Trine AXION Series User manual

Index No.

Name Part Number

PARTS LIST

1Latch EN-430/435-LCH

2Slider EN-430/435-SLR

3Coil Assembly (12 V) EN-CA-12AC EN-CA-12DC

Coil Assembly (24 V) EN-CA-24AC EN-CA-24DC

4Screw 4-40 x 1/8 (Cover) EN-SCR.1/8

5Frame Cover EN-FR.C

6Screw 4-40 x 1/4 (Coil) EN-SCR.1/4

7Frame EN-F430, F435 (Specify LH or RH)

8Assembly Pin* EN-ASS.PN

9Spring EN-SPR

10 Latch Pivot Shaft EN-LCH-PV-ST

11 Guard EN-GRD

12 Face Plate EN-430FACE, 435FACE

13 Mounting Screws (2) 12-24-1/2” EN-MTS

14 Shim Kit (4) 1/16” Shim EN-UNV-SHIM

15 Shim Screws (2) 6-32-1/4” EN-SHIM-SCR-S

16 Shim Screws (2) 6-32-3/8” EN-SHIM-SCR-L

NOTE: Number in parenthesis ( ) indicates

part in Parts List.

UL LISTED – 10B fire rated (class A, 3-hour,

Single Swing Doors)

UL LISTED – 1034 Burglary Resistant Locking

Mechanism for Indoor or Outdoor Use

ANSI/BHMA A156.5-1992 – 4-7/8” X 1-1/4” Fits

Cutout Specification A115.1 (with Slight Jamb

Modification)

BHMA – Grade1

NYC MEA 79-01-E

NOTE: UL 10B fire listing is void when using

fail safe action.

* NOT PART OF ASSEMBLY. USED ONLY DURING DISASSEMBLY OR REPAIR.

** UNLESS OTHERWISE SPECIFIED, FRAME IS SUPPLIED AS SATIN STAINLESS STEEL -

US32D. SPECIFY OTHER FINISHES AS FOLLOWS: BRIGHT BRASS - US3;

SATIN BRASS - US4; DARK BRONZE -10B; BRIGHT CHROME -US26.

Instruction Manual

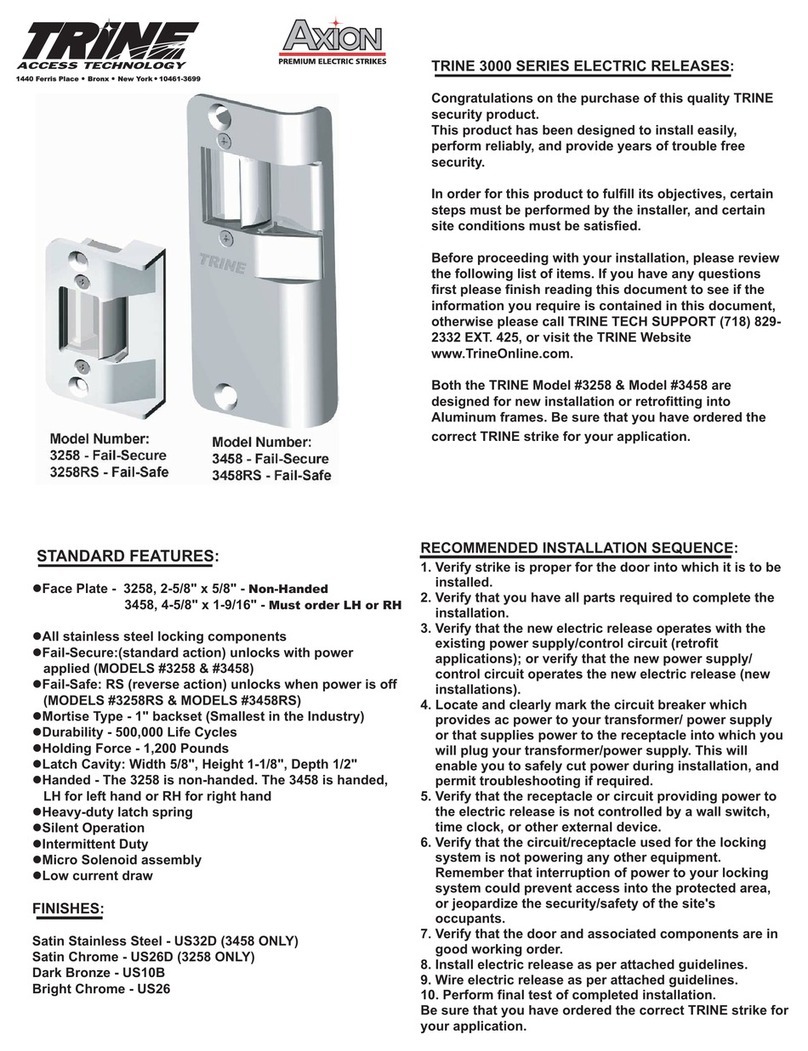

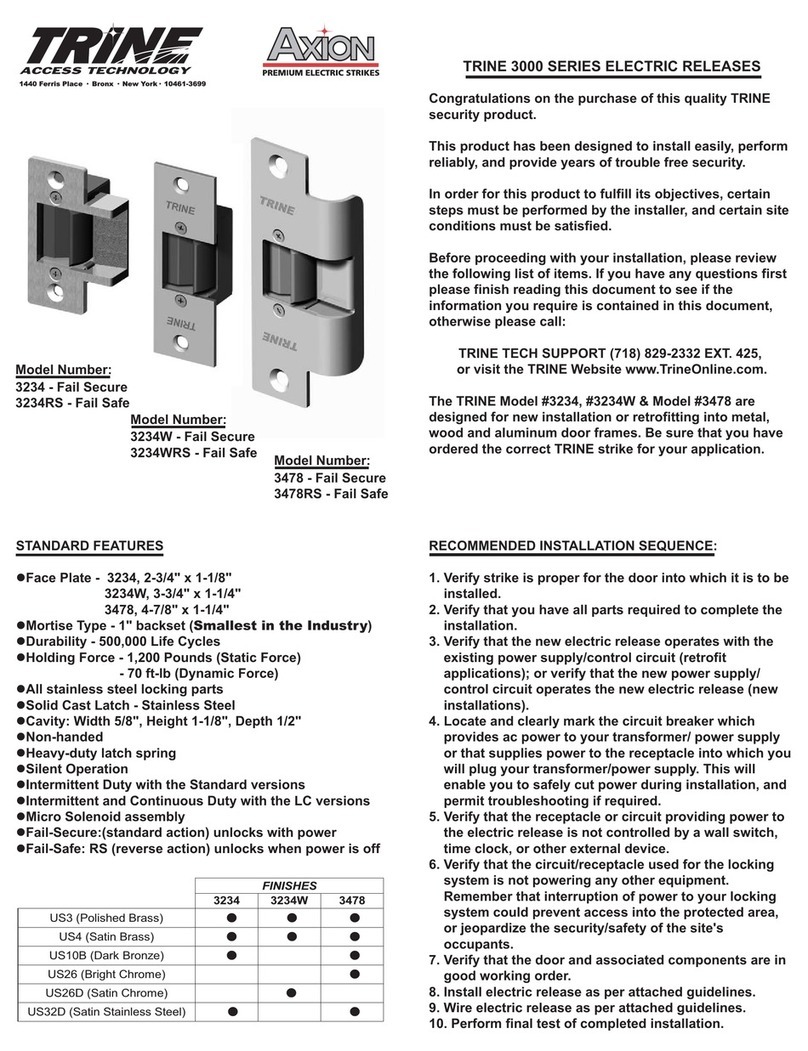

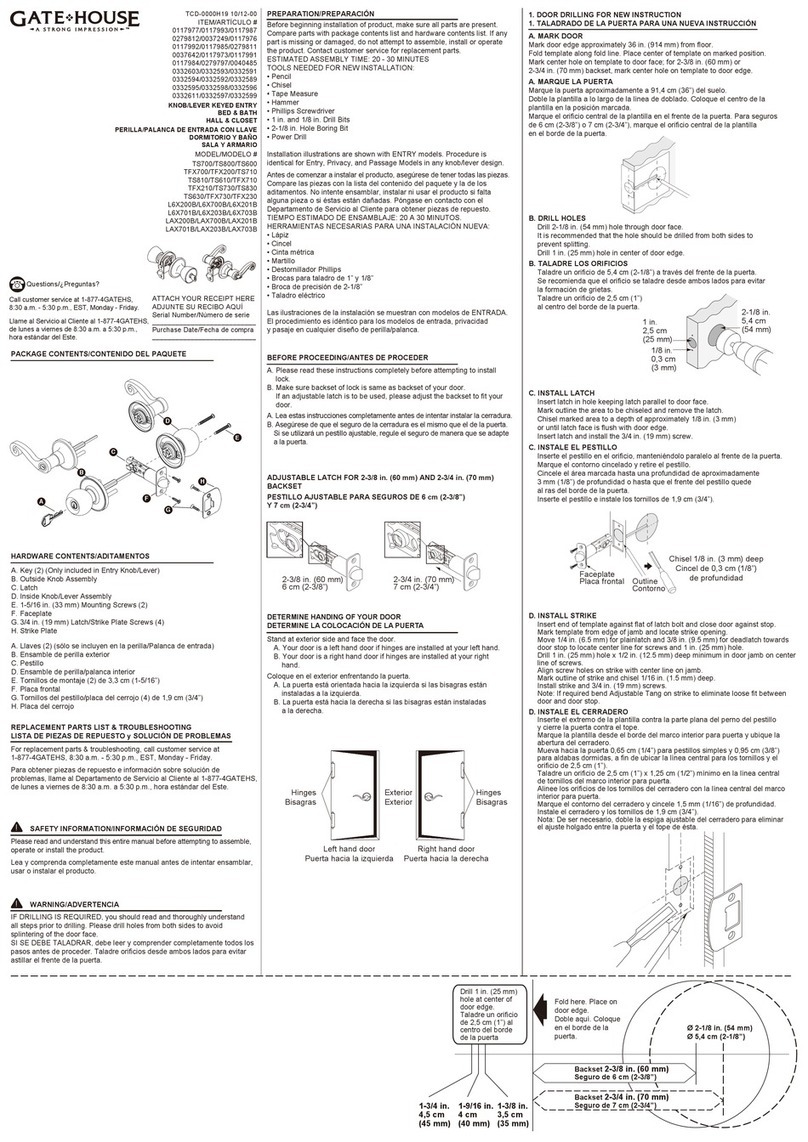

Figure 1

EN430 Electric Strike

8*

3

AXION SERIES - ELECTRIC STRIKE

MODEL EN 430/435

TRINE ACCESS TECHNOLOGY

1440 Ferris Place, Bronx, NY 10461-3699

Phone: 718 829-2332 Fax: 718 829-6405

www.trineonline.com

HAND OF DOOR IS ALWAYS DETERMINED

FROM THE OUTSIDE

Figure 2. Door Handing Positions

Spring

Tail

Latch

Fail Secure

6A

Fail Safe

6B

Figure 3. Position of Electric Strike

for Right Handed Door.

Wiring

Latch

Wiring

Latch

Latch Side

Dimple

Fail Secure Fail Safe

HANDING DETERMINATION

The handing of a door is determined

by the position of the hinges, as

viewed from the outside of the room,

building, office, etc. If the door hinges

are on the left, the door is termed

left-handed; if the door hinges are on

the right, the door is termed right-

handed. In addition, a door is either

inswinging (opens into the room), or

outswinging (opens to the outside of

the room), as illustrated in Figure 2.

NOTE

The EN430 and 435 are available

in either LH (Left-handed) or RH

(Right-handed). This needs to be

specified when ordering.

The position of the Electric Strike

within the door jamb will be the same

for a right-handed inswinging door and

a left-handed outswinging door. For

these installations, the Electric Strike

position within the door jamb will be as

viewed in Figure 3.

In a similar manner, the position of the

Electric Strike within the door jamb will

be the same for a left-handed inswinging

door and a right-handed outswinging

door. For these installations, the

Electric Strike position within the door

jamb will be as viewed in Figure 4.

Figure 4.

Position of

Electric Strike

for Left

Handed Door

ACTION (FAIL SECURE OR FAIL

SAFE)

The standard action is fail secure and is

field changeable to fail safe when

replaced with special order part

EN-SLR-RS. When using the fail safe

Slider, a DC Coil must be used.

The fail safe Slider is identified by the

small dimple below the welded tip.

CHANGING THE ACTION

1. Place Electric Strike face down

and, from back of assembly,

remove Screw (4) from Frame

Cover (5). Remove Frame Cover

from Electric Strike.

2. On side of Electric Strike, remove

Screw (6), which holds Coil Assembly

(3) to Frame (7).

3. Remove Coil Assembly from Electric

Strike.

NOTE

The Latch (1) is removed in the

following step. Assembly Pin (8) is

pushed through Latch to keep

Spring (9) in place. If Assembly

Pin is not available, use care when

removing Latch Pivot Shaft (10) to

keep Spring within Latch. If Spring

comes out of Latch, reinstall

Spring as shown in Figure 5.

The four EN latch shims provide

cavity width adjustment in 1/16”

incraments.

From top of frame remove Slider (2)

from beneath Guard (11). Figure 6A.

Take replacement fail safe Slider and

insert through top opening with welded

tip in upright position. Make sure the

Slider rests on the bottom of the cavity.

Figure 6B.

Place Electric Strike on a flat surface

with front of frame (7) facing up and

insert Assembly Pin (8) into Latch to

push out Latch Pivot Shaft (10).

Remove Latch (1) containing Assembly

Pin.

Figure 6.

Slider and Guard Positions

Hold Latch by satin side and roll into

frame cavity with back end and

exposed tip of Spring at the bottom of

the cavity. Insert tail end of Spring into

hole on the side of frame while

replacing latch.

Figure 7.

Figure 5.

Correct orientation of Latch Spring

Welded

Position of

slider

Slider (2)

located

beneath

Guard (11)

Make sure

Spring Tail

goes through

this hole

Spring Tail

1440 Ferris Place • Bronx, NY 10461-3699

Phone: 718 829-2332 • Fax: 718 829-6405

Figure 8.

Figure 9.

Take Latch Pivot Shaft with crown

end in upright position and insert

through shaft hole at the top of

the frame. This will push the

Assembly Pin out through bottom

hole.

Check Slider action. Make sure Slider

is free to move up and down with no

resistance.

Before replacing cover, make sure the

unit operates properly by testing with

appropriate voltage. NOTE: Do not

attempt to lubricate Electric Strike!!!

Place Strike face down and attach the

cover over the Coil with wire leads

seated through the notched hole.

5. Splice Electric Strike wiring to power wiring and secure with

wire nuts supplied.

6. Install Electric Strike into door jamb and secure with Screws

supplied into the Strike Face Plate..

7. Verify that door operates correctly when Electric Strike is

energized and not energized.

Insert

Latch Pin

Screw

(6)

Slider must rest inside of

Coil Assembly Bracket

NOTE

1. Rectifier can be located either between transformer and push button or

between push button and Electric Strike.

2. Use a current-regulating rectifier (CR-1) for converting AC voltage at the

transformer secondary to DC for operating a DC Electric Strike.

3. AC units should not be operated at continuous duty.

4. Improperly installed or misused units are not covered by manufacturer’s

warranty.

5. In UL listed systems, a UL listed burglar alarm power supply and annuncia-

tor of compatible rating should be employed.

ELECTRICAL CHARACTERISTICS CHART

FAIL SECURE(Intermittent Duty) NORMALLY LOCKED

VOLTAGE CURRENT/AMPS OHMS SOUND DUTY

12 VAC .70 4.5 Buzz Intm

24 VAC .37 18.0 Buzz Intm

12 VDC .28 43.0 Silent Intm/Cont

24 VDC .15 64.0 Silent Intm/Cont

TOTAL WIRING

LENGTH TO

TRANSFORMER 12V 24V

Up to 50 ft 18 AWG 20 AWG

50 to 150 ft 16 AWG 18 AWG

150 to 300 ft 14 AWG 16 AWG

300 to 600 ft 12 AWG 14 AWG

INSTALLATION PROCEDURE

For new or replacement installation:

1. Verify that voltage rating of Electric Strike is compatible

with voltage supply at installation. Coil assembles are wire

lead color coded for voltage as shown:

WIRE LEAD CODE/STRIPE

12AC Blue/Orange Stripe

12DC 2 Orange Stripe

24AC Blue/Black Stripe

24DC 2 Black Stripe

2. Using dimensions of template supplied with Electric Strike,

mark door frame for cutout and screw holes.

3. Prepare door jamb (cut out frame if required) for Electric

Strike. Leave sufficient wire length or splicing between power

wiring and Electric Strike wire leads.

4. If required, run new wiring to door frame mounting

hole. See Figure 10 for typical wiring installations. Refer to

wiring chart below for correct wire size. (Total wiring length

includes routing to door-release push button.)

NOTE

For DC operation, to obtain an audible signal when

Electric Strike is energized, install buzzer type BZ-12 for

12 VDC operation, or BZ-24 for 24 VDC operation

(purchased separately), as illustratd in Figure 10. DC

buzzer must be wired in parallel.

110-120 VAC House Current

Primary Side (Input)

Transformer (Stepdown)

BZ 12 or BZ24

Buzzer (Optional)

Secondary Side (Output)

See Notes

Rectifier

Rectifier

Figure 10.

Typical Electric Strike Wiring

Door lockset is not 1. Centerline of lockset not Check for proper cutout installation of Electric Strike by

secured by Electric properly aligned to centerline referring to template and door frame and lockset position.

Strike of Electric Strike.

2. Latch does not project Check for excessive gap between door and jamb.

properly into cavity of

Electric Strike. Check that lockset is compatible with EN series cavity

and requirements. If necessary, use other type of lockset or

Electric Strike (refer to Trine Catalog for more information).

3. Latch Spring broken or Hold Electric Strike so that wiring faces down and apply

missing. pressure to Latch. Verify that Latch releases and that there is

sufficient Spring tension to push it to closed positionwhen released.

If Latch does not have Spring tension, disassemble Electric Strike

and inspect for improperly installed or broken Spring.

Electric Strike does 1. Wiring to Electric Strike Check that electrical connections are secure and that no fraying

not energize open or shorted. has occurred during installation. Use voltmeter to verify that

Electric Strike is receiving energizing voltage and that wiring is

not shorted.

2. Insufficient voltage to Verify that voltage rating on Electric Strike label is compatible

Electric Strike. with voltage from secondary transformer (12V or 24V). If

voltages do not match, either replace transformer or change

Electric Strike or Coil Assembly.

Use voltmeter to verify that Electric Strike is receiving proper

voltage and that wiring is not shorted.

If voltage is too low because wire size is too small for length or

wiring to Electric Strike (see wiring-length data on previous page),

either replace wiring or use transformer with higher VA rating.

3. Slider does not move when Using an OHM meter, verify that resistance of the Coils matches

Coil receives proper voltage. the chart on page 3. If Coil is open (burned out), verify that

transformer for Electric Strike has correct voltage current AC/DC

and is wired correctly. AC Coils do not operate at continuous

duty, or on DC voltage.

Check that Slider (2) floats freely, as follows:

Remove Electric Strike from jamb and hold with wires facing up.

Test that Strike is locked by applying pressure to Latch. Then

turn Strike upside down with wires facing down and verify that

Latch opens freely by applying pressure. The locking Slider (#2)

must float freely for unit to operate properly.

Electric Strike ener- 1. Lockset is applying pressure Check for proper cutout installation of Electric Strike. Latch

gizes but does not to Electric Strike, preventing requires proper clearance to open correctly and provide path

disengage lockset Latch from releasing. for Lockset Latch to engage Strike.

Check that Lockset Latch is not binding to bottom of Strike cavity

due to door sag.

Check if foam insulation or the materials around door jamb are

preventing door from closing flush, causing door to put pressure

on Latch.

Possible Trouble Probable Cause Suggested Remedy

TROUBLESHOOTING

EN430

Electric Strike

Metal Frame

Preparation

LEFT HAND (LH) SHOWN

3 7/16"

1 3/4"

7/8"

4 7/8"

1 1/4"

4 1/8"

1"

OFFSET FROM CENTER

OF FACE PLATE

EN435

Electric Strike

Metal Frame

Preparation

LEFT HAND (LH) SHOWN

3 7/16"

1 1/4"

4 1/8"

13/16"

4 7/8"

1 3/4"

3/4"

OFFSET FROM CENTER

OF FACE PLATE

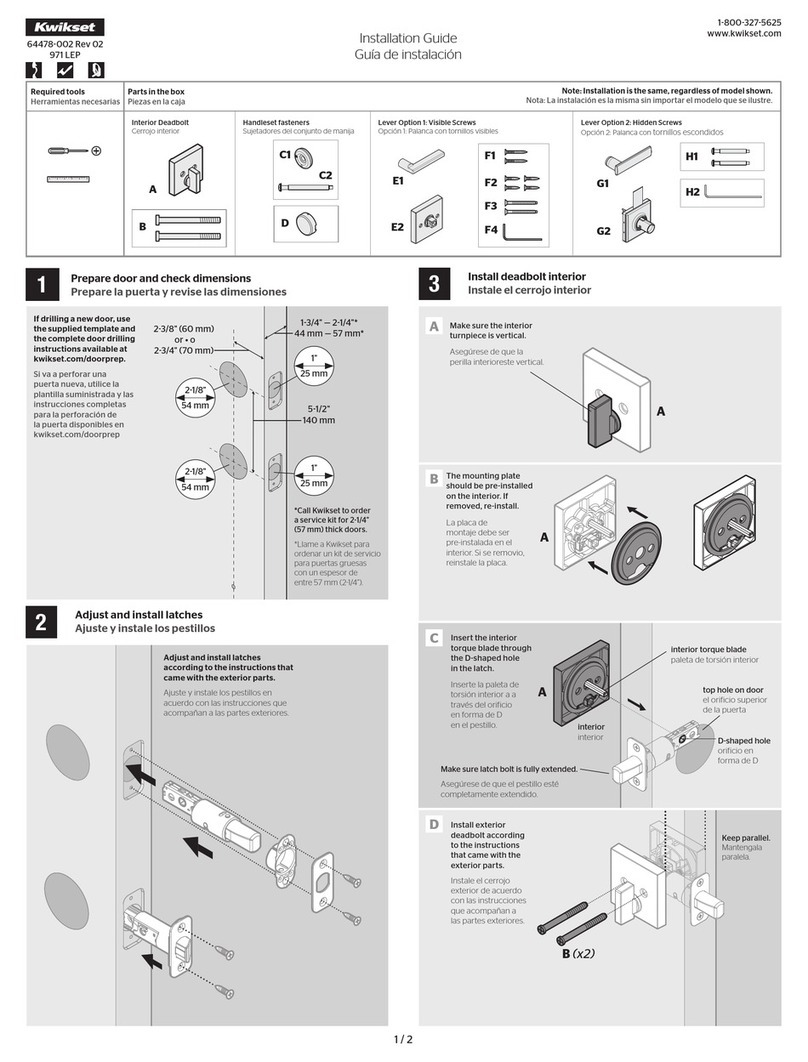

This manual suits for next models

2

Table of contents

Other Trine Door Lock manuals

Popular Door Lock manuals by other brands

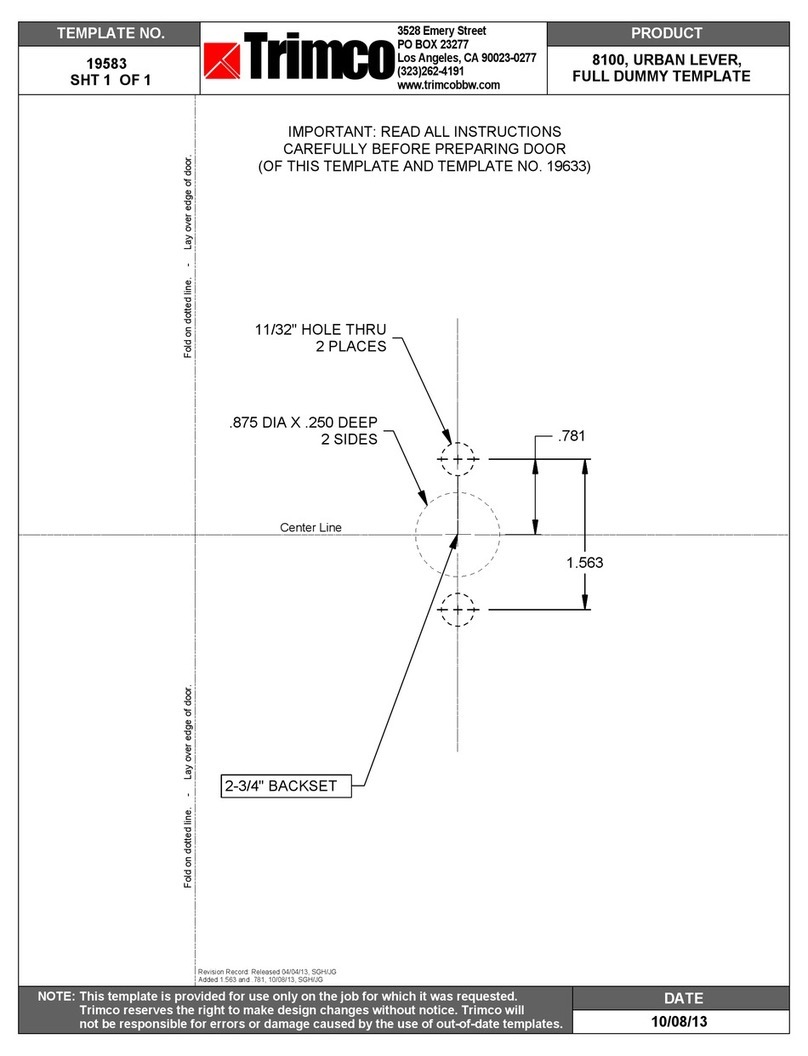

Trimco

Trimco 8100 quick start guide

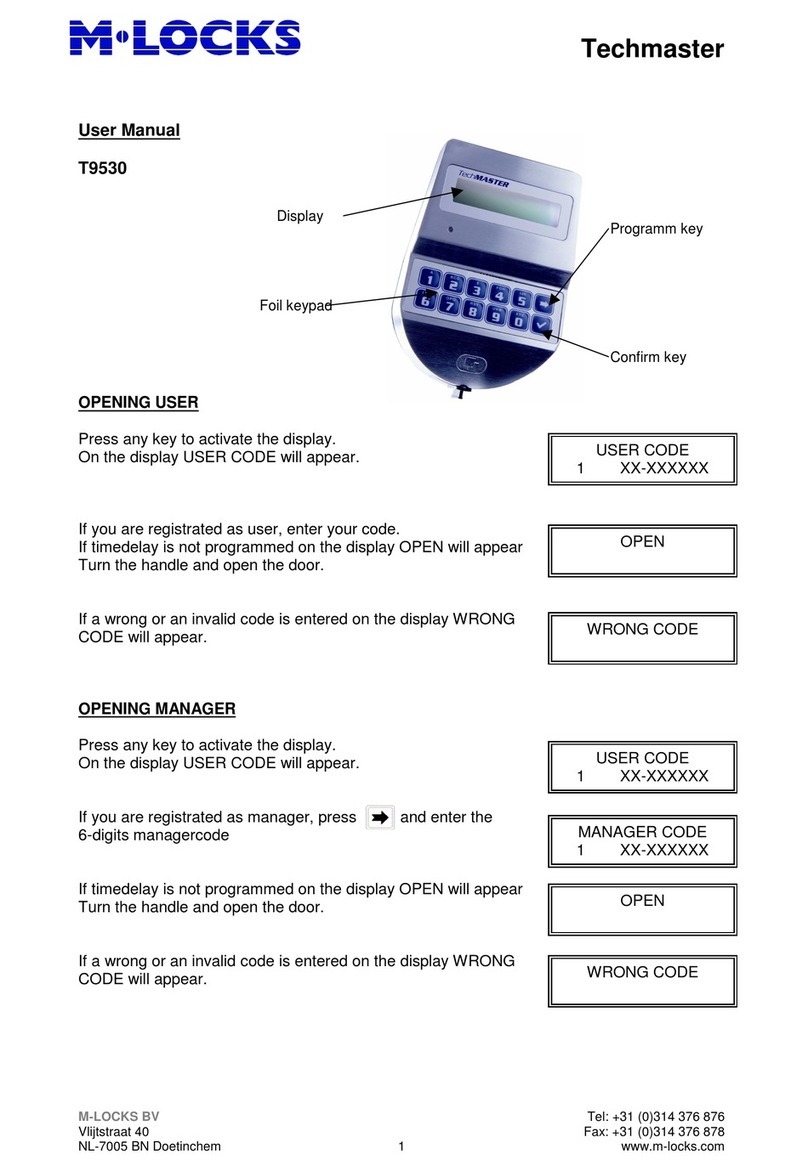

M-LOCKS

M-LOCKS T9530 Techmaster user manual

Schlage

Schlage Connect Smart Deadbolt quick start guide

Assa Abloy

Assa Abloy Effeff 309 Installation and fitting instructions

Assa Abloy

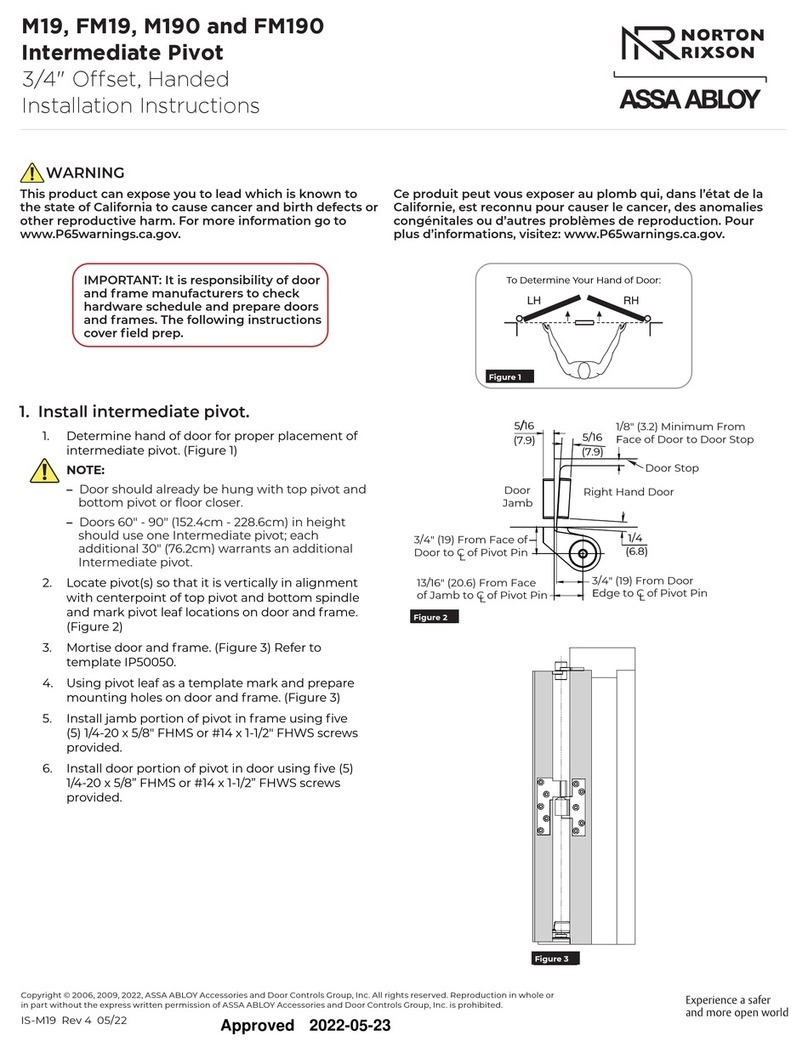

Assa Abloy NORTON RIXSON M19 installation instructions

Cal-Royal

Cal-Royal CRCODE-203 Instruction and programming manual