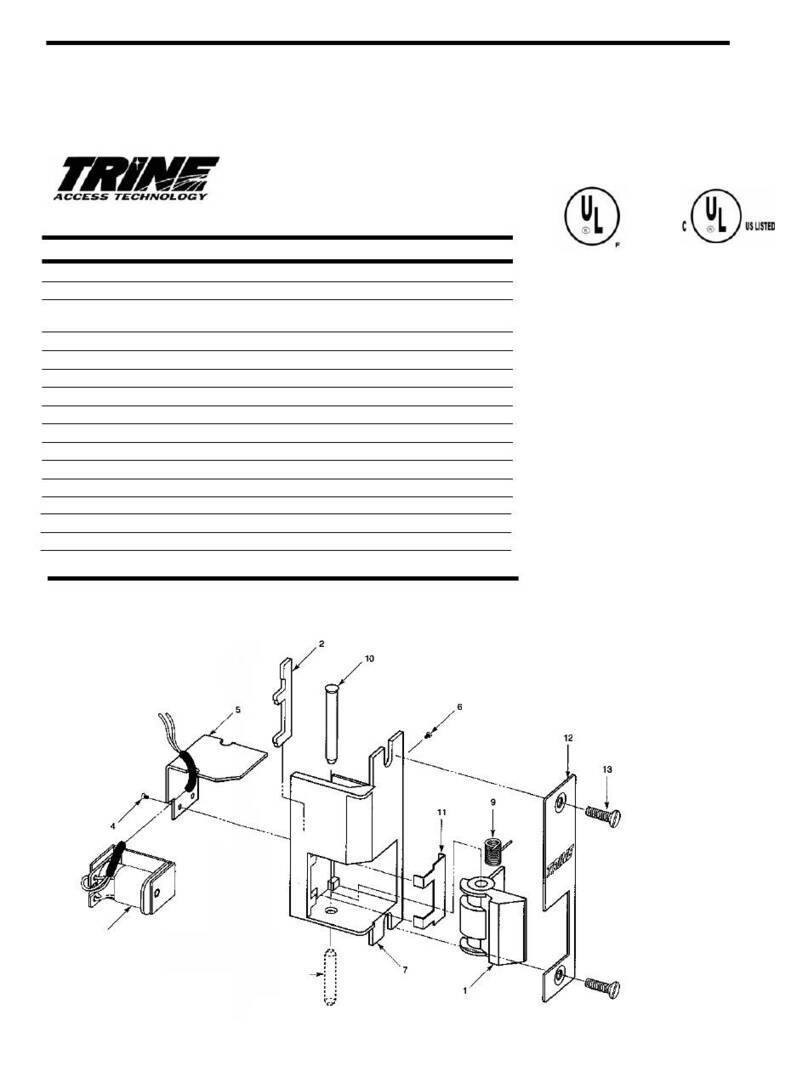

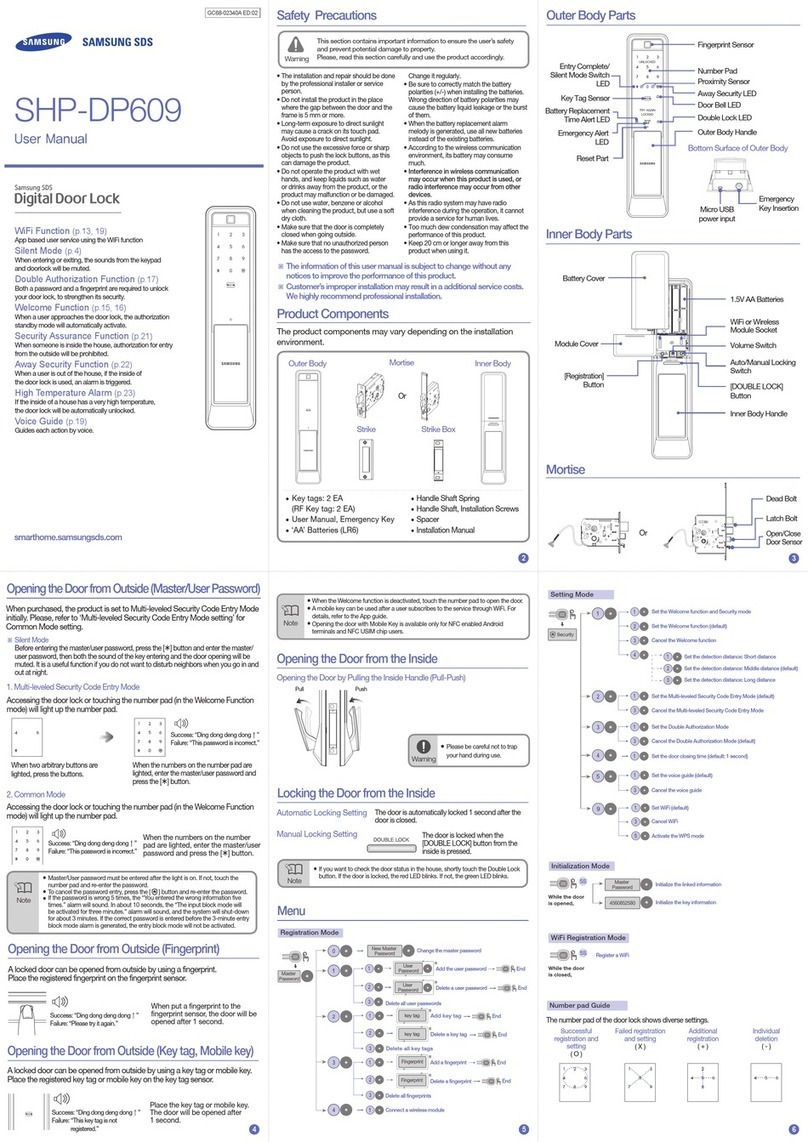

Trine 3000 Series User manual

Model Number:

3478 - Fail Secure

3478RS - Fail Safe

Model Number:

3234W - Fail Secure

3234WRS - Fail Safe

Model Number:

3234 - Fail Secure

3234RS - Fail Safe

1440 Ferris Place · Bronx · New York· 10461-3699

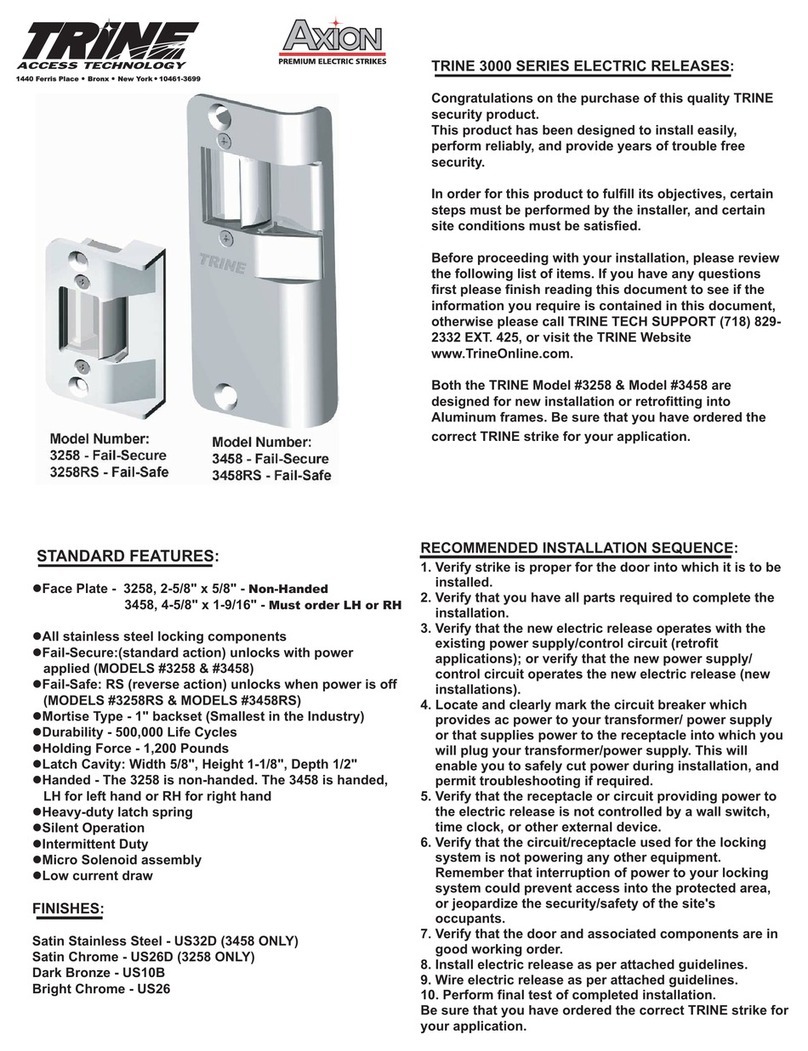

TRINE 3000 SERIES ELECTRIC RELEASES

Congratulations on the purchase of this quality TRINE

security product.

This product has been designed to install easily, perform

reliably, and provide years of trouble free security.

In order for this product to fulfill its objectives, certain

steps must be performed by the installer, and certain site

conditions must be satisfied.

Before proceeding with your installation, please review

the following list of items. If you have any questions first

please finish reading this document to see if the

information you require is contained in this document,

otherwise please call:

TRINE TECH SUPPORT (718) 829-2332 EXT. 425,

or visit the TRINE Website www.TrineOnline.com.

The TRINE Model #3234, #3234W & Model #3478 are

designed for new installation or retrofitting into metal,

wood and aluminum door frames. Be sure that you have

ordered the correct TRINE strike for your application.

FINISHES

3234 3234W 3478

US3 (Polished Brass)

US4 (Satin Brass)

US10B (Dark Bronze)

US26 (Bright Chrome)

US26D (Satin Chrome)

US32D (Satin Stainless Steel)

STANDARD FEATURES

Face Plate - 3234, 2-3/4" x 1-1/8"

3234W, 3-3/4" x 1-1/4"

3478, 4-7/8" x 1-1/4"

Mortise Type - 1" backset (Smallest in the Industry)

Durability - 500,000 Life Cycles

Holding Force - 1,200 Pounds (Static Force)

- 70 ft-lb (Dynamic Force)

All stainless steel locking parts

Solid Cast Latch - Stainless Steel

Cavity: Width 5/8", Height 1-1/8", Depth 1/2"

Non-handed

Heavy-duty latch spring

Silent Operation

Intermittent Duty with the Standard versions

Intermittent and Continuous Duty with the LC versions

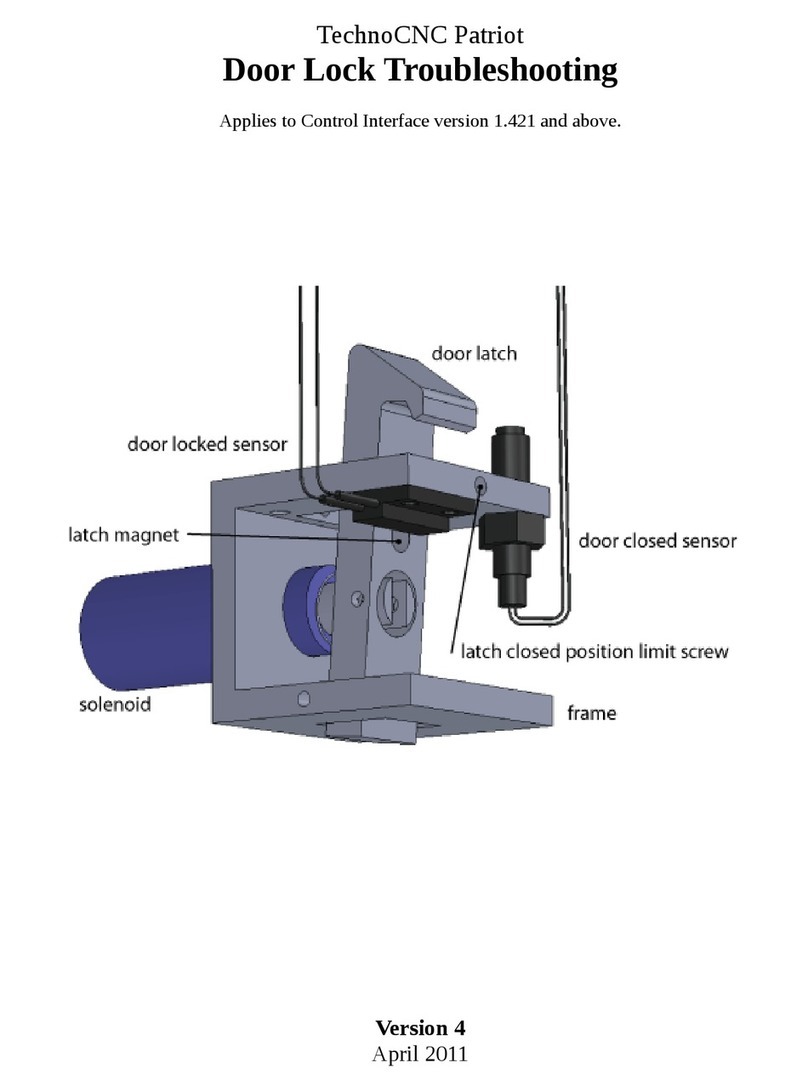

Micro Solenoid assembly

Fail-Secure:(standard action) unlocks with power

Fail-Safe: RS (reverse action) unlocks when power is off

RECOMMENDED INSTALLATION SEQUENCE:

1. Verify strike is proper for the door into which it is to be

installed.

2. Verify that you have all parts required to complete the

installation.

3. Verify that the new electric release operates with the

existing power supply/control circuit (retrofit

applications); or verify that the new power supply/

control circuit operates the new electric release (new

installations).

4. Locate and clearly mark the circuit breaker which

provides ac power to your transformer/ power supply

or that supplies power to the receptacle into which you

will plug your transformer/power supply. This will

enable you to safely cut power during installation, and

permit troubleshooting if required.

5. Verify that the receptacle or circuit providing power to

the electric release is not controlled by a wall switch,

time clock, or other external device.

6. Verify that the circuit/receptacle used for the locking

system is not powering any other equipment.

Remember that interruption of power to your locking

system could prevent access into the protected area,

or jeopardize the security/safety of the site's

occupants.

7. Verify that the door and associated components are in

good working order.

8. Install electric release as per attached guidelines.

9. Wire electric release as per attached guidelines.

10. Perform final test of completed installation.

LEFT HAND

(LH)

LEFT HAND

REVERSE BEVEL

(LRB)

RIGHT HAND

(RH)

RIGHT HAND

REVERSE BEVEL

(RRB)

OUTSIDE

OUTSIDE

DOOR HANDING GUIDE

HANDING OF DOOR IS ALWAYS DETERMINED

FROM THE OUTSIDE.

VOLTAGE DROP GUIDE

Length to Transformer 12V 24V

Up to 50 feet 18 AWG 20 AWG

50 to 150 feet 16 AWG 18 AWG

150 to 300 feet 14 AWG 16 AWG

300 to 600 feet 12 AWG 14 AWG

The TRINE MODEL # 3234, #3234W and #3478:

FAIL-SECURE "INTERMITTENT DUTY" units are designed for

momentary application of voltage for access control purposes,

and cannot be continuously powered without permanent and

irreversible damage to the electric strike's solenoid.

The TRINE MODEL #3234-RS, #3234W-RS and #3478-RS:

FAIL-SAFE "CONTINUOUS DUTY" versions may be used for

applications where the release must remain UNLOCKED for

extended periods. Please contact TRINE for other additional

TRINE electric release solutions for those applications requiring

a continuous duty FAIL-SECURE electric release that may be

powered for extended periods, commonly referred to as

CONTINUOUS DUTY.

The TRINE LC version of MODEL # 3234, 3234W, #3478, #

3234-RS, #3234W-RS and #3478-RS can be used for

"INTERMITTENT DUTY" AND "CONTINUOUS DUTY"

3000 SERIES ELECTRICAL CHARACTERISTICS CHART:

STANDARD MODELS

VOLTAGE CURRENT (AMPS)

COIL

RESISTANCE

(OHMS) DUTY AUDIBLE SOUND WIRE COLOR MODEL

12V DC 0.480 25 Int Silent Blue-Blue STD

24V DC 0.240 100 Int Silent White-White STD

LC & RS MODELS

VOLTAGE

CURRENT (AMPS)

PULL-IN/HOLDING

COIL

RESISTANCE

(OHMS) DUTY AUDIBLE SOUND WIRE COLOR MODEL

12V DC 0.743/0.298 13 Int./Cont. Silent Red-Red LC

12V AC 0.715/0.277 13 Int./Cont. Silent Red-Red LC

24V DC 0.397/0.170 13 Int./Cont. Silent Red-Red LC

24V AC 0.378/0.173 13 Int./Cont. Silent Red-Red

LC

Page 2

LUBRICATION: The TRINE Model #3234, #3234W & #3478

do not require lubrication. Lubricating these units will actually

hamper their performance by attracting dust and debris into the

tight tolerance precision Micro Solenoid assembly.

GETTING STARTED: Before proceeding with your

installation, verify that the door to which the electric release is

being applied is in good working condition.

These items are essential for either new installations or retrofits

Items which should be specifically checked prior to beginning

the installation include:

The hinges (or pivots) are in good condition

If your installation is a retrofit, that the existing latch

lines up perfectly with the existing strike plate.

The door is not rubbing on the saddle or anywhere on

the frame

The door closer is not leaking and is in good condition

and properly adjusted.

The door is not warped or otherwise damaged which

might hamper its operation or otherwise affect your

installation or the final system's performance.

That the door frame member into which the door

release is to be installed is deep enough (1 inch) for the

body of the electric strike, and that the wiring to

operate the electric release can be installed for your

application.

HANDING: The TRINE Model #3234, #3234W and #3478 are

non-handed.

DUTY & VOLTAGES: The TRINE Model #3234, #3234W &

Model #3478 are available as FAIL-SECURE (Normally Locked,

Power to Unlock), INTERMITTENT DUTY and are supplied in

two different operating voltage and the LC VERSION, suitable

for use in a range of voltages from 12V to 24V AC or DC. The

TRINE Model #3234RS, 3234WRS & Model #3478RS are FAIL-

SAFE (Normally Unlocked, Power to Lock), continuous duty and

are supplied with LC module.

LC units will operate on any input voltage from 12V to 24V AC

or DC, and offer both the benefits of reducing inventory by

enabling you to stock one strike. In addition, they offer both

surge suppression and inductive kickback protection.

Please refer to the accompanying VOLTAGE DROP CHART for

recommended wire gauges for various voltages and wire

lengths.

LOCK

LATCH

LOCK

SHIM

LATCH

LOCK - LATCH

ENGAGEMENT

LOCK - LATCH

ENGAGEMENT

FIGURE 4

Page 3

ELECTRICAL: If you are performing a new installation, be

certain that you make provisions for the proper voltage power

supply for your electric strike. If you are performing a retrofit

type installation, determine that the voltage present at the

location of the strike is appropriate for the TRINE strike you

have, that the circuitry supplying the voltage is operating

properly, and also verify that you are able to cut the power

completely to the door location so that you may perform the

installation safely without endangering yourself or causing

damage to the power supply or other devices connected to the

circuit. It is strongly recommended that you also test for high

voltages which may exist between each lead of the power wiring

to the electric release solenoid, and to the door frame which is

an earth ground. Dangerous voltages or currents may occur due

to a miswire or other pre-existing fault conditions in the system

you are servicing.

TESTING YOUR ELECTRIC STRIKE; POWER SUPPLY; &

SWITCHING CIRCUIT PRIOR TO FINAL MOUNTING OF THE

ELECTRIC RELEASE IS RECOMMENDED

POWER SOURCES:

The TRINE MODEL #5208 (12 VDC) or MODEL # 5209 (24

VDC) are suitable DC POWER SUPPLIES which are plug-in

and therefore do not require that the installer perform line

voltage wiring.

TRINE offers several low voltage transformers suitable for use

with the TRINE MODEL #3234, #3234W & #3478 electric

releases.

HARDWIRED POWER SUPPLY MODELS are also available -

see our website or call our Customer Support Line for details.

SILENT OPERATION: The TRINE #3234, #3234W & #3478 are

referred to as "Silent Operating"; unlike some types of AC

electric releases which make a "buzzing sound" when activated.

For some applications, such as entrances into apartment

buildings or storerooms, an audible sound is desirable, and

even expected. For other applications, such as offices, silent

operation is preferred because a buzzing sound is distracting or

disturbing. Verify with your client which they require, and if an

audible signal when the electric release is activated is desirable,

then add a sounding device as shown in the accompanying

wiring diagrams.

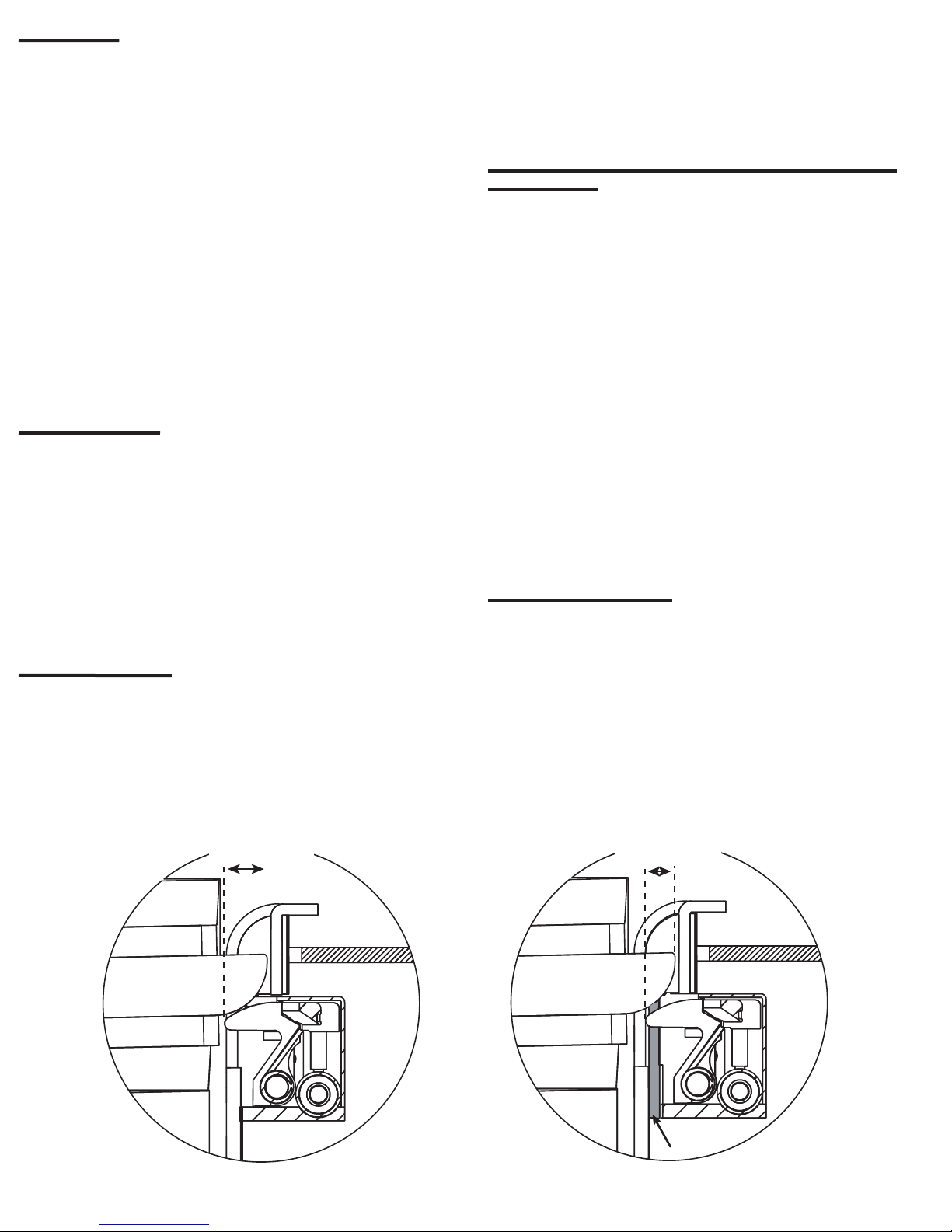

CONFIRMING PROPER LOCK-LATCH ENGAGEMENT &

CLEARANCES:

The latch and the lock must engage properly for the electric

strike to operate as intended. On doors where the gap between

the edge of the door and the jamb are within standard tol-

erances and the latch is the proper length, no adjustments will

be required and this is true for the majority of installations.

But too little lock-latch engagement will result in an installation

were the door may be easily spread; allowing the locked door to

be forced open.

Too much lock-latch engagement will result in a situation where

the door release will interfere with the door latch, causing

binding; improper operation and premature mechanical wear on

the latch and release.

Extended latch length (LL) minus the gap (G) between the edge

of the door and the edge of the jamb equals the amount of lock-

latch engagement.

"Lock-Latch Engagement = LL - G"

INSTALLATION OF SHIM:

An adequate amount of clearance must exist between the door

latch and the strike keeper so that they do not interfere or bind

when the door opens or closes. Two 1/16" thick shims are

supplied with the TRINE #3234, #3234W and #3478 which may

be installed as shown in the "Installation Drawings section" to

resolve this situation if this problem is encountered. (also See

Figure 4 below).

INSTALLATION DRAWINGS

WOOD FRAME INSTALLATION

The 3234W's 3-3/4" x 1-1/4" faceplate requires the

least amount of jamb preparation when compared

with other electric strikes.

3/32"

1 1/4"

1 11/16"

1 1/8"

7/16"

1 1/64"

1 1/16"

1 5/16"

3 3/4"

3 3/4"

1 11/16"

1 1/32"

1 1/4"

3 1/8"

1 1/8"

1 5/16"

9/16"

3/32"

5/16"

1"

OPTIONAL

1/16" THICK

SHIM

Page 4

4 7/8"

1 1/4"

1 7/8"

1 1/32"

1 11/16"

1"

3/32"

4 1/8"

3/4"

3 11/32"

5/8"

3/8"

OPTIONAL

1/16" THICK

SHIM

1 1/4"

4 7/8"

3/32"

1 1/16"

1 9/16"

1 1/4"

9/16"

1 3/4"

1 13/16"

1 1/4"

3 3/8"

3/4"

1 1/4"

4 7/8"

1 3/8"

1/8"

3 3/8"

7/16"

METAL AND WOOD FRAME INSTALLATION

The 3478's 4-7/8" x 1-1/4" faceplate

requires the least amount of jamb

preparation when compared

with other electric

strikes.

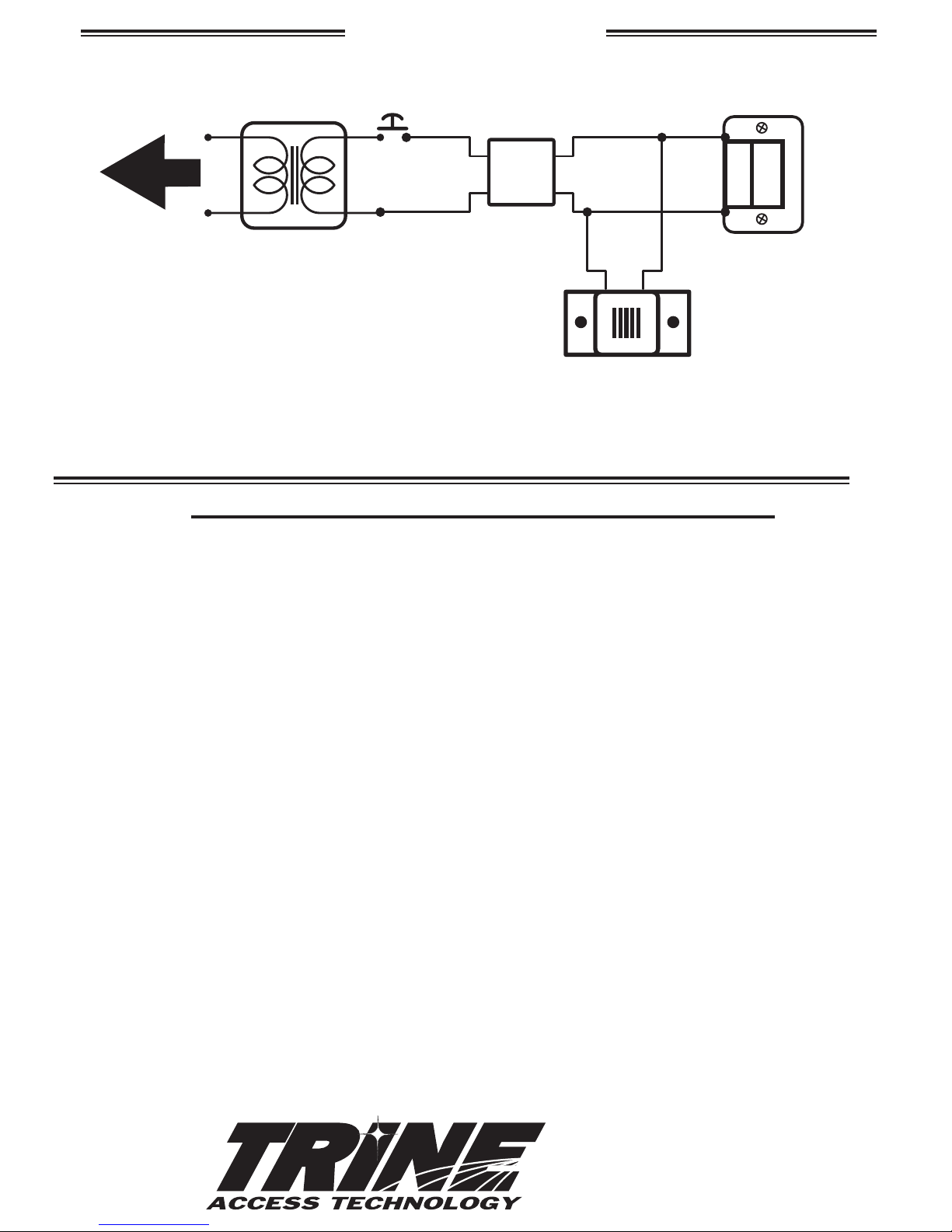

24V OR 12V AC/DC

TRANSFORMER

LC100

TO 120V AC LINE

FIGURE 2

FAIL-SAFE MODELS

PUSH

BUTTON

NORMALLY

CLOSED

+

-

FAIL-SAFE

ELECTRIC

STRIKE

OPTIONAL

LED

INSTALLATION DRAWINGS (Continued)

1 1/32"

1 11/16"

1"

1 1/8"

5/8"

1 7/16"

5/8"

2 1/8"

1 11/16"

2 3/4"

1/8"

9/16"

5/16"

OPTIONAL

1/16" THICK

SHIM

2 3/4"

1 7/16"

5/8"

1 1/8"

METAL FRAME INSTALLATION

The 3234's 2-3/4" x 1-1/4" faceplate requires the

least amount of jamb preparation when compared

with other electric strikes.

WIRING DIAGRAM

24V DC OR 12V DC

TRANSFORMER

OPTIONAL BUZZER

BZ-12 or BZ-24

TO 120V AC LINE

FIGURE 1

USING DC TRANSFORMER

PUSH

BUTTON

NORMALLY OPEN

** When wiring the optional buzzer, polarity must be

observed. Connect the (+ or RED) positive wire to the

(+) positive side of the circuit and the (- or BLACK)

negative side wire terminal to the negative side of the

circuit.

+

-

+

RED

-

BLACK

FAIL-SECURE

ELECTRIC

STRIKE

Page 5

Page 6

24V AC OR 12V AC

TRANSFORMER

OPTIONAL***

BUZZER

BZ-12

BZ-24

BZ-6 - for the LC Version

RECTIFIER*

or

LC100**

TO 120V AC LINE

FIGURE 3

USING AC TRANSFORMER

PUSH

BUTTON

NORMALLY OPEN

* The rectifier can be positioned before of after the push button in

the circuit. The LC module can ONLY be positioned after the push

button as shown above.

** The LC100 module is wired-in like a rectifier and the above

schematic will work also with a DC output transformer.

*** When wiring the optional buzzer, polarity must be observed.

Connect the (+ or RED) positive wire to the (+) positive side of the

circuit and the (- or BLACK) negative side wire terminal to the

negative side of the circuit.

+

-+

RED

-

BLACK

FAIL-SECURE

ELECTRIC

STRIKE

WIRING DIAGRAM (continued)

PHONE: (718) 829-2332 FAX: (718) 829-6405

1440 FERRIS PLACE

BRONX, NY 10461

email: CustomerService@TrineOnline.com

website: www.TrineOnline.com

TROUBLESHOOTING THE COMPLETED INSTALLATION:

SYMPTOM: Electric release is not actuating:

1. Verify proper voltage is present AT STRIKE. If voltage IS present: the strike may have been damaged

during the installation, or dirt or debris may be preventing proper operation.

2. Verify for proper electric release coil resistance (REFER TO COIL ESISTANCE CHART), for either a short

circuit or open circuit. Coil is NOT a serviceable part. Note that intermittent coils can only receive

power for 1 minute or less.

3. If voltage IS NOT present:

Verify Circuit breaker is on

Verify voltage at the transformer/power supply output.

Verify output from rectifier (if used)

Verify that there are no additional, unknown external switches or devices which may be interrupting

your circuit.

Check for damaged wiring or bad wire splices.

SYMPTOM: Door will not open but strike is working

Check for other locks on door

Check for proper lock-latch engagement (SEE SECTION: "CONFIRMING PROPER LOCK-LATCH

ENGAGEMENT & CLEARANCES").

Lock latch engagement may be not set correctly. (If proper clearance cannot be achieved by installing

a shim; a shorter lock latch may be required for your installation.)

Check for excessive backpressure on door release latch by following these steps:

While observing the electric release and latch; apply enough pressure on the door so that the lock's

latch does not press on the electric release's latch. If applying pressure as described does not cause

any movement of the lock away form the latch, then there may be too much pressure on the electric

release's latch. If electric release works properly while you are applying this pressure, then steps must

taken to relieve this pressure. Possible remedies include:

Re-adjust (or install) a door closer

Remove door silencers

Correct excessive door warpage

Re-center electric release in jamb

Remove or trim weather stripping around the door

This manual suits for next models

6

Table of contents

Other Trine Door Lock manuals

Popular Door Lock manuals by other brands

Assa Abloy

Assa Abloy mFlipLock standard Assembly and operating instructions

LOCKLY GUARD

LOCKLY GUARD ATHENA 228SL installation guide

CODELOCKS

CODELOCKS KL1200 Programming and operating instructions

Schlage

Schlage L9000 Series installation instructions

Philips

Philips EasyKey Alpha user manual

Schlage

Schlage S-260 Product Installation