Trinity Highway MPS 350X User manual

MPS

®

is

a

www.trini

t

The MP

S

Program

Federal

H

reimbur

s

This ma

times. F

o

The inst

informati

system i

n

changes

current i

n

a

registered t

r

t

yhighway.co

m

Truc

k

S

350

®

X s

y

(“NCHRP”)

H

ighway Ad

ement unde

Imp

o

asse

m

for st

a

the s

p

from

engin

e

use

o

High

w

nual must

b

o

r addition

a

ructions co

n

on, illustrati

n

formation

a

at any tim

e

n

structions.

r

ademark of

T

m

M

k

Mo

u

y

stem has

b

Report 350

ministration

r

the Federa

P

o

rtant:

T

h

m

bly, maint

e

a

ndard ass

e

p

ecified sy

s

standard a

e

e

r

. This sy

s

o

n the natio

n

w

ay repres

e

b

e availabl

e

a

l copies,

c

n

tained in t

ons, and s

p

a

vailable to

T

e

. Please c

o

T

rinity Indust

r

M

P

S

u

nte

d

b

een tested

specificati

o

(“FHWA”)

l-aid Highw

a

P

rodu

c

Asse

m

2525 N.

Dall

h

ese instru

c

e

nance, and

e

mblies spe

c

s

tem assem

ssembly p

a

s

tem has b

e

n

al highwa

y

e

ntatives are

e

to the wo

r

c

ontact Trin

his manual

p

ecification

s

T

rinity High

w

o

ntact Trinit

y

r

ies, Inc.

1

S

35

Atte

n

pursuant

t

o

ns. Based

o

determined

a

y Program.

c

t Des

c

m

bly

M

Stemmons

F

as, Texas 7

5

c

tions are

t

repair of M

c

ified by the

bly, mainte

n

a

rameters,

c

e

en deemed

y

system un

available f

o

r

ke

r

overse

e

ity Highwa

y

supersede

s

in this Ma

w

ay at the ti

m

y

Highway t

o

© 201

7

0

®

X

n

uat

o

t

o National

o

n a review

that the M

P

c

riptio

n

M

anual

F

reewa

y

5

207

t

o be use

d

M

PS 350

®

X

appropriat

e

n

ance, or r

e

c

ontact the

eligible for

n

der criteria

o

r consultati

o

e

ing and/o

r

y

at (888) 3

2

all previou

a

nual are b

a

me of printi

n

o

confirm t

h

7

Trinity High

w

Revision

X

o

r (“T

Cooperativ

e

of these c

r

P

S 350

®

X

s

n

d

only in

c

systems. T

h

e

highway a

e

pair would

appropriat

e

reimburse

m

utilized by

o

n if require

d

r

assembli

n

2

3-6374.

s informati

o

a

sed on th

e

n

g. We rese

h

at you are

r

Part No. 6

2

w

ay Product

s

C Decembe

r

MA”)

e

Highway

R

r

ash test re

s

s

ystem is el

c

onjunction

h

ese instru

c

uthority. In

t

require a

e

highway

m

ent by the

F

that agenc

y

d

.

n

g the prod

u

o

n and ma

n

e

latest MP

S

rve the righ

t

r

eferring to

2

0298

s

, LLC

r

2017

R

esearch

s

ults, the

igible for

with the

c

tions are

t

he event

deviation

authority

F

HW

A

for

y

. Trinity

u

ct at all

n

uals. All

S

350

®

X

t

to make

the most

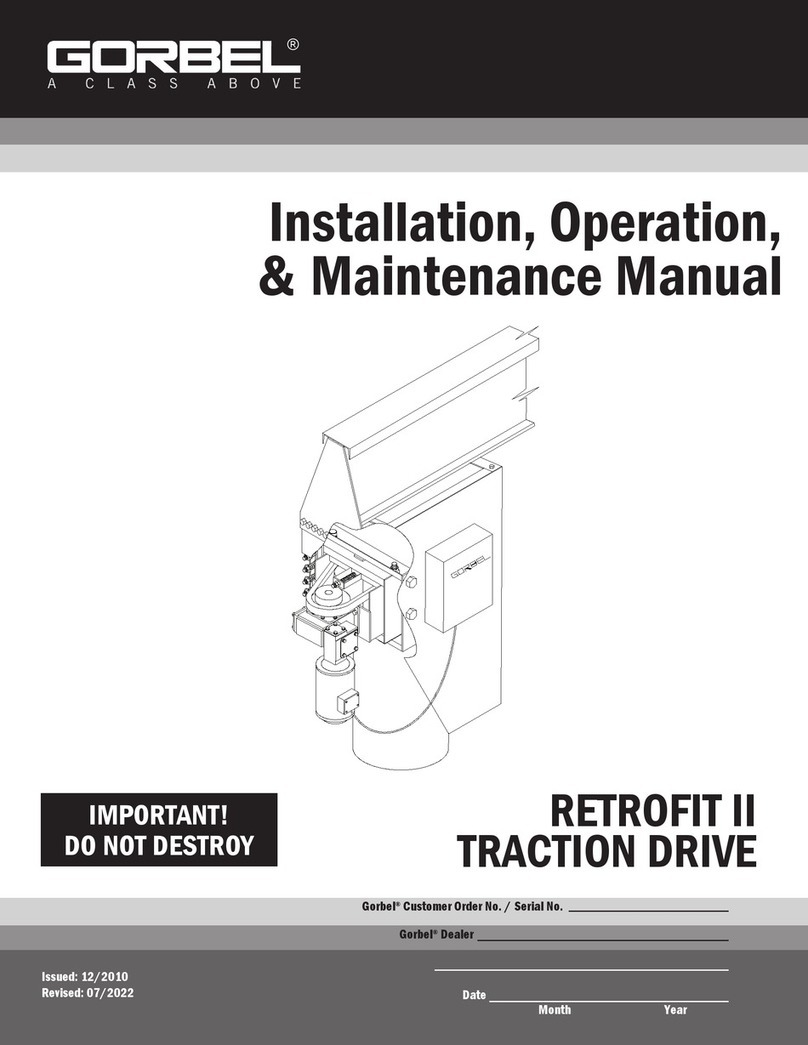

www.trinityhighway.com 2 Revision C December 2017

Table of Contents

Customer Service Contacts..........................................................................................................3

Important Introductory Notes ........................................................................................................3

Safety Rules for Assembly............................................................................................................4

Safety Symbols.............................................................................................................................5

Limitations and Warnings..............................................................................................................6

Safety Instructions ........................................................................................................................7

Controlling Skid Distance (Roll Ahead).......................................................................................10

Assembly ....................................................................................................................................11

Inspect Shipment ..................................................................................................................11

Recommended Tools............................................................................................................11

Unpacking and Attaching the MPS 350®X ...........................................................................12

Operation Guidelines..................................................................................................................17

Raising and Lowering the System.........................................................................................17

Maintenance ...............................................................................................................................19

Recommended Routine Maintenance...................................................................................19

Winch System Operation............................................................................................................20

Lowering the MPS 350®X.....................................................................................................21

Raising the MPS 350®X.......................................................................................................22

Chain Retainer......................................................................................................................23

Removing the MPS 350®X From the Truck..........................................................................23

When the MPS 350®X is Impacted ............................................................................................24

Rapid Field Replacement of Shear Bolts..............................................................................24

Low-Speed Impact................................................................................................................25

Medium-Speed Impact..........................................................................................................25

High-Speed Impact ...............................................................................................................25

Troubleshooting Table ..........................................................................................................26

FRAME ASSEMBLY, MPS 350®X .......................................................................................27

HOIST ASSEMBLY, MPS 350®X, 12V ................................................................................29

MISC HARDWARE, MPS 350®X .........................................................................................31

LIGHT ASSEMBLY, MPS 350®X .........................................................................................32

STRIPING ASSEMBLY, MPS 350®X...................................................................................35

UNDERRIDE ASSEMBLY, RECEIVER TMA .......................................................................37

ATTACHMENT ASSEMBLY, MPS 350®X ...........................................................................38

CAB CONTROL ASSEMBLY, MPS 12V...............................................................................39

www.trin

Cust

o

Trinity H

i

350

®

X

s

welcom

e

Trinity

H

Teleph

o

E-mail:

Websit

e

Region

a

Center

v

Dallas,

Elizabe

t

Girard,

Orange

Impo

r

Proper

a

evaluate

d

in their

e

to be us

e

assembl

i

or have

planned

Departm

authority

this Man

ityhighway.

c

o

mer Se

i

ghway is c

o

s

ystem, its

e

. Additional

H

ighway

o

ne:

e

:

a

l Telepho

v

ille, Utah

Texas

t

htown, Ken

Ohio

burg, South

r

tant Int

r

a

ssembly o

f

d

and acce

p

e

ntirety and

u

e

d only in c

i

es only as

s

questions

a

and specifi

e

ent. This p

r

. If there ar

e

u

al, the dev

i

Imp

o

teste

d

c

om

rvice C

o

o

mmitted to

t

a

ssembly p

information

ne Conta

c

tucky

Carolina

r

oducto

f

the MPS

3

p

ted by the

u

nderstood

onjunction

w

s

pecified by

a

bout the M

P

e

d this ass

e

r

oduct must

e

deviations

i

ce may not

o

rtant:

DO

d

and/or ap

p

3

o

ntacts

t

he highest

rocedures,

s

can be obt

a

c

ts:

ry Note

s

3

50

®

X sys

FHWA per

N

before ass

e

w

ith the ass

e

the applica

b

P

S 350

®

X

e

mbly and,

i

be deploy

e

, alteration

s

perform as

NOT use a

p

roved fo

r

th

i

3

level of cus

t

s

upporting

d

a

ined from t

h

(888) 323

-

+1 (214)

5

product.in

f

www.trinit

y

(800) 772

-

(800) 527

-

(800) 282

-

(800) 321

-

(800) 835

-

s

tem is criti

c

N

CHRP Re

p

e

mbling the

M

e

mbly of th

e

b

le highway

system, ple

i

f needed,

c

e

d in the lo

c

s

, o

r

depart

u

i

t was teste

d

ny compon

e

i

s system d

u

t

omer servi

c

d

ocumentat

i

h

e contact i

n

-

6374 (USA

)

5

89-8140 (In

f

y

highway.c

o

-

7976

-

6050

-

7668

-

2755

-

9307

c

al to achi

e

p

ort 350. T

h

M

PS 350

®

X

e

MPS 350

®

authority. If

e

ase contac

t

c

ontact Trin

i

c

ation speci

f

u

res from th

e

d

.

e

nt part tha

t

u

ring the as

s

Revision

C

c

e. Feedbac

i

on, and pe

n

formation b

)

ternational)

o

m

e

ve perform

h

ese instruc

t

X

system. T

h

®

X system

a

you need a

d

t

the highw

a

i

ty Highway

’

f

ied by the

e

assembly

t

has not b

e

s

embly or r

e

C

Decembe

r

k regarding

rformance i

elow:

ance that

h

t

ions shoul

d

h

ese instru

c

a

nd are for

d

ditional inf

o

a

y authority

’s Custome

r

appropriate

protocol sp

e

e

en specific

a

e

pair of this

s

2017

the MPS

s always

h

as been

d

be read

c

tions are

standard

o

rmation,

that has

r

Se

r

vice

highway

ecified in

a

lly crash

s

ystem.

www.trin

This pr

o

provided

should b

possess

qualified

for an in

d

selected

Safet

y

* Import

a

This ma

n

experien

of this

m

product.i

informati

A

lways

equipme

protectio

Safety

m

used to

control p

ityhighway.

c

o

duct has b

to that use

r

e permitted

the unique

to both rea

d

d

ividual exp

e

by the high

w

Imp

o

and s

350

®

X

work

e

FHW

A

invol

v

War

n

and I

m

Failu

r

collisi

o

y

Rules

a

nt Safety I

n

ual must b

e

ced in the

a

m

anual are

t

on in this m

a

use appro

p

nt or MPS

3

n shall be u

s

m

easures in

c

provide saf

e

lan that has

c

om

een specifi

e

r

who has u

n

to assist in

knowledge

d

and accur

a

e

rienced an

d

w

ay authori

t

o

rtant:

Rea

d

uggested s

a

X

system.

F

e

rs and/or b

y

A

. Please k

e

v

ed in the as

n

ing:

Ens

u

m

portant st

a

r

e to follow

t

o

n.

for Ass

e

nstruction

s

e

kept in a l

a

ssembly, m

available

f

t

. Please c

o

a

nual or ab

o

p

riate safet

y

3

50

®

X com

s

ed.

c

orporating

e

ty for pers

o

been estab

4

e

d for use

n

ique knowl

e

the assem

b

described

a

a

tely interpr

e

d

skilled in t

t

y.

d

safety ins

t

a

fe practice

s

F

ailure to fol

y

standers. I

t

e

ep up-to-d

a

sembly of t

h

u

re that all

o

a

tements wi

t

his warning

e

mbly

s

*

ocation wh

e

aintenance,

f

rom Trinity

o

ntact Trini

t

o

ut the MPS

y

precautio

n

ponents. W

traffic contr

o

o

nnel while

lished by th

e

4

by the ap

p

e

dge of ho

w

b

ly, mainten

a

bove. Thes

e

e

t them as

w

he assembl

y

t

ructions th

o

s

before as

s

low this wa

r

t

further co

m

a

te instructi

h

e product.

o

f the MPS

thin the M

P

could resul

e

re it is rea

d

or repair o

f

Highway

b

t

y Highway

350

®

X sys

t

n

s when o

p

ork gloves,

o

l devices

s

TMA is in

e

highway a

p

ropriate hi

g

w

this syste

m

ance, or re

p

e instructio

n

w

ritten. The

s

y

of highwa

y

o

roughly an

d

s

embling, m

r

ning can r

e

m

promises t

h

ons for lat

e

350

®

X sy

s

P

S 350

®

X

m

t in serious

d

ily availabl

e

f

the MPS 3

b

y calling (

if you hav

e

t

em.

p

erating po

w

safety gog

g

s

pecified b

y

use. TMA

p

uthority for

T

Revision

C

g

hway aut

h

m

is to be a

s

p

air of this

s

n

s are inten

d

s

e instructi

o

y

products t

h

d

follow the

aintaining,

o

e

sult in seri

o

h

e eligibility

e

r use and

r

s

tem Dange

m

anual are

injury or d

e

e

to person

s

3

50

®

X syst

e

888) 323-6

3

e

any ques

t

wer equip

m

g

les, safety-

t

y

the highw

a

p

ersonnel

m

T

MA use.

C

Decembe

r

h

ority and

h

s

sembled. N

s

ystem that

d

ed for an i

o

ns are inte

n

h

at are spe

c

assembly

d

o

r

r

epairing

o

us injury or

of this syst

e

r

eference b

y

r, Warning,

completely

e

ath in the e

s

who are s

k

e

m. Addition

3

74 or by

t

ions conce

r

m

ent, movi

n

t

oe shoes,

a

a

y authority

m

ust follow t

2017

h

as been

o person

does not

ndividual

n

ded only

c

ified and

d

irections

the MPS

death to

e

m by the

y

anyone

Caution,

followed.

vent of a

k

illed and

al copies

email at

r

ning the

n

g heavy

a

nd back

must be

he traffic

www.trin

Safet

y

This se

c

manual

f

Symbo

l

ityhighway.

c

y

Symb

o

c

tion descri

b

f

or complete

l

Mean

Safe

t

read

a

in ser

War

n

serio

u

been

War

n

have

Dang

e

comp

unde

r

War

n

speci

f

deplo

y

in th

e

autho

War

n

MPS

3

utiliz

e

are o

t

have

unsp

e

could

UNA

C

War

n

War

n

feder

a

War

n

Traffi

c

c

om

o

ls

b

es the saf

e

safety, ass

e

ing

t

y Alert S

y

a

nd follow t

h

ious injury

o

n

ing:

Failu

u

s injury or

accepted b

y

n

ing:

Do n

o

read this

m

e

r, Warnin

g

l

etely follo

w

r

stand these

n

ing:

Safe

t

f

ied by the

h

y

ment site.

e

event of

rity must al

w

n

ing:

Use

3

50

®

X for

a

e

or other

w

t

her Trinity

they been

d

e

cified parts

result in s

C

CEPTED s

y

n

ing:

Do N

O

n

ing:

Ensu

r

a

l, state, sp

e

n

ing:

Ensu

r

c

Control D

e

5

e

ty symbol

s

e

mbly, oper

a

y

mbol:

Indi

c

h

e Danger,

o

r death to

w

re to compl

death in th

e

y

the FHWA

.

o

t assembl

e

m

anual thor

o

g

, Caution,

w

ed. Please

inst

r

uction

s

t

y measur

e

h

ighway aut

h

Failure to f

o

a collision.

w

ays be obs

only Trinit

y

a

ssembling,

w

ise comin

g

Highway

s

d

eemed eli

g

or access

o

erious injur

y

y

stem.

O

T modify t

h

r

e that the

e

cifying age

n

r

e that you

r

e

vices (“MU

T

5

s

that appe

a

a

ting, maint

e

c

ates Import

Warning, C

a

w

orkers and/

o

y with thes

e

e

event of

a

.

e

, maintain,

o

ughly and

and Imp

o

call Trinity

s

.

e

s, incorpo

r

h

ority, must

o

llow this w

a

The traffic

erved in util

i

y

Highway

maintaining

g

le parts fr

o

s

ystems. S

u

g

ible for us

e

o

ries is stric

t

y

or death

h

e MPS 350

®

MPS 350

®

n

cy, and loc

a

r

assembly

T

CD”) and l

o

a

r in this

M

e

nance, rep

t

ant, Cautio

n

a

ution, or I

m

o

r bystande

e

warnings

a

vehicle im

p

or repair th

completel

y

o

rtant state

m

Highway a

r

ating app

r

be used to

p

a

rning could

control pl

a

i

zing this pr

o

parts that

, or repairin

g

o

m other s

y

u

ch configur

a

e

.

A

ssembl

y

t

ly prohibite

in the eve

®

X system i

X system

al specifica

t

meets all

a

o

cal standar

d

Revision

C

M

PS 350

®

X

air, and ser

v

n

, Warning,

o

m

portant st

a

rs.

could resul

t

p

act with a

e MPS 350

®

y

understan

d

m

ents with

t (888) 32

3

r

opriate tra

f

p

rotect all p

e

result in s

e

a

n establis

h

o

duct.

are speci

g

the MPS

3

y

stems ev

e

a

tions have

y

, maintena

n

d. Failure t

o

nt of a ve

h

n any way.

and deline

a

t

ions.

a

ppropriate

d

s.

C

Decembe

r

X

manual.

R

v

ice informa

o

r Danger.

F

a

tements co

u

t

in increas

e

system tha

t

®

X system

d

it. Ensur

e

in the ma

n

3

-6374 if yo

f

fic control

e

rsonnel w

h

e

rious injury

h

ed by the

fied herein

3

50

®

syste

m

e

n if those

not been t

e

n

ce, or rep

a

o

follow thi

s

h

icle impac

t

a

tion used

Manual on

2017

R

ead the

tion.

F

ailure to

u

ld result

e

d risk of

t

has not

until you

e

that all

n

ual are

u do not

devices

h

ile at the

or death

highway

for the

m

. Do not

systems

e

sted, nor

a

irs using

s

warning

t

with an

meet all

Uniform

www.trinityhighway.com 6 Revision C December 2017

Limitations and Warnings

Trinity Highway, in compliance with the NCHRP Report 350 “Recommended Procedures for the

Safety Performance of Highway Safety Features”, contracts with FHWA approved testing facilities

to perform crash tests, evaluation of tests, and submittal of results to the FHWA for review.

The MPS 350®X system was tested to meet the impact criteria, requirements, and guidelines of

NCHRP Report 350. These tests, specifically set forth by FHWA, evaluate product performance by

utilizing established impacts outlined by NCHRP Report 350 involving a range of vehicles on the

roadways, from lightweight cars (approx. 820kg [1800 lb.]) to full size pickup trucks (approx. 2000

kg [4400 lb.]) as specified by the appropriate highway agency. A product can be certified for

multiple Test Levels. The MPS 350®X system is certified to the Test Level(s) as shown below:

Test Level 3: 100 km/h [62 mph]

These FHWA directed tests are not intended to represent the performance of systems when

impacted by every vehicle type or every impact condition existing on the roadway. This

system is tested only to the test matrix criteria of NCHRP Report 350 as approved by FHWA.

Additionally, the MPS 350®X system was tested to meet the impact criteria, requirements, and

guidelines of TD 49. These tests, specifically set forth by The Highways Agency, evaluate product

performance by simulating those impacts outlined by TD 49 involving a typical range of vehicles on

our roadways, from lightweight cars (approx. 900 kg [2000 lbs.]) to heavier cars (approx. 1500 kg

[3300 lbs.]) as specified by The Highways Agency. A product can be certified for various speed

levels as shown below:

TL3.UK: 110 km/h [68 mph]

Highways Agency directed tests are not intended to represent the performance of systems

when impacted by every vehicle type or every impact condition existing on the roadway.

This system is tested only to the test matrix criteria of TD 49 as approved by the Highways

Agency.

Trinity Highway expressly disclaims any warranty or liability for injury or damage to persons or

property resulting from any impact, collision or harmful contact with products, other vehicles, or

nearby hazards or objects by any vehicle, object or person, whether or not the products were

assembled in consultation with Trinity Highway or by third parties.

The MPS 350®X system is intended to be assembled, delineated, and maintained within specific

state and federal guidelines. It is important for the highway authority specifying the use of a highway

product to select the most appropriate product configuration for its site specifications. The customer

should be careful to properly select, assemble, and maintain the product. Careful evaluation of the

site lay out, vehicle population type; speed, traffic direction, and visibility are some of the elements

that require evaluation in the selection of a highway product.

After an impact occurs, the debris from the impact should be removed from the area immediately

and the product should be evaluated and restored to its original specified condition or replaced as

soon as possible. All components and assemblies should be inspected and any parts that are

damaged should be replaced with original Trinity Highway replacement parts. Contact the Customer

Service Department prior to repair if you have any questions (see p. 3).

www.trin

Safet

y

For the

s

When til

t

1.

T

T

o

T

w

2. J

a

F

a

ityhighway.

c

y

Instru

c

s

afety of the

t

ing the TM

A

T

he TMA sh

a

T

MA shall b

e

n p. 11). Th

T

MA can onl

y

w

hen in the

D

a

cks shall

b

igure 2). R

o

t

tached to t

h

War

n

Jack

s

maint

e

Dan

g

oper

a

c

om

c

tions

operato

r

, th

A

, stay clear

a

ll be fasten

e

e

280 to 33

0

e TMA mu

s

y

absorb th

e

D

OWN (hori

z

b

e used to

s

o

tate or sw

i

h

e truck.

n

ing:

Do n

o

s

provided.

e

nance acti

v

g

er:

Ensur

e

tion.

7

e operator

s

of all movin

e

d to the tru

0

mm [11" t

o

s

t be left in t

e

energy of

a

z

ontal) posi

t

s

upport the

i

vel Jacks i

n

o

t use han

d

A

lways ke

e

v

ities.

e

that no o

n

7

s

hall stand

a

g parts.

ck. In the D

O

o

13"] from

t

he DOWN

(

a

n impactin

g

t

ion.

Figur

e

MPS 350

®

n

to the sto

r

Figur

e

s or feet to

e

p feet cle

a

n

e is near,

a

t the rea

r

o

f

OWN (horiz

t

he ground

a

(

horizontal)

p

g

vehicle, wi

e

1

X when it

i

r

age (horiz

o

e

2

lift or supp

o

a

r of frame

under or b

e

Revision

C

f

the truck o

n

z

ontal) positi

o

a

nd level (s

e

p

osition wh

e

i

thin NCHR

P

i

s detached

o

ntal) positi

o

o

rt the MPS

when in o

e

hind the

M

C

Decembe

r

n

the non-tr

a

o

n, the bott

o

e

e

A

ssembl

y

e

never pos

s

P

Report 35

0

from the t

r

o

n when th

e

350

®

X. Al

w

peration a

n

M

PS 350

®

X

2017

a

ffic side.

o

m of the

y

section

s

ible. The

0

criteria,

r

uck (see

e

TM

A

is

w

ays use

n

d during

when in

www.trin

3.

B

o

t

h

4.

W

s

e

F

5.

C

i

s

d

i

n

Safety

C

ityhighway.

c

Caut

i

not d

r

not si

t

B

efore raisi

n

peration.

A

l

l

h

e system.

N

W

hen traveli

e

cure the fr

a

igures 3 &

4

Figu

r

C

onfirm all p

e

s

stopped in

irectly behi

n

n

the raised

Caut

i

the U

P

C

hains

c

om

i

on:

The

M

r

ag the TM

A

t

, stand, or l

e

g or loweri

l

operators

s

N

ever stand

ng long dis

a

me with th

e

4

).

e 3

e

rsons are

s

full UP (ve

r

n

d the eleva

t

position or

w

i

on:

Whe

n

P

(vertical)

t

8

M

PS 350

®

X

A

or place a

e

an on any

p

ng the TM

A

s

hall fully u

n

under the T

tances or

s

e

Safety Ch

s

tanding cle

a

r

tical) positi

o

t

ed system.

w

hile it is be

i

n

traveling t

o

t

raveling po

s

Linchpi

n

Chain

(

S

8

X

system is i

nything on

t

p

art of the

T

A

, the oper

a

n

derstand t

h

MA when a

t

s

toring the

T

ains using

t

a

r before ra

i

o

n and retai

Never allo

w

i

ng lowered.

o

and from

a

s

ition.

n

Securing S

a

(

Chain Cove

r

hown For Cl

a

i

ntended to

t

op of the s

y

T

MA.

a

tor shall

b

h

e contents

o

t

tempting to

T

MA in the

t

he Linchpin

i

sing or low

e

ning chain i

w

anyone to

.

a

work zon

e

a

fety

r

Not

a

rity)

Revision

C

only suppo

r

y

stem as d

a

b

e fully trai

n

of this Man

u

lower it.

UP (vertic

a

n

s provided

w

Figure 4

e

ring the T

M

s in use be

f

stand und

e

e

, travel wit

h

C

Decembe

r

r

t its own w

e

a

mage will r

e

n

ed as to i

t

u

al prior to

o

a

l) position,

w

ith the sys

M

A. Verify th

e

f

ore allowin

g

e

r the TMA

w

h

the MPS

3

2017

e

ight. Do

e

sult. Do

t

s proper

o

perating

properly

s

tem (see

e system

g

anyone

w

hen it is

3

50

®

X in

www.trin

6.

B

p

N

a

7.

T

e

8. It

6

a

9.

T

D

10.

T

p

11.

T

t

r

t

r

12.

T

I

m

t

o

13.

T

i

m

ityhighway.

c

B

allast and

o

revent shifti

n

N

ote:

The

f

n impact.

T

he agency

o

quipment (

e

is required

804 kg [15

,

ppropriate

s

T

he driver s

h

D

OWN (hori

z

T

he driver s

h

osition. The

Caut

i

while

Fram

e

T

his system

i

r

affic lane w

r

uck and/or i

T

he Winch

A

m

proper us

a

o

the syste

m

T

he system

m

pact. Do n

o

Caut

i

(55 k

m

slow

e

occur

s

c

om

o

ther heav

y

n

g during a

n

f

orce on the

o

r authority

r

e

.g., seat bel

that the M

,

000 lbs.]

t

s

tate and fe

d

h

all be caut

i

z

ontal) posit

i

h

all be cau

t

TMA exten

d

i

on:

Do n

o

the MPS 3

5

e

Assembly

i

s an impac

t

henever po

s

mpacting v

e

A

ssembly

s

a

ge will cau

s

m

.

must be in

o

t leave the

i

on:

While

m

/hr) with

M

e

r than 35

m

s

or various

9

y

objects M

n

impact (se

e

tie-down s

t

r

esponsible

ts, head re

s

PS 350

®

X

t

o achieve

d

eral guideli

n

i

ous while

o

on so that i

n

t

ious while

d

s beyond t

h

o

t leave th

e

5

0

®

X is bei

n

could be da

t

attenuator

s

sible. If th

e

e

hicle that c

o

s

ystem was

s

e the lift m

e

the DOW

N

system rais

e

traveling in

M

PS 350

®

X

m

ph (55 km/

h

road condit

i

9

UST BE A

D

e

Figure 5).

t

raps could

b

Figure 5

for the truc

k

s

ts, etc.).

system be

intended i

m

n

es (see p.

1

o

perating th

e

n

jury and/or

Figure 6

making tur

n

h

e end of th

e

e

Winch St

r

n

g used as t

maged.

and is ofte

n

e

system is

i

o

uld cause i

n

solely de

s

e

chanism to

N

(horizont

a

e

d, even sli

g

a moving

w

X

in a DO

W

h

r) will be r

e

i

ons dictate.

D

EQUATE

L

be 20 time

s

k

shall inspe

c

mounted t

o

m

pact perf

o

1

0).

e

truck with

damage wil

n

s with the

e

truck and

w

r

ap tight in

he Winch a

n

n

used in hi

g

impacted, t

h

n

jury or dea

s

igned to li

f

o

malfunctio

n

a

l) position

t

g

htly, during

w

ork zone,

N

W

N (horizo

n

e

quired wh

e

Revision

C

L

Y ANCHO

R

s

the weight

c

t it for ade

q

o

trucks wei

o

rmance o

f

the TMA i

n

l not result

(

TMA in th

e

w

ill swing w

the DOWN

n

d/or the at

t

g

h traffic ris

k

h

ere may b

e

th.

f

t and low

e

n

and caus

e

t

o perform

g

worksite o

p

N

EVER driv

e

n

tal) operati

e

n bouncin

g

C

Decembe

r

R

ED to the

of the ball

a

q

uate opera

t

ghing a mi

n

f

the syste

m

n

the UP (v

e

(

see Figure

6

e

DOWN (h

o

w

ide while tu

r

(horizontal

)

t

achment p

o

k

areas. Sta

y

e

fragments

e

r the TMA

e

permanen

t

as tested

d

p

erations.

e

faster tha

n

ng position

.

g

of the MP

S

2017

truck to

a

st during

t

or safety

n

imum o

f

m

under

e

rtical) or

6

).

o

rizontal)

r

ning.

)

position

o

int to the

y

clear of

from the

system.

t

damage

d

uring an

n

35 mph

.

Speeds

S

350

®

X

www.trinityhighway.com 10 Revision C December 2017

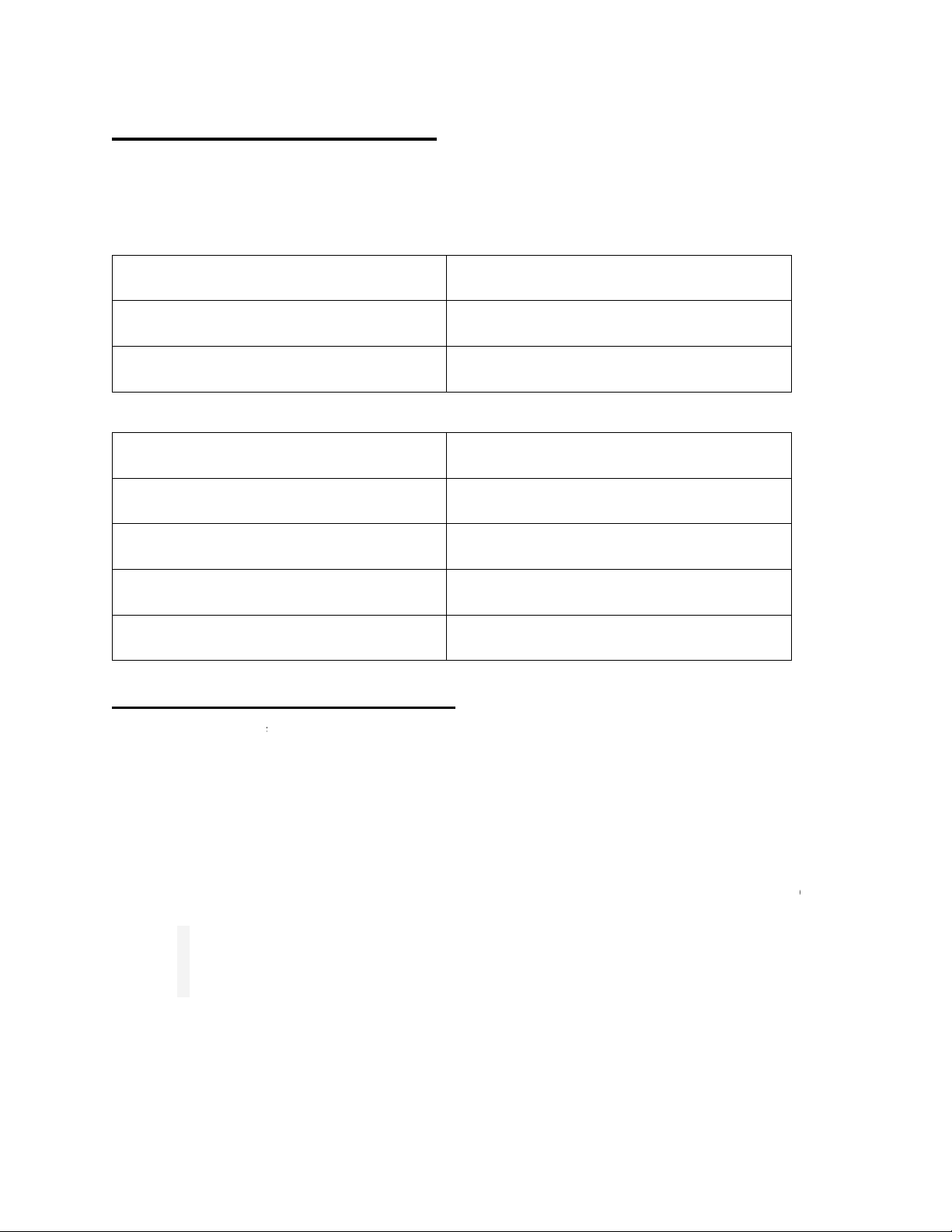

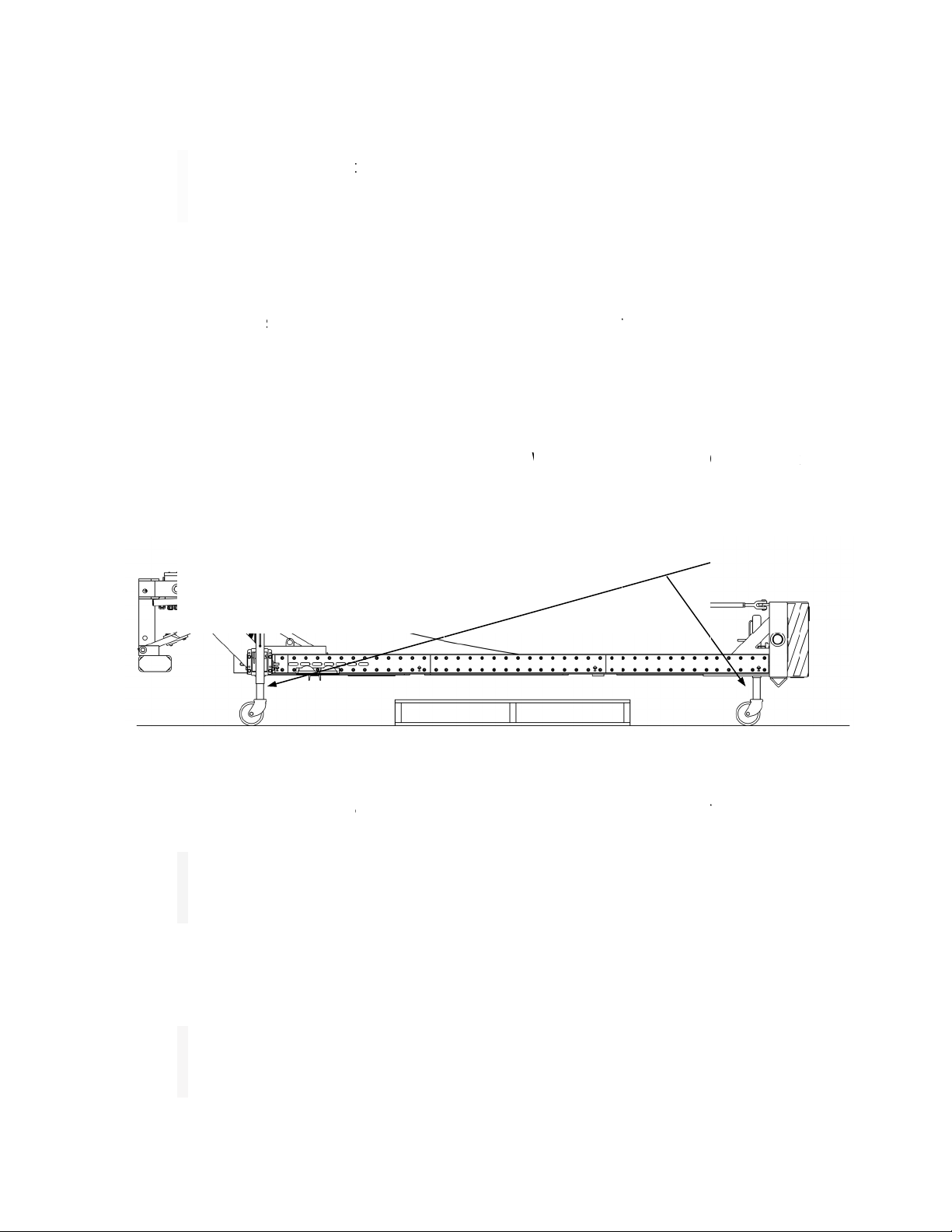

Controlling Skid Distance (Roll Ahead)

The use of a TMA on the back of a truck will not:

Affect the skid (roll ahead) distance of an impacted truck. KEEP WORK CREWS CLEAR!

Controlling skid distance (roll ahead):

Skid distance is significantly increased and is less predictable for lightweight shadow

vehicles.

Skid distance is reduced and is more consistent when heavier shadow vehicles are used.

Required minimum truck weight: 6,804 kg. [15,000 lbs.] or greater.

Roll-Ahead Distance for Shadow Vehicles

Weight of Shadow

Vehicle (Moving)

Prevailing

Speed km/h

[mph]

Weight of Impacting Vehicle to be Contained*

2,040 kg

[4,500 lbs] 4,536 kg

[10,000 lbs] 6,804 kg

[15,000 lbs] 10,886 kg

[24,000 lbs]

6,804 kg [15,000 lb] 96-105 [60-65] 23 m [75 ft] 46 m [150 ft] 53 m [175 ft] 69 m [225 ft]

80-88 [50-55] 23 m [75 ft] 38 m [125 ft] 46 m [150 ft] 53 m [175 ft]

72 [45] 15 m [50 ft] 30 m [100 ft] 30 m [100 ft] 30 m [100 ft]

10,886 kg [24,000 lb] 96-105 [60-65] 23 m [75 ft] 30 m [100 ft] 46 m [150 ft] 53 m [175 ft]

80-88 [50-55] 15 m [50 ft] 23 m [75 ft] 30 m [100 ft] 46 m [150 ft]

72 [45] 15 m [50 ft] 23 m [75 ft] 23 m [75 ft] 30 m [100 ft]

Note: Distances are applicable for shadow vehicle speeds up to 25 km/h [15 mph].

Roll-Ahead Distance for Barrier Vehicles

Weight of Barrier

Vehicle (Stationary)

Prevailing

Speed km/h

[mph]

Weight of Impacting Vehicle to be Contained*

2,040 kg

[4,500 lbs] 4,536 kg

[10,000 lbs] 6,804 kg

[15,000 lbs] 10,886 kg

[24,000 lbs]

6,804 kg [15,000 lb] 96-105 [60-65] 8 m [25 ft] 23 m [75 ft] 30 m [100 ft] 46 m [150 ft]

80-88 [50-55] 8 m [25 ft] 15 m [50 ft] 23 m [75 ft] 30 m [100 ft]

72 [45] 8 m [25 ft] 8 m [25 ft] 15 m [50 ft] 23 m [75 ft]

10,886 kg [24,000 lb] 96-105 [60-65] 8 m [25 ft] 15 m [50 ft] 23 m [75 ft] 30 m [100 ft]

80-88 [50-55] 8 m [25 ft] 8 m [25 ft] 15 m [50 ft] 23 m [75 ft]

72 [45] 8 m [25 ft] 8 m [25 ft] 8 m [25 ft] 15 m [50 ft]

*Weights of Typical Vehicles:

Midsize automobile - 1,020 kg [2,250 lb]

Full-size automobile - 1,500 kg [3,500 lb]

Loaded 3/4-ton pickup truck - 2,750 kg [6,000 lb]

Loaded 1-ton cargo truck - 4,500 kg [10,000 lb]

Loaded 4-yard dump truck - 11,000 kg [24,000 lb]

Source: "Use of Truck Mounted Attenuators in Work Zones" by Jack B. Humphreys, P.E. and T.

Darcy Sullivan, P.E., University of Tennessee.

www.trin

Asse

m

Read an

d

If syste

m

rear lea

f

(AWS)

q

battery

b

The tru

c

question

s

that spe

agency.

Only us

e

specifyin

Inspe

c

Carefull

y

parts ag

a

Reco

m

W

C

H

T

1

/

1

/

O

1

M

F

C

W

B

Note:

T

extensi

v

specifie

d

what to

o

highwa

y

system

a

ityhighway.

c

m

bly

d

understan

Imp

o

[15,0

0

appr

o

m

must be a

f

spring ha

n

q

ualified wel

efore any w

k frame m

u

s

regarding

cified this

s

e

reflective

s

g the use o

f

c

t Shipm

e

y

uncrate all

a

inst the shi

p

m

mended

W

elding equi

C

utting torch

H

amme

r

T

ape measu

r

/

2” drive so

c

/

2” drive so

c

O

pen end wr

e

2” crescent

M

arking impl

e

loor jack or

C

enter punc

h

W

ork gloves

B

ubble level

T

he above l

i

v

e list. Dep

d

by the a

p

o

ls are nee

d

y

authority

a

t the auth

o

c

om

d all instruc

t

o

rtant:

Th

e

0

0 lbs.] to

o

priate state

ttached to t

n

gers to en

s

ders to ens

elding on th

u

st be suita

b

the suitabil

s

ystem for

s

triping patt

e

f

this TMA.

e

nt

componen

t

p

ping list su

Tools

pment GM

A

r

e

c

ket wrench

c

kets (9/16”,

e

nches (9/1

w

renches (

2

e

ment (pen

c

Forklift

h

and other p

e

i

st of tools

ending on

p

propriate

h

d

ed to perf

and the a

u

o

rity’s spe

c

1

t

ions before

e

truck wei

g

achieve i

n

and federal

he truck by

s

ure struct

u

ure durable

e truck or T

M

b

le and ac

c

ity, please

guidance.

T

e

rns that ha

v

t

s. Before a

s

pplied with

t

A

W or SMA

W

w/ 6” exten

s

1-1/8”, 1-1/

6

”, 1-1/8”,1-

2

)

c

il, soap sto

n

e

rsonal prot

e

is a gener

a

specific si

h

ighway au

t

o

rm the jo

b

u

thority’s s

e

c

ified asse

m

1

beginning

a

g

ht, excludi

n

tended i

m

guidelines.

welding pa

r

u

ral integrity

attachmen

t

M

A.

c

essible for

c

ontact the

T

rinity High

w

v

e been sp

e

s

sembling t

h

t

he system.

V

W

s

ion

2”)

1/2”)

n

e)

e

ction equi

p

a

l recomme

n

te conditi

o

t

hority the

b

are entir

e

e

lected co

n

m

bly site.

a

ssembly.

ng TMA,

m

m

pact perfo

r

r

ts to the fr

a

y

of frame.

t

of the TM

A

mounting

a

appropriat

e

w

ay is ava

i

e

cifically ap

p

h

e MPS 35

0

V

erify that

a

p

ment as re

q

n

dation an

d

o

ns and th

e

required t

o

e

ly within t

h

n

tractor pe

Revision

C

m

ust be a

m

rmance of

a

me, do no

t

Use

A

meri

c

A system.

D

a

TMA syst

e

e

highway

a

i

lable for c

o

proved by t

h

0

®

X system

a

ll parts wer

e

q

uired

d

should n

o

e

complexi

t

o

ols may v

a

h

e discreti

o

rforming t

h

C

Decembe

r

m

inimum o

f

the syste

m

t

weld forw

a

c

an Weldin

g

D

isconnect

e

m. If there

a

uthority or

e

o

nsultation

w

h

e highway

, check the

e

received.

o

t be consi

d

t

y of the a

a

ry. Decisi

o

o

n of the s

p

h

e assemb

l

2017

6804 kg

m

under

a

rd of the

g

Society

the truck

are any

e

nd user

w

ith that

authority

received

d

ered an

ssembly

o

ns as to

p

ecifying

l

y of the

www.trin

Unpa

c

1.

R

2.

R

m

3.

R

c

a

4.

O

H

m

5.

R

x

t

h

R

6.

C

7. I

n

C

8.

A

M

b

ityhighway.

c

c

king and

Caut

i

is mo

10’-6

”

R

ead safety i

R

emove the

m

aterials.

R

emove pla

s

a

rdboard b

o

O

pen the

M

H

ardware

As

m

issing (see

R

emove the

1” Hex Bol

t

h

e Misc. Ha

r

R

aise the M

P

C

onfirm the t

n

form the tr

u

C

hock the w

h

Caut

i

attac

h

the ig

NOT

S

A

dd load to t

h

M

PS 350

®

X

e different f

o

War

n

other

oper

a

c

om

Attachi

n

i

on:

Prior

t

re than 10’

-

(3.2 m), co

n

nstructions

t

shipping

b

s

tic Stripin

g

o

x with the

M

M

iscellaneo

u

s

sembly (se

e

p. 3).

s

hipping st

a

t

s (PN 113

5

r

dware Ass

e

P

S 350

®

X o

f

r

uck is on fl

a

u

ck driver th

a

h

eels to pre

v

i

on:

A

lwa

h

ed, repaire

d

nition of th

e

S

TART EN

G

h

e truck; if

a

is attached

o

r local reg

u

n

ing:

Do

n

loose acc

e

tion.

1

n

g the M

P

t

o mounting

-

6” (3.2 m)

n

tact Trinity

t

horoughly

b

b

ands and

g

Assembl

y

M

iscellaneou

s Hardwar

e

e

drawing

6

a

nds and att

5

98G) and f

o

e

mbly.

f

f the shippi

n

a

t level grou

a

t the MPS

v

ent truck m

ys i

nform t

d

, operated,

e

truck and

G

INE.

a

pplicable, t

h

. The mini

m

u

lations. Co

n

n

ot operate

t

e

ssories, w

h

2

P

S 350

®

X

the MPS 3

5

from the re

Highway a

b

b

efore oper

a

protective

m

y

compone

n

s Hardware

e

box and

6

20358 on

p

a

ch the thr

e

o

u

r

(4) 3/8”

W

n

g pallet usi

n

Figure 8

nd.

350

®

X is g

o

ovement. D

o

he truck dr

i

or adjuste

d

place signs

h

e truck mu

s

m

um loaded

n

sult your lo

c

t

he MPS 3

5

h

ich may b

e

X

5

0

®

X, verify

ar of the tr

u

b

out various

a

ting the M

P

m

aterial. P

r

n

ts (see d

r

.

inventory

p

. 31). Con

t

e

e (3) Jacks

W

hiz Nuts (

ng the stora

o

ing to be a

o

not start

t

i

ver when t

h

d

. Chock th

e

on the tru

c

s

t be loade

d

weight is 6,

c

al governin

5

0

®

X while

e

come tang

Revision

C

that the fu

e

u

ck. If the

d

extensions

P

S 350

®

X.

r

operly dis

p

r

awing 620

3

items from

t

act Trinity

H

(PN 00567

8

(

PN 003257

G

a

ge Jacks.

ssembled,

r

t

ruck engi

n

h

e MPS 3

5

e

wheels. R

e

c

k that it is

b

d

to the corr

e

804 kg (15,

g specificati

wearing lo

o

led in the

M

J

C

Decembe

r

e

l tank(s) on

d

istance is l

(see p. 3).

p

ose of all

3

44 on p.

the Misc

e

H

ighway if

p

8

B) with fou

G

) per Jac

k

r

epaired, or

a

n

e.

5

0

®

X is goi

e

move the

k

b

eing servi

c

e

ct weight b

000 lbs.). T

i

ons.

o

se fitting cl

M

PS 350

®

J

acks

2017

the truck

ess than

shipping

35) and

e

llaneous

p

arts are

r (4) 3/8”

k

found in

a

djusted.

ng to be

k

eys from

c

ed – DO

efore the

his could

othing or

X during

www.trin

9.

M

a

(

9

10.

S

ityhighway.

c

M

ove the M

P

ssembled h

e

9

15 mm) an

d

Imp

o

perfo

r

crash

Caut

i

A

sse

m

not o

b

the tr

u

S

elect the b

e

A. This

fram

e

atta

c

shou

of th

e

brac

e

Wel

d

rear-

reco

m

c

om

P

S 350

®

X i

n

e

ight at 915

d

maximum

o

rtant:

Pro

p

r

mance of t

h

.

i

on:

Leav

e

m

bly and di

r

b

structed du

u

ck and the

e

st mounting

option uses

e

rails as s

h

c

hment poin

ld allow 1/2

”

e

MPS 350

®

e

d to the t

r

u

d

the Chan

n

most leaf

s

m

mendatio

n

1

n

to position

a

mm [+ 12

m

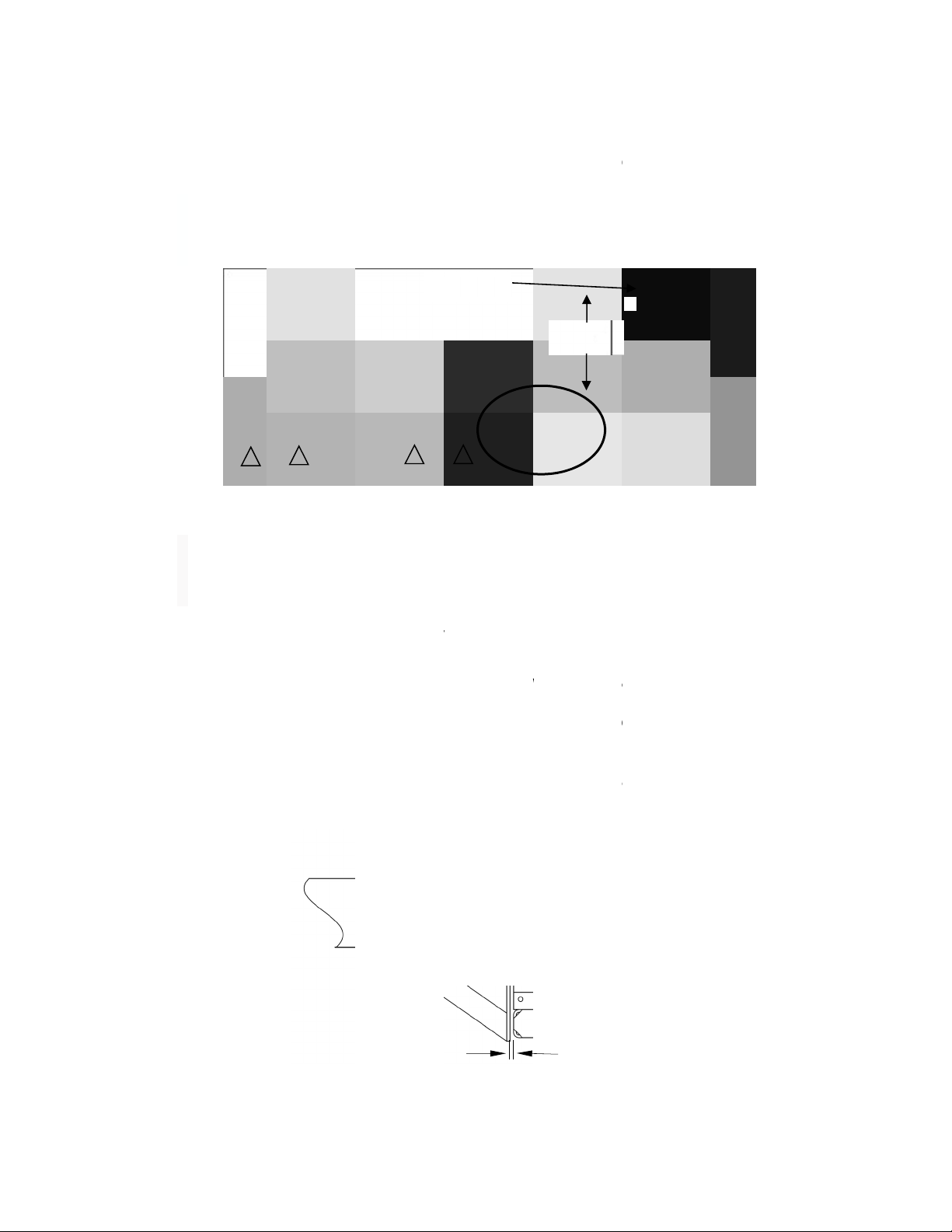

height of 3

6

p

er mountin

g

h

e system

u

e

adequate

r

ectly in fro

n

ring an imp

a

MPS 350

®

X

option for

y

a minimum

h

own in Fig

u

ts for the

M

”

(13 mm)

o

®

X Bumper

u

ck frame u

n

els to the

t

s

pring han

g

n

s regarding

P

1

/

2” [13

m

3

a

t the back

o

m

m /- 0 mm

]

6

-1/2” (927

m

g

height mu

s

u

nder appro

Figure 9

(4” minim

u

n

t of the Sh

e

a

ct. Failure

t

X

.

y

our applica

t

1/2” (13 m

m

u

re 10 belo

w

M

PS 350

®

X

o

f clearance

and the M

o

sing the “C

”

t

ruck

f

rame

g

er, followin

attachment

Figure 10

ivot Bolt

m

m]

o

f the truck.

]

(36” [+ 1/2

m

m) to the c

e

st be maint

a

priate state

u

m) clear a

r

e

ar Bars to

t

o follow thi

s

t

ion.

m

) Plate wel

w

. Mount T

a

X

Bumper.

between th

e

o

unting Plat

e

”

Channels

as fa

r

forw

a

n

g the truc

k

methods.

36”

915 mm

Revision

C

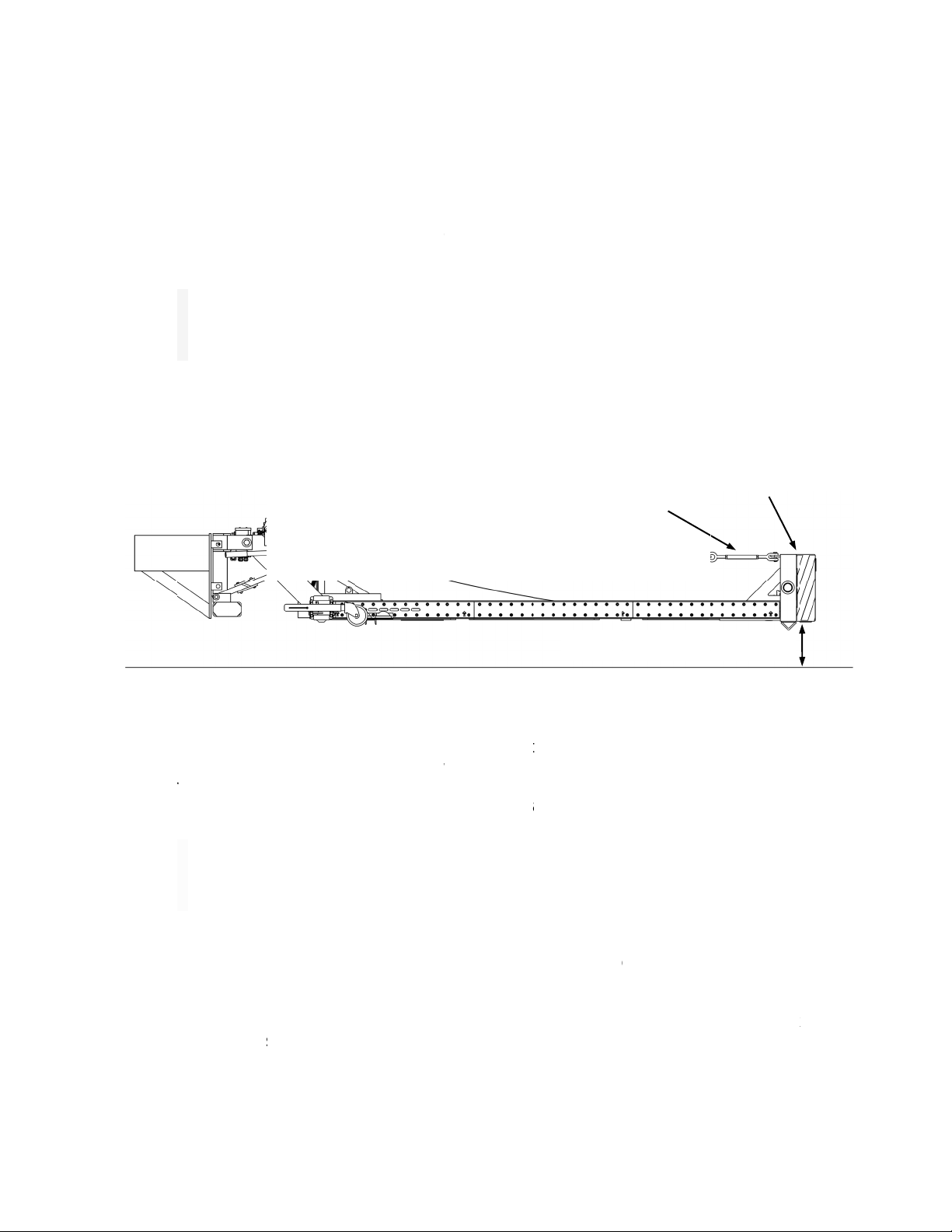

Use the Ja

c

” /- 0”]), (mi

enter of the

a

ined to ach

and federa

r

ea directly

ensure tha

t

s

warning wi

l

ded across

abs welded

The length

e Lower Bu

e

. The Mou

n

provided w

i

ard as pos

s

k

manufact

u

C

Decembe

r

c

ks to set t

h

nimum hei

g

Pivot Bolt.

ieve intend

e

l guidelines

behind the

t

the Shear

ll result in d

a

the back of

to the plat

e

of the Mo

u

mper Cross

n

ting Plate

s

i

th the MP

S

s

ible, but b

e

u

rer’s warn

i

2017

h

e correct

g

ht of 36”

e

d impact

during a

Bumper

Bars are

a

mage to

the truck

e

provide

u

nt Tabs

Member

s

hould be

S

350

®

X.

e

hind the

i

ngs and

www.trin

11.

A

T

t

o

p

12.

C

g

w

f

r

C

13.

P

W

(

s

P

t

h

S

o

ityhighway.

c

B. This

rails.

for t

h

Low

e

to th

e

C. Soc

k

Con

t

parti

c

Imp

o

A

WS

A

fter the M

P

T

urnbuckles.

o

330 mm) f

r

osition on t

h

C

onnect the

W

round cond

u

w

elding cabl

e

r

om the truc

C

ontrols. Tri

n

Caut

i

batte

r

truck

P

ush and h

o

W

inch Strap.

s

ee Figures

P

osition the

W

h

rough the

C

S

ecure by in

s

ut the ends

c

om

option invo

Welding o

n

h

e Lower B

u

e

r Bumper

C

e

truck fram

e

k

et Hitch Op

t

act Trinity

H

c

ular applic

a

o

rtant:

A

ll

w

D1.1. Disco

P

S 350

®

X i

The botto

m

r

om the gro

u

h

e TM

A

for l

a

W

inch by ro

u

ctors) fro

m

e

quick-dis

c

k and enab

l

n

ity Highwa

y

i

on:

For o

v

r

y should b

e

b

attery.

o

ld the DO

W

Un-spool t

h

12 and 1

3

W

inch Stra

p

C

ross Bar

T

s

erting the

C

of the cotte

r

1

lves weldin

g

n

the “C” Ch

a

u

mper Cros

C

ross Mem

b

e

rails.

t

ion (see p.

3

H

ighway to

a

tion (see p.

w

elding mu

s

nnect truck

s mounted

m

edge of th

e

u

nd (see Fi

g

a

ter use (se

e

uting two (2

)

m

the charg

e

c

onnect allo

w

l

es easy ro

u

y

can provid

e

v

e

r

-current

e

protected

w

W

N button o

h

e Winch S

t

3

). Remove

p

between t

h

T

abs and th

e

C

otter Pin i

n

r

pin.

4

g

the MPS

a

nnel supp

o

s Membe

r

.

b

er extendin

3

7 and 38).

discuss a

n

3).

s

t be perfor

m

battery prio

r

to the truc

k

e

Impact F

a

g

ure 12). Ro

e

Figure 2

o

Figure 11

)

2 AWG (m

e

d truck bat

w

s easy at

t

u

ting of the

c

e

optional C

a

protection,

t

w

ith a 200

a

n the unit's

t

rap until it i

s

the 1” (25

h

e two Cros

e

loop on t

h

n

to the hole

350

®

X Bu

m

o

rt(s) provid

e

Adequate

b

g forward a

n

y special

m

m

ed by a w

r

to welding.

k

, adjust th

e

a

ce should

m

tate or swiv

e

o

n p. 7).

ax 15’ in le

n

t

tery to the

t

achment a

n

c

ables. Co

n

able Kits in

t

he positive

a

mp fuse or

rocker swi

t

s

long enou

g

mm) diam

e

s Bar Tabs

.

h

e end of th

in the 1” (

2

Tur

n

11

”

Revision

C

m

per directl

e

s the requi

r

b

racing sho

u

a

s far as po

s

m

ounting r

e

elder certifi

e

e

Impact F

a

m

easure be

t

e

l Jacks int

o

n

gth) batter

y

back of the

n

d removal

n

firm operati

15’, 20’, or

2

cable lead

circuit bre

a

t

ch while h

o

gh to attac

h

e

ter Pin fro

.

Insert 1” (

2

e Winch St

r

2

5 mm) dia

m

n

Buckles

”

to 13" [280

t

C

Decembe

r

y to the tru

r

ed structur

a

u

ld be weld

e

s

sible for at

t

e

quirements

e

d by AWS

a

ce height

u

t

ween 11 to

o

storage (h

o

y

cables (po

s

truck. The

of the MP

S

on of the

W

2

5’ lengths.

coming off

a

ker within 1

o

lding the e

n

h

to the Cro

s

m the Win

c

2

5 mm) dia

m

r

ap (see ne

x

m

eter Pin a

n

Impact F

a

t

o 330 mm]

2017

ck frame

a

l support

e

d to the

t

achment

for your

D14.3 or

u

sing the

13” (280

o

rizontal)

s

itive and

use of a

S

350

®

X

W

inch and

the truck

8” of the

n

d of the

s

s Frame

c

h Strap.

m

eter Pin

x

t page).

n

d flaring

a

ce

www.trin

14.

A

f

a

15.

M

A

c

Wire Co

White

Brown

Green

Red

Yellow

Black

Blue

Note:

W

wrap o

v

Winch

S

ityhighway.

c

Caut

i

of the

A

ttach the

D

a

steners pr

o

M

ount the L

A

ssembly, a

n

h

art referen

c

l

o

r

Funct

i

Groun

d

Tail /

C

Right

H

Stop

L

Left H

a

Tail /

C

Not U

s

W

inch Stra

p

v

er the TOP

S

pool

c

om

i

on:

The

W

Winch Dru

m

D

urashell

®

N

o

vided as sh

o

ighting Jun

c

n

d on the l

o

c

es the wiri

n

i

on

d

C

learance,

a

H

and Turn

a

L

amp

a

nd Turn an

C

learance,

a

s

ed

p

MUST

of the

1

W

inch Strap

o

m

to ensure

N

ose and S

t

o

wn in dra

w

c

tion Box

o

o

wer chann

e

n

g color cod

e

a

nd ID Lamp

a

nd Hazard

d Hazard

a

nd ID Lamp

5

Figure 12

Figure 13

o

n the MPS

proper func

t

t

riping Ass

e

w

ing 620344

o

n the Low

e

e

l o

f

the I

m

e

and functi

o

s

s

350

®

X sh

o

t

ion of Winc

e

mbly on t

h

on page 35

.

e

r Bumper

m

pact Fenc

e

o

n for the c

o

(VIEW I

S

Revision

C

o

uld

A

LWA

Y

c

h (see Figu

r

h

e Impact

F

.

Cross Me

m

e

(see Figur

o

nnector wi

r

Figure 1

4

S

LOOKIN

G

Pull Winc

h

location sh

C

Decembe

r

Y

Swrap ov

e

r

e 12).

F

ence first

u

m

ber of the

e 14). The

r

ing.

4

G

AT PLUG)

h

Strap to

own here

2017

e

r the top

u

sing the

Bumper

following

www.trin

16.

M

r

o

17.

R

o

a

L

18.

W

t

h

L

p

ityhighway.

c

M

ount the L

i

o

uting instru

R

aise the M

P

v

er the Fra

m

nd secure t

h

imit Switch

w

W

ith the MP

S

h

e end (see

inchpin thro

lace. Repe

a

Linch

p

c

om

i

ghting Sys

t

ctions (see

p

P

S 350

®

X t

o

m

e Cross-m

h

e Frame C

w

ill activate

S

350

®

X in

Figure 16).

ugh the Ch

a

a

t this step f

o

p

in w/Clip

1

t

em on the

p

. 32, 33, a

n

o

the UP (v

e

ember on t

h

ross-memb

e

and the Wi

n

a

n UP (vert

i

Insert the

C

a

in Retaine

r

o

r the Chain

6

MPS 350

®

n

d 34).

e

rtical) posi

t

h

e Frame A

s

er

(see Figu

n

ch will auto

m

Figure 15

i

cal) positio

n

C

hain betwe

e

r

Tabs and

C

on the oth

e

Figure 16

X. Use dr

a

t

ion until th

e

s

sembly. T

h

re 15). Wh

e

m

atically po

n

, remove t

h

e

n the Chai

n

C

hain. Lock

e

r side of th

e

Revision

C

a

wing 6201

3

e

Latch Bar

A

h

e Latch Ba

e

n the unit i

s

we

r

down.

h

e Linchpin

a

n

Retainer

T

the Clip on

e

system.

Frame C

La

C

Decembe

r

3

9 for mou

n

A

rms drop i

n

r Arms mus

s

secured, t

h

a

nd open th

T

abs. Next, i

the end to

s

ross Memb

e

tch Bar Ar

m

2017

n

ting and

n

to place

t engage

h

e Upper

e Clip on

nsert the

s

ecure in

er

m

s

www.trin

Oper

a

Before

o

safety s

e

The MP

S

raise the

possible

The driv

e

When th

e

lowered

not be s

o

While ra

i

side of t

h

allow an

y

The co

n

located i

n

of the sy

side of t

h

Note:

M

Raisin

When o

p

Raisin

g

There is

up, pres

s

ityhighway.

c

a

tion G

u

o

perating th

e

e

ction of this

S

350

®

X s

y

TMA up fr

o

scraping of

e

r simply ac

e

operato

r

r

e

back to the

o

lely suppor

t

Imp

o

Imp

o

(horiz

atten

u

i

sing or low

e

h

e truck an

d

y

one to sta

n

n

trols can

b

n

the truck

c

stem. To c

h

h

e TMA Fra

m

M

ove contr

o

g and L

o

Caut

i

Unde

r

being

p

erating fro

m

g

the Syst

e

one UP (ve

r

s

and hold t

h

Dan

g

MPS

Failu

r

in ser

Caut

i

syste

m

the R

e

c

om

u

ideline

s

e

MPS 35

0

Manual. V

e

y

stem has b

e

o

m its DOW

N

the rear en

d

tivates the

U

e

moves his

horizontal

p

t

ed by the

W

o

rtant:

A

n

a

o

rtant:

In

a

ontal) posi

t

u

ato

r

when

t

e

ring the T

M

d

remain a

w

d under the

b

e located

o

c

ab. The co

n

h

ange the m

o

m

e.

o

l switch a

n

o

wering t

h

i

on:

Make

r

no circum

raised or lo

w

m

the cab, al

w

m

r

tical) positi

o

h

e UP switc

h

g

er:

Know

t

350

®

X und

r

e to follow t

h

ious person

a

i

on:

If so

m

m

is to be s

t

e

taining Ch

a

1

s

0

®

X, thoro

u

e

rify that the

e

en equipp

e

N

(horizont

a

d

of the sys

t

U

P button fr

o

finger from

p

osition by p

W

inch Strap

f

a

larm will s

o

a

work zone

,

t

ion whene

v

t

he system i

s

M

A from out

w

are of traffi

TM

A

when

o

n either s

i

n

trols on th

e

o

unting pos

i

n

d release l

e

h

e Syste

m

sure the to

p

stances sh

o

w

ered.

w

ays be aw

o

n switch o

n

h

until the s

y

t

he overhea

er any over

h

h

is warning

a

l injury or

d

m

eone will b

e

t

ored in the

U

a

in as show

n

7

u

ghly read

a

system is p

e

d with an

E

a

l) position.

T

t

em as the

t

o

m inside t

h

the button,

ressing the

f

or extende

d

und if the T

M

,

the truck s

v

er possibl

e

s

in the DO

W

s

ide the ca

b

c condition

s

it is in the r

a

i

de of the

T

e

TMA Fram

i

tion, the s

w

e

ver on MP

S

m

p

of the syst

o

uld anyon

e

are of obje

c

n

each set o

f

y

stem reach

e

d clearance

h

ead obstr

u

could caus

e

d

eath.

e

doing mai

n

U

P (vertical

)

n

in Figure 1

a

nd unders

t

roperly ass

e

E

lectric Hoi

s

T