Date: 2019.9.24 Doc No: PS-M-0691 Ver. A B Page - 3 - of 24

1. DISCLAIMER OF LIABILITY

The installation, handling and use of Trina Solar DUOMAX crystalline series modules are beyond company

control. Accordingly, Trina Solar does not assume responsibility for loss, damage, injury or expense resulting

from improper installation, handling, use or maintenance.

Trina Solar assumes no responsibility for any infringement of patents or other rights of third parties that may

result from use of the module. No license is granted by implication or under any patent or patent rights.

Specifications included in this manual are subject to change without prior notice.

2. SAFETY PRECAUTIONS

1. When designing the PV system, please always take into consideration the variation of the voltage under

different temperatures (please check the respective temperature coefficient specifications of the modules,

the Voc of the modules will rise when the temperature drops);

2. Trina Solar requires that every DUOMAX series PV module string should be fused prior to be connected

with other strings. For the maximum fuse rate, please refer to the detailed SPEC in the last page.

3. Solar photovoltaic (PV) modules generate electricity when exposed to light. An array of manysuch modules

can cause lethal shocks and/or burn hazards. Only authorized and trained personnel should have access to

the modules.

4. Use properly insulated tools and appropriate protective equipment to reduce risk of electric shock.

5. Do not stand or step on the module.

6. Do not damage or scratch the front or backside surfaces of the module.

7. Never use a module with broken glass or top substrate. Broken modules should not be repaired and contact

with any module surface can lead to electrical shock.

8. Do not disassemble the modules or remove any part of the module.

9. Protect plug contacts against soiling and do not make any plug connections using soiled plug contacts.

10. Do not install or handle modules when they are wet or during periods of high wind.

11. Do not connect cable from the positive terminal to the positive terminal of one single PV module.

12. Make sure connectors have no gap between insulators. A gap can cause fire hazard and/or danger of an

electrical shock.

13. Make sure that the polarity of each module or a string is not reversed relative to the other the modules or

strings

14. Artificially concentrated sunlight should not be used on the PV module.

15. In markets conforming to IEC standard, maximum system voltage must not exceed 1500V DC. In markets

conforming to UL standard, maximum system voltage must not exceed 1000V(frameless)/1500V(full

frame) . For roof use, the maximum system voltage must not exceed 600V according to National Electrical

Code.

16. Under normal conditions, a photovoltaic module is likely to experience conditions that produce more current

and/or voltage than reported at standard test conditions. The requirements of the National Electrical Code

(NEC) in Article 690 shall be followed to address these increased outputs. In installations not under the

requirements of the NEC, the values of ISC and VOC marked on this module should be multiplied by a factor

of 1.25 when determining component voltage ratings, conductor ampacities, over-current device ratings,

and size of controls connected to the PV output.

17. Our module application class is class A, modules rated for use in this application class may be used in

systems operating at greater than 50V DC or 320W, where general contact access is anticipated..

18. Installation shall be in accordance with CSA C22.1, Safety Standard for Electrical Installations, Canadian

Electrical Code, Part 1.

19. A module with exposed conductive parts is considered to be in compliance with UL 1703 only when it is

electrically grounded in accordance with the instructions presented below and the requirements of the

National Electrical Code.

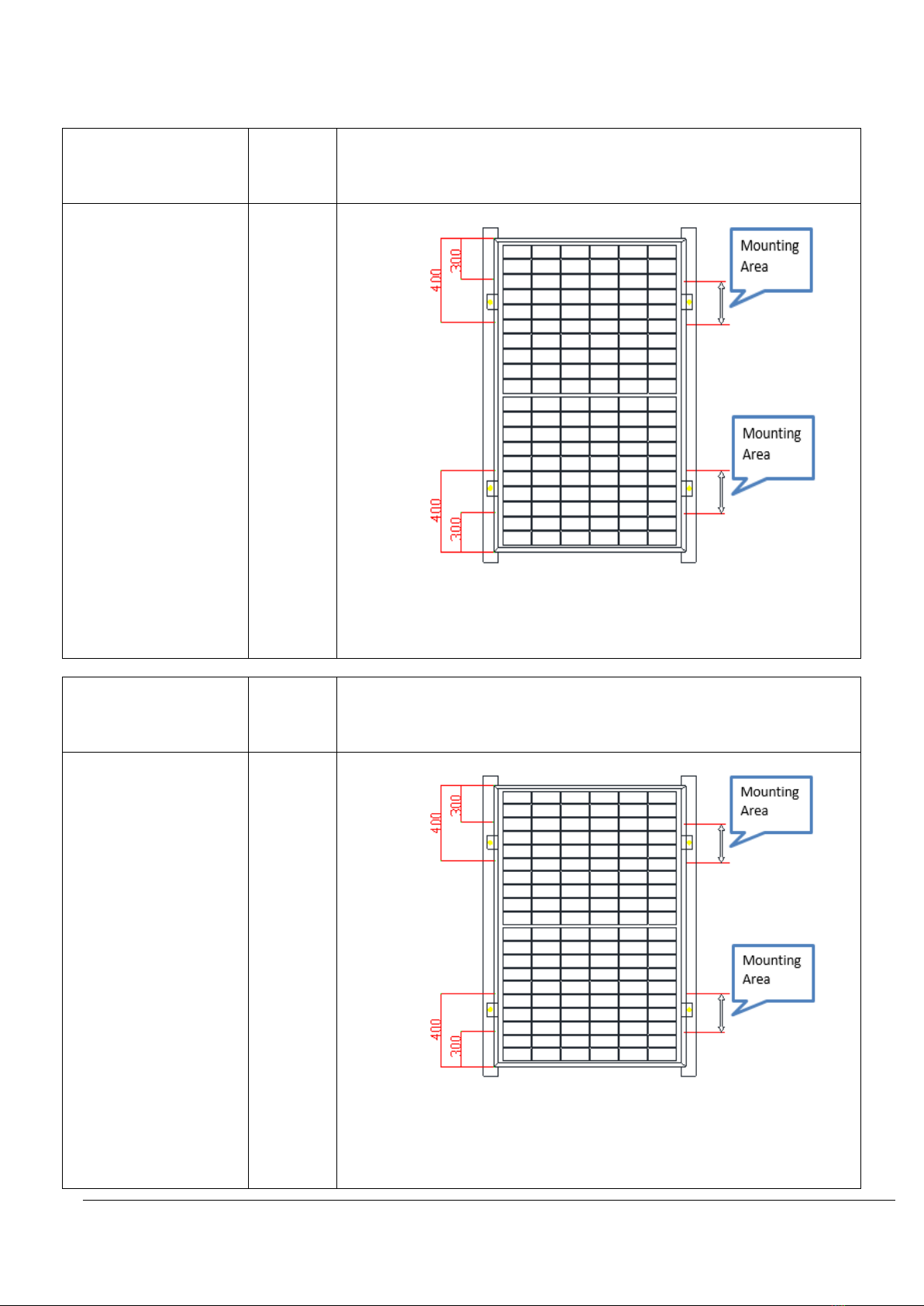

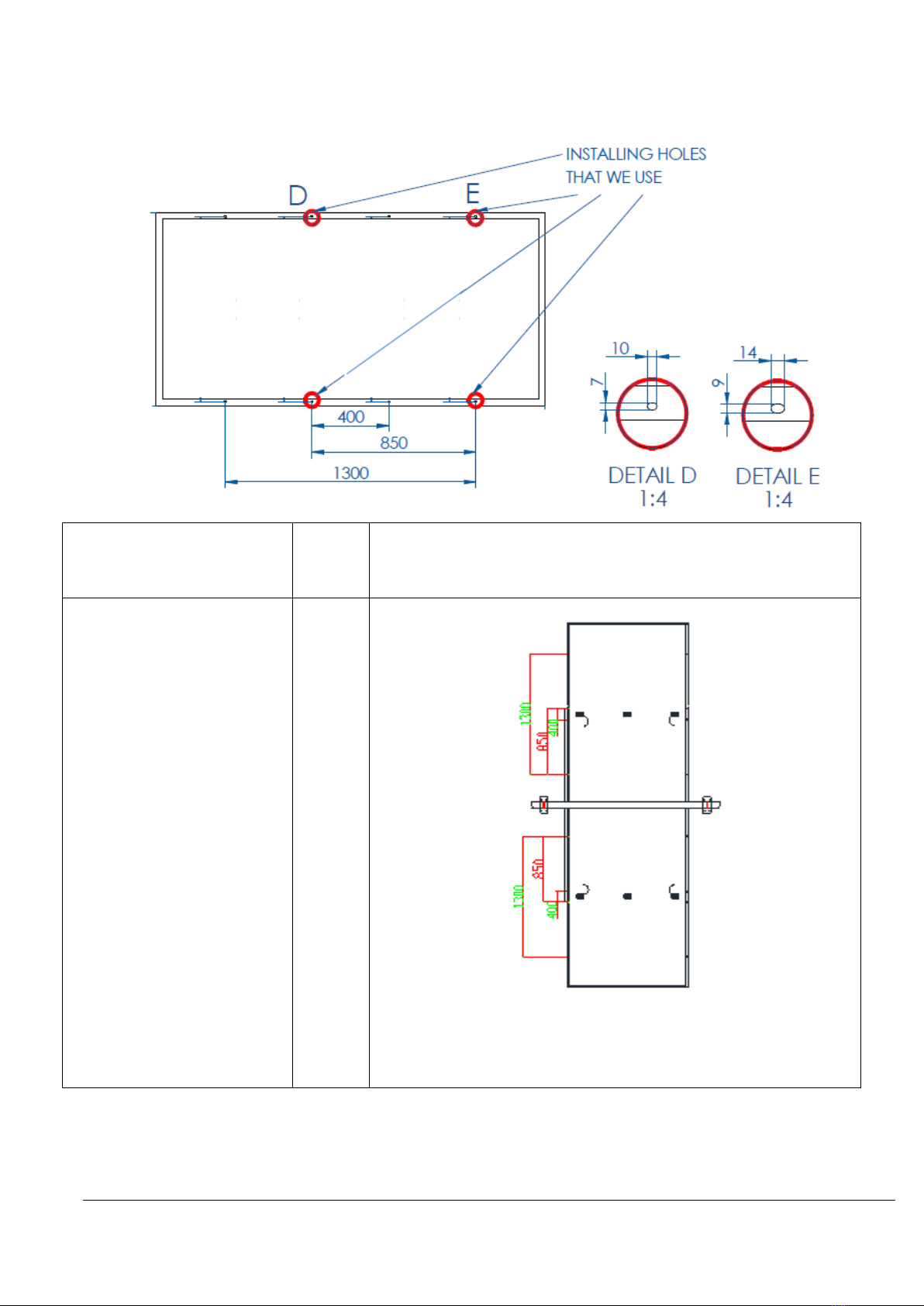

20. The DUOMAX modules have achieved fire rating Type 13 according UL1703 updated on 20th May 2014.

The fire rating of this module is valid only when mounted as specified in the mechanical mounting

instructions in this document.

21. The actual system fire rating should always be evaluated along with the roof cover and mounting.

22. Any module without a frame (laminate) shall not be considered to comply with the requirements of UL 1703

unless the module is mounted with hardware that has been tested and evaluated with the module under this

standard or by a field Inspection certifying that the installed module complies with the requirements of UL

1703.

3. UNPACKING AND STORAGE