Trinix TX6000 Series Installation manual

Operation Manual

LCR Meter

(TX6000 Series)

DAE KWANG T&M CO.,LTD

http://www.kdk.co.kr

TEL :02)2617-0787

TX6000 Series Operation Manual Ver1.4

I

Contents

Chapter 1 Out of Box Audit.......................................................................................... 1

1.1 To Inspect the package................................................................................ 1

1.2 Power connection ....................................................................................... 1

1.3 Fuse ............................................................................................................. 1

1.4 Environment................................................................................................ 2

1.5 Use of Test Fixture....................................................................................... 2

1.6 Warm-up ..................................................................................................... 2

1.7 Other features............................................................................................. 3

Chapter 2 Introduction ................................................................................................ 4

2.1 Introduction to front panel ......................................................................... 4

2.2 Introduction to rear panel........................................................................... 6

2.3 Introduction to display zone ....................................................................... 7

2.4 Main menu keys and corresponding displayed pages ................................ 8

2.4.1 [DISP]............................................................................................. 8

2.4.2 [SETUP].......................................................................................... 8

2.4.3 [SYSTEM SETUP]............................................................................ 9

2.5 Basic Operation ........................................................................................... 9

2.6 Start the instrument.................................................................................... 9

Chapter 3 Introduction to [DISP] ............................................................................... 10

3.1 <MEAS DISPLAY> ....................................................................................... 10

3.1.1 Test function................................................................................ 10

3.1.2 Test range .................................................................................... 13

3.1.3 Test frequency............................................................................. 14

3.1.4 Test level...................................................................................... 15

3.1.5 DC BIAS........................................................................................ 16

3.1.6 Test speed.................................................................................... 16

3.1.7 Tools ............................................................................................ 17

3.2 <BIN NO. DISP> ......................................................................................... 17

3.2.1 Comparator function................................................................... 18

3.3 <BIN COUNT DISP>.................................................................................... 19

3.3.1 PARAM......................................................................................... 19

3.3.2 NOM............................................................................................ 20

3.3.3 BIN............................................................................................... 20

3.3.4 HIGH/LOW................................................................................... 20

3.3.5 COUNT......................................................................................... 20

3.3.6 AUX.............................................................................................. 20

3.3.7 OUT ............................................................................................. 20

3.4 <LIST SWEEP DISP>.................................................................................... 21

3.4.1 Sweep mode................................................................................ 21

3.4.2 FREQ (Hz)..................................................................................... 22

3.4.3 R[:] X[:] ........................................................................................ 22

3.4.4 CMP (Compare)........................................................................... 22

TX6000 Series Operation Manual Ver1.4

II

3.5 <MEASURE SETUP> ................................................................................... 22

3.5.1 Trigger mode ............................................................................... 23

3.5.2 Auto level control function ......................................................... 24

3.5.3 Output impedance ...................................................................... 25

3.5.4 Average ....................................................................................... 25

3.5.5 Voltage/Current Level Monitor function .................................... 25

3.5.6 DCR polarity ................................................................................ 26

3.5.7 Trigger Delay ............................................................................... 26

3.5.8 Step delay.................................................................................... 26

3.5.9 DC resistance range..................................................................... 27

3.5.10 DC level ....................................................................................... 27

3.5.11 Deviation test function................................................................ 27

3.6 <CORRECTION> ......................................................................................... 28

3.6.1 OPEN ........................................................................................... 30

3.6.2 SHORT ......................................................................................... 31

3.6.3 LOAD............................................................................................ 32

3.6.4 Load correction test function...................................................... 34

3.6.5 Cable length selection................................................................. 34

3.7 <LIMIT TABLE>........................................................................................... 34

3.7.1 Swap parameter.......................................................................... 35

3.7.2 Limit modes of compare function............................................... 35

3.7.3 Set nominal value of tolerance mode......................................... 37

3.7.4 Comparator function ON/OFF..................................................... 37

3.7.5 Auxiliary bin ON/OFF .................................................................. 37

3.7.6 HIGH/LOW................................................................................... 38

3.8 <LIST SWEEP SETUP>................................................................................. 39

3.8.1 MODE .......................................................................................... 40

3.8.2 Test parameter ............................................................................ 40

3.8.3 Sweep parameter setup.............................................................. 40

3.9 TOOLS ........................................................................................................ 41

3.9.1 CORR DATA .................................................................................. 41

Chapter 4 [SYSTEM] and <FILE MANAGE>................................................................. 42

4.1 <SYSTEM SETUP> ...................................................................................... 42

4.1.1 MAIN FUNC ................................................................................. 42

This item is reserved function.......................................................................... 42

4.1.2 PASS BEEP.................................................................................... 42

4.1.3 FAIL BEEP..................................................................................... 43

4.1.4 LANGUAGE .................................................................................. 43

4.1.5 PASS WORD ................................................................................. 43

4.1.6 BUS MODE................................................................................... 44

4.1.7 GPIB ADDR (Reserved function).................................................. 44

4.1.8 TALK ONLY ................................................................................... 44

4.1.9 BIAS SRC ...................................................................................... 45

4.1.10 BAUD RATE .................................................................................. 45

TX6000 Series Operation Manual Ver1.4

III

4.1.11 MENU DISP.................................................................................. 45

4.1.12 DATA/TIME .................................................................................. 46

4.2 LCR <FILE MANAGE> ................................................................................. 46

4.2.1 Setup file for single-group component (*.STA)........................... 46

4.2.2 U-disk manage performance....................................................... 47

4.2.3 Operation steps for file management......................................... 48

Chapter 5 Execute LCR operation and some examples ............................................. 50

5.1 Correction operation................................................................................. 50

5.1.1 Sweep correction ........................................................................ 50

5.1.2 Point-frequency correction ......................................................... 50

5.2 Correct connection of DUT ....................................................................... 51

5.3 Eliminate the influence of stray impedance ............................................. 52

5.4 Operation example for testing inductance with TX6000 .......................... 53

5.5 Operation example of testing capacitance by multi-frequency list sweep55

5.6 Setup example of comparator................................................................... 57

5.6.1 Capacitor sorting......................................................................... 57

5.6.2 Operation example of load correction........................................ 58

Chapter 6 Performance and Test ............................................................................... 60

6.1 Test function.............................................................................................. 60

6.1.1 Parameter and symbol ................................................................ 60

6.1.2 Equivalent mode ......................................................................... 60

6.1.3 Range .......................................................................................... 60

6.1.4 Trigger ......................................................................................... 60

6.1.5 Delay time ................................................................................... 61

6.1.6 Connection modes of test terminals........................................... 61

6.1.7 Test speed (Frequency>=10kHz) ................................................. 61

6.1.8 Average ....................................................................................... 61

6.1.9 Display digit................................................................................. 61

6.1.10 Test signal frequency................................................................... 61

6.1.11 Signal mode................................................................................. 61

6.1.12 Test signal level ........................................................................... 62

6.1.13 Output impedance ...................................................................... 62

6.1.14 Monitor for test signal level ........................................................ 62

6.1.15 Maximum measurement display range ...................................... 62

6.1.16 DC bias voltage source ................................................................ 63

6.1.17 Accuracies of │Z│,│Y│, L, C, R, X, G, B ................................ 63

6.1.18 Accuracy of D .............................................................................. 63

6.1.19 Accuracy of Q .............................................................................. 64

6.1.20 Accuracy of θ............................................................................... 64

6.1.21 Accuracy of G .............................................................................. 64

6.1.22 Accuracy of Rp............................................................................. 64

6.1.23 The accuracy of Rs....................................................................... 65

6.1.24 Accuracy factor............................................................................ 65

6.1.25 Accuracy of DCR .......................................................................... 68

TX6000 Series Operation Manual Ver1.4

IV

6.1.26 Accuracy of leakage inductance Lk ............................................. 68

6.2 Safety requirement ................................................................................... 69

6.2.1 Insulation resistance ................................................................... 69

6.2.2 Insulation intensity...................................................................... 69

6.2.3 Leakage current........................................................................... 69

6.3 Electromagnetic compatibility .................................................................. 69

6.4 Performance test....................................................................................... 69

6.4.1 Working condition....................................................................... 69

6.4.2 The used instruments and devices.............................................. 69

6.4.3 Function check ............................................................................ 70

6.4.4 Test signal level ........................................................................... 70

6.4.5 Frequency.................................................................................... 71

6.4.6 Measurement accuracy............................................................... 71

6.4.7 Accuracy of C and D .................................................................... 71

6.4.8 Accuracy of L ............................................................................... 71

6.4.9 Accuracy of Z ............................................................................... 71

6.4.10 Accuracy of DCR .......................................................................... 72

Chapter 7 Command Reference................................................................................. 73

7.1 Subsystem commands for TX6000............................................................ 73

7.1.1 DISPlay subsystem commands.................................................... 73

7.1.2 FREQuency subsystem commands.............................................. 75

7.1.3 VOLTage subsystem commands .................................................. 75

7.1.4 CURRent subsystem commands ................................................. 76

7.1.5 AMPLitude subsystem commands.............................................. 76

7.1.6 Output RESister subsystem commands ...................................... 77

7.1.7 BIAS subsystem commands......................................................... 77

7.1.8 FUNCtion subsystem commands ................................................ 79

7.1.9 LIST subsystem commands ......................................................... 83

7.1.10 APERture subsystem commands................................................. 87

7.1.11 TRIGger subsystem commands................................................... 87

7.1.12 FETCh? subsystem commands .................................................... 88

7.1.13 CORRection subsystem commands............................................. 91

7.1.14 COMParator subsystem commands............................................ 97

7.1.15 DCR subsystem commands ....................................................... 102

7.1.16 Mass MEMory subsystem commands ...................................... 104

7.2 GPIB Common Commands...................................................................... 104

Chapter 8 The description for Handler (optional) ................................................... 108

8.1 Technical description............................................................................... 108

8.2 The operation description....................................................................... 108

8.2.1 The definition for the signal line............................................... 108

8.2.2 Electrical feature ....................................................................... 116

8.2.3 HANDLER Interface board circuit .............................................. 117

8.2.4 Operation .................................................................................. 120

TX6000 Series Operation Manual Ver1.4

V

Ver@1.4------------------------------------------------------------2016/04/27

Announcement

The description of the manual may not cover all contents of the instrument, and

our company is subject to change and to improve the performance, function,

inner structure, appearance, accessory and package of the instrument without

notice. If there is puzzle caused by inconsistency of manual and instrument, then

you can contact with our company by the address on the cover.

TX6000 Series Operation Manual Ver1.4

1

Chapter 1 Out of Box Audit

When you receive the instrument, some inspections are necessary, and the

condition must be understood and available before installing the instrument.

1.1 To Inspect the package

Inspect the shipping container for damage after unpacking it. It is not

recommended to power on the instrument in the case of a damaged container.

If the contents in the container do not conform to the packing list, notify us or

your dealer.

1.2 Power connection

1) Power-supplying voltage range: 198~242Vac.

2) Power-supplying frequency range: 47~63Hz.

3) Power-supplying power range: not less than 80VA.

4) Power supplying input phase line L, zero line N, ground lead E should be as

same as the power plug of the instrument.

5) After careful design, the instrument can reduce the clutter jamming caused

by AC power terminal input, however, it should be used under the

environment with low-noise. Please install power filter if being unavoidable.

———————————————————————————————————————

Warning: In order to prevent user and instrument from being hurt by

leakage, it is necessary for user to guarantee the ground line of supply

power being reliably grounded.

———————————————————————————————————————

1.3 Fuse

The instrument has installed fuse, so operators should use the installed fuse of

our company.

———————————————————————————————————————

Warning: Be sure that the location of fuse is consistent with

power-supplying voltage range before charging.

———————————————————————————————————————

TX6000 Series Operation Manual Ver1.4

2

1.4 Environment

1) Please do not operate the instrument in the place that is vibrative, dusty,

under direct sunlight or where there is corrosive air.

2) The normal working temperature is 0℃~40℃, relative humidity ≤75%, so

the instrument should be used under above condition to guarantee the

accuracy.

3) There is heat abstractor on the rear panel to avoid the inner temperature

rising. In order to keep good airiness, please don’t obstruct the left and right

airiness holes to make the instrument maintain the accuracy.

4) Although the instrument has been specially designed for reducing the noise

caused by ac power, a place with low noise is still recommended. If this

cannot be arranged, please make sure to use power filter for the instrument.

5) Please store the instrument in the place where temperature is between 5℃

and 40℃, humidity is less than 85%RH. If the instrument will not be put in

use for a time, please have it properly packed with its original box or a similar

box for storing.

6) The instrument, especially the test cable should be far from strong

electro-magnetic field, to avoid the jamming on measurement.

1.5 Use of Test Fixture

Please use the accessory test fixture or cable, the test fixture made by user or

from other company may cause the incorrect measurement result. The

test fixture or cable should be kept clean, as well as the pin of DUT, thus to

guarantee the good connection between DUT and fixture.

Connect the fixture or cable to four test terminals Hcur, Hpot, Lcur, Lpot on the

front panel. As for the DUT with shielding shell, connect shielding layer or ground

“┴”.

Note: When test fixture or cable has not being installed, the instrument will

display an unstable test result.

1.6 Warm-up

1) To guarantee the accurate measurement, the warm-up time is no less than

15min.

2) Please not turn on or off instrument frequently, in order to avoid the inner

data fluster.

TX6000 Series Operation Manual Ver1.4

3

1.7 Other features

1) Power: consumption power≤80VA.

2) Dimension (W*H*D): 235mm*105mm*360mm

3) Weight: About 3.6 kg.

TX6000 Series Operation Manual Ver1.4

4

Chapter 2 Introduction

In this chapter, the basic operation features of TX6000 series are described.

Please read the content carefully before using TX6000 series instruments, thus

you can learn the operation of TX6000 series.

2.1 Introduction to front panel

Figure 2-1 shows the front panel of TX6000.

Figure 2-1 Front panel

1) Brand and model

Brand and model.

2) [DISP]

Press this key to enter into the corresponding measurement display page of

instrument functions.

3) [SETUP]

Press this key to enter into the corresponding measurement setup page of

instrument functions.

4) CURSOR

This key is used to move the cursor on the LCD displayed page. When the

cursor moves to a zone, the corresponding zone will be lightened.

5) Numerical keys

These keys are used to input data to the instrument. The key consists of

TX6000 Series Operation Manual Ver1.4

5

numerical keys [0] to [9], decimal point [.] and [+/-] key.

(NOTE: long press [.] key is equivalent to copying screen function)

6) [KEYLOCK]

Press [KEYLOCK], it will be lighted, which means the function of current panel

is locked. Press it again, it will be off, which means discharging the lock status.

If the password function is ON, it means correct password is necessary when

discharging the key-lock, or the key cannot be unlocked.

When the instrument is controlled by RS232, [KEYLOCK] will be lighted. Press

[KEYLOCK] again, it will be off, which means returning to the local

discharging lock status.

7) [BIAS]

[BIAS] is used to permit or forbid the output of 0-50mA/5V DC bias source.

Press this key, it will be lighted which means DC bias output is permitted.

Press this key once more, it will be off which means DC bias output is

prohibited. The key is useless in some pages where the DC BIAS cannot be

added. (No this function in TX6000 series). When the FUNC is set as DCR,

Lp-Rd, Ls-Rd, this function is invalid.

8) PASS/FAIL indicator

PASS LED indicator shows the test result has passed.

FAIL LED indicator shows the test result has failed.

9) USB HOST interface

Connect U flash disk so as to save or load the file.

10) [RESET]

Press this key to stop scanning only in transformer automatic scanning. No

operation will be executed on other pages.

11) [TRIGGER]

When the trigger mode is set to MAN mode, press this key to trigger the

instrument.

12) Test terminals (UNKNOWN)

4-teminal test pair is used to connect 4-terminal test fixture or cable to

measure DUT.

The 4 terminals are respectively as follows: Hcur, Hpot, Lpot and Lcur.

13) LCD

480*272 colorful TFT LCD displays measurement results and conditions.

14) Soft keys

TX6000 Series Operation Manual Ver1.4

6

Five soft keys are used to select parameters. The corresponding function of

each soft key has been displayed above. The function definition varies with

different pages.

15) POWER

Power switch

2.2 Introduction to rear panel

Figure 2-2 shows the rear panel of TX6000 series.

RS-232C

DEVICETRIGGER

GPIB HANDLER

!

TO AVOID ELECTRIC SHOCK,

THE POWER CORD PROTECTIVE GROUNDING

CONDUCTOR MUST BE CONNECTED TO GROUND.

DISCONNECT POWER SUPPLY BEFORE

REPLACING FUSE.

WARNING

FUSE

220V/50Hz 80VA T2AL 250V

~

RATING

贴标签

1 2

5 4 3

67

8

Figure 2-2 Rear panel

1) IEEE-488 (GPIB) interface

The tester can communicate with PC through GPIB interface.

2) HANDLER interface

Handler interface is used to realize the sorting output of test results.

3) RS232C interface

Series communication interface can realize the communication with PC.

4) USB DEVICE interface

The tester can communicate with PC through the USB DEVICE interface.

5) TRIGGER interface

The tester can communicate with foot control and other external trigger

devices.

TX6000 Series Operation Manual Ver1.4

7

6) Power socket

Input AC power.

7) Ground terminal

The ground terminal is connected with instrument casing, being available for

protecting or shielding ground connection.

8) Nameplate

Information about production date, instrument number and manufacturer

etc..

———————————————————————————————————————

Warning: Be sure that the direction of fuse is accordant with

power-supply voltage range before charging.

———————————————————————————————————————

2.3 Introduction to display zone

TX6000 series applies a 65k, 4.3-inch TFT display. The display screen is divided

into the following zones:

1

2 3

Figure 2-3 display zones

1) Display page name

Indicate the name of the currently displayed page.

2) Soft keys

The zone is used to display the function definition of soft key. The definition of

TX6000 Series Operation Manual Ver1.4

8

soft key can be different as the difference of cursor’s direction in the zone.

3) Test result/ condition display zone

In this zone, test result information and current condition are displayed.

2.4 Main menu keys and corresponding displayed

pages

2.4.1[DISP]

When the LCR function is active, press this key-[DISP]to enter into the LCR

measurement display page, the following soft keys will be displayed in the soft

key zone.

<MEAS DISPLAY>

<BIN NO.>

<BIN COUNT>

<LIST SWEEP>

MORE

1/2

<FILE MANAGE>

<SAVE LOG>

MORE

2/2

-

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

-

N

N

NO

O

OT

T

TE

E

E:

:

:

< SAVE LOG> key is valid in <MEAS DISPLAY> and <LIST SWEEP>

interface. Press < SAVE LOG > after inserting the USB disk, the state

changes to ON and the test data will be saved in .CSV format to the CSV

directory in U disk. Press < SAVE LOG> again, the state changes to OFF

and data storage is finished.

-

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

--

-

-

The instrument will automatically record the test data after inserting the

USB disk in MEAS interface.

2.4.2 [SETUP]

When the LCR function is active, press this key-[SETUP], the following soft keys

will be displayed in the soft key zone on the LCR measurement setup page.

<MEAS SETUP>

<CORRECTION>

<LIMIT TABLE>

<LIST SETUP>

MORE

1/2

TX6000 Series Operation Manual Ver1.4

9

<FILE MANAGE>

<SYSTEM SETUP>

MORE

2/2

2.4.3[SYSTEM SETUP]

This key-[SYSTEM SETUP]is used to enter into the system setup page. The

following soft keys will be available:

<SYSTEM SETUP>

<MEAS SETUP>

<DEFAULT SETTING>

<SYSTEM RESET>

2.5 Basic Operation

Basic operation of TX6000 series is as follows:

Use menu keys ([DISP], [SETUP]) and soft keys to select the desired page.

Use cursor keys ([←][→] [↑] [↓]) to move the cursor to the desired zone.

When the cursor moves to a specified zone, the zone will become reverse

expression.

The soft key functions corresponding to the current zone of the cursor will be

displayed in the soft key zone. Users can select and use the desired key.

Numeric keys, [←] and [ENTER] are used to input data.

When a numeric key is pressed down, the usable unit soft key will be

displayed in the soft key zone. You can choose a unit soft key or press [ENTER]

to end data inputting.

2.6 Start the instrument

Plug in 3-line power plug.

Caution: Keep the power-supply voltage and frequency conform to above

specifications. Power input phase line L, zero line N, ground line E should be the

same as that of the instrument.

Press the power switch at the left corner on the front panel and then a boot screen

will appear which displays our company logo, instrument model, and the version

number of the software.

TX6000 Series Operation Manual Ver1.4

10

Chapter 3 Introduction to [DISP]

3.1 <MEAS DISPLAY>

When the LCR function is applied, press [DISP], the <MEAS DISPLAY> page will

be displayed on screen as shown in the following figure.

On this page, the test result is displayed in upper-case character. The

measurement control parameters can be set on this page:

Test function (FUNC)

Test frequency (FREQ)

Test level (LEVEL)

Test range (RANGE)

DC BIAS (BIAS)

Test speed (SPEED)

There are 6 zones in this page: FUNC, FREQ, LEVEL, RANG, BIAS and SPEED.

The details will be discussed later.

The test result/ condition display zone shows the information about test condition.

These conditions can be set on <MEAS SETUP> page or <CORRECTION> page.

Signal source voltage/ current monitor (Vm, Im)

Open, short, load correction ON/OFF status (CORR)

3.1.1Test function

In a measurement period, TX6000 series can test two parameters for an

impedance component: one primary parameter and one secondary parameter.

Parameters that can be tested are as follows:

TX6000 Series Operation Manual Ver1.4

11

Primary parameters

|Z| (Module of impedance)

|Y| (Module of admittance)

L (Inductance)

C (Capacitance)

R (Resistance)

G (Conductance)

DCR (DC resistance)

Secondary Parameters

D (Dissipation factor)

Q (Quality factor)

Rs(Equivalent Series Resistance ESR)

Rp(Equivalent Parallel Resistance)

Rd (DC resistance)

X (Reactance)

B (Susceptance)

θ (Phase Angle)

Test results of primary and secondary parameters are respectively displayed in

two lines in the form of upper-case characters. The primary parameter displays in

the upper line while the secondary parameter displays in the lower line.

Operation steps for setting test function:

1) Move the cursor to FUNC zone, the following soft keys will be displayed on the

screen.

Cp—…→

Cs—…→

Lp—…→

Ls—…→

MORE→

1/3

2) Press the soft key corresponding to Cp—…→, the following parameters will be

shown for your choice.

Cp-D

Cp-Q

Cp-G

Cp-Rp

RETURN←

Press the soft key corresponding to your desired parameter. Then press

RETURN←to return to upper soft key menu.

3) Press Cs—…→, the following parameters will be shown for your choice.

Cs-D

Cs-Q

TX6000 Series Operation Manual Ver1.4

12

Cs-Rs

RETURN←

Press the soft key corresponding to your desired parameter. Then press

RETURN←to return to upper soft key menu.

4) Press Lp—…→, the following parameters will be shown for your choice.

Lp-Q

Lp-Rp

Lp-Rd

MORE→

1/2

RETURN←

Press the soft key corresponding to your desired parameter. Then press

RETURN←to return to upper soft key menu.

5) Press MORE→,the following parameters will be shown for your choice.

Lp-D

Lp-G

MORE→

2/2

RETURN←

Press the soft key corresponding to your desired parameter. Then press

RETURN←to return to upper soft key menu.

6) Press Ls—…→, the following parameters will be shown for your choice.

Ls-D

Ls-Q

Ls-Rs

Ls-Rd

RETURN←

Press the soft key corresponding to your desired parameter. Then press

RETURN←to return to upper soft key menu.

7) Press MORE→, the following parameters will be shown for your choice.

Z—…→

Y—…→

R—…→

G-B

MORE→

2/3

8) Press Z—…→, the following parameters will be shown for your choice.

Z-d

Z-r

TX6000 Series Operation Manual Ver1.4

13

RETURN←

Press the soft key corresponding to your desired parameter. Then press

RETURN←to return to upper soft key menu.

9) Press Y—…→, the following parameters will be shown for your choice.

Y-d

Y-r

RETURN←

Press the soft key corresponding to your desired parameter. Then press

RETURN←to return to upper soft key menu.

10) Press R—…→, the following parameters will be shown for your choice.

R-X

Rp-Q

Rs-Q

RETURN←

Press the soft key corresponding to your desired parameter. Then press

RETURN←to return to upper soft key menu.

11) Press MORE→, the following parameters will be shown for your choice.

DCR

MORE→

3/3

Press DCR, choose the desired parameter. Then press MORE→to return to the

first page of soft key menu.

3.1.2Test range

Measurement range should be selected in accordance with the impedance value

of the tested LCR component.

TX6000 has 10 AC measurement ranges: 3Ω, 10Ω, 30Ω, 100Ω, 300Ω, 1kΩ, 3kΩ,

10kΩ, 30kΩ, 100kΩ.

TX6000 has 11 DCR measurement ranges: 1Ω, 3Ω, 10Ω, 30Ω, 100Ω, 300Ω, 1kΩ,

3kΩ, 10kΩ, 30kΩ, 100kΩ.

Operation steps for setting test range:

1) Move the cursor to the RANGE zone, the following soft keys will be displayed:

AUTO The soft key is used to set the range mode to AUTO.

HOLD The soft key is used to switch the AUTO mode to the HOLD mode.

When the range mode is set to HOLD, the range will be locked in the

current measurement range. The current measurement range will be

displayed in the range zone.

DECR- The soft key is used to decrease the range under HOLD mode.

TX6000 Series Operation Manual Ver1.4

14

INCR-The soft key is used to increase the range under HOLD mode.

2) Use soft keys to set measurement range.

3.1.3Test frequency

The measurement range of TX6000 ranges from 20Hz to 200kHz with an increase

or decrease of 0.01Hz. When the test function is set as DCR, the FREQ zone will

display “---”.

Model

Frequency range

Points

TX6100

50Hz-100kHz

34

TX6200

50Hz-200kHz

37

Operation steps for setting test frequency:

TX6000 provides two methods to set measurement frequency. The first one is to

use soft keys and the other one is to input data by using numeric keys.

1) Move the cursor to the FREQ zone, the following soft keys will be displayed.

INCR(++)

This is a coarse adjustment soft key used to increase the frequency. Press

this key, the frequency will change between the following six typical

frequencies.

Model Frequency point

TX6000 50Hz,100Hz,kHz,5kHz,100kHz,100kHz

TX6200 50Hz,100Hz,1kHz,10kHz,100kHz,200kHz

TX6201 20Hz,100Hz,1kHz,10kHz,100kHz,200kHz

INCR(+)

This is a fine adjustment soft key used to increase the frequency. Press

this key, the frequency will switch between the following ones:

20Hz 25Hz 30Hz 40Hz 50Hz 60Hz 75Hz

100Hz 120Hz 150Hz 200Hz 250Hz 300Hz 400Hz 500Hz

600Hz 750Hz 1 kHz 1.2kHz 1.5kHz 2kHz 2.5kHz 3kHz 4kHz

5kHz 6kHz 7.5kHz 10kHz 12kHz 15kHz 20kHz 25kHz 30kHz

40kHz 50kHz 60kHz 75kHz 100kHz 120kHz 150kHz 200kHz

NOTE: according to the different frequency range, the minimum

and maximum frequency of TX6000 SERIES is different.

DECR(-)

This is a fine adjustment soft key used to decrease the frequency. The

selectable frequencies are the same as that of INCR(+).

DECR(--)

This is a coarse adjustment soft key used to decrease the frequency. The

selectable frequencies are the same as that of INCR(++).

Table of contents

Other Trinix Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Vermason

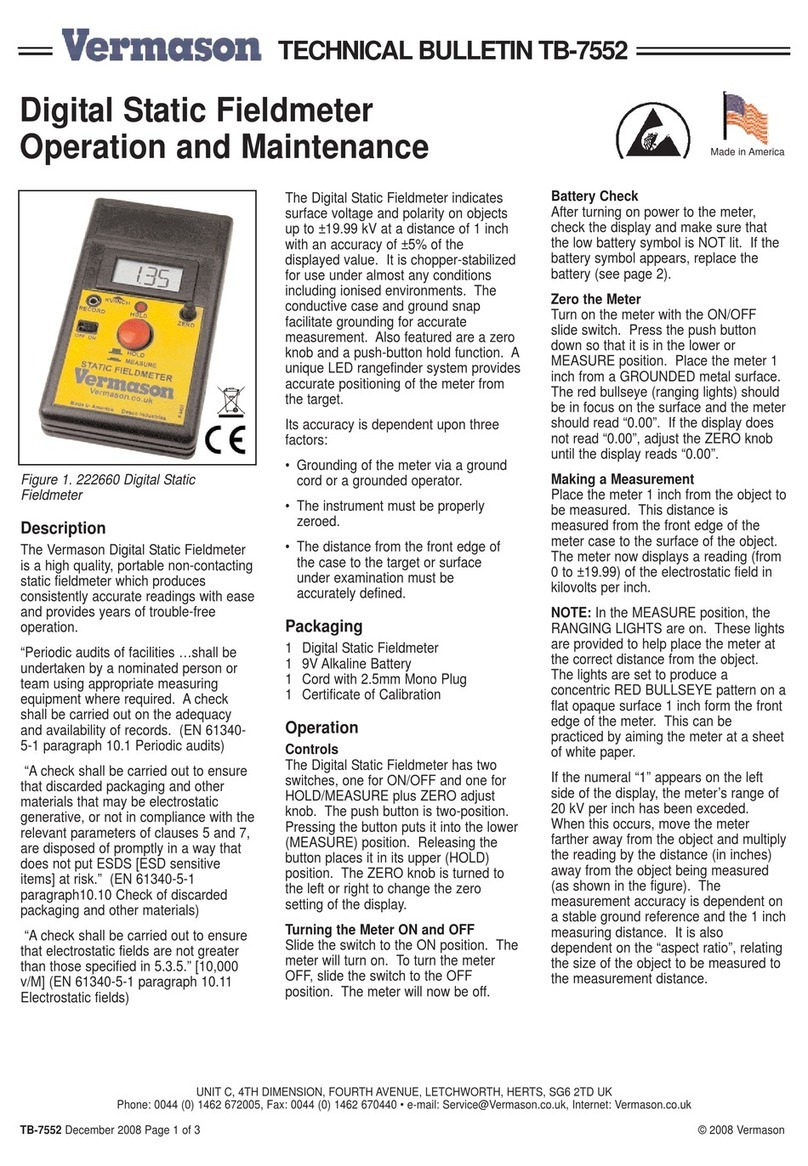

Vermason 222660 Operation and maintenance manual

RigExpert

RigExpert AA-2000 ZOOM user manual

Union Instruments

Union Instruments INCA6002 Translation of the original operating instructions

Flexitron

Flexitron MTX-StarSensor user guide

VWR

VWR MCT 100 instruction manual

SUKU

SUKU 3319 operating manual