ABB ACS 6000 Installation and user guide

Other ABB Controllers manuals

ABB

ABB PSTX30 Parts list manual

ABB

ABB ACS580-01 drives User manual

ABB

ABB ACS880-37 User manual

ABB

ABB RSD Series User manual

ABB

ABB AC500 Series Manual

ABB

ABB PST Manual

ABB

ABB ACS55-01E-01A4-2 User manual

ABB

ABB Relion 670 series REC670 User manual

ABB

ABB ACS 501 Installation and operation manual

ABB

ABB Welcome M2300 User manual

ABB

ABB ControlMaster CM10 User manual

ABB

ABB ControlMaster CM10 User manual

ABB

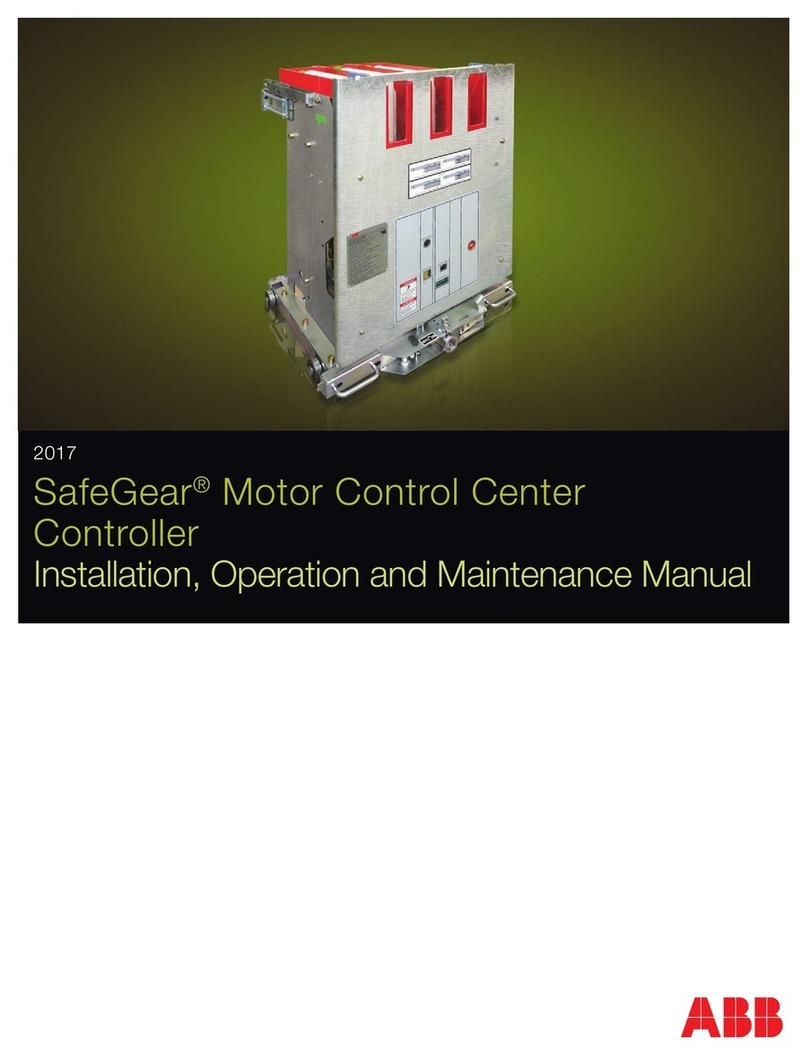

ABB SafeGear User manual

ABB

ABB i-bus 6164 U-500 User manual

ABB

ABB Command Series User manual

ABB

ABB ACS550-01 User manual

ABB

ABB TZIDC-110 User manual

ABB

ABB BALDOR ACB530 User manual

ABB

ABB ACS180 Use and care manual

ABB

ABB COMMANDER 500 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions