目次

1 ご使用に当たって、安全の為に ····································· 1

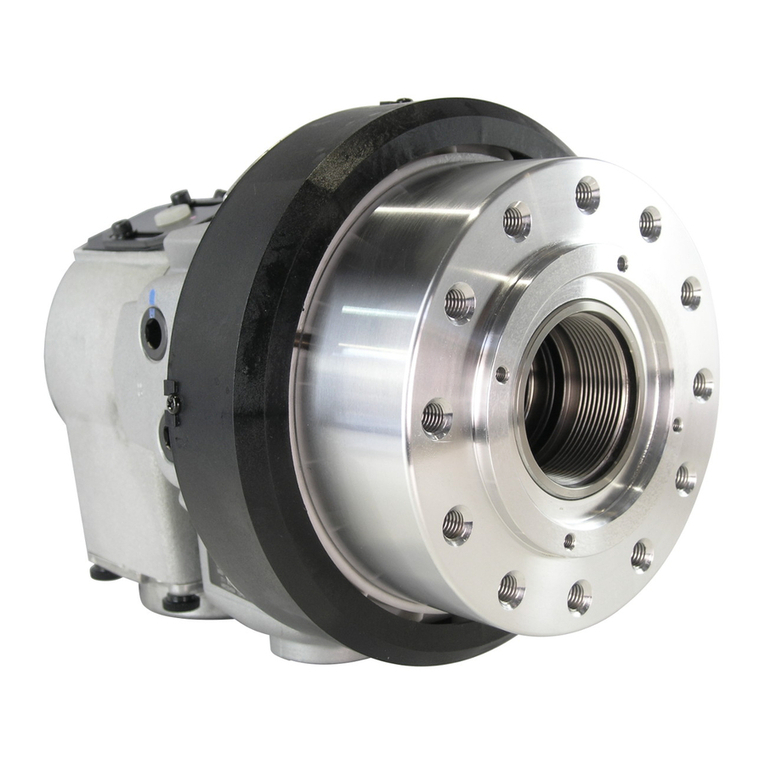

2 外観図 ············································································· 7

3 仕様 ··············································································· 8

4 精度規格 ········································································· 9

5 運転準備 ······································································· 10

5-1 運搬と工作機械への取付け

5-2 給油

5-3 潤滑油必要油量

5-4 作動油必要油量

(傾斜軸空油圧仕様時、エアハイドロブースタ用、エア抜き含む

)

5-5 推奨潤滑油

5-6 推奨作動油

(傾斜軸空油圧仕様時、エアハイドロブースタ用)

5-7 回転軸と傾斜軸のクランプ方式

5-8 エアパージについて

6 テーブルクランプの説明 ············································· 14

6-1 テーブルクランプの注意事項

6-2 クランプ・アンクランプ確認装置

6-3 クランプ・アンクランプ用ソレノイドバルブ

7 傾斜軸エア抜き ··························································· 15

7-1 傾斜軸エア抜き方法

7-2 保守点検

8 点検作業 ······································································· 17

9 工作物の取付け···························································· 17

10 ウォームギヤのバックラッシ調整 ······························· 18

10-1 回転軸ウォームギヤのバックラッシ量の測定

方法

10-2 傾斜軸ウォームギヤのバックラッシ量の測定

方法

10-3 回転軸ウォームギヤのバックラッシ量の調整

方法

10-4 傾斜軸ウォームギヤのバックラッシ量の調整

方法

11 平歯車のバックラッシ量の調整 ································ 22

11-1 回転軸駆動平歯車のバックラッシ調整方法

11-2 傾斜軸駆動平歯車のバックラッシ調整方法

12 原点復帰装置 ··························································· 24

12-1 回転軸原点復帰装置

12-2 傾斜軸原点復帰装置

13 傾斜軸オーバートラベル停止装置 ·························· 26

13-1 傾斜軸オーバートラベル停止装置

13-2 水平オーバートラベル用ドッグの調整方法

13-3 垂直オーバートラベル用ドッグの調整方法

Contents

1 Operation for Safety ························································1

2 Outside view·····································································7

3 Specifications····································································8

4 Accuracy Standard···························································9

5 Operation Ready ····························································10

5-1 Table transfer and mounting to machine tool

5-2 Oiling

5-3 Required lubrication oil volume

5-4 Required operation oil volume

(For air hydro booster at pneumatic/hydraulic spec.)

5-5 Recommended lubrication oil

5-6 Recommended operation oil

(For air hydro booster at pneumatic/hydraulic spec.)

5-7

Clamping method of rotating axis and tilting axis

5-8 Air purge

6 Table CLAMP·································································14

6-1 Precautions for table clamp

6-2 Checking device for CLAMP/UNCLAMP

6-3 Solenoid valve for CLAMP/UNCLAMP

7 Air Bleeder of Tilting axis·············································15

7-1 Air bleeding method on tilting axis side

7-2 Maintenance inspection

8 Inspection ·······································································17

9 Mounting of Workpiece ·················································17

10 Backlash Adjustment of Worm Gears·························18

10-1 Backlash measuring method of worm gear of

rotating axis

10-2 Backlash measuring method of worm gear of

tilting axis

10-3 Backlash adjusting method of rotating axis

worm gear

10-4 Backlash adjusting method of tilting axis

worm gear

11 Backlash Adjustment of Spur Gears ·························22

11-1

Backlash adjusting method of rotating axis drive spur gears

11-2

Backlash adjusting method of tilting axis drive spur gears

12 ZRN (Zero Return) Device ··········································24

12-1 Rotating axis ZRN device

12-2 Tilting axis ZRN device

13 Tilting Axis Over Travel Stop Device ·······················26

13-1 Tilting axis over travel stop device

13-2

Adjusting methods of dog for horizontal over-travel

13-3

Adjusting methods of dog for vertical over-travel