D#ZZ-TF223-002EN

Page 2 of 2

4 Installation (continued)

4.5 Wiring

1) Avoid repeatedly bending or stressing lead wires.

Broken lead wires can result from wiring layouts which repeatedly

apply bending stress or stretching force to the lead wires.

2) Be sure to connect the load before power is applied.

If the power is turned ON when an auto switch is not connected to a

load, the switch will be instantly damaged due to excess current.

3) Confirm proper insulation of wiring.

Check that there is no faulty wiring insulation (contact with other

circuits, ground fault, improper insulation between terminals, etc.)

Damage may occur due to excess current flow into a switch.

4) Do not route wiring with power lines or high voltage lines.

Avoid parallel wiring or wiring in the same conduit with these lines.

Control circuits containing auto switches may malfunction due to noise.

5) Do not allow short circuit of loads.

If power is turned ON with a load in a short circuit condition, the switch

will be instantly damaged due to excess current flow.

6) Avoid incorrect wiring

An auto switch with indicator light has polarity. The brown [red] lead

wire is (+), and the blue [black] lead wire is (–).

If connections are reversed, the switch will operate, however, the LED

will not light up. Also note that a current greater than that specified will

damage the LED and it will no longer operate.

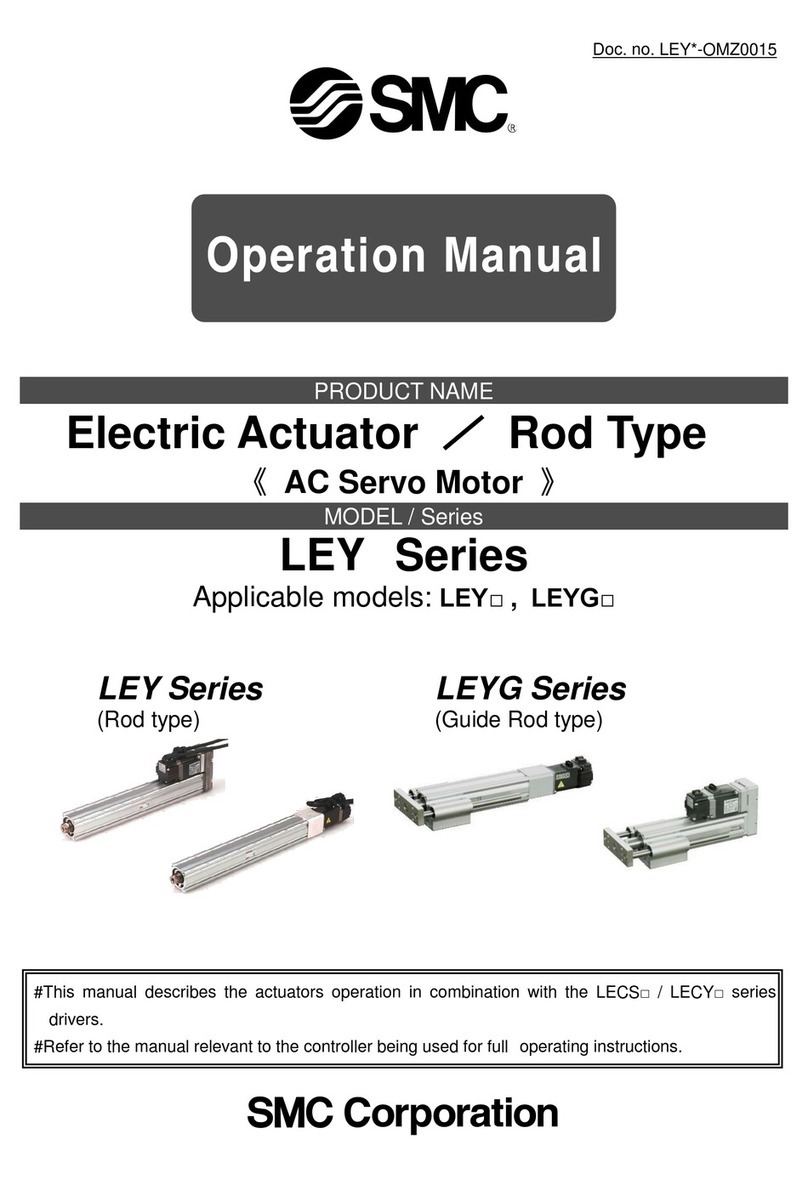

4.5.1 Wiring diagram

4 Installation (continued)

4.6 Environment

Warning

•Do not use in an environment where oil, corrosive gases, chemicals,

salt water or steam are present.

•Do not install in a location subject to vibration or impact in excess of

the product specifications.

•Do not mount in a location exposed to radiant heat that would result in

temperatures in excess of the product specification.

•Do not use in an area where a magnetic field is generated.

Auto switches can malfunction or magnets inside actuators can

become demagnetized.

•Do not use in an environment where the auto switch will be continually

exposed to water.

•Do not use in an environment with temperature cycles.

•Avoid accumulation of iron waste or close contact with magnetic

substances. A large amount of accumulated iron waste such as

machining chips or spatter may cause the auto switch to malfunction.

5 How to Order

Refer to the catalogue or operation manual on the SMC website (URL:

https// www.smcworld.com ) for How to order information.

6 Outline dimensions

Refer to the catalogue or operation manual on the SMC website (URL:

https// www.smcworld.com ) for outline dimensions.

7 Maintenance

7.1 General Maintenance

Caution

•Not following proper maintenance procedures could cause the product

to malfunction and lead to equipment damage.

•If handled improperly, compressed air can be dangerous.

•Maintenance of pneumatic systems should be performed only by

qualified personnel.

•Before performing maintenance, turn off the power supply and be sure

to cut off the supply pressure. Confirm that the air is released to

atmosphere.

•After installation and maintenance, apply operating pressure and

power to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

•If any electrical connections are disturbed during maintenance, ensure

they are reconnected correctly and safety checks are carried out as

required to ensure continued compliance with applicable national

regulations.

•Do not make any modification to the product.

•Do not disassemble the product, unless required by installation or

maintenance instructions.

•Perform the following maintenance periodically in order to prevent

possible danger due to unexpected auto switch malfunction.

1) Securely tighten switch mounting screws. If screws become loose

or the mounting position is dislocated, re-tighten them after readjusting

the mounting position.

2) Confirm that there is no damage to lead wires. To prevent faulty

insulation, replace switches or repair lead wires, etc., if damage is

discovered.

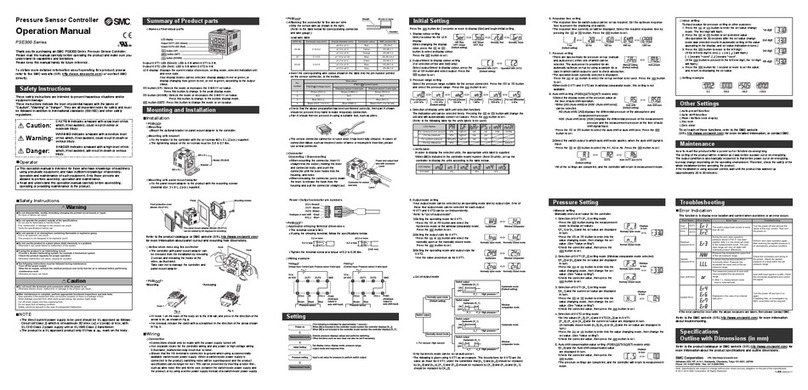

8 Troubleshooting

When detection failure occurs check the switch according to the chart

9 Limitations of Use

9.1 Limited warranty and Disclaimer/Compliance Requirements

Refer to Handling Precautions for SMC Products.

10 Product disposal

This product should not be disposed of as municipal waste. Check your

local regulations and guidelines to dispose of this product correctly, in

order to reduce the impact on human health and the environment.

11 Contacts

Refer to www.smcworld.com or www.smc.eu for your local

distributor/importer.

SMC Corporation, Akihabara UDX15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101 0021

Specifications are subject to change without prior notice from the manufacturer.

© 2021 SMC Corporation All Rights Reserved.

Template DKP50047-F-085M

Stays ON

(sometimes stays ON)

Lamp lights up

Stays OFF

(sometimes stays OFF)

Lamp does not light up

Problem

Output Normal,

Lamp does not light up

Check Wiring (output)

Normal

Normal

Normal Abnormal

Abnormal

Replace the auto switch

Check operating

environment,

Load specification

Abnormal

Abnormal

Check Wiring (output)

Check operating environment,

Load specification and Wire length

Normal

(A) (B) (C) (D) (A) (E) (D)

(A) = Auto switch failure

(B) = Replace the actuator. Detectable magnetic field inadequate (or no magnet).

(C) = Correct the wiring, replace the load or replace the auto switch after correcting the wiring.

(D) = After checking the operating environment, replace the auto switch.

(E) = Replace the auto switch after correcting the wiring.

Resistor LED

Reed

switch

Zener diode

OUT (+)

Brown

OUT (-)

Blue

D-B59W

OUT (-)

Zener

diode

Resistor LED

OUT (+)

OUT (-)

Zener

diode

Reed

switch

Surge

absorber

Surge

absorber

Reed

switch

OUT (-)

OUT (+)