BNP-160 TUMBLE BASKET BLAST CABINET Page 2

© 2018 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 25993 Rev B 05/18

Troubleshooting ........................................................7.0

Dust Leaking from Cabinet Enclosure .........................7.1

Abnormally High Media Consumption .........................7.2

Reduction in Blast Cleaning Rate ...............................7.3

Plugged Nozzle ...........................................................7.4

Media Bridging ............................................................7.5

Neither Media Nor Air Comes Out the Nozzle

During Blast Cycle ....................................................7.6

Blockage in Media Hose ..............................................7.7

Poor Suction in Media Hose ........................................7.8

Air Only (no media) from Nozzle .................................7.9

Blowback through Media Hose .................................7.10

Media Buildup in Cabinet Hopper, Media Does

Not Convey to Reclaimer .......................................7.11

Static Shocks .............................................................7.12

Dust Leaking from Dust Collector Door......................7.13

Dust Leaking from Exhaust Muffler ...........................7.14

Dust Collector Not Pulsing ........................................7.15

Pulse is Steady Stream of Air

Instead of Quick Pulse ...........................................7.16

Exhauster Not Running .............................................7.17

High Reading on Differential Pressure Gauge ..........7.18

No or Low Reading on Differential Pressure Gauge 7.19

Accessories and Replacement Parts ......................8.0

Optional Accessories ...................................................8.1

Electrical Components ............Refer to Elect. Schematic

Cabinet and Exhauster Assembly ...............................8.2

Basket and Drive Assembly ........................................8.3

Gun, Media Feed, and Plumbing Assembly ................8.4

Reclaimer Assembly ....................................................8.5

Dust Collector Assembly .............................................8.6

Dust Collector Pulse and Plumbing .............................8.7

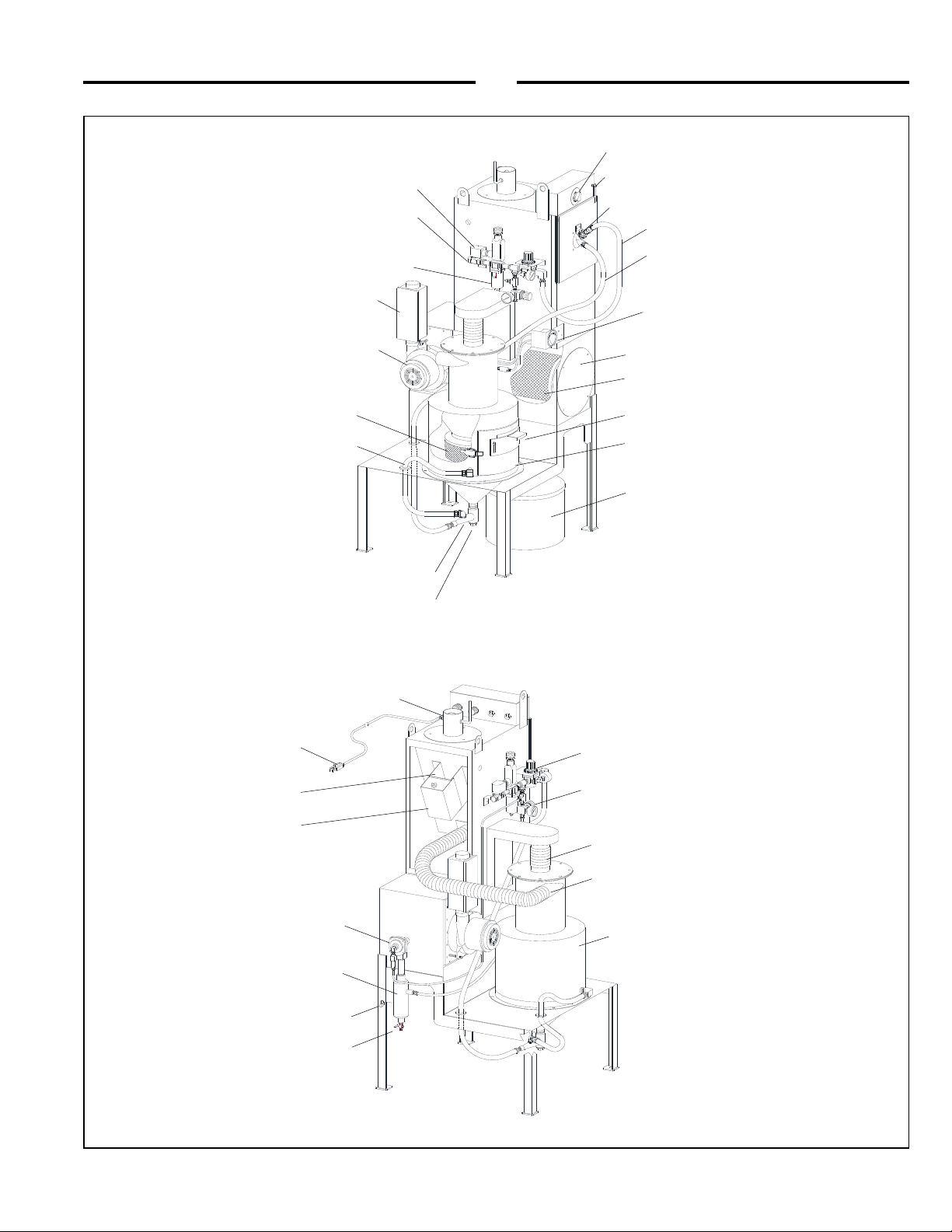

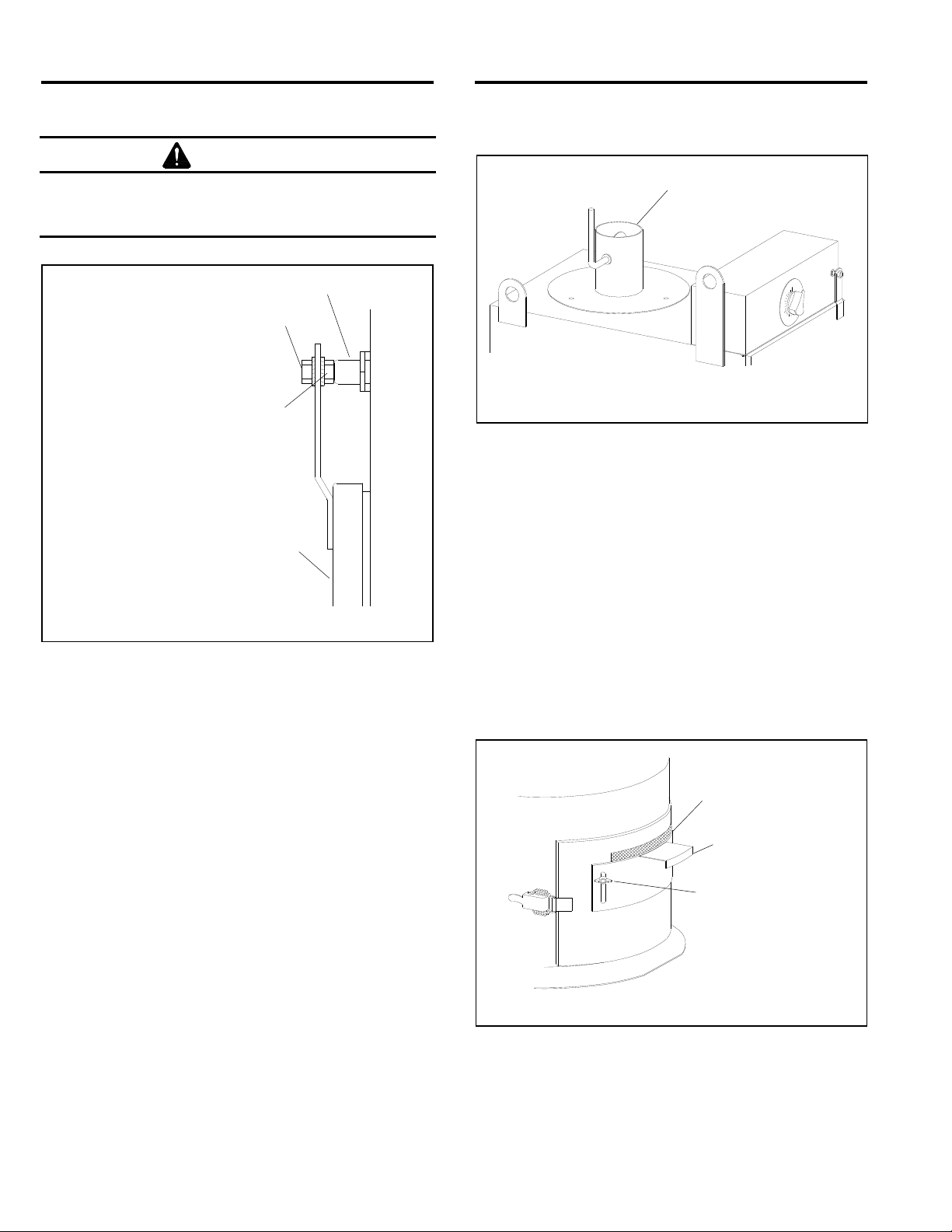

1.4 General Description

1.4.1 The BNP-160 tumble cabinet blasts small

batches of parts using a fixed nozzle and rotating

basket. Refer to Figure 1 for arrangement and callouts of

primary components. The cabinet consists of three major

segments:

1. Cabinet enclosure

2. Reclaimer

3. Reverse-pulse dust collector

1.4.2 The maximum capacity of the basket is 25 lbs.

1.4.3 The cabinet requires approximately 33 cfm of

compressed air at a maximum of 80 psi.

1.5 Theory of Operation

1.5.1 After parts are loaded into the basket, the air

supply and exhauster are turned ON, and the cabinet door

is closed, the cabinet is then ready for operation by setting

the timer located in the control box atop the cabinet

enclosure. Turn the dial to set the blast duration between

1 minute and 60 minutes. Blasting begins once the timer

is set. Air moving through the gun draws media into the

blast gun mixing chamber. The media mixes with the air

and is propelled out the nozzle. As the basket rotates, the

parts tumble in the blast stream, ensuring that all parts

and surfaces are uniformly blasted. The blast media

flows through the perforated drum and into the cabinet

hopper. These particles are drawn into the reclaimer for

separation. First dust and fines are separated from the

reusable blast media. Reusable media is retained in the

reclaimer hopper for reuse. Then dust and fines are drawn

out of the reclaimer and through the filter cartridge in the

reverse-pulse dust collector. The filter cartridge traps dust

on the outer surface and discharges clean air through the

outlet damper atop the collector. The filter cartridge is

cleaned by a pulse of high-velocity compressed air

expanding against the inner surface of the cartridge at

regular intervals. The expanding air momentarily reverses

airflow through the cartridge to release dust accumulated

on the outer surface. The dust particles fall away from the

cartridge and into the hopper and dust container for

removal. Blasting automatically stops when the timed cycle

is completed.

1.6 Dust Collector

1.6.1 The BNP-160 cartridge dust collector is not

suitable for use in applications that generate dust from

lead coatings, heavy metals, or any other toxic materials.

WARNING

Prolonged exposure to any dust can result in

serious lung disease and death. Short-term

ingestion of toxic materials, such as lead dust

or dust from other heavy metals and

corrosives, can cause serious respiratory injury

or death. This machine is not to be used in

applications which generate dust from lead

coatings, heavy metals or any other toxic

materials. Identify all materials that are to be

removed by blasting and obtain a safety data

sheet (SDS) for the blast media.

1.7 Nozzle Options

1.7.1 Ventilation requirements limit standard cabinets

to No. 5 (5/16" orifice) nozzle and No. 5 (5/32" orifice) air

jet. Unless otherwise specified at the time of order,

cabinets are supplied with a tungsten carbide lined

nozzle. Ceramic nozzle are available but should be

limited to occasional blasting and with mild media. More

durable boron carbide nozzles should be used when

blasting with aggressive media such as those listed in

Section 1.9.4. Nozzle options are shown under Gun,

Media Feed, and Plumbing Assembly in Section 8.4.