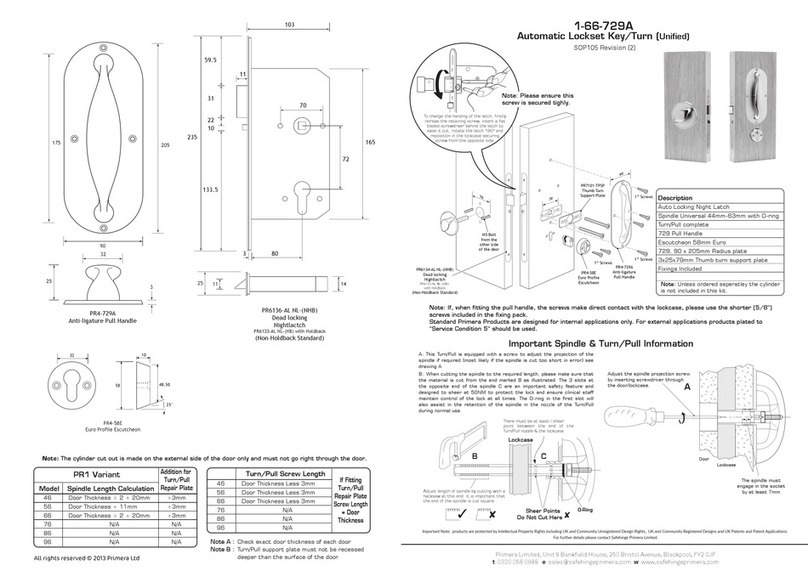

Installation Instructions for Trilock Contemporary

These instructions apply to both Lever and Knob versions

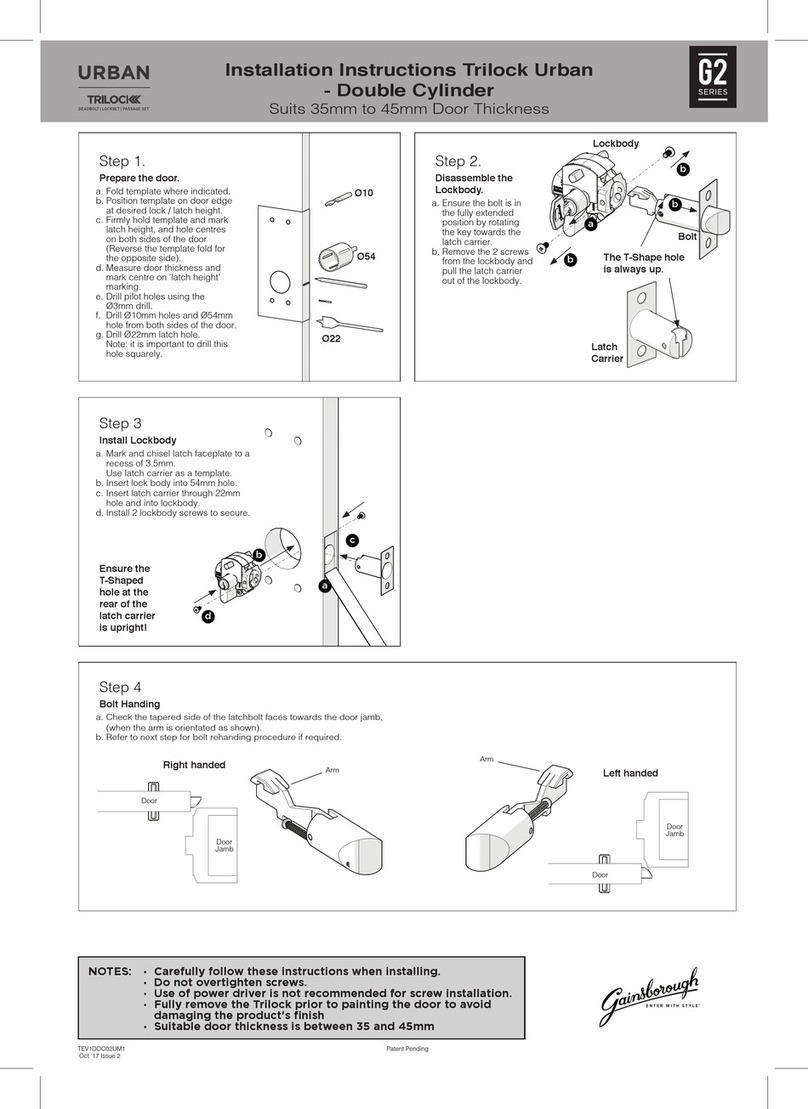

Step 2.

• Fold template where

indicated.

• Position template on

door edge at desired

lock / latch height.

• Firmly hold template

and mark latch height

and 54mm (2 1/8") lock

body hole centre.

• Measure door

thickness and mark

centre on 'latch height'

marking.

• Drill 22mm (7/8") latch

hole. NOTE: it is

important to drill this

hole squarely.

• Drill pilot hole for lock body

[suggested size 3mm (1/8")].

Then enlarge hole to 54mm (2 1/8"),

drilling from both sides of the door.

• Mark and chisel

latch faceplate to a

recess of 2.5mm. Use

latch carrier as a

template.

• Insert lock body into

54mm (2 1/8") hole.

• Insert latch carrier through 22mm

(7/8") hole into lock body assembly and

fix with 2 screws. Ensure T-shaped hole at rear of latch carrier is upright!

Step 4.

Suits 33mm to 45mm door thicknesses

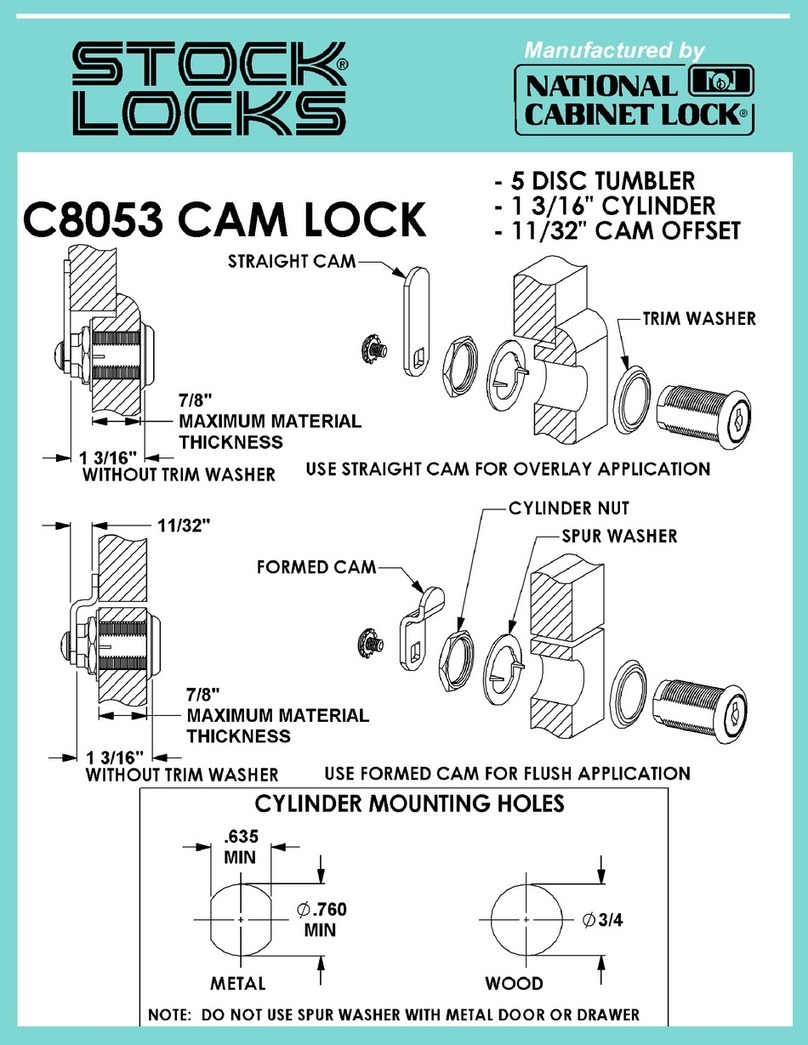

• Remove cut-outs from card-

board template and place over

lock body, making sure template

is square to door edge.

• While holding template firmly in

position, mark remaining 5 holes

as indicated on both sides of the

door (reversing template as

required).

• Drill pilot holes from both sides

of the door [suggested size 3mm

(1/8")] then enlarge, again from

both sides of the door, to sizes

indicated on template.

• In particular, ensure the 32mm

(1 1/4") dia. hole through door

face (located above lock body

hole) is drilled only to this size,

otherwise correct functioning

may be impeded–refer template.

• Install posts to Trilock external

faceplate (this is the faceplate

without the rectangular snib

push-button).

Step 1.

template

NOTE: • carefully follow these instructions when installing.

• do not overtighten screws.

• use of power driver is not recommended.

• screws to be tightened to a recommended 2.5Nm torque.

• fully remove the Trilock prior to painting the door

to avoid harming the product's finish.

template

Step 6.

PAIT 067

Please note:

Ensure the template

position and orientation

is as shown,

incorrect installation

voids warranty.

Step 5.

• Hold Trilock faceplate up to door to check lever

orientation (this will need to be done on both levers).

• To rehand lever, if required, insert flat blade

screwdriver under handing-plate and twist.

• Rotate lever 180˚ toward bottom of faceplate,

as shown, until it clicks into place.

handing information

NOTE: The step is applicable to leverset only.

Step 3.

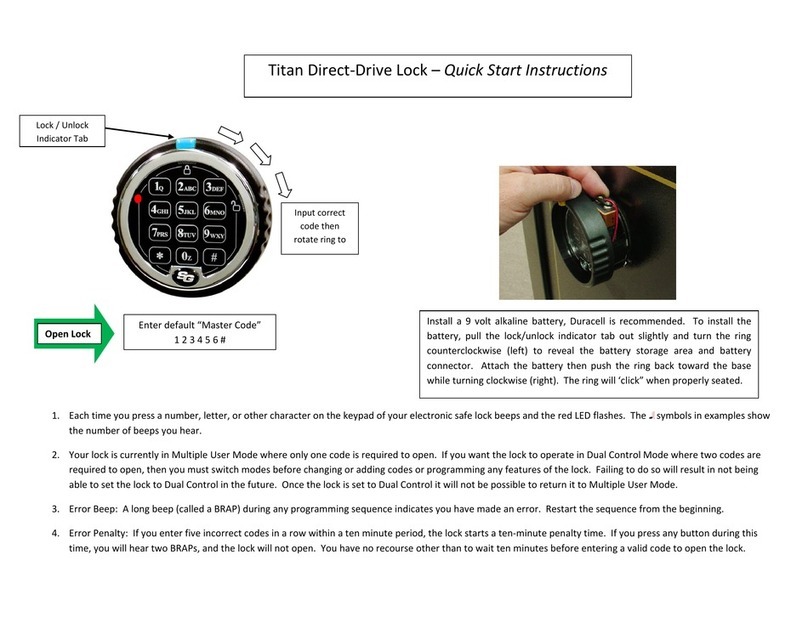

• Insert the latch through the slot in

the carrier until it can go no further.

• Insert the key and turn to retract

the latch bolt.

• Ensure cardboard aligning template

is NOT removed from lock body.

• Install plastic faceplate shim

and faceplate, then screw into

position.

• Check that tapered side of the latch

bolt faces towards the door jamb, it

may be necessary to un-clip the rear

arm of the latch bolt and rotate

180˚, this is achieved by pushing the

bolt and arm together and

un-clipping.

A

A

A

B

B

D

D

CDo not remove

(If aligning template

has been removed

turn square spindle

away from the latch bolt

housing as far as it

can go before inserting

the latch bolt).

square spindle

DONOT REMOVE

C