3

IQ251 Controller Data Sheet TA102315 Issue 4, 8/10/08

Data Sheet IQ251

FIRMWARE

Communications: When operating as part of a Building Management System, the IQ251 will be connected to other devices using the

IQ system Network. This means that information within the IQ251 can be accessed using one of the IQ system supervisor programs, or

passed to other IQ controllers using inter-controller communications, enabling the sharing of information across the whole system.

When connected to the network the controller can use up to 3 different addresses. One address is for the controller itself (set by front

panel switch) the second and third are optional, and are for the locally connected supervisors (supervisor port address), (ndp port

address). Thus a locally connected supervisor has its own network address when connected to the network using the controller.

The controller’s address is set by a switch, and the supervisor and ndp port adresses are set up in the strategy configuration

(address module).

Battery Status: The IQ251 has a battery status checking circuit that checks the battery on power up and thereafter every midnight

and sets byte 506 bit 0 if the voltage has falls below a threshold value. This bit being set indicates that the battery needs to be changed.

It should be used within the strategy to generate an alarm (e.g. critical alarm). The battery should be changed after the first indication.

The battery will have a typical life of 10 years at 20 °C (68 °F). It is recommended that the battery is replaced every 5 years.

HARDWARE

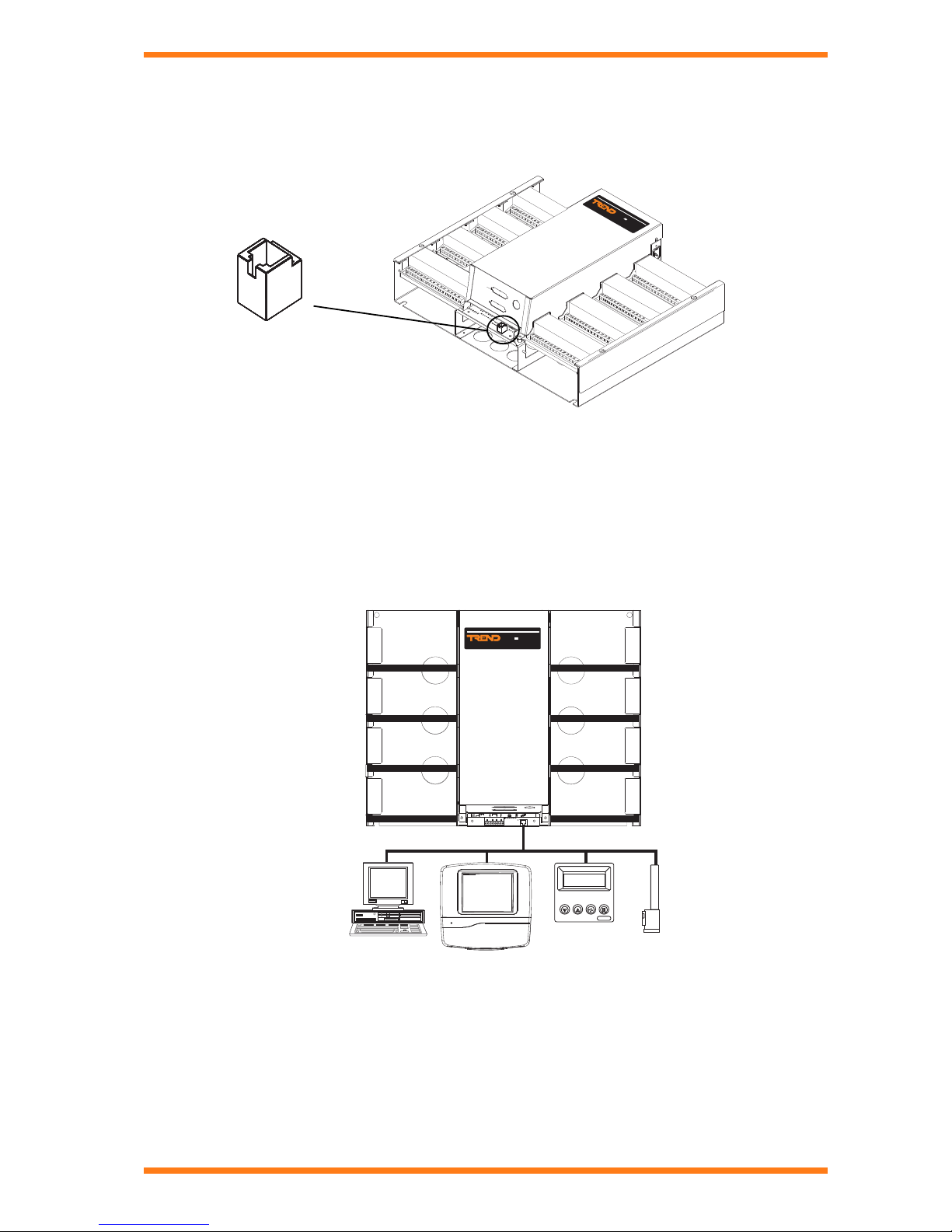

Unit: The IQ251 has a metal chassis and a metal front cover. The

I/O modules are of aluminium extrusion. The I/O modules are fitted

to the controller by snapping off a section in the cover and removing

the relevant side plate. The module connector then slides into a

socket on the controller. There is an option to fit a 16 terminal earthing

(grounding) bar below each I/O module for cable screens (Part/

LA102359K). Cable access is using holes in the rear plate, or from

top or bottom, cables can be run down the central column behind

the controller board. Cleats are fitted to the rear plate to facilitate

cable mounting. There is a 25 Way D type knockout on the bottom

of the front panel for RS232 connection to an auxiliary node, and

a circular knockout for M20 gland or grommet for internetwork,

PSTN, ISDN or Lon cables. If required the IQ251 can be fitted in an

IP55 metal enclosure (ENCLS).

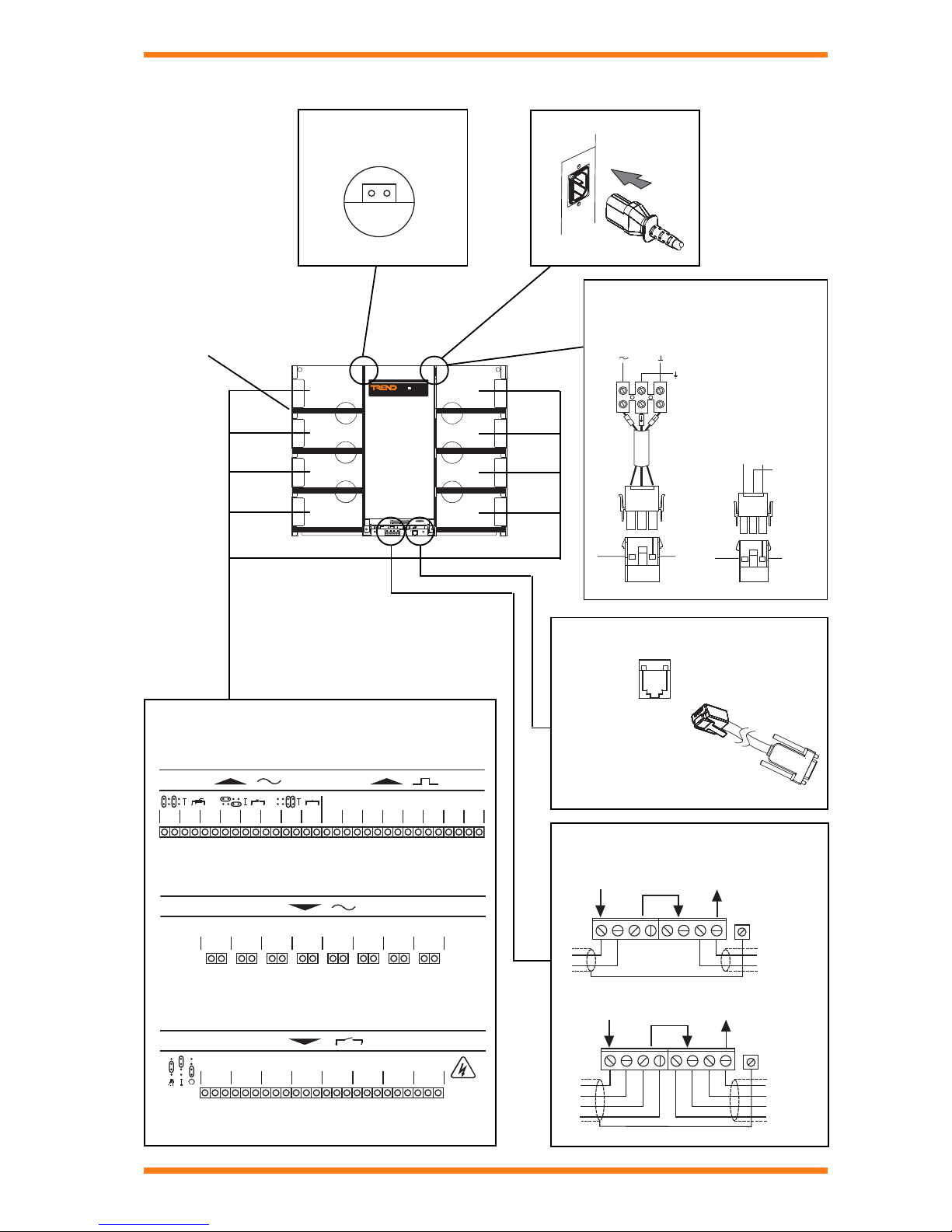

Connectors: Two part connectors are used throughout to facilitate

wiring. A busbar is provided for screen termination.

Power: 230 Vac 50/60 Hz, 24 Vac 50/60 Hz, or 24 Vdc. The 24 Vac

input power must be isolated and can only power 1 controller. The

24 Vdc input power may be earthed (grounded) but polarity must be

correct; it can power several controllers in parallel.

Fusing: The controller has no replaceable fuses; protection is

providedbymeans of a self-resetting thermally protected transformer.

The 24 V ac or dc versions have a 4A replaceable 1¼” fuse fitted

in line of input power cable inside the unit and a solid state multifuse.

The I/O modules are also individually protected against short circuits.

Indicators: LED indicators for receive and transmit network current flow

(RX, TX) and network OK ( ), also for power ( ), all I/O channels ( ),

and watchdog ( ). See specification section for details.

Network: The network terminals facilitate connection of 2 or 4 wire

cables. The standard IQ system node features are included (TX,

RX, and network OK, , indicators, bypass relay, and network alarm

generation). There is also the facility for connection of a supervisor

and integral network display panel to the network using the controller

without the need for additional node controllers.

Note that the IQ251 does not have a balanced line transmitter

like other IQ2 series controllers and this may result in reduced

network resilience.

Address/Baud rate switch: The address on the Lan is set by

poles 1 to 7 in range 1, 4 to 9, 11 to 119 and must be unique on

the Lan. The baud rate is set by poles 8 to 10 in the range 1k2,

9k6, 19k2 and must match the other nodes on the Lan. The

address/baud rate switch may also be used to perform a strategy

cleardown; this is done by setting all the address/baud rate poles

to zero before power up (see Installation Instructions, TG103483

sheet 4 and IQ Configuration Manual Addendum). For this reason

the address should normally be set non-zero.

These loads can be calculated as follows:

Input module

8 digital inputs @ 8 mA per channel

8 analogue inputs @ 20 mA per channel (thermistor and

voltage inputs can be ignored)

Max total for whole I/O module = (8x8)+(20x8) = 224 mA

Output module

8 analogue outputs @ 20 mA per channel

Max total for whole board = 20x8 = 160 mA

8 digital outputs @ 24 mA per channel

Max total for whole I/O module = 24x8 = 192 mA

Integral Node (e.g. TMN) = 250 mA.

(For consumption of other nodes see the respective data sheet).

For example:

IQ251 with 4 input I/O modules, 2 digital output I/O modules, 2

analogue output I/O modules, an integral NDP, and an MNC.

How much current is available from the auxiliary output supply?

Current consumed:

4 input I/O modules (all analogues are current) 4 x 224 =896 mA

2 digital output I/O modules 2 x 192 mA=384 mA

2 analogue output I/O modules (at max). 2 x 160 mA=320 mA

1TMN 250 mA

Total 1850 mA

Current available: 2100 - 1850 =250 mA

Battery Backup: Details about the strategy configuration, time

and date, and logged data are stored in RAM. A plug-in lithium

cell provides power to maintain the data in the event of power

failure, or the controller being switched off.

Auxiliary output supply: There is a 24 Vdc auxiliary output

supply provided on the input power board to power external relay

modules, sensors, etc. It is thermally protected and can provide

a maximum of 500 mA. This will normally be available, but if the

IQ251 has a full complement of I/O modules, and an integral

comms node fitted the amount of auxiliary power available for

other purposes will have to be calculated. The 24 Vdc input

power in the IQ251 has 2100 mA available after deduction of

current required for main board and network. This has to power I/O

modules, integral node, and the 24 Vdc auxiliary output supply.

I/O

node

AUX

variable

(e.g. 250) optional

500 mA (maximum)

2100 mA