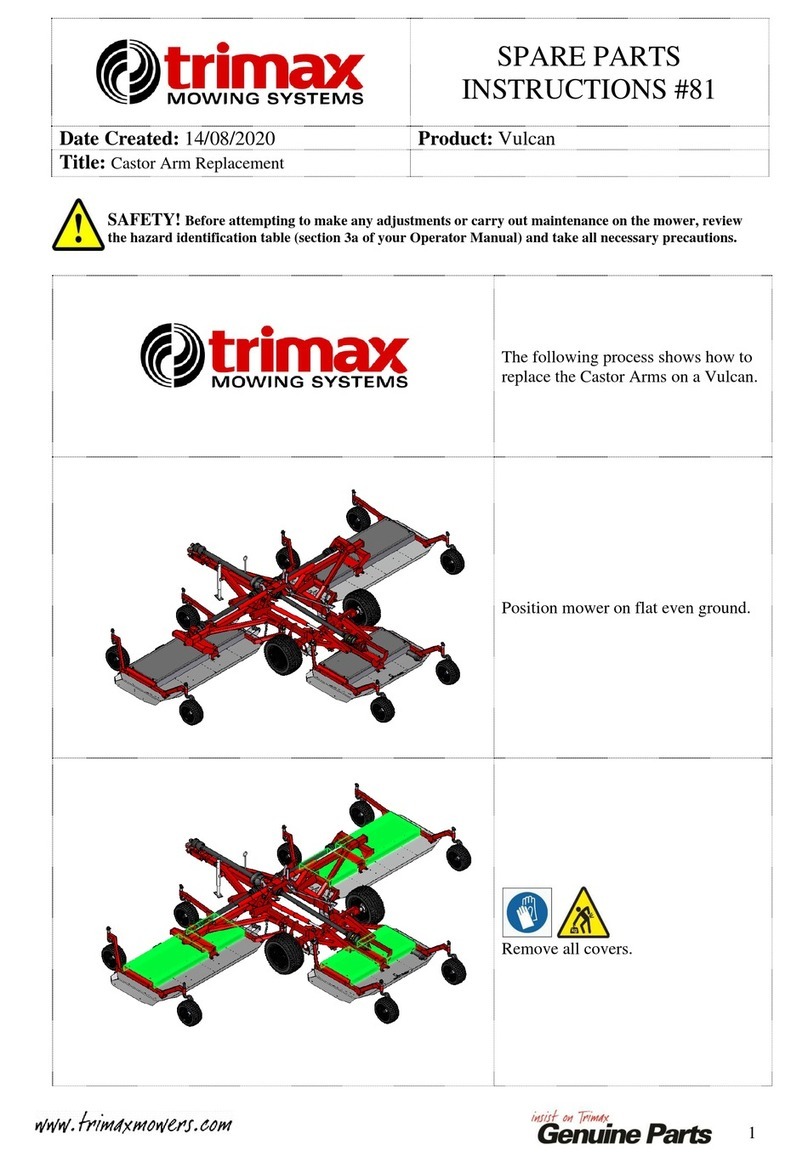

Trimax Snake User manual

Other Trimax Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Woods

Woods D80-2 Operator's manual

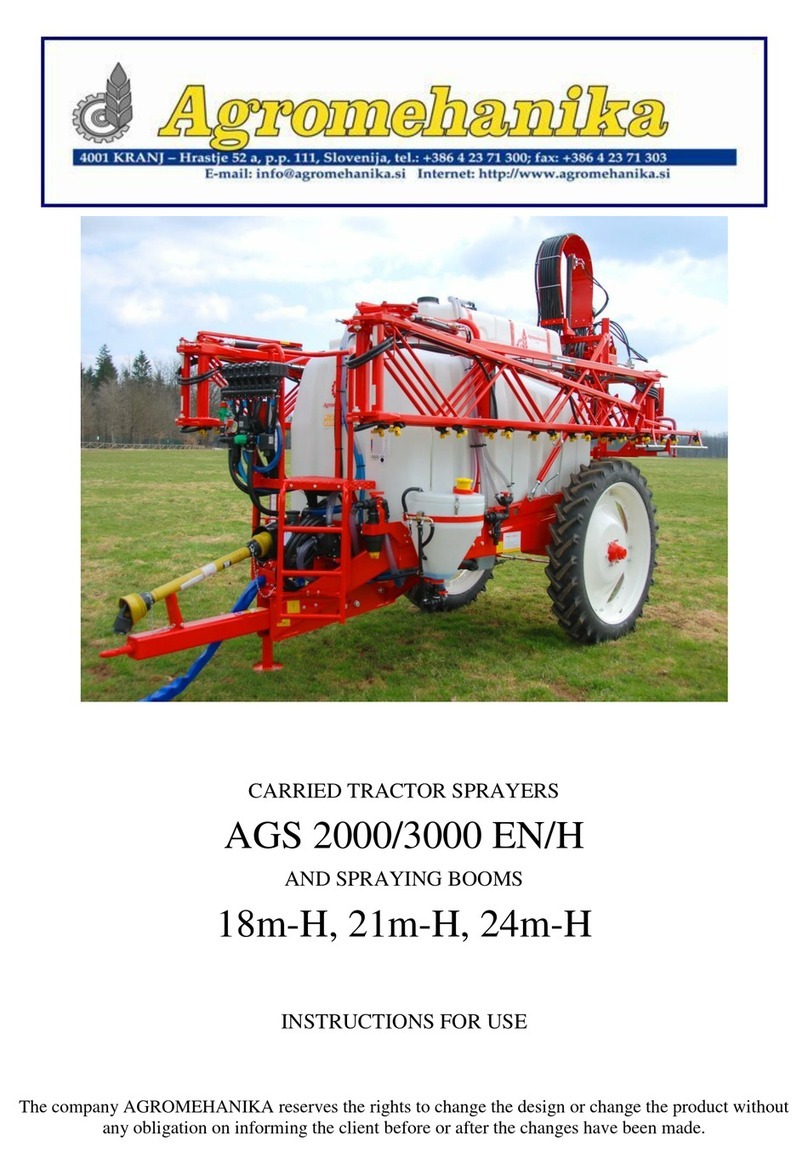

Agromehanika

Agromehanika AGS 2000 Series Instructions for use

Molon

Molon MINI 120 Use and maintenance manual

Worldwide Construction And Forestry Division

Worldwide Construction And Forestry Division 410J Technical manual

MANN LAKE

MANN LAKE Langstroth Assembling

paladin

paladin FFC LAF5647 Operator and parts manual