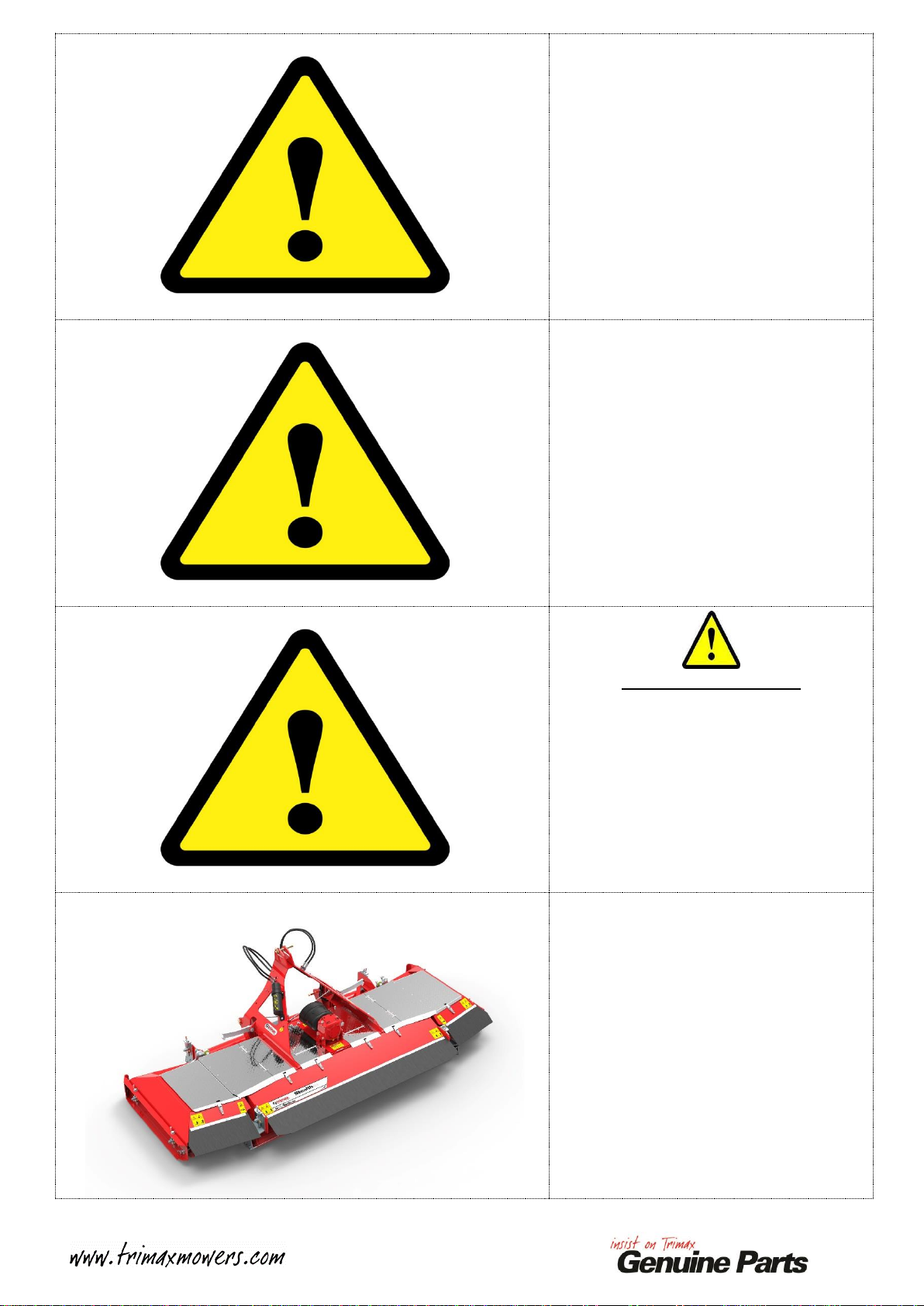

Trimax Genuine Parts Stealth S3 User manual

1

SPARE PARTS

INSTRUCTIONS # 48

Date Created: 20/04/2017

Product: Stealth S3

Title: Gearbox removal and replacement

SAFETY! Before attempting to make any adjustments or carry out maintenance on the mower, review

the hazard identification table (section 3a of your Operators Manual) and take all necessary precautions.

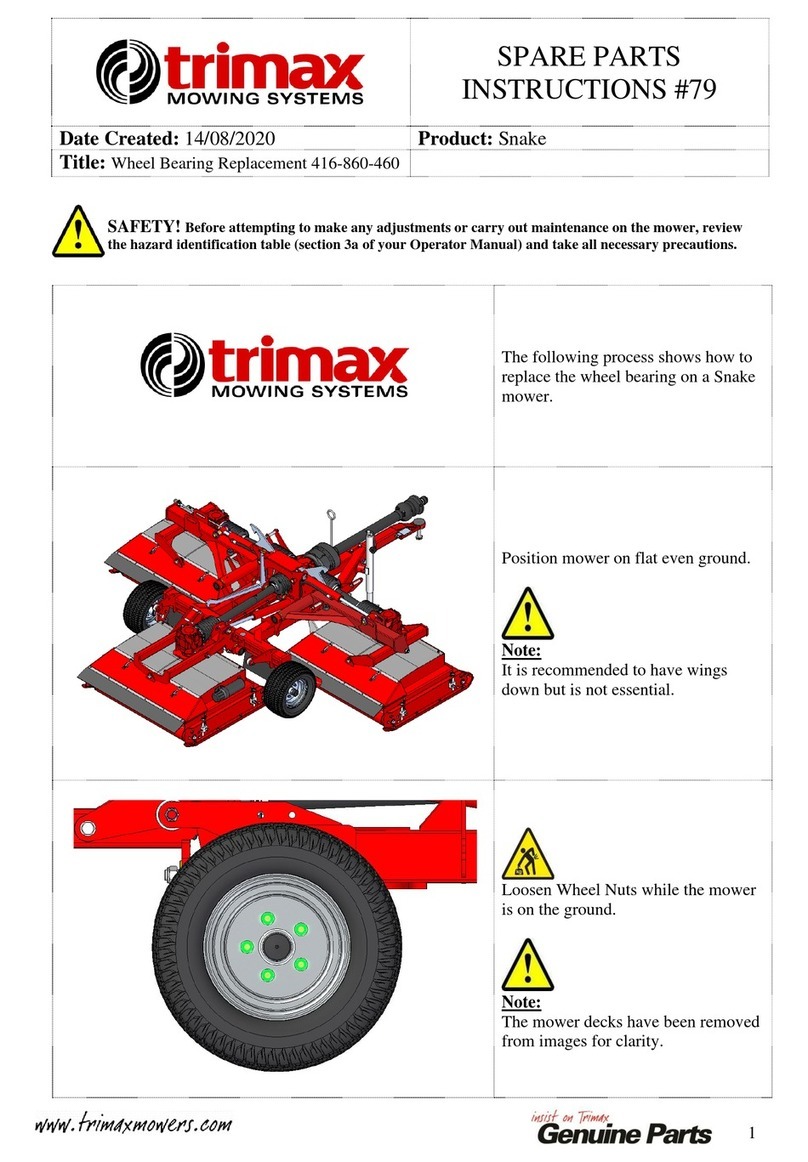

Lower the Stealth S3 onto the ground.

Raise the Transport Locks.

Lower the Wings down onto the ground.

Note:

Ensure the Tractor P.T.O is disengaged

and the Tractor is turned off!

Remove the P.T.O Shaft connecting the

Tractor to the Stealth S3.

Place to one side.

Please see the Operators Manual for

further detail if required!

Remove the four M12 Nyloc Nuts used

to secure the Centre Covers.

Place these to one side for re-fitment

later.

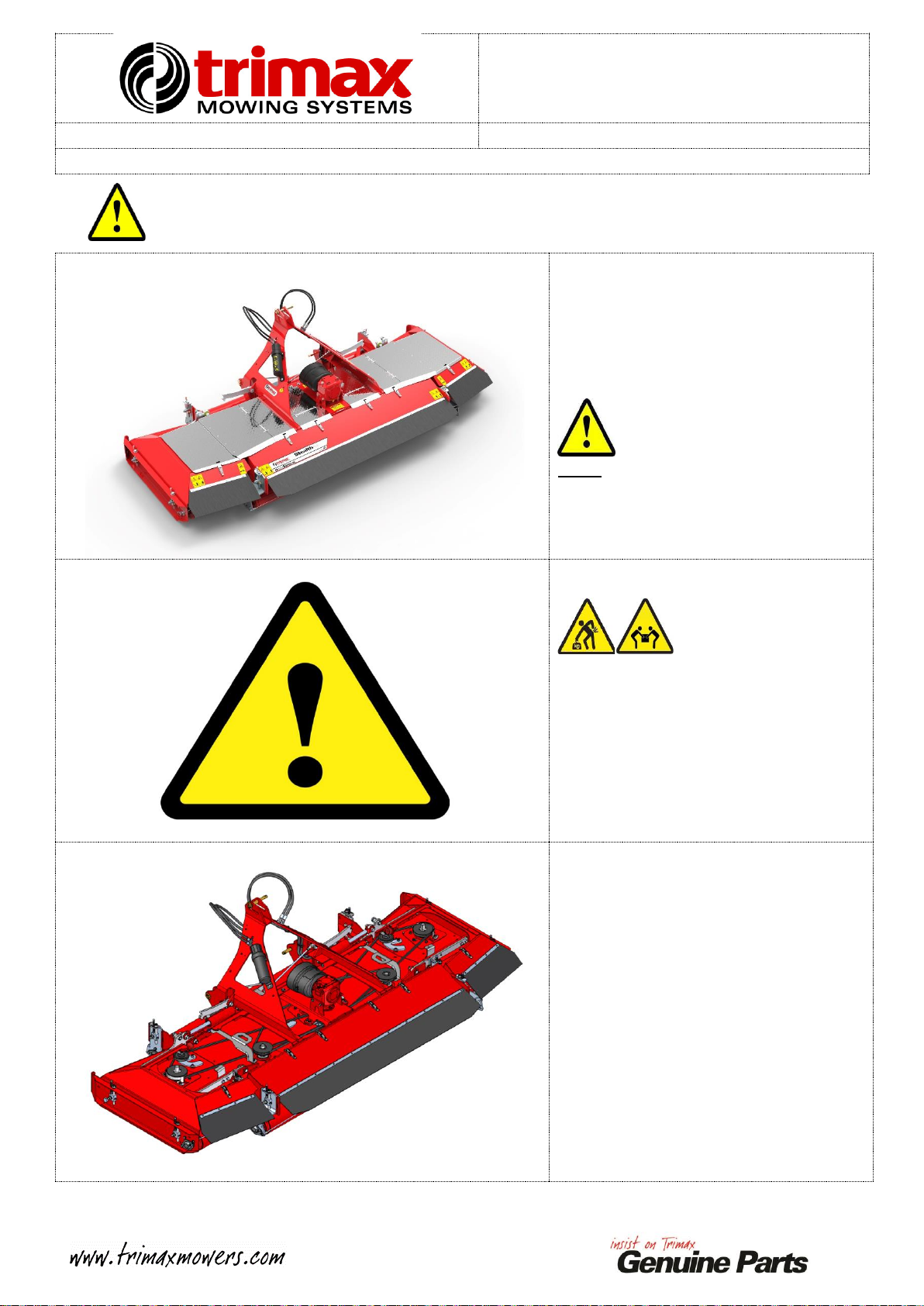

Unlatch ALL Covers.

Remove ALL Covers and place to one

side.

2

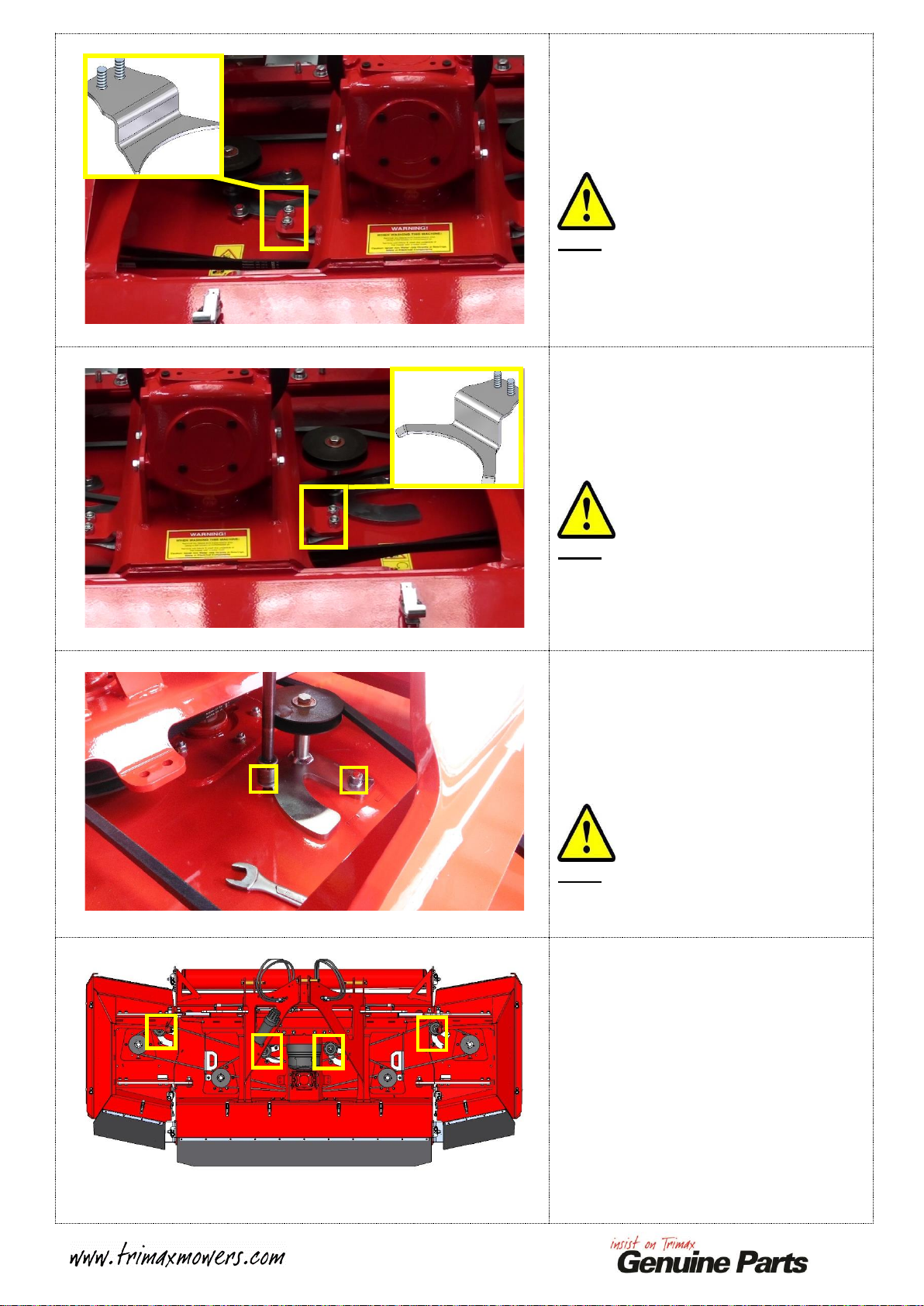

Remove the SHORT Left-Hand

Gearbox Belt Guide.

Place the M12 Nyloc Nuts and Belt

Guide to one side.

Note:

The Left and Right Hand Gearbox Belt

Guides are different from each other!

See inset for detail!

Remove the TALL Right-Hand Gearbox

Belt Guide.

Place the M12 Nyloc Nuts and Belt

Guide to one side.

Note:

The Left and Right Hand Gearbox Belt

Guides are different from each other!

See inset for detail!

Slacken ALL Idler Mounting Nuts.

One Idler shown.

Back the Idlers off to relieve belt

tension.

See below for Idler positions.

Note:

DO NOT REMOVE THE IDLER

MOUNTING NUTS!

The image opposite shown the four Idler

positions.

3

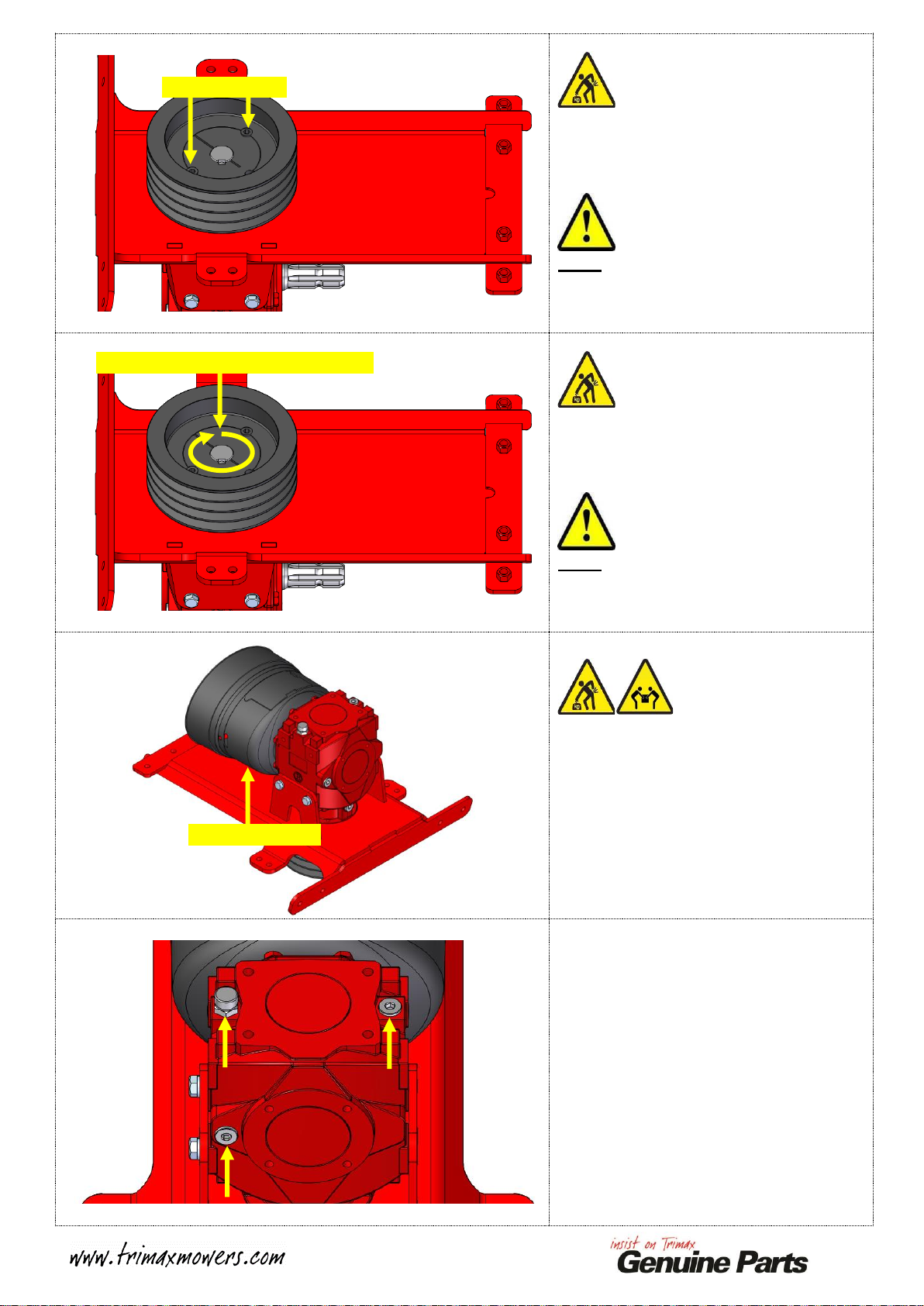

Take note of the Belt positions on the

Gearbox Pulley.

Remove each Belt from around the

Gearbox Pulley.

These DO NOT have be removed

completely, just clear of the Gearbox

Pulley is adequate!

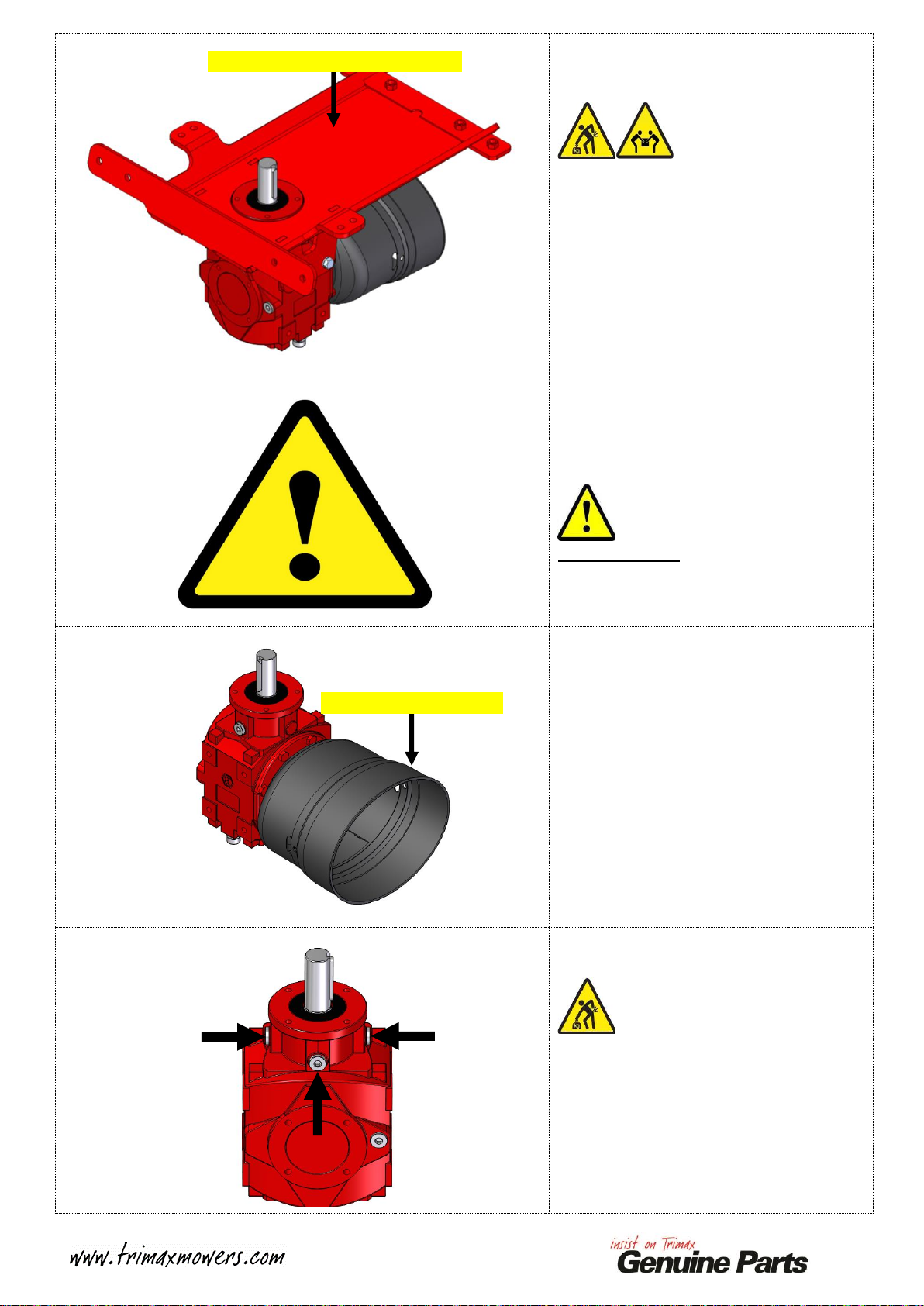

Support the weight of the Gearbox

Assembly.

Remove the Front and Rear Fasteners.

Place these to one side.

Remove the Gearbox Assembly from the

Stealth S3.

Place on a Workbench in the orientation

shown.

Note:

A support will need to placed under the

FRONT of the Gearbox Mount to

support as the assembly will become

unbalanced once the Pulley is removed!

Measure and record the distance shown

from the Pulley to the Gearbox Mount.

IMPORTANT:

This is CRITICAL, this measurement

will be used to set the Pulley back in the

CORRECT location on installation of

the replacement Gearbox.

Place support under here

Measure and

Record this

distance

4

Remove the two highlighted Grub

Screws from the Gearbox Pulley.

Re-insert one of the Grub Screws in the

hole highlighted.

Gradually tighten until the Pulley

separates from the Taper Lock Bush.

Continue to tighten this Grub Screw to

drive the Taper Lock Bush upwards.

Insert a Flat Bladed Screwdriver in the

Slot in the Biloc Bush.

Carefully lever the Bush open slightly.

Slide the Bush up and off the Gearbox

Output Shaft.

Remove the Pulley.

IMPORTANT:

Apply MINIMAL leverage while

removing the Taper Lock Bush,

otherwise cracking can occur through

the thinnest section of the Taper Lock

Bush!

Clean the Bore in the Centre of the

Pulley and the whole Taper Lock Bush

with White Spirits and a Clean Cloth

Re-assemble the Pulley as shown with

MEDIUM STRENGTH THREAD

LOCKING COMPOUND applied to

the Grub Screws.

Leave the Grub Screws loose at this

stage.

Grub screws with MEDIUM STRENGTH THREAD

LOCKING COMPOUND applied

Insert Flat Screw driver here to lever bush open slightly

Leave empty, used for pulley removal ONLY

5

Support the Gearbox Mounting Plate.

Remove the fasteners and place these to

one side.

Remove the Gearbox Mount Plate from

the Gearbox.

Discard the old Gearbox.

THIS GEARBOX HAS BEEN

FILLED APPROXIMALY 1400ml

OF SAE80W90 EP GEAR OIL.

IMPORTANT:

Ensure that the oil is disposed of in

accordance with local regulations

regarding waste oil disposal!

Remove the P.T.O Cone from the

Gearbox.

Place the P.T.O Cone and Fasteners to

one side.

Collect the Replacement Gearbox.

Place on the Workbench as shown.

Check that the three plugs shown are

TIGHT!

Remove the Gearbox Mount Plate

Remove the P.T.O Cone

6

Remove the Key from the OUTPUT

Shaft.

Using White Sprits and a Clean Cloth,

clean the OUTPUT Shaft and the Key.

Apply a small bead of HIGH

STRENGTH RETAINING

COMPOUND to the Keyway.

Refit the Key into the Keyway and

ensure it is fully seated.

Offer up the Gearbox Mount Plate in the

orientation shown.

Secure using the original fasteners.

One side shown.

MEDIUM STRENTH THREAD

LOCKING COMPOUND is used on

the threads of the Bolts.

Fully tighten.

Place the support back under the

Gearbox Mount Plate as before.

Using the measurement recorded earlier,

place two spacers of the required

thickness onto the Gearbox Mounting

Plate.

Note:

These will be used to set the correct

Pulley Spacing.

Align the Keyway with the Key fitted to

the OUTPUT Shaft.

Lower the Pulley onto the OUTPUT

Shaft.

Gently Drive the Pulley DOWN until it

is HARD against the Spacers

Place Spacers here

Drive Pulley onto Spacers

7

Tighten the Grub Screws to secure the

Gearbox Pulley in position.

Torque the Grub Screws to 90Nm.

Note:

An assistant may be required to hold the

assembly steady!

Gently tap around the Bush with a

Hammer.

Then re-torque to 90Nm.

Note:

This will ensure the Bush is seated

correctly in the Pulley.

Flip the Gearbox Assembly over.

Refit the P.T.O Cone using its original

fasteners.

MEDIUM STRENTH THREAD

LOCKING COMPOUND is used on

the threads of the Bolts.

Tighten to secure.

Remove the Breather, Top Plug and Fill

Level Plug from the Gearbox.

Place to one side.

Torque to 90Nm

Tap around Bush, re-torque to 90Nm

P.T.O Cone fitted

8

Pour 1400ml of SAE80W90 EP GEAR

OIL into the Gearbox through one of the

Top Holes. Oil will JUST start to seep

out from the Fill Level Hole.

Refit the Fill Level Plug and fully

tighten.

IMPORTANT:

It is CRITICAL that the correct type

and quantity of oil is used! Gearbox

failure may result from using incorrect

oil!

Refit the Top Plug and Breather as

shown.

Fully tighten.

Note:

Ensure that the Breather is in the

position shown, this prevents seepage

from the breather by placing it opposite

Gearbox rotation.

Offer up the Gearbox Assembly back to

its original position.

Secure using the original fasteners.

MEDIUM STRENTH THREAD

LOCKING COMPOUND is used on

the threads of the Bolts.

Fully tighten.

Apply a coating of Grease or Copper

Anti-seize to the Gearbox Input Shaft to

minimise corrosion.

Fill Level

Breather

Top Plug

9

Refit and tension the Belts.

Ensure these are fitted to their original

locations.

Installation is the reverse of removal.

See your Operators Manual for further

detail on the belt tensioning process.

Refit the SHORT and TALL Gearbox

Belt Retainers.

Ensure these are fitted to their original

locations. See PAGE 2 for detail.

Installation is the reverse of removal.

It is CRITICAL these are fitted to the

correct locations otherwise the Wing

Belts will not re-engage with the

Gearbox Pulley as the wings are

lowered!

VERY IMPORTANT!

•Check ALL Bolts and Nuts are

tight.

•Check ALL Belts are tensioned

correctly.

•Check Belts DO NOT foul on

ANY components.

•Ensure that no Tools or loose

parts are left behind!

Refit the Covers.

Installation is the reverse of removal.

See your Operators Manual for further

detail on the Cover fitment process.

10

Refit the P.T.O Shaft.

Installation is the reverse of removal.

See your operators Manual for further

detail on the Cover fitment process.

This process is now complete.

Other manuals for Genuine Parts Stealth S3

1

Table of contents

Other Trimax Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions