Trimec 310 Series User manual

IMPORTANT NOTE: Ensure any rebate strips or door stops are fitted before proceeding.

For double-leaf doors, the inactive leaf must be securely fixed in the closed position and a rebate strip fitted to prevent

door over-travel.

Strike is suitable for 15mm latches, based on a 3mm door gap.

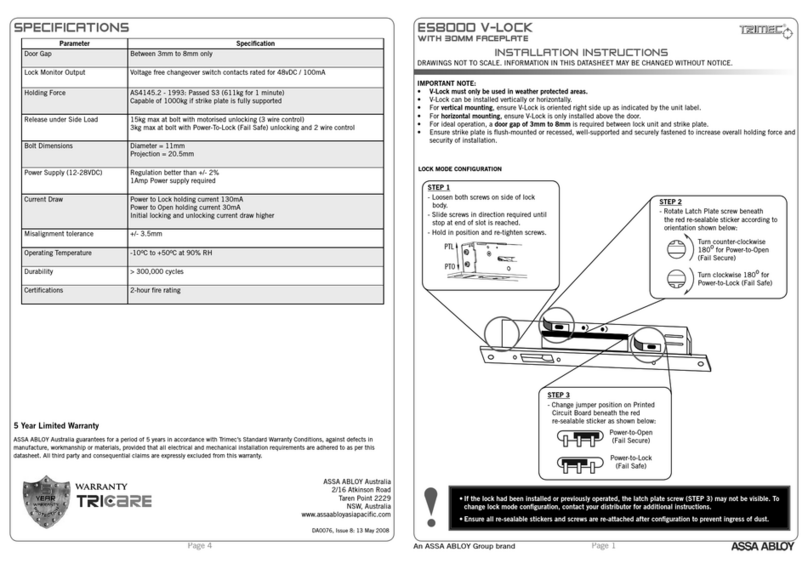

INSTALLATION INSTRUCTIONS

310/3100/320/3200 SERIES ELECTRIC STRIKE

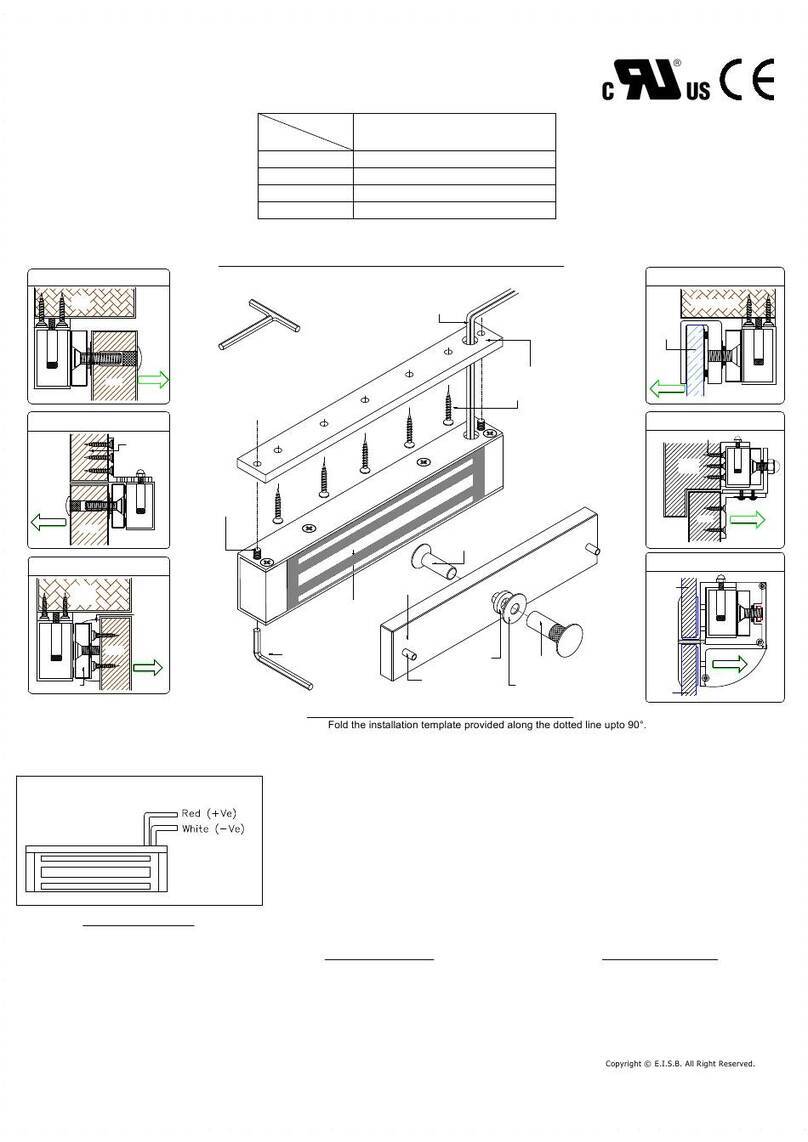

Mark positions X and Y of door latchbolt on door jamb (see Fig. 1).

Remove the backing of supplied stick-on template, and apply to door jamb. Ensure the lines “Front face of Lock Latch” on both template

and door jamb are aligned (see Note 1).

Scribe the door jamb according to template outline (see Fig. 2).

Prepare door jamb as per appropriate strike face plate, as shown in Fig. 3. Install mounting tabs where applicable. (see Note 2).

Ensure all wiring is correctly connected and not rubbing on sharp edges or interfering with any strike mechanism.

Install the strike temporarily in position and check there is no interference between the door, strike and lock face plates, and the extension

lip of strike during door closing. Ensure the deadlatching auxiliary bolt does not enter the strike keeper area when door is closed.

Check there is no pressure on the strike keeper when door is closed.

When all above checks are complete, secure strike with appropriate screws and re-check operation.

NOTE 1 : A 1mm clearance has been designed into the template to prevent the door exerting pressure on the strike when closed.

NOTE 2 : Allow sufficient space between the electric strike unit and jamb cut-out for the wires. Bunching of wires may cause the unit to

malfunction.

1.

2.

3.

4.

5.

6.

7.

8.

Fig. 2 - 310 / 3100 / 320 / 3200 Series Electric Strike Template Outline

Fig. 1 - Door Frame Preparation

Align with

“Front Face

of Lock

Latch” line

on Template

y

x

y

X

X

y

or

Bevelled Face

*These dimensions have a tolerance of +0.8mm/-0

Template outline may vary depending on strike face plate used.

P

age

1

DRAWINGS NOT TO SCALE. INFORMATION IN THIS DATASHEET MAY BE CHANGED WITHOUT NOTICE.

P

age

4

310/3100/320/3200 SERIES

The following are available as optional extras:

SPARE PARTS

* When the use of extension lips is required, the standard model numbers of electric strikes must be suffixed with “X” to denote

pre-drilled extension holes (e.g. 3100X).

25mm extension lip (A),

50mm extension lip (B)

75mm extension lip (C)

available as optional extras.

B

50mm

A

25mm 75mm

C

xx

yy

Door Edge

or

Mortice Lock Tubular/Cylindrical

Latch

Part Number Qty Per Pack Description

220200-501 1 Strike Status Microswitch Assembly

220200-502 1 Door Latch Microswitch Assembly

220200-504 1 set Screw Kit - Installation

220200-508 5 x (2 short, 1 long) Locking Pins

220200-509 5 Spring - For Striker

220200-511 5 Spring - Locking Pin

220200-520 5 Spring - Microswitch Retainer

220200-513 1 12 V Solenoid Coil

220200-514 1 24 V Solenoid Coil

220200-515 1 48 V Solenoid Coil

ACCESSORIES

Part Number Qty Per Pack Description

220200-519 1 Mounting Kit

5 Year Limited Warranty

ASSA ABLOY Australia guarantees for a period of 5 years in accordance with Trimec’s Standard Warranty Conditions, against defects in

manufacture, workmanship or materials, provided that all electrical and mechanical installation requirements are adhered to as per this

datasheet. All third party and consequential claims are expressly excluded from this warranty.

warranty

An ASSA ABLOY Group brand

DA0014, Issue 8: 16th Feb 2007

ASSA ABLOY Australia

2/16 Atkinson Road

Taren Point 2229

NSW, Australia

www.assaabloyasiapacific.com

SPARE PARTS & ACCESSORIES

Front Face of Lock Latch

NOT TO SCALE

310/3100 Series

Limits of Extension Lip (ANSI)

61mm

*36.5mm

*47.5mm

Keeper Width

38mm

*201.5mm

310/3100 Series *86mm

320/3200 Series Limits of Extension Lip (Wide) 100mm

320/3200 Series *123mm

185.5mm

EXTENSION LIPS* & STRIKE FACE PLATES

For a wide range of extension lips and strike face plates to suit a particular application, please contact your nearest distributor.

To change the electric strike’s mode of lock operation, remove the back cover and the 2 screws securing the solenoid.

Remove solenoid from strike housing, and invert the strike. This will release three locking pins from the strike and keeper chambers.

CAUTION! When removing solenoid, please be mindful to keep the plunger in the solenoid as it is not secured, and may be easily mis-

placed.

Re-insert the pins as shown in the diagrams for desired mode of lock operation (Power to Open: see Fig. 4; Power to Lock: see Fig. 5).

Place solenoid back in strike housing, and secure with solenoid screws. Press strike back cover into position.

1.

2.

3.

4.

P

age

2

P

age

3

Solenoid Leads Colour

Red

Blue

Black

Supply Voltage

12 VDC

24 VDC

48 VDC

Current Draw

175 mA

88 mA

45 mA

CAUTION! Incorrect supply voltage may cause damage not covered by warranty. Please check supply voltage with a suitable meter

to ensure it is within +/- 15% of the nominal voltage shown above with the strike powered.

This product has been designed for use in weather protected areas only. DO NOT OIL OR LUBRICATE.

3100 / 3200 Series Microswitch Monitoring

The 3100 / 3200 Series electric strike is fitted with a UL approved changeover microswitch (max. rating: 125 VAC, 3 A / 60 VDC, 200 mA)

to monitor the latch and strike status. The wiring diagram for the monitoring schematic is shown in Fig. 6 and on the back of the strike.

N.C. (Normally Closed)

Common

N.O. (Normally Open)

White

Orange

Grey

Strike

Common

N.O. (Normally Open)

Yellow

Violet

Brown

Latch

N.C. (Normally Closed)

Certification

AS4145.2 compliant

BS5872 approved

CE compliant

up to 4-hours fire rating, depending on type of doorset

(in accordance with AS1905.1 - 1997, Part 1: Fire-resistant Doorsets)

Wiring methods and materials shall be in accordance with the National Electric Code, ANSI/NFPA 70 - 1996

Unit must be powered by a UL listed limited energy power source

Use only those mounting screws and hardware supplied with the product for installation. Do not use substitute installation fasteners or

hardware

UL listed for burglary resistance category 1034

Standard UL 1034 Tested and Listed for:

1,500 lbs. (680 kg) static strength rating

70 foot-lbs. dynamic strength rating

250,000 cycles endurance rating

At the request of ASSA ABLOY Australia, this model was tested to the following VOLUNTARY ratings:

1,000,000 cycles of operation

•

•

•

•

•

•

•

•

•

•

•

•

4

Hour

UL Listing

Fig. 4 - Power To Open (Fail-Safe) Configuration

Fig. 5 - Power To Lock (Fail-Secure) Configuration

Solenoid

Plunger

Solenoid Leads

Strike Body

Locking Pins

(Long - Short - Short)

Pin Chamber

Locking Pins

(Short - Short - Long)

Solenoid

Plunger

Solenoid Leads

Strike Body

Pin Chamber

24mm

3100 series strike shown

Mounting tabs

CHANGING MODE OF LOCK OPERATION

ELECTRICAL SPECIFICATIONS

Fig. 3 - Door Jamb Installation

Fig. 6 - Monitoring Schematic

Fig. 6 - Monitoring Schematic

This manual suits for next models

13

Other Trimec Lock manuals

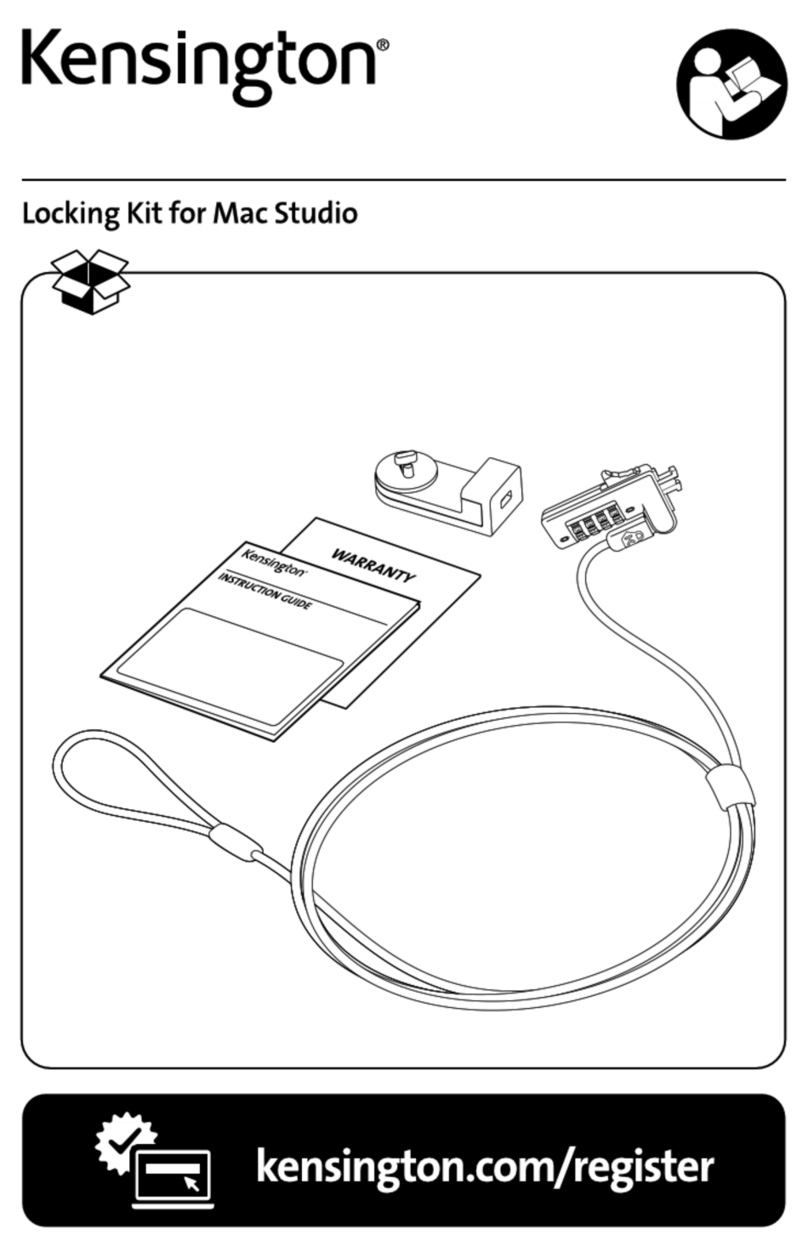

Popular Lock manuals by other brands

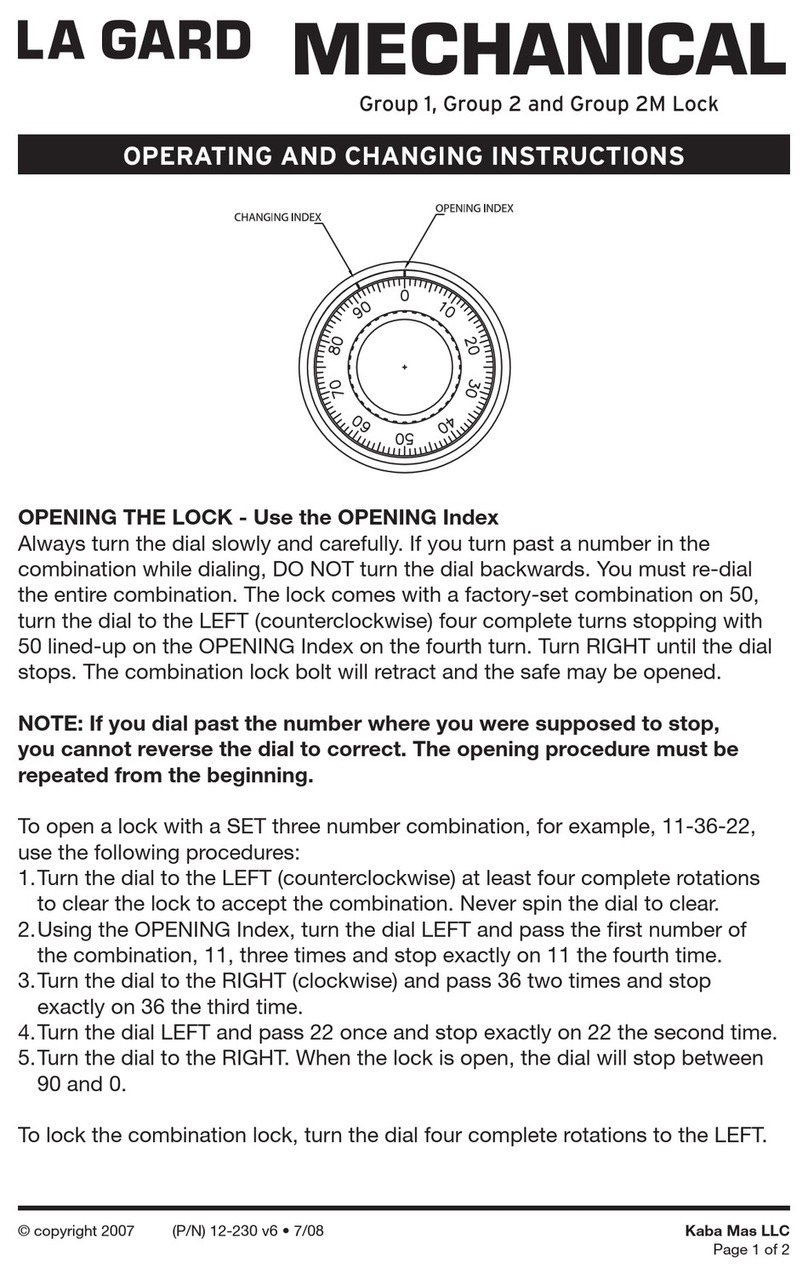

Kaba

Kaba La Gard MECHANICAL OPERATING AND CHANGING INSTRUCTIONS

Lock4Safe

Lock4Safe Pulse PRO Technical manual

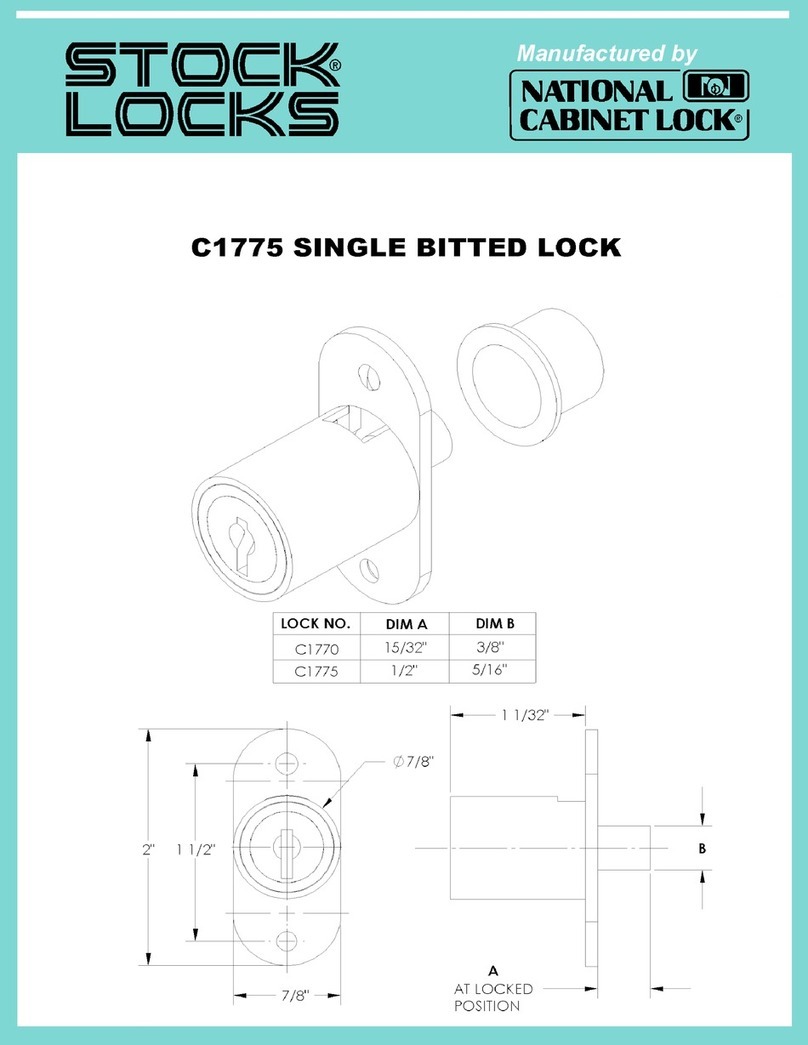

COMPX

COMPX Stock Locks C1775 Dimensional drawing

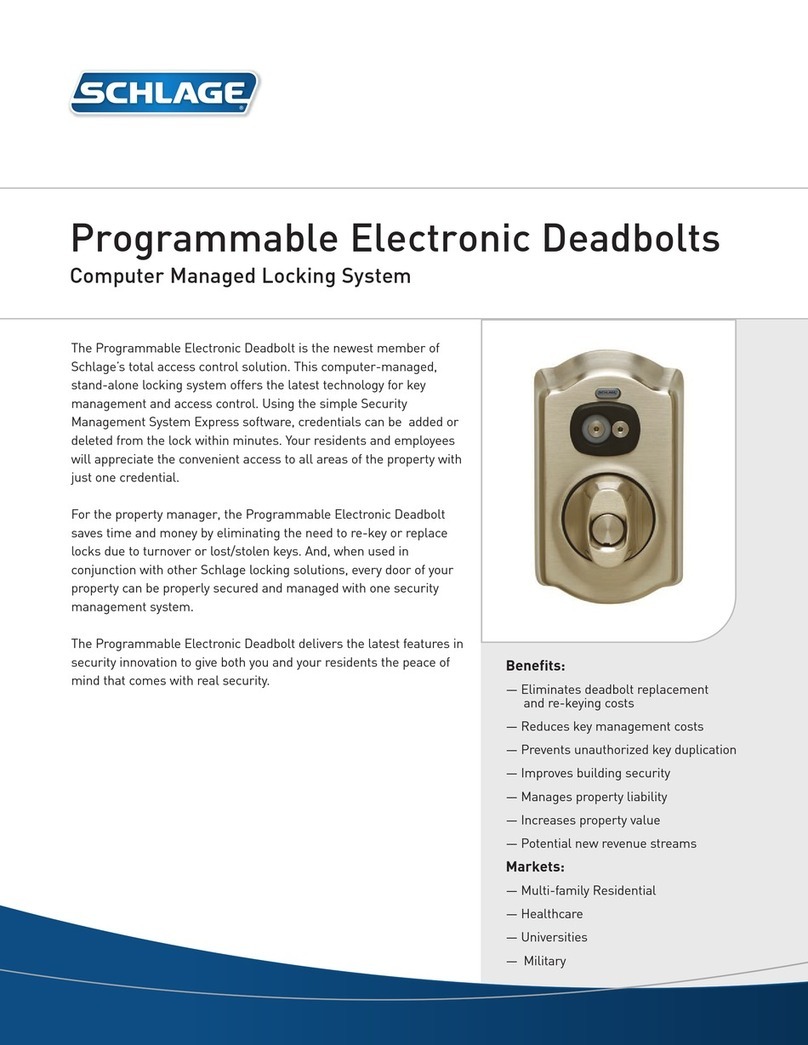

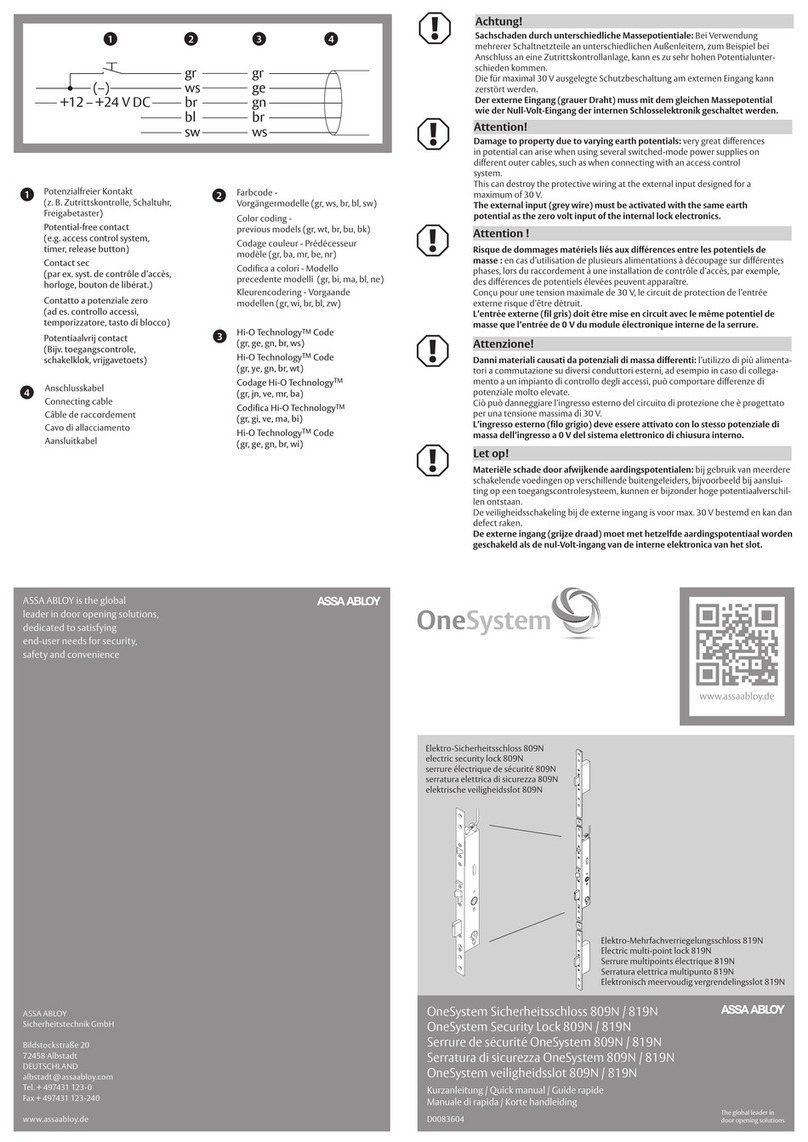

Assa Abloy

Assa Abloy OneSystem 819N Quick manual

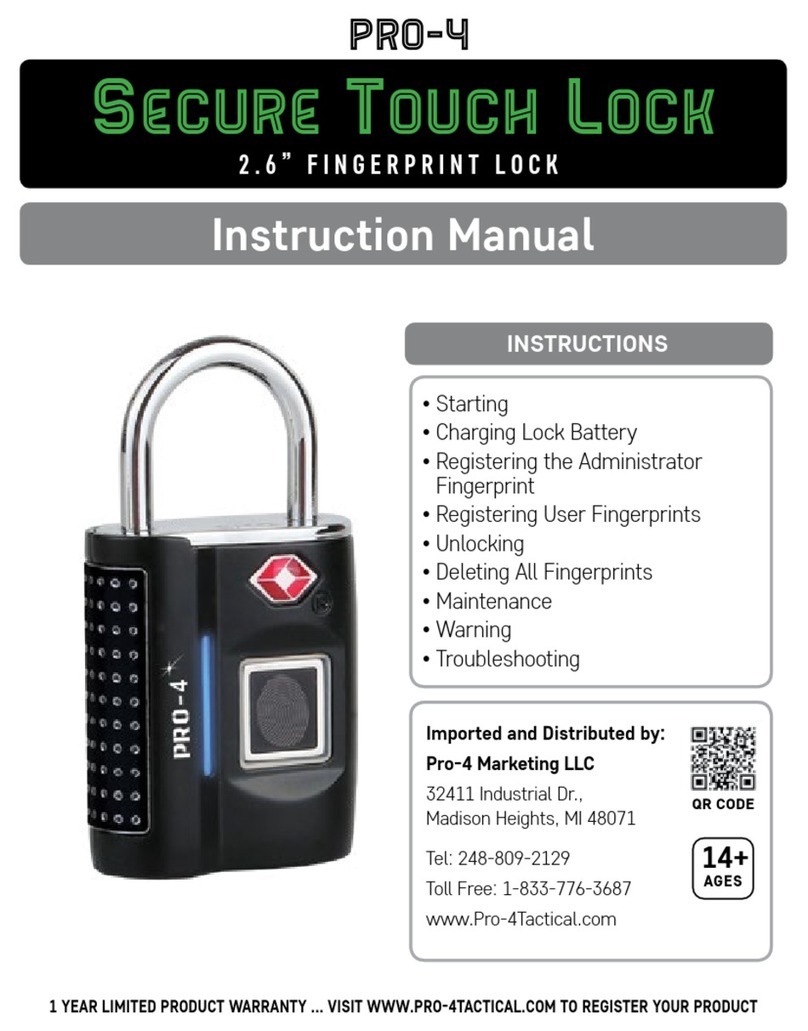

Pro-4 Tactical

Pro-4 Tactical Secure Touch Lock instruction manual

Ebelco

Ebelco 300-S Installation instruction guide