3

EN

This manual applies to the Kongskilde Compact Unit

all-in-one trim handler.

The target group for this manual are operators, (electri-

cal) installers as well as maintenance and service sta.

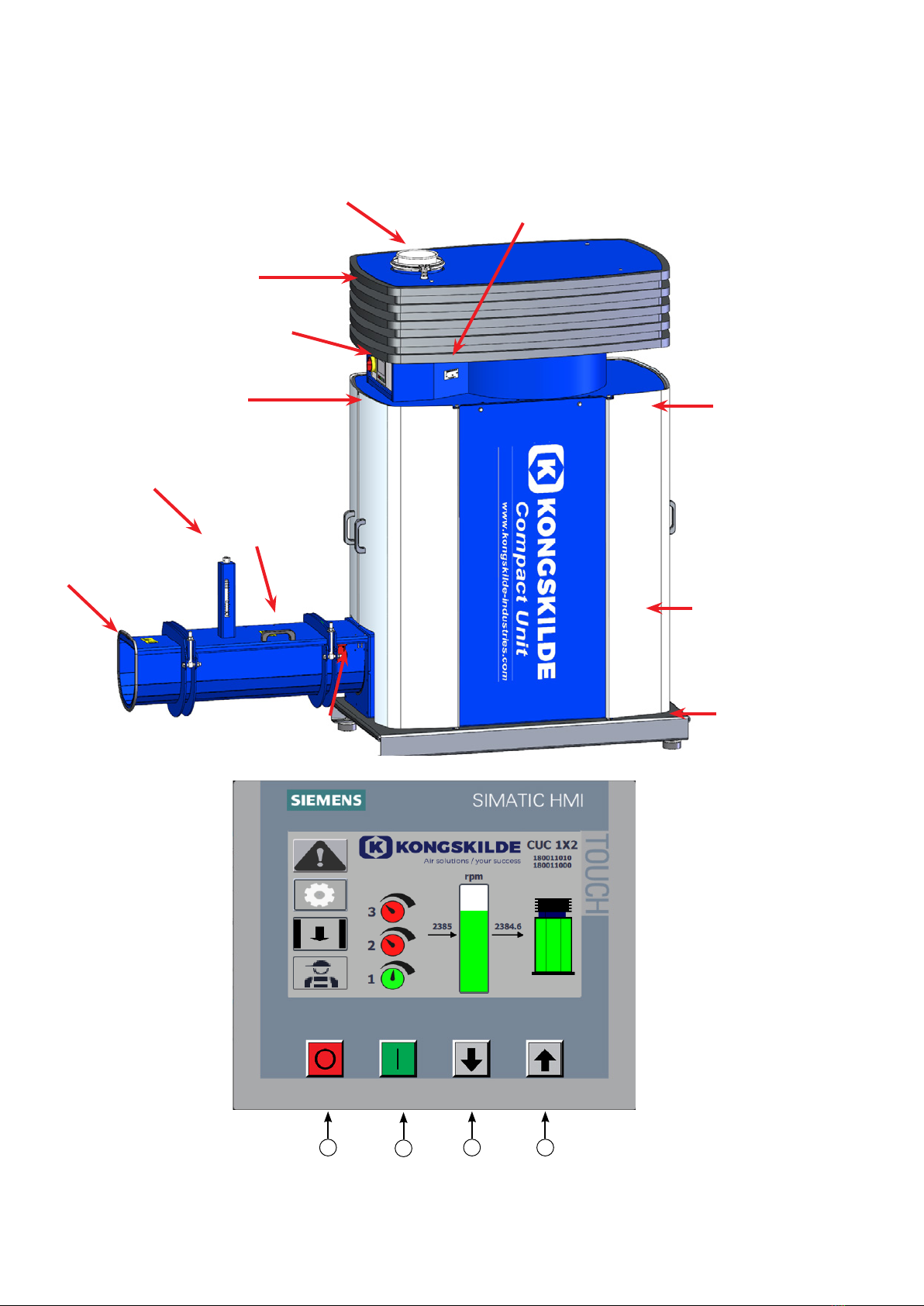

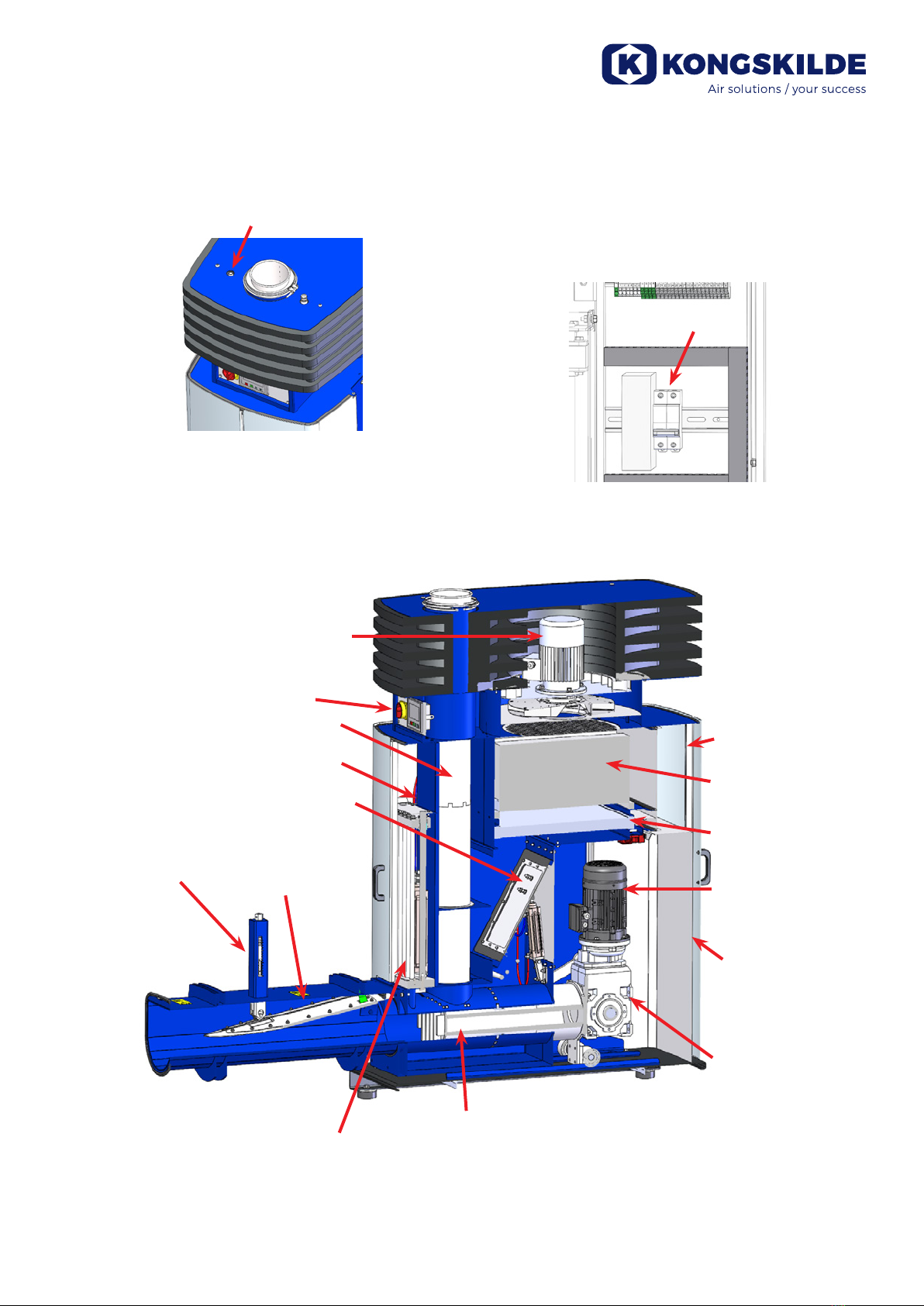

Description:

The product is a trim handler designed to suck up cut

strips of paper and plastic / metal foil, and compact the

strips. Recommended material thickness is 8 - 150µm.

The compressed material is pressed out through the

outlet, and can then be pushed into bags or fall into a

container. The conveying air is cleaned in a built-in lter

system, and is sent puried out of the trim handler.

In order to achieve correct suction of material and pre-

vent blockage of material in the trim handler, it is im-

portant that both the pipework and the screen pipe are

adapted to the given installation. The screen pipe can

therefore be replaced to adapt the Compact Unit to the

installation (see section "Operation").

The trim handler is powered by a built-in blower that

creates the conveying air, and an electric gear motor

that creates the compression of the material via a pis-

ton.

The trim handler is designed to be easily moved using

a pallet lifter or forklift, and can easily be connected to

the piping with a quick clamp at the top of the trim han-

dler.

Operation of the trim handler takes place on the front,

where it can be started and stopped, blower speed

adjusted, and the status of lter changes etc. read.

The trim handler is not designed for moist, sticky or

hard materials.

Warning notes:

Avoid accidents by always following the safety regula-

tions stated in the user manual and on the trim handler.

The trim handler must be mounted in a closed pipe

system, with no access for people to moving parts.

There is a risk of damage to the trim handler if foreign

bodies of a certain size are sucked up / dropped into

the pipe system.

Lack of supervision of the trim handler can lead to wear

and tear of vital parts, see section "Service and mainte-

nance".

The installation and fastening must be carried out in

accordance with regulations (see section "Installation"),

otherwise the stability will deteriorate and the wear and

tear will increase.

Make sure all covers and doors are in place and prop-

erly secured during operation.

Always disconnect power and pressurized air to the

trim handler prior to repair and maintenance. The

main switch must be switched o and locked to en-

sure the trim handler cannot be started by mistake.

Ensure that there are safe access routes that can be

used for repair and maintenance of the trim handler.

The working area around the trim handler should be

clear and trip free so that there is no risk of falling ac-

cidents.

Ensure sucient lighting conditions for safe operation

of the trim handler.

Be careful not to tear or pinch ngers when opening the

material outlet cover.

If any abnormal vibrations or noise are observed, the

trim handler must be stopped immediately, and quali-

ed assistance must be called.

Use eye protection when working close to the air outlet

of the blower. In case of small particles in the conveyed

material, these might be blown from the air outlet of the

blower, causing eye damage.

Make sure that the trim handler stands on a stable,

level surface so that it is secured against falling and

tipping over.

Be careful not to get ngers or hands pinched when

opening or closing the doors, or the outlet lid. Also be

aware that there is a risk of pinching ngers if a hand is

put into the material outlet, in e.g. removal of blocked

material. Be aware of the risk of crushing around the

piston mechanism when the cover is removed.

Also be careful when handling the output lid, as it is

heavy.

The trim handler's blower speed can be set steplessly

using the operator panel. In order not to overload the

blower and motor, the speed cannot be set higher than

what the blower is designed for. It is not permitted to

modify the electrical equipment to increase the blower´s

maximum speed.

The trim handler is designed so that it is not possible to

come into contact with rotating parts during normal op-

eration. However, be aware that if guards are removed

and stop switches are short-circuited and the trim han-

dler is started, there is risk of personal injury.

Warning signs:

Avoid accidents by always following the safety instruc-

tions which are specied in the manual and on the

blower.

Warning labels with symbols without text are located on

the blower. The meaning of the symbols is explained

below. If a warning label gets damaged, and is no long-

er legible, it must be replaced. New labels are available

in the spare parts list.