operate the speed control at

the higher limits of its capabilities, cut ventilation

holes into the body for the heat sinks. Monitoring

temperatures will extend the lives of the batteries and

motors and proper ventilation and cooling will prevent premature thermal

shutdown. The VXL-3s is equipped with an additional connector to supply

power to an optional heat sink cooling fan. An optional heat sink cooling

fan can assist in cooling the VXL-3s in high current motor applications.

• Mount the speed control where it will be protected from crash damage.

Also protect the speed control from dirt and debris kicked up by the tires.

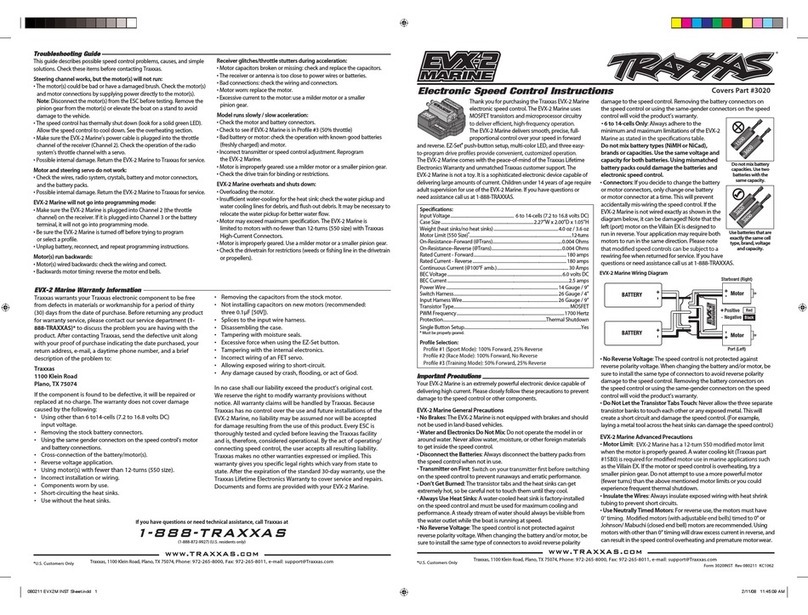

VXL-3s Electronic Speed Control Instructions

Covers Part #3355

Specifications:

Input voltage ...................................................... 4.8 - 11.1V (4 - 9 cells NiMH or 2S - 3S LiPo)

Supported motors ............................................. Brushed / Brushless / Sensorless brushless

Motor limit .........................................................................................................................................None

Continuous current ........................................................................................................................200A

Peak current .............................................................................................................................. 320A

BEC voltage ..................................................................................................................................6.0V DC

Transistor type .......................................................................................................................... MOSFET

On-resistance .................................................................................0.00075 Ω Max (0.006/8 FETs)

PWM frequency .......................................................................................................................12,000Hz

Battery connector ..................................................................Traxxas High-Current Connector

Motor connectors ........................................................................TRX 3.5mm bullet connectors

Motor/battery wiring ...............................................................................12-gauge Maxx® Cable

Thermal protection ...........................................................................2-stage thermal shutdown

Case size (l/w/h) ..................................................55mm (2.19”)/ 39mm (1.54”)/ 33mm (1.3”)

Weight .................................................................................................................................. 90g (3.17oz)

Profile Selection:

Prole #1 (Sport Mode): 100% Forward, 100% Brakes, 100% Reverse

Prole #2 (Race Mode): 100% Forward, 100% Brakes, No Reverse

Prole #3 (Training Mode): 50% Forward, 100% Brakes, 50% Reverse

www.TRAXXAS.com

Traxxas, 1100 Klein Road, Plano, TX 75074,

Form 3355INST Rev 070706 KC1097

Troubleshooting Guide

This guide describes possible speed control problems, causes, and simple

solutions. Check these items before contacting Traxxas.

Steering channel works but the motor will not run:

• The speed control has thermally shut down. Allow the speed control to cool

down. Use a milder motor or a smaller pinion gear. Check

the drive train for restrictions. Check the motor connections. Check the motor.

• Make sure the speed control is plugged into the throttle channel of the receiver.

Check operation of the throttle channel with a servo.

• Bad battery or motor. Check the operation with known good battery and motor.

• VXL-3s: Possible internal damage. Return the VXL-3s to Traxxas for service.

Steering servo does not work:

• Check the wires, radio system, crystals, battery and motor connectors, and the

battery pack.

• Possible internal damage. Test the servo on channel 2 of the receiver or in

another model. Return the servo to Traxxas for service.

Motor runs backwards:

• Motor wired backwards - Check the wiring and correct.

Motor runs as soon as the battery is plugged in:

• Internal damage, return VXL-3s to Traxxas for service.

VXL-3s will not go into programming mode:

• Make sure the VXL-3s is plugged into Channel 2 (the throttle channel) on

the receiver. If it is plugged into the battery terminal, it will not go into

programming mode.

• Be sure the VXL-3s is turned off before trying to program or select a profile.

• Unplug battery, reconnect, and repeat programming instructions.

• Check if transmitter is turned on.

Receiver glitches/throttle stutters during acceleration:

• The receiver or antenna is too close to power wires or the batteries.

• Bad connections - Check the wiring and connectors.

• Motor worn - Replace the motor.

• Excessive current to motor (over-geared motor) - Use a smaller pinion gear.

• Battery voltage low. Recharge and/or verify charged status.

• Disconnected brushless motor lead. Reconnect according to appropriate

wiring diagram.

Model runs slowly / slow acceleration:

• Check the motor and battery connectors.

• Check to see if VXL-3s is in Profile #3 (50% throttle)

• Bad battery or motor. Check the operation with known good battery and motor.

• Incorrect transmitter or speed control adjustment. Refer to the “Transmitter

Setup” and “VXL-3s Setup Programming” sections.

• VXL-3s is in Thermal Shutdown Protection. Allow to cool and check for

proper gearing.

• VXL-3s has entered Low-Voltage Protection.

Model will not go in reverse:

• Make sure the throttle trim is in the correct position (LED on VXL-3s should be lit

solid at neutral throttle)

• Check for correct VXL-3s profile (Profile #2 does not have reverse).

• If brushed motor is being used, verify proper connection to VXL-3s. Correct

if necessary.

VXL-3s Warranty Information

Traxxas warrants your Traxxas electronic component to be free from

defects in materials or workmanship for a period of thirty (30) days

from the date of purchase. Before returning any product for warranty

service, please contact our service department (1-888-TRAXXAS)* to

discuss the problem you are having with the product. After contacting

Traxxas, send the defective unit along with your proof of purchase

indicating the date purchased, your return address, e-mail, a daytime

phone number, and a brief description of the problem to:

Traxxas

1100 Klein Road

Plano, TX 75074

If the component is found to be defective, it will be repaired or

replaced at no charge. The warranty does not cover damage caused

by the following:

• Allowing water, moisture, or other foreign material to enter speed

control or get onto PC board.

• Using other than 4 to 9-cells NiMH or 2S to 3S LiPo (4.8-11 volts)

input voltage.

• Removing the stock battery connectors.

• Using the same gender connectors on the speed control’s motor and

battery connections.

• Cross-connection of the battery/motor(s).

• Reverse voltage application.

• Incorrect installation or wiring.

• Components worn by use.

• Short-circuiting the heat sinks.

• Use without the heat sinks.

• Splices to the input wire harness.

• Disassembling the case.

• Excessive force when using the EZ-Set button.

• Tampering with the internal electronics.

• Incorrect wiring of an FET servo.

• Allowing exposed wiring to short-circuit.

• Any damage caused by crash, flooding, or act of God.

In no case shall our liability exceed the product’s original cost.

We reserve the right to modify warranty provisions without notice. All

warranty claims will be handled by Traxxas. Because Traxxas has no

control over the use and future installations of the VXL-3s, no liability

may be assumed nor will be accepted for damage resulting from the

use of this product. Every ESC is thoroughly tested and cycled before

leaving the Traxxas facility and is, therefore, considered operational.

By the act of operating/connecting speed control, the user accepts

all resulting liability. Traxxas makes no other warranties expressed or

implied. This warranty gives you specific legal rights which vary from

state to state. After the expiration of the standard 30-day warranty,

use the Traxxas Lifetime Electronics Warranty to cover service and

repairs. Documents and forms are provided with your VXL-3s.

If you have questions or need technical assistance, call Traxxas at

1-888-TRAXXAS

(1-888-872-9927) (U.S. residents only)

*U.S. Customers Only

www.TRAXXAS.com

Traxxas, 1100 Klein Road, Plano, TX 75074,

*U.S. Customers Only

Traxxas High Current Connector

Your VXL-3s is equipped with the Traxxas High-Current Connector. Standard

connectors restrict current flow and are not capable of delivering the power

needed to maximize the output of the VXL-3s. The Traxxas connector’s gold-

plated terminals with a large contact surfaces ensure positive current flow with

the least amount of resistance. Secure, long-lasting, and easy to grip, the Traxxas

connector is engineered to extract all the power your battery has to give.

To run this system, your batteries must be equipped with Traxxas High-Current

Connectors. Batteries can either be purchased new with Traxxas connectors

installed or Traxxas connectors can be purchased to install on battery packs you

already own. For best performance, your system requires NiMH battery packs that

have cells rated for high discharge and use high-quality, low-resistance assembly

techniques. Cheaply made battery packs do not retain their performance

characteristics after repeated uses in high-powered electric applications. They will

lose their punch and run time and may require frequent replacement. In addition,

poor-quality, high-resistance cell connectors could fail, requiring disassembly and

repair. The main goal is to reduce all sources of high resistance in the pack. This

includes the connector, the wire, and the bars attaching the cells together. High

pack resistance will create additional heat and rob you of the full power the cells

are capable of producing.