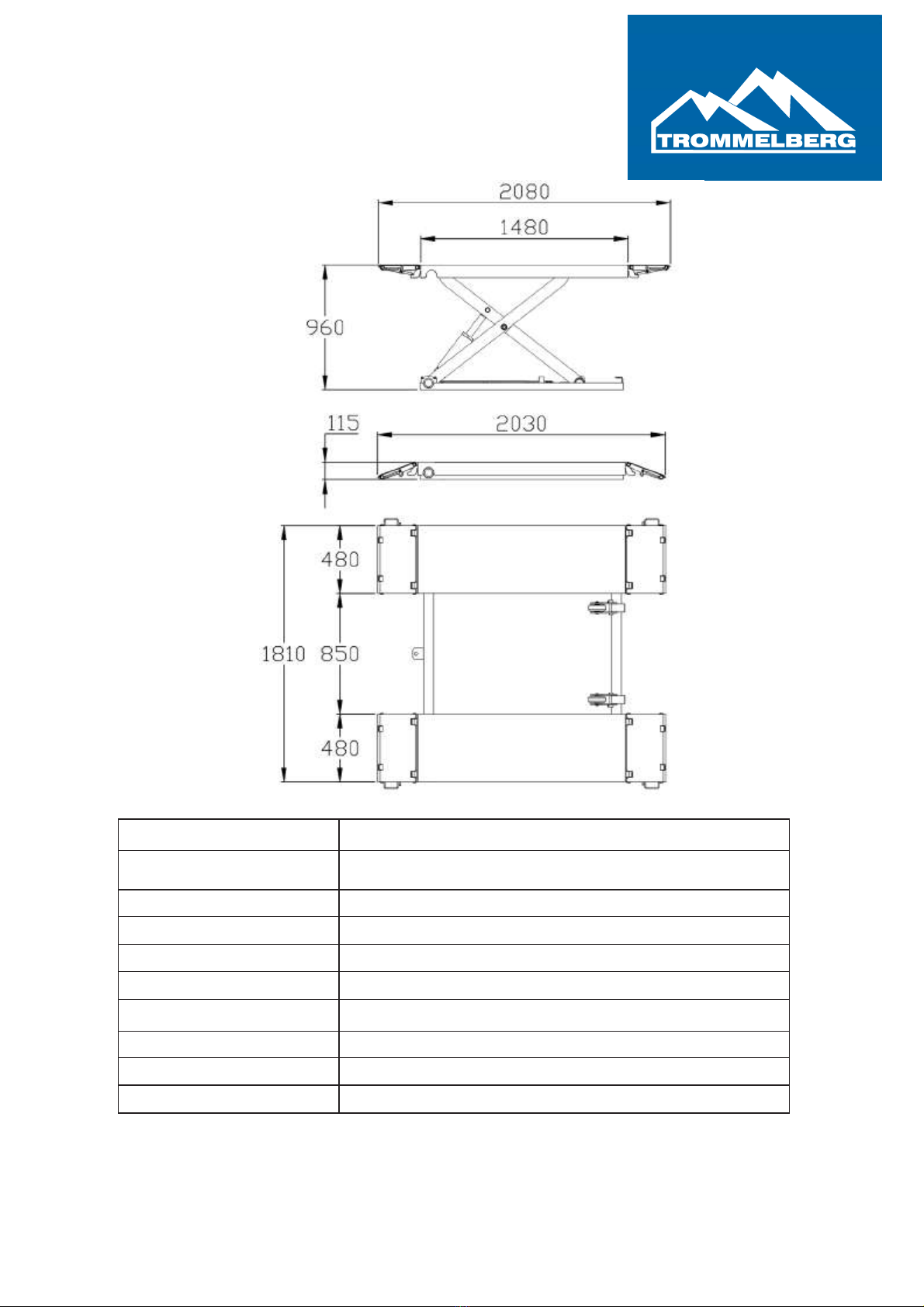

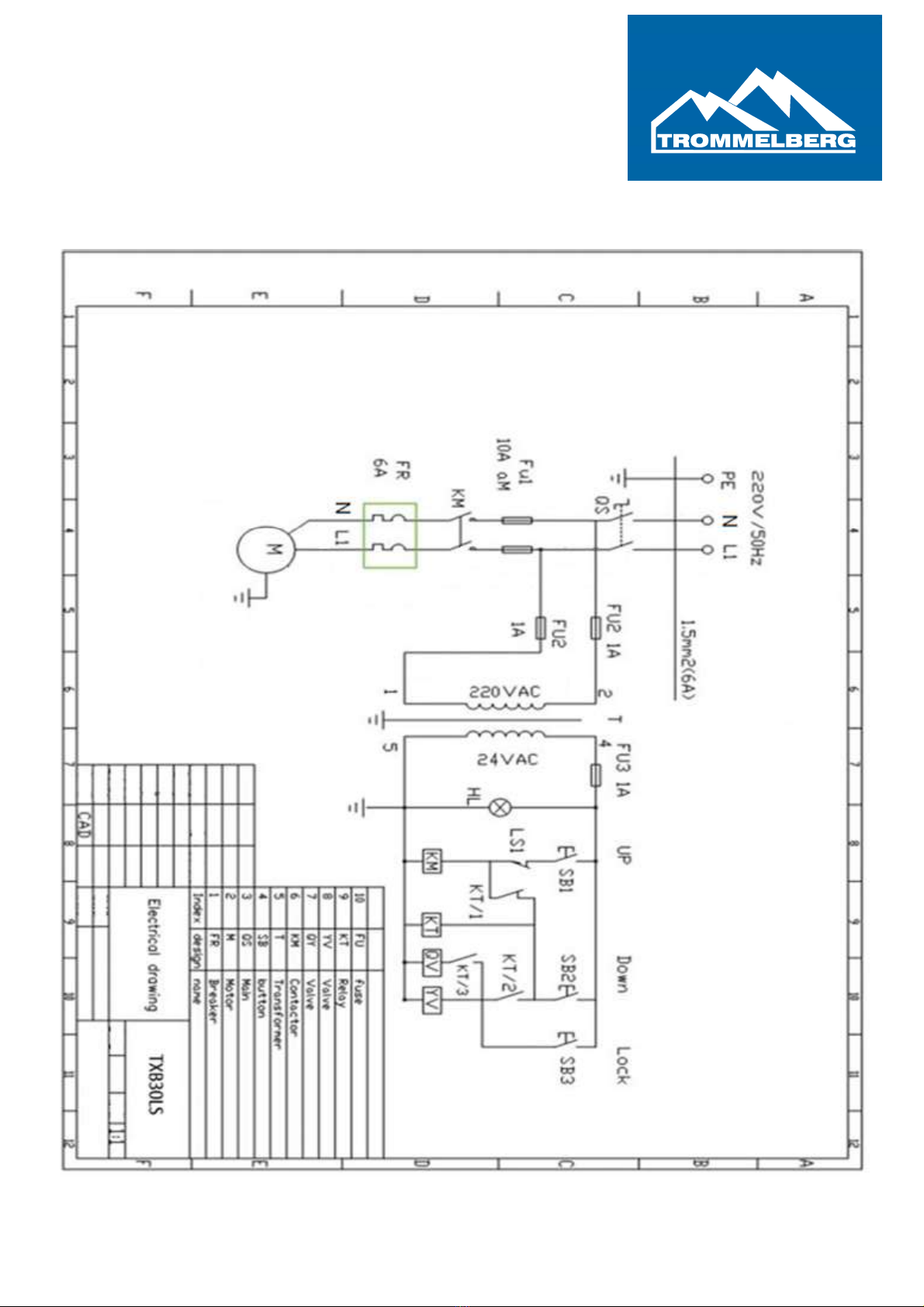

TROMMELBERG TXB30LS User manual

Table of contents

Other TROMMELBERG Scissor Lift manuals

Popular Scissor Lift manuals by other brands

POP UP

POP UP PUSH 6 ECO Operator's Safety and Maintenance Handbook

Hy-Brid Lifts

Hy-Brid Lifts SERIES II Operation & safety manual

Sealey

Sealey MT680.V2 instructions

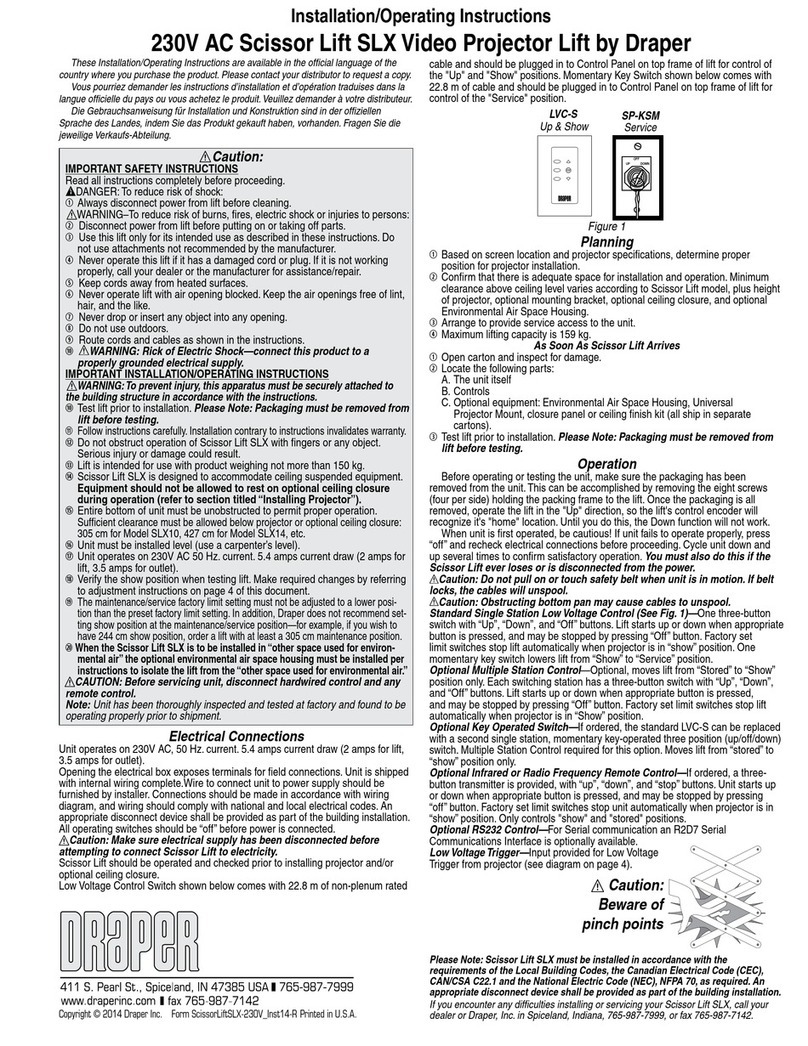

Draper

Draper SLX14 Installation & operating instructions

ALMAC

ALMAC Athena 870-BL EVO TRANSLATION OF ORIGINAL INSTRUCTIONS

Bike-Lift

Bike-Lift TWIN-ARMS MTA 516 Use and maintenance manual

Molnar

Molnar SM300 manual

AUTEC

AUTEC ASB-2503 user manual

TLS

TLS TLSS10ALORR1 Installation, operation & service manual

Kleton

Kleton MJ519 instruction manual

WERTHER INTERNATIONAL

WERTHER INTERNATIONAL SATURNUS 50R Original instructions

Oshkosh Corporation

Oshkosh Corporation JLG ES2632 Operation and safety manual

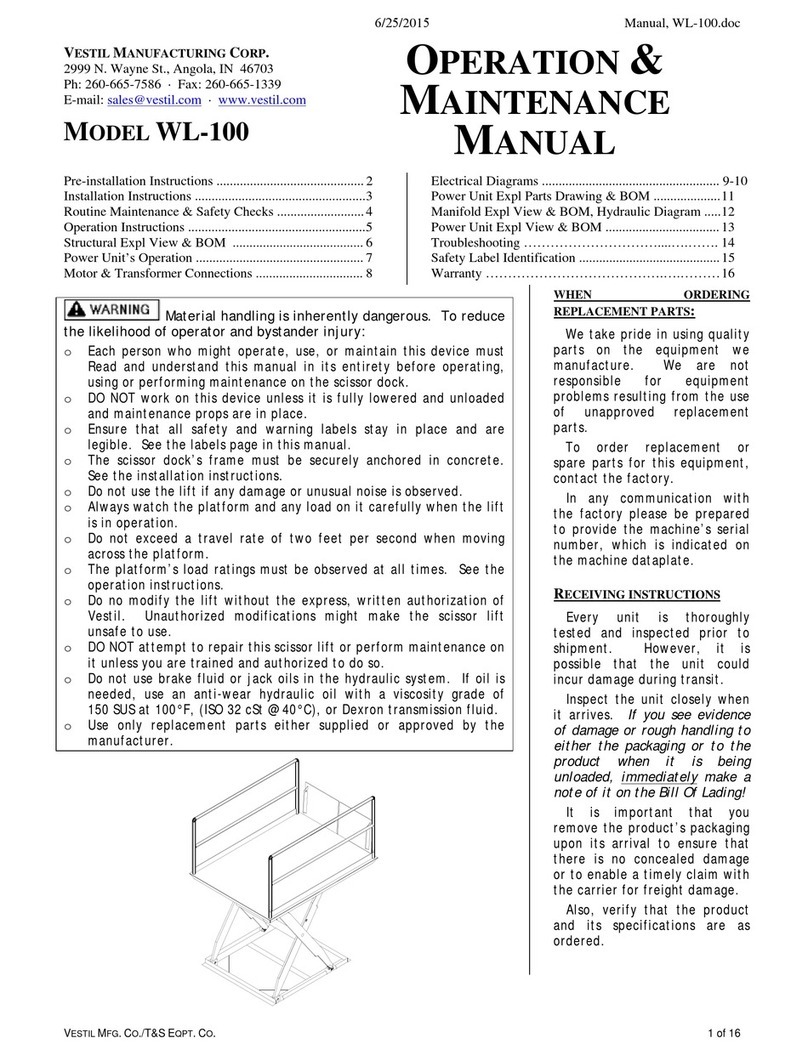

Vestil

Vestil WL-100 Operation & maintenance manual

Terex

Terex Genie GS-3384 Operator's manual

Terex

Terex Genie GS-2668 RT Operator's manual

Oshkosh Corporation

Oshkosh Corporation JLG 400RTS Operation & safety manual

B-TEC

B-TEC Carry Operating Manual and Test Log Book

Haulotte

Haulotte COMPACT 8 Operator's manual