Trelawny VL223EX Series User manual

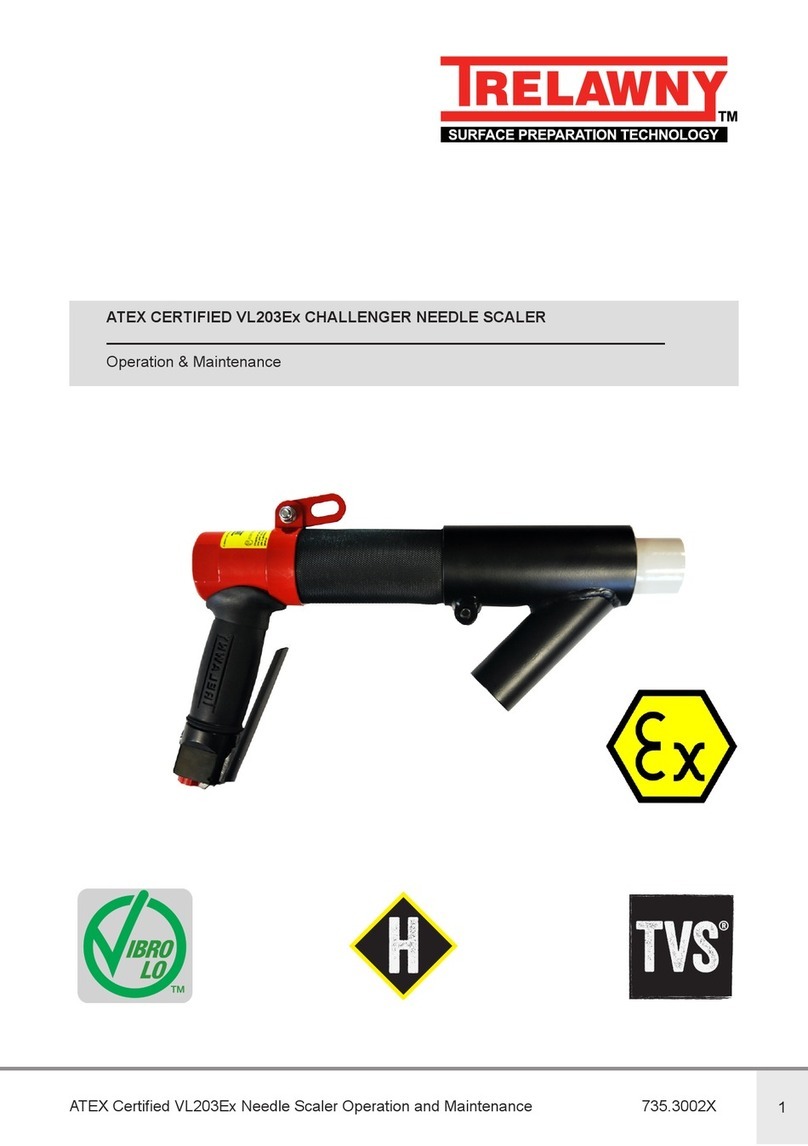

ATEX Certified VL223Ex Challenger Needle Scaler

Operation and Maintenance Manual

www.trelawnyspt.co.uk

OPERATION

General Information

Before operating, performing maintenance or repairing

the ATEX Certified VL223Ex Needle Scaler, this manual

must be read and understood. If in any doubt, ask your

supervisor before using this equipment.

Local safety regulations must be followed at all times.

Failure to follow these instructions could result in damage

to the Scaler and/or personal injury.

Operators should be familiar with the data given in the

specification section. Please keep these instructions in a

safe and accessible place.

Trelawny SPT Limited disclaims all responsibility for

damage to persons or objects arising as a consequence

of incorrect handling of the tool, failure to inspect the tool

for damage or other faults that may influence the

operation prior to starting work, or failure to follow the

safety regulations listed or applicable to the job site.

The tool is primarily designed for the removal of paint,

rust and scale, it can be used both indoors and out.

This tool must not be used in a fixture.

Air Supply

The compressed air must be free from water and dirt. The

installation of a filter/regulator/lubricator air preparation

set (with moisture trap) adjacent to the tool is strongly

recommended.

In particularly cold temperatures it is recommended that a

proprietary anti-freeze lubricating oil is used.

Always clear the air hose before connection to the tool.

Ensure that no moisture (condensation) is present in the

air hose.

Ensure that only 10mm (3/8”) bore Antistatic air hose is

used and that all couplings are secure, leak free and in

good condition. (See Parts list for recommended hose.)

For maximum efficiency, limit the length of air hose to

10M (33ft). Where extra length is necessary, for each

additional 15M (50ft) of air hose used, the pressure drop

is approximately 0.16bar (3psi).

The correct air pressure for this machine is to 6.2bar

(90psi).

Do not let the operating pressure fall below 5.5bar

(80p.s.i.) or rise above 6.9bar (100 psi) absolute

maximum.

The compressor should be able to supply a minimum of

3.77 L/s (8cfm) of free air not displaced as quoted by

some compressor manufactures, this will give 3cfm of

headroom, so that the compressor isn’t continually

running.

NOTE:

If this tool stops working, it is most likely that the plastic

(17) ball has worn excessively and may have passed into

the cylinder, check the cylinder exhaust holes for the

remnant also. This is designed to run for approximately

160hrs before requiring replacement. (Spare balls are

supplied with the tool)

Safety

Always, read instructions first before use.

Do -

Be aware that this tool is not electrically insulated.

Be aware that the tool can create dust and flying debris.

Keep hands and clothing away from moving parts.

Be aware of others working around you.

Ensure that this tool is lubricated daily.

Store this tool in a secure and dry environment.

Wear Personal Protective Equipment including safety

goggles, footwear, ear defenders and gloves. In some

environments it will be necessary to wear facemasks or

breathing apparatus. (Vacuum shroud available)

Always observe safe-working practices at all times.

Do not -

Allow the tool to run unattended.

Use the Scaler as a lever.

Modify this tool in any way, this will invalidate the

warranty and could also lead to serious injury.

Use wire or any other fixing to lock the throttle lever in the

on/open position.

Operate tool with the front tube (34) removed.

Use the tool in potentially explosive environments.

Drag the tool by the air hose.

Use petrol (gasoline), thinners or any other high flash

point solvent to clean the tool.

Use the tool if you become tired, this can lead to physical

strain or injuries; where practical; use a spring balance,

balance weights or similar equipment to take the weight

of the tool.

Hold the exposed needles, whilst the tool is in use, this

could cause vibration damage to the hands.

Please note:

Unrestrained hoses can whip if they become detached.

Care must be taken to avoid damaging or tripping over

the trailing air hose.

Always use a suitable vacuum system connected to the

38mm vacuum take-off port fitted to the tool.

The Beryllium Copper spark resistant needles may create

airborne dust, which maybe harmful to health if ingested.

A Trelawny ATEX rated, 30 litre air operated vacuum

system with a HEPA filter, is available as a separate

vacuum or as a Kit containing either a VL203, VL223 or

the VL303 Needle Scaler and also comes with an Anti-

static tool air hose.

30 litre ATEX Vacuum

Part Number: 303.10KAV30/DH

30 litre ATEX Vacuum Kit with a VL203

Part Number: 139.2503

30 litre ATEX Vacuum Kit with a VL223

Part Number: 139.2523

30 litre ATEX Vacuum Kit with a VL303

Part Number: 139.2533

MAINTENANCE

Starting work

Please note,

Always use a lanyard or strap attached to a belt or

harness, but preferably this should be attached to a fixed

and secure mounting point.

Always use Trelawny Beryllium Copper Needles.

Prior to operating the tool check: -

That all fittings are secure, free from leaks and air hoses

are in good condition.

That the air pressure is correct for this tool 6.2 bar

(90 p.s.i.).

Put a few drops of a recommended lubricant into the air

inlet of the tool.

Safe use of this tool requires a solid stance and secure

foothold, the tool may be used in other postures but care

must be taken that the operator adopts a firm and stable

position.

Maintain contact with the work surface with sufficient

pressure only to keep the tool from bouncing.

Excessive pressure can prevent the tool from working to

its full capacity.

Handled correctly the VL223Ex Needle Scalers will work

quickly and efficiently.

Excessive operator pressure will not improve the tool

efficiency but could cause premature tool failure and

operator fatigue.

Never allow the tool to run continuously whilst not in

contact with the surface being prepared.

To operate the tool, pull the throttle lever (7) towards the

handle and then apply the needles to the surface to be

worked.

Do not place needles on the surface, and then pull the

throttle lever as this will result in the tool bouncing off the

surface.

To switch off, simply release the throttle lever.

Gloves and personal protective equipment must be worn

when using this tool.

Maintenance

Maintenance must only be carried out by a competent

person, in a suitably equipped workshop.

Disconnect the tool from the air supply before

carrying out any of the following operations.

Clean all debris from the exterior of the tool.

This tool has been designed so that you only require a

vice, screwdriver, 3mm pin punch and light hammer, no

other specialist tools are required to completely strip and

service the tool.

For safe efficient running and at intervals of no more than

120 hours, dismantle and clean with highly refined

paraffin.

Check all components for wear, replace the ball valve

(Item 17) and all O’Rings. Immediately after cleaning,

thoroughly oil the tool with one of the recommended

lubricants.

Removing Needles

Disconnect from air supply, hold the Cover (10a) in a vice

using the flats provided, keeping the tool vertical, unscrew

by hand, the Front Tube assembly complete with Return

Spring (32), Needles (31), and Needle Holder (30).

Check the condition of the Front Tube Locking O’Ring

(25). Take care not to invert the Needle Scaler while

removing the Front Tube (34) or the Piston (26) and

Cylinder (15) may fall out of the Intermediate Tube (22).

Remove the Needles from the Needle Holder and dispose

of the used Needles in an appropriate manner.

Re-fitting the Needles

Insert the new needles into the Needle Holder location

holes; ensure that the Needles are inserted into the

chamfered side of the holes. Fit new Front Tube Locking

O’Ring to the Intermediate Tube. Fit the Return Spring

(32) over the needles and insert the Needle assembly into

the Front Tube. Screw the Front Tube assembly onto the

intermediate Tube until hand tight.

Recommended lubricants

Oil the tool daily during use. Put a few drops of one of

the following bio-degradable air tool lubricants through

the air inlet.

SHELL Naturelle HF

CASTROL Carelube HTG 22

Always use clean oil from a sealed container and ensure

ignition temperature is above 100deg C.

Tool Dismantling

Before carrying out any dismantling, ensure the air supply

is turned off and remove the air-line from the tool. Clean

all deposits from the outside of the tool. Service kits are

available, see parts section.

Piston and Cylinder removal

Hold the Cover in a vice using the flats provided, keeping

the Front Tube (34) horizontal. Unscrewing anti-clockwise

VERY IMPORTANT

Only Trelawny Beryllium Copper Needles must be used

in this tool.

DO NOT substitute with any other needle.

IMPORTANT:

The plastic tool box containing the ATEX tool is not

ATEX certified or anti-static, neither is the foam inserts

containing the equipment.

Do not take the tool box into an ATEX restricted area.

MAINTENANCE

Vacuum Take-off

The vacuum take-off fitted is also available as a spare

part. (See parts list for take-off and cuff) which fits over

the front tube. Position the front of the cuff with the needle

tips 20mm inside, adjust as the needles wear. Tighten the

caphead screw to secure. Use a Trelawny recommended

ATEX certified vacuum, fitted with a HEPA filter for 99.9%

dust containment.

Assembly

Ensure all parts are clean and internal parts have a film of

recommended lubricant. Replace any parts that show

signs of wear. If the tool is being fully serviced, it is

strongly recommended to change all O’Rings (2), (5),

(14), (18), (25), Cushion Ring (19), Seals (13,) (29), 6mm

Ball (17) and Needle Holder (30) during assembly.

Valve assembly

Re-assembly of the VL223 is the reverse of stripping.

Secure the Cover (10a) in a vice, holding on the flats

provided, with the valve opening uppermost.

Replace the O’Ring (2) on the Valve Cap (1). Fit a new

Valve seat O’Ring (5) in the Cover with the chamfer

uppermost. Insert the Valve Stem (4), in the Valve Body

(6). Place the Valve Spring (3) on top of the Valve Stem

(4),screw down the Valve Cap (1) by hand, and then

fasten until fully tight with a flat blade screwdriver. Locate

Throttle Lever (7) in the Valve Body (6) using a 3mm

punch to align holes.

Secure by inserting Spring Pin (8).

Tool assembly

Ensure that all components are clean and lubricated with

a thin film of the recommended lubricating oil. Assembly

is the reverse of dismantling.

Secure the Cover (10) vertically in a vice using the flats

provided, insert the Cylinder Guide Plate (12) ensuring

that the flat face is uppermost, ensure that it is located

onto the shoulder at the bottom of the threaded section

inside the Cover. Fit the Cylinder’s stem into the bore of

the Cylinder Guide Plate. With the removal holes

uppermost carefully slide the Intermediate Tube over the

Cylinder, screwing down by hand. Finally tighten by using

a 6mm bar x 200mm through the holes provided. (Do not

over tighten). Gently insert the Piston (26), small

diameter first into the Intermediate Tube (22), if

resistance is felt, turn the Piston slightly until it is located

in the Cylinder.

Note: When removing tool from vice, do not point the

front of the tool downward; the piston will fall out of the

tube and become damaged. Remove the tool from the

vice and follow as per Re-fitting the Needles, hold the tool

vertical when completing this operation.

Disposal

Dismantle into component form, segregate according to

material composition and dispose of using waste

recycling processes specified by local regulations.

by hand, remove the Front Tube complete with the

Needles (31), Needle Holder (30) and Spring (32) as an

assembly.

Note: When removing tool from vice, do not point the

front of the tool downward; the Piston and Cylinder may

fall out of the Intermediate Tube causing damage.

Hold a clean lint free cloth over the open end of the

Intermediate Tube, remove from vice and tilt the Tube

downwards to remove the Piston (26) and Cylinder (15).

Secure the Cover (10a) in a vice with the Intermediate

Tube in the vertical position, using the flats provided.

Use a suitable 6mm bar through the holes provided,

unscrew the Intermediate Tube (22) anticlockwise.

Carefully remove the Intermediate Tube from the cover

and remove the Cylinder Guide Plate (12), which is fitted

in the Cover. The Cylinder Guide Plate can be pulled out

of the cover to gain access to the Guide Plate Seal (13).

Cylinder Ball Valve replacement

This is a consumable item and may require replacing

after approximately 120 -160 hours use; this is dependant

on the cleanliness of the air supply and frequency of

lubrication.

Do not replace this plastic ball with a steel version, as

it will damage the cylinder valve seat and piston valve pin.

The ATEX certification will also become invalid.

Remove the ball retaining O’Ring (18) from its groove just

inside the bore of the stem using a suitable pointed

implement. Remove the ball from the bore or if it has

worn excessively and may have passed into the cylinder,

check the cylinder exhaust holes for the remnant also.

Replace and refit new O’Ring into groove.

Piston Valve Pin replacement

Hold the piston in a vice by the stem, using a pair of

cutters remove the top of the Valve Pin (28), using a drill

& 6mm drill bit and remove the remainder from the piston.

A small socket (4mm) which just fits over the actual pin,

will stop damage occurring. Drive the valve pin in up to its

shoulder using a vice or a small hammer.

Valve Body - Valve Stem removal

Hold the Valve Body (6) in a vice using the flats provided.

Using a 3 mm diameter punch, drive the Throttle Lever

retaining Spring Pin (8) out of the Valve Body (6) and

withdraw the Throttle Lever (7). Remove the Valve Cap

with O’Ring (2), Valve Spring (3), Valve Stem (4) and the

Valve Seat O’Ring (5).

Valve Body removal

Remove the Front Tube and remove Needle Holder,

Needles and Return Spring as per instructions for Needle

replacement above. Replace the Front Tube without the

Needles etc, onto the Intermediate Tube and screw up

until hand tight. Hold the Valve Body flats securely in a

vice, with the Cover (10) uppermost. Turn the tool anti-

clockwise around the Valve Body by holding the Cover

and Front Tube, unscrew the Valve Body from the handle

until loose, remove from vice and finally unscrew by hand.

EXPLODED VIEW

EXPLODED VIEW

This tool is manufactured from material that does

not contain by mass more that 7.5% magnesium

in reference to metallic components.

ITEM No. PART No. DESCRIPTION

VL223Ex Components

1 615.3021 Valve Cap

2 809.0139 Valve Cap O’Ring

3 712.3022 Valve Spring

4 618.3022 Valve Stem

5 809.0089 Valve Seat O’Ring

7 716.1000 Safety Throttle Lever

8 813.0108 Roll Pin

10a 423.2023 VL223Ex Cover now only supplied as an assembly BSP Thread (inc 1-8 )

12 652.2003 Guide Plate

13 829.2003 Guide Plate Seal

14 809.0299 Guide Plate O’Ring

15 428.2003 Cylinder

17 816.3003 Plastic Ball 6mm diameter

18 809.0080 Ball Retaining O’Ring

19 809.2004 Piston Cushion

22 622.2031 Intermediate Tube

23 721.2003 Intermediate Tube Outer Sleeve

25 809.0299 Front Tube Locking O’Ring

26 612.2003 Piston

28 636.3003 Valve Pin

29 829.2002 Piston Ring

30 601.2030 3mm Needle Holder

31 403.1319 Needle set (1 x set Beryllium Copper (19 needles)

32 712.2003 Front Spring

33 620.2003 Front Tube Insert

33A 620.2003A Front Tube Spacer

34 622.2030 Front Tube

35 809.3005 Cylinder Stem Reaction Ring

NOT SHOWN IN EXPLODED VIEW

418.2003 Vacuum take-off (with flat cuff)

731.2103 Flat Cuff

732.2101 Corner Cuff

732.2102 Edge Cuff

720.2003 Fall Arrester

415.3003 Anti-Static Lanyard

819.2375 Connector 1/4” BSPT-3/8” Stem

843.0825 Adapter 1/4” BSP to 1/4” NPT

458.1530 1/4” BSP Oiler with whip hose and whip check

427.5330 Claw Coupling Y-Connector with snap connectors. (Comes with two 3/8” hose connectors & hose clips)

421.3530 Anti-static air hose (10mtr) 1/4” BSP/Open

446.2003X Service Kit for ATEX (VL203/223)

PARTS LIST VL223Ex

TECHNICAL SPECIFICATION

Machinery Directive Information:

This tool has been designed and produced in accordance with the following directives: 2006/42/EC Machinery Directive

and applicable harmonised standard: EN ISO 1 1148-4:2012

EN ISO 11148-4: 2010 Hand Held Non-Electric (Non-Rotary Percussive Tools)

This tool conforms with the following EC legislation: ATEX directive 94/9/EC

Based on the following harmonised standards:

EN13463-1:2009

EN13464-5:2011

Notified Body: TRaC Global Ltd.

Certificate Number: TRaCC15ATEX0029X

If your company has any problem with our products or would like to discuss the possibility of an improvement being made to them, then please do not hesitate to contact us. Your

comments are both important and appreciated.

Trelawny tools are thoroughly tested under specified conditions in accordance with applicable internationally recognised standards. When a tool is used on site the

conditions may not be the same as those used in our tests.

Trelawny Surface Preparation Technology operates a policy of continuous product development and refinement and therefore reserves the right to change technical

specifications and product designs without giving prior notice.

© Copyright 2015, Trelawny SPT Limited, CV31 1XT. UK All rights reserved. Any unauthorised use or copying of the contents or part thereof is prohibited. This applies to

trademarks, model denominations, part numbers and drawings. Use only genuine Trelawny spares.

The use of non-Trelawny spare parts will invalidate the ATEX certification and also the warranty .

VL223Ex INLINE

NEEDLE

Piston Diameter 23.5mm (0.925”)

Piston Stroke (approximate) 11mm (0.43”)

BPM 2400

Air Consumption @ 6.2bar 1.89lps (4.0cfm)

Overall Length 370mm (14.5”)

Weight 2.35kg (5.18lbs)

Needle 19 x 3mm

Beryllium Copper

Noise LwA (Power Level) 90.7 db(A)

Vibration (AEQ) Primary 2.56 m/s2 (k)

Vibration (AEQ) Secondary 2.95 m/s2 (k)

TROUBLE SHOOTING CAUSE ACTION

Poor performance or lack of

power.

Low air pressure. Ensure that the air pressure is correct at 90psi, max 100psi.

If tool has been left for some time without use, the oil

may dry out slightly, causing a sticky residue.

Strip tool down, clean and re-oil.

Needles worn or some missing. Replace with new set of BC needles and needle holder.

Piston seal worn. Remove seal from piston and fit into bore of cylinder. If it

drops to the bottom of the bore, a replacement is required.

Valve pin worn. Replace valve pin and 6mm plastic ball.

Tool continues to run with

trigger released.

Valve seal may have become dislodged through the tool

being disconnected with the trigger in the open position.

Ensure that the trigger has not been taped or wired in the

open position, reposition or replace valve seat o'ring.

High vibration. High air pressure. Ensure that the air pressure is correct at 90psi, max 100psi.

Lack of lubrication. Lubricate with the recommended air tool oil daily.

Low air pressure 70-80psi can also cause high vibration. Ensure that the air pressure is correct at 90psi, max 100psi.

Front return spring weak or broken. Replace return spring.

Guide plate seal worn. Replace guide plate seal.

Piston cushion failed. (This is a split o’ring) Replace with a new piston cushion.

6mm plastic ball worn out. Check for and remove the remains of the ball, possibly in

an exhaust hole of cylinder and renew 6mm plastic ball.

Valve pin worn. Replace valve pin and 6mm plastic ball.

Tool stopped working.

Noise Levels Noise level measured in accordance with: EN ISO 15744: 2008

Vibration Levels Vibration measured in accordance with: EN ISO 28927-9:2012 and

EN ISO 20643:2005. (k) Equals the factor of uncertainty, which allows for variations

in measurement and production. Vibration Data figures are tri-axial, which gives the

total vibration emission. Because of various factors, the range of vibration from these

tools may vary between -0% +40%. The vibration is dependent on the task, the

operators grip and feed force employed etc.

NOTE: The above vibration levels were obtained from tri-axial measurements to

comply with the requirements of “The Control of Vibration at Work Regulations

2005*” and the revisions to the (8662) now EN ISO 28927-9:2012 and EN ISO

20643:2005 series of standards. These values are at least 1.4 times larger than the

values obtained from single axis measurements.

*Based on European Union Council Directive 2002/44/EC (Physical Agents

(Vibration) Directive)).

Risk of Hand Arm Injury

Because of various factors, the vibration from this range of tools may be between

2.95 m/s2 – 4.13m/s2

The vibration is dependent on the task, the operators grip, and feed force employed.

NOTES

NOTES

Trelawny SPT Ltd

13 Highdown Road, Sydenham Industrial Estate, Leamington Spa,

Warwickshire, CV31 1XT, United Kingdom

Telephone: +44 (0)1926 883781 - Fax: +44 (0)1926 450352

Email: sales@trelawny.co.uk

© TSPT UK 2015 Part No: 735.3004X issue 1 www.trelawnyspt.co.uk

This manual suits for next models

3

Table of contents

Other Trelawny Tools manuals

Trelawny

Trelawny VL203Ex Troubleshooting guide

Trelawny

Trelawny SF11EX User manual

Trelawny

Trelawny SF3EX User manual

Trelawny

Trelawny VLSF1EX User manual

Trelawny

Trelawny Single Scaler Standard Duty User manual

Trelawny

Trelawny LPS55 User manual

Trelawny

Trelawny Vibro Lo Troubleshooting guide

Trelawny

Trelawny Trident Neptune User manual