TrinityHighway.com 4 Created July 2021

Perimeter Security with Fence Panel Deployment (Not MASH Tested)

Warning: The 2001MB with Fence Panels should only be deployed on level

ground.

1. Position each 2001MB in line with the next using Interlocking Couplers.

2. If a connection is required to make a corner, use the 2001MB Corner Connector and join

it to the adjacent 2001MB Barricade run using an Interlocking Coupler (p. 3).

3. Ensure that all Drain Plugs are properly secured.

4. Remove both Fill Caps.

5. Completely fill each 2001MB Barricade with water to the top of the fill port. Failure

to completely fill the barricades could result in unwanted tipping of the system.

6. Slide Rubber Grommets onto each Fence Panel Post. With two people, lift the Fence

Panel on top of the barricade and place the Fence Panel Posts into the Fill Holes. The

posts should seat firmly within the post boots at the base of the barricade with the Rubber

Grommets snug in the fill holes at the top of the barricade. The chain link mesh should be

faced out from the barricade.

7. Interconnect the Fence Panels using two (2) Fence Panel Clamps, each one

approximately 12” from the top and bottom of the Fence Panel.

8. Trinity does not recommend the use of non-permeable panels, banners, or tarps;

however, if a permeable privacy screening or debris netting is required, attach to

the top and bottom of the Fence Panel Frame to secure all screen grommets.

Danger: Do not attach privacy, debris or windscreens (or remove if already

in place) if wind gusts are expected to exceed 45 mph. Failure to do so may

result in the system being blown over and causing property damage, personal

injury or death.

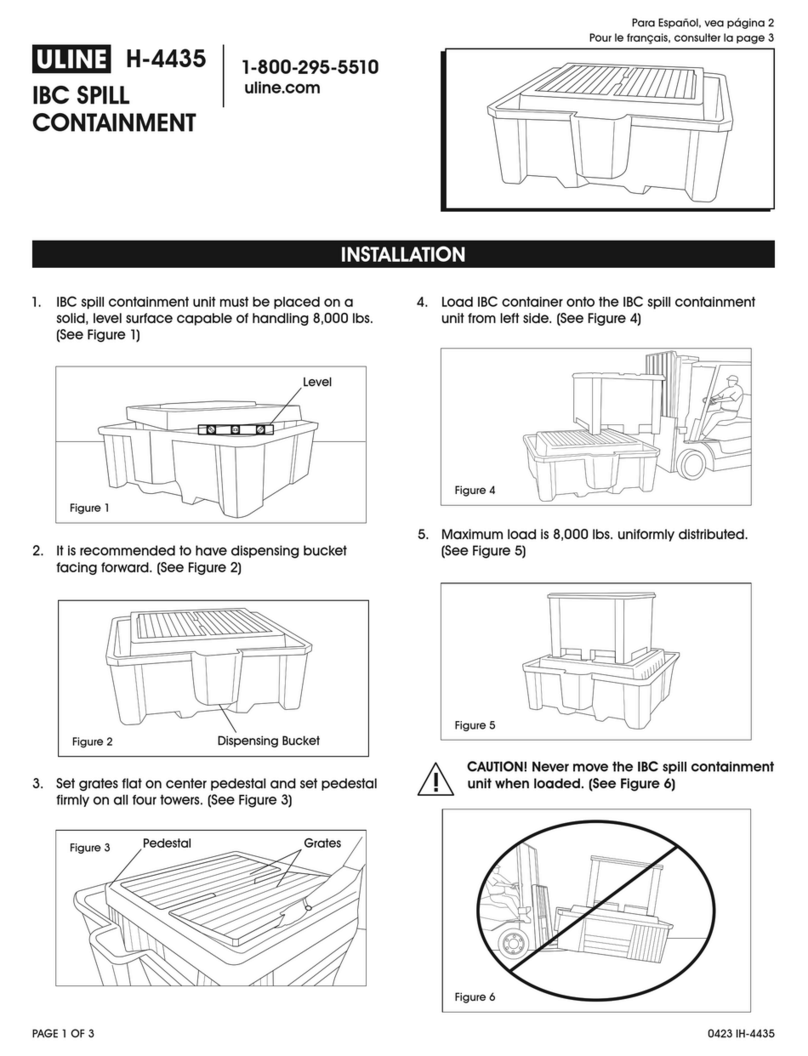

Fence

Panel

Clamps

Fence Panel

Rubber Grommet

Fence Panel Post