Trox FKRS-EU User manual

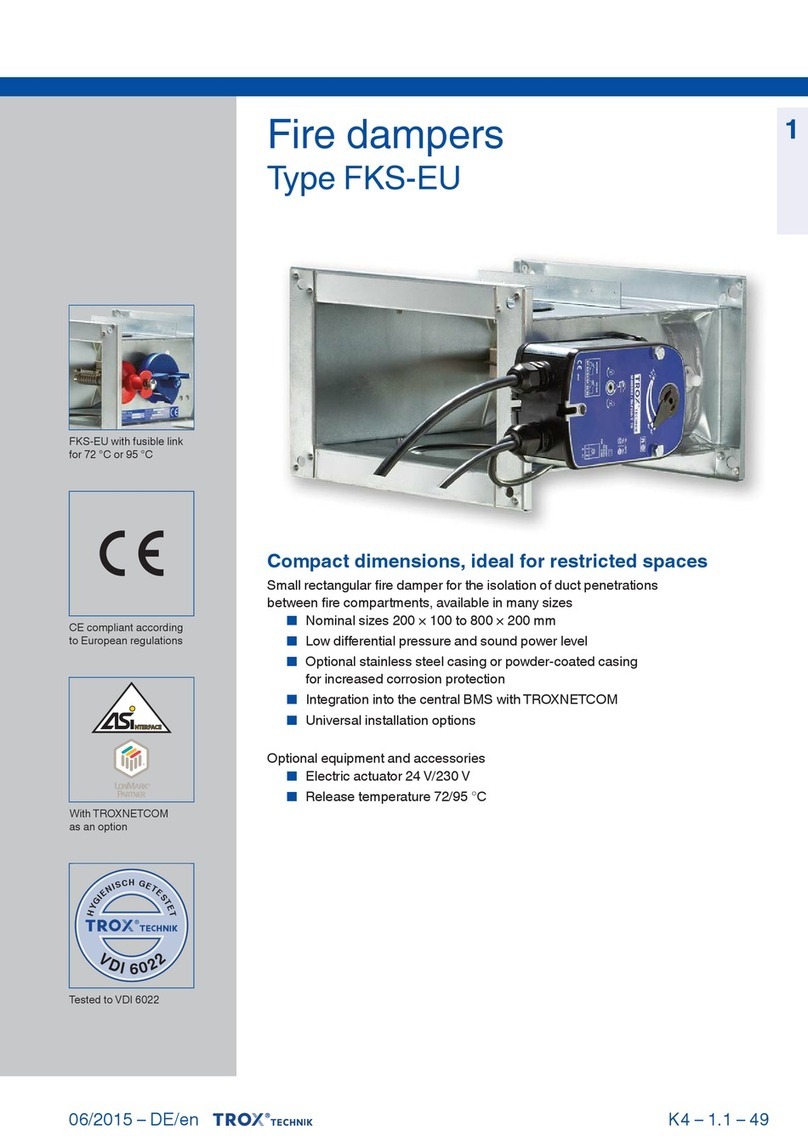

Fire damper

Type FKRS-EU

Installation and operating manual

Read the instructions prior to performing any task!

according to Declaration of Performance

DoP / FKRS-EU / DE / 002

GB/en

M375EE7, 2, GB/en

Translation of the original

© 2014

TROX GmbH

Heinrich-Trox-Platz

47504 Neukirchen-Vluyn

Germany

Phone: +49 (0) 2845 2020

Fax: +49 (0) 2845 202-265

E-mail: [email protected]

Internet: http://www.trox.de

11/2014

Fire damper Type FKRS-EU2

General information

About this manual

This operating and installation manual enables oper-

ating or service personnel to correctly install the TROX

product described below and to use it safely and effi-

ciently.

This operating and installation manual is intended for

use by fitting and installation companies, in-house tech-

nicians, technical staff, properly trained persons, and

qualified electricians or air conditioning technicians.

It is essential that these individuals read and fully under-

stand this manual before starting any work. The basic

prerequisite for safe working is to comply with the safety

notes and all instructions in this manual.

The local regulations for health and safety at work and

general safety regulations also apply.

This manual must be given to the facilities manager

when handing over the system. The facilities manager

must include the manual with the system documenta-

tion. The manual must be kept in a place that is acces-

sible at all times.

Illustrations in this manual are mainly for information

and may differ from the actual design.

Copyright

This document, including all illustrations, is protected by

copyright and pertains only to the corresponding

product.

Any use without our consent may be an infringement of

copyright, and the violator will be held liable for any

damage.

This applies in particular to:

Publishing content

Copying content

Translating content

Microcopying content

Saving content to electronic systems and editing it

TROX Technical Service

To ensure that a fault is processed as quickly as pos-

sible, please keep the following information ready:

Delivery date of the TROX components and sys-

tems

TROX order number

Product name

Brief description of the fault

Contact in case of a fault

Online www.troxtechnik.com

Phone +49 2845 202-400

Limitation of liability

The information in this manual has been compiled with

reference to the applicable standards and guidelines,

the state of the art, and our expertise and experience of

many years.

The manufacturer does not accept any liability for dam-

ages resulting from:

Non-compliance with this manual

Incorrect use

Operation or handling by untrained individuals

Unauthorised modifications

Technical changes

Use of non-approved replacement parts

The actual scope of delivery may differ from the infor-

mation in this manual for bespoke constructions, addi-

tional order options or as a result of recent technical

changes.

The obligations agreed in the order, the general terms

and conditions, the manufacturer's terms of delivery,

and the legal regulations in effect at the time the con-

tract is signed shall apply.

We reserve the right to make technical changes.

Defects liability

For details regarding defects liability please refer to

Section VI, Warranty Claims, of the Delivery and Pay-

ment Terms of TROX GmbH.

The Delivery and Payment Terms of TROX GmbH are

available at www.troxtechnik.com.

General information

Fire damper Type FKRS-EU 3

Safety notes

Symbols are used in this manual to alert readers to

areas of potential hazard. Signal words express the

degree of the hazard.

DANGER!

Imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING!

Potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION!

Potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE!

Potentially hazardous situation which, if not avoided,

may result in property damage.

ENVIRONMENT!

Environmental pollution hazard.

Tips and recommendations

Useful tips and recommendations as well as infor-

mation for efficient and fault-free operation.

Safety notes as part of instructions

Safety notes may refer to individual instructions. In this

case, safety notes will be included in the instructions

and hence facilitate following the instructions. The

above listed signal words will be used.

Example:

1. Untighten the screw.

2.

CAUTION!

Danger of finger entrapment when closing

the lid.

Be careful when closing the lid.

3. Tighten the screw.

Specific safety notes

The following symbols are used in safety notes to alert

you to specific hazards:

Warning signs Type of danger

Warning – danger zone.

General information

Fire damper Type FKRS-EU4

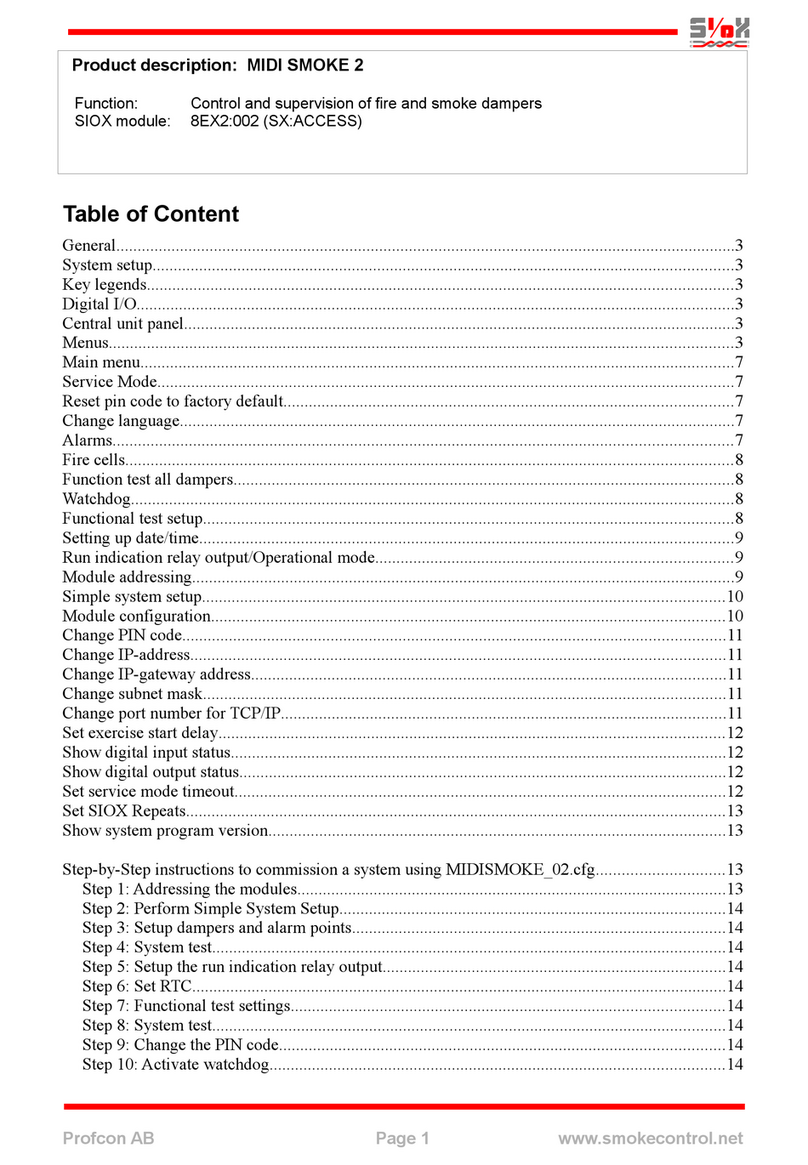

1 Safety................................................................... 6

1.1 General safety notes................................ 6

1.2 Correct use.............................................. 6

1.3 Qualified staff........................................... 6

2 Technical data..................................................... 7

2.1 General data............................................ 7

2.2 FKRS-EU with fusible link........................ 8

2.3 FKRS-EU with spring return actuator...... 9

3 Transport and storage...................................... 11

4 Parts and function............................................. 12

4.1 FKRS-EU with fusible link...................... 12

4.2 FKRS-EU with spring return actuator.... 12

5 Installation......................................................... 13

5.1 Installation situations............................. 13

5.2 Safety notes on installation.................... 14

5.3 General installation information............. 14

5.3.1 After installation..................................... 14

5.4 Solid walls.............................................. 16

5.4.1 Mortar-based installation....................... 16

5.4.2 Dry mortarless installation with circular

installation block ER.............................. 17

5.4.3 Dry mortarless installation with fire

batt......................................................... 18

5.4.4 Dry mortarless installation with wall face

frame WA............................................... 20

5.5 Solid ceiling slabs.................................. 21

5.5.1 Mortar-based installation....................... 21

5.5.2 Dry mortarless installation with circular

installation block ER.............................. 23

5.5.3 Dry mortarless installation with fire

batt......................................................... 24

5.5.4 Mortar-based installation into concrete

bases..................................................... 25

5.6 Lightweight partition walls...................... 27

5.6.1 Mortar-based installation....................... 29

5.6.2 Dry mortarless installation with square

dry mortarless installation kit TQ........... 32

5.6.3 Dry mortarless installation with fire

batt......................................................... 34

5.6.4 Dry mortarless installation with installa-

tion kit GL............................................... 36

5.7 Fire walls................................................ 37

5.7.1 Mortar-based installation....................... 40

5.7.2 Dry mortarless installation with square

dry mortarless installation kit TQ........... 41

5.8 Shaft walls............................................. 42

5.8.1 Mortar-based installation....................... 44

5.8.2 Dry mortarless installation with square

installation block EQ.............................. 45

5.9 Suspended installation of the fire

damper................................................... 46

5.9.1 General.................................................. 46

5.9.2 Fixing to the ceiling slab........................ 46

5.9.3 Fire dampers with fire batt..................... 46

6 Connecting the ductwork................................. 49

6.1 Ducts...................................................... 49

6.2 Removing the transport/installation pro-

tection.................................................... 49

6.3 Limiting duct expansion......................... 49

6.3.1 Flexible connectors................................ 49

6.4 Cover grille............................................. 50

6.5 Inspection access.................................. 50

7 Making electrical connections......................... 51

7.1 Connecting the limit switches (fire

dampers with fusible link)...................... 51

7.2 Connecting the spring return actuator... 51

7.3 Equipotential bonding............................ 51

8 Functional test................................................... 52

8.1 Fire damper with fusible link.................. 52

8.2 Fire damper with spring return

actuator.................................................. 53

9 Commissioning................................................. 56

10 Maintenance...................................................... 57

10.1 General.................................................. 57

10.2 Lubricating points................................... 57

10.3 Replacing the fusible link....................... 58

10.4 Inspection, maintenance and repair

measures............................................... 59

11 Decommissioning, removal and disposal...... 61

12 Index................................................................... 62

Table of contents

Fire damper Type FKRS-EU 5

1 Safety

1.1 General safety notes

Sharp edges, sharp corners and thin sheet metal

parts

CAUTION!

Danger of injury at sharp edges, sharp corners

and thin sheet metal parts!

Sharp edges, sharp corners and thin sheet metal

parts may cause cuts or grazes.

– Be careful when carrying out any work.

– Wear protective gloves, safety shoes and a hard

hat.

Electrical voltage

DANGER!

Danger of electric shock! Do not touch any live com-

ponents! Electrical equipment carries a dangerous

electrical voltage.

– Only skilled qualified electricians are allowed to

work on the electrical system.

– Switch off the power supply before working on

any electrical equipment.

1.2 Correct use

The fire damper is used as an automatic shut-off

device to prevent fire and smoke from spreading

through ducting.

The fire damper is suitable for supply air and extract

air systems.

Operation of the fire damper is allowed only in com-

pliance with installation regulations and the technical

data in this operating and installation manual.

Modifications of the fire damper and the use of

replacement parts that have not been approved by

TROX are not permitted.

Incorrect use

WARNING!

Danger due to incorrect use!

Incorrect use of the fire damper can lead to dan-

gerous situations.

Never use the fire damper

– in areas with potentially explosive atmospheres

– as a smoke extract damper

– outdoors without sufficient protection against the

effects of weather

– in atmospheres where chemical reactions,

whether planned or unplanned, may cause

damage to the fire damper or lead to corrosion

1.3 Qualified staff

WARNING!

Danger of injury due to insufficiently qualified

individuals!

Incorrect use may cause considerable injury or

damage to property.

– Only skilled qualified personnel must carry out

work.

The following degrees of qualification are required for

the work described in the operating manual:

Skilled qualified electrician

Skilled qualified electricians are trained individuals who

have specialist knowledge and experience and who

know the relevant standards and guidelines to be able

to work on electrical systems and to recognise and

avoid potential dangers.

Specialist personnel

Specialist personnel are trained individuals who have

specialist knowledge and experience and who know the

relevant guidelines to be able to carry out the assigned

duties and to recognise and avoid potential dangers.

Safety

Qualified staff

Fire damper Type FKRS-EU6

2 Technical data

2.1 General data

Nominal sizes 100 – 315 mm

Volume flow rate range up to 770 l/s

up to 2770 m³/h

Differential pressure range up to 1500 Pa

Operating temperature 1At least 0 – 50 °C

Release temperature 72 °C or 95 °C (for warm air ventilation systems)

Upstream velocity 2≤ 8 m/s with fusible link

≤ 10 m/s with spring return actuator

Closed blade air leakage EN 1751, Class 3

Casing air leakage EN 1751, Class C

EC conformity Construction Products Regulation (EU) no. 305/2011

EN 15650 – Ventilation for buildings – Fire dampers

EN 13501-3 – Classification – Part 3: Fire resisting ducts

and fire dampers

EN 1366-2 – Fire resistance tests for service installa-

tions – Part 2: Fire dampers

EN 1751 Ventilation for buildings – Air terminal devices

Declaration of Performance DoP / FKRS-EU / DE / 002

1) Temperatures may differ for units with attachments

2) Data applies to uniform upstream and downstream conditions for the fire damper

Rating plate

A###########

Jahr/year-## DoP / XXX-XX / DE / 0##

Brandschutzklappe/fire damper

XXX-XX

EI TT (ve-ho, i

o) S - (300 Pa)

TROX GmbH

Heinrich-Trox-Platz

47504 Neukirchen-Vluyn

GERMANY

www.trox-docs.com

12

EN 15650: 2010 0749 / 1322

①

⑦ ⑨⑧ ⑩⑥⑤

③ ④②

Fig. 1: Rating plate (example)

①CE mark

②Manufacturer's address

③Number of the European standard and year of its

publication

④Notified body

⑤The last two digits of the year in which the CE

marking was affixed

⑥Year of manufacture

⑦No. of the declaration of performance

⑧Website from which the DoP can be downloaded

⑨Regulated characteristics; the fire resistance class

depends on the application and may

vary

Ä

Chapter 5.1 ‘Installation situations’

on page 13

⑩Type

Technical data

General data

Fire damper Type FKRS-EU 7

2.2 FKRS-EU with fusible link

Dimensions and weight

L = 400

Ø DN

50 ~ 75

~ 180

220

270

50

①

Fig. 2: FKRS-EU with fusible link

①Keep clear to provide access for operation

Weight [kg]

Nominal size [mm] 100 125 150 160 180 200 224 250 280 315

ØDN [mm] 99 124 149 159 179 199 223 249 279 314

FKRS-EU with fusible link 1.3 1.6 1.8 2.0 2.3 2.5 2.7 3.3 3.8 4.4

... with circular installation block (ER) 5.7 8.6 7.6 7.3 11.0 9.8 13.5 12.1 16.0 15.0

... with square installation block (EQ) 7.3 11.2 10.2 9.9 13.3 13.6 18.8 17.3 22.9 20.0

... with square installation block (TQ) 5.4 6.1 7.0 7.9 8.8 9.7 10.6 12.0 13.7 15.8

... with wall face frame (WA) 4.4 5.2 6.1 6.6 7.4 8.2 9.0 10.2 11.7 13.6

Technical data

FKRS-EU with fusible link

Fire damper Type FKRS-EU8

Limit switches

Connecting cable length / cross section 1 m / 3 × 0.34 mm²

Protection level IP 66

Type of contact 1 changeover contact, gold-plated

Maximum switching current 0.5 A

Maximum switching voltage 30 V DC, 250 V AC

Contact resistance approx. 30 mΩ

2.3 FKRS-EU with spring return actuator

Dimensions and weight

L = 400

Ø DN

50 ~ 115

~ 190

220

270

50

①

Fig. 3: FKRS-EU with spring return actuator

①Keep clear to provide access for operation

Weight [kg]

Nominal size [mm] 100 125 150 160 180 200 224 250 280 315

ØDN [mm] 99 124 149 159 179 199 223 249 279 314

FKRS-EU with spring return actuator 3.1 3.4 3.6 3.7 4.0 4.2 4.5 5.0 5.5 6.2

... with circular installation block (ER) 7.5 10.4 9.4 9.1 12.8 11.6 15.3 13.9 17.8 16.8

... with square installation block (EQ) 9.1 13.0 12.0 11.7 15.1 15.4 20.6 19.1 24.7 21.8

Technical data

FKRS-EU with spring return actuator

Fire damper Type FKRS-EU 9

Weight [kg]

Nominal size [mm] 100 125 150 160 180 200 224 250 280 315

... with square installation block (TQ) 7.2 7.9 8.8 9.7 10.6 11.5 12.4 13.8 15.5 17.6

... with wall face frame (WA) 6.2 7.0 7.9 8.4 9.2 10.0 10.8 12.0 13.5 15.4

Spring return actuator BLF...

Construction 230-T TR 24-T-ST TR

Supply voltage 230 V AC ±14 % 50/60 Hz 24 V AC ±20 % 50/60 Hz

or 24 V DC –10 % / +20 %

Power rating Spring compression 6 W 5 W

Hold position 3 W 2.5 W

Rating 7 VA

Running time Motor / spring return 40 – 75 s / 20 s

Limit switches Type of contact 2 changeover contacts

Switching voltage 5 – 120 V DC / 5 – 250 V AC

Switching current 1 mA – 3 A

Contact resistance < 100 mΩ

IEC protection class II III

Protection level IP 54

Storage temperature -40 to 50 °C

Ambient temperature -30 to 50 °C ¹

Ambient humidity ≤ 95 % RH, non-condensing

Connecting cable Actuator 1 m / 2 × 0.75 mm²

Limit switches 1 m / 6 × 0.75 mm²

¹ Up to 75 °C the safe position will definitely be reached.

Technical data

FKRS-EU with spring return actuator

Fire damper Type FKRS-EU10

3 Transport and storage

Delivery check

Check delivered items immediately after arrival for

transport damage and completeness. In case of any

damage or an incomplete shipment, contact the ship-

ping company and your supplier immediately.

Fire damper

– Attachments/accessories, if any

Operating manual (1 per shipment)

Colour hues on the damper blade

The blades of fire dampers are treated with a

greenish impregnating agent. Resulting colour hues

on the damper blade are due to technical reasons

and do not constitute a defect of any kind.

Transport on site

If possible, take the fire damper in its transport pack-

aging up to the installation location.

Storage

If the unit has to be stored temporarily:

Remove any plastic wrapping.

Protect the unit from dust and contamination.

Store the unit in a dry place and away from direct

sunlight.

Do not expose the unit to the effects of weather (not

even in its packaging).

Do not store the unit below -40 °C or above 50 °C.

Packaging

Properly dispose of packaging material.

Transport and storage

Fire damper Type FKRS-EU 11

4 Parts and function

Fire dampers are used as safety related components in

ventilation systems. The fire damper is used as a shut-

off device to prevent fire and smoke from spreading

through ducting. During normal operation the damper

blade is open to enable air passage through the ventila-

tion system.

If the temperature increases in the event of a fire, the

damper blade closes. Closure is triggered at 72 °C

( 95 °C in warm air ventilation systems). If the damper

blade closes due to a temperature increase (i.e. in the

event of a fire), it must not be reopened.

To ensure proper functioning of the fire damper, a test

can be carried out.

Ä

52

4.1 FKRS-EU with fusible link

①

②

④

⑥

③⑤

Fig. 4: FKRS-EU with fusible link

①Casing

②Fusible link

③Damper blade with seal

④Inspection access

⑤Lip seal

⑥Handle with interlock and damper blade position

indicator

⑦Release mechanism

Functional description

In fire dampers with a fusible link, damper closure is

triggered by the fusible link. If the temperature inside the

fire damper rises to 72 °C or 95 °C, the fusible link trig-

gers a coil spring mechanism. The coil spring mecha-

nism then causes the fire damper to close.

As an option, the fire damper can be either supplied or

subsequently fitted with one or two limit switches. The

limit switches can signal the damper blade position to

the central BMS or fire alarm system. One limit switch

each is required for damper blade positions OPEN and

CLOSED.

4.2 FKRS-EU with spring return

actuator

①

②

④

⑥

③⑤

Fig. 5: FKRS-EU with spring return actuator

①Casing

②Temperature sensor

③Damper blade with seal

④Inspection access

⑤Lip seal

⑥Spring return actuator

⑦Thermoelectric release mechanism

Functional description

The spring return actuator enables the motorised

opening and closing of the damper blade; it can be acti-

vated by the central BMS. As long as power is supplied

to the actuator, the damper blade remains open. In the

event of a fire, the internal thermoelectric release mech-

anism closes the damper blade when at least one of the

following is true:

Temperature in the fire damper > 72 °C or > 95 °C

Ambient temperature outside the release mecha-

nism > 72 °C

The power supply is interrupted (power off to close)

As standard, the spring return actuator is equipped with

limit switches that can be used to indicate the damper

blade position.

Parts and function

FKRS-EU with spring return actuator

Fire damper Type FKRS-EU12

5 Installation

5.1 Installation situations

Note

The performance classes of the fire damper and the wall or ceiling slab may differ. The lower performance class

determines the performance class of the overall system.

Installation situations

Supporting construc-

tion

Installation location Minimum

thickness

[mm]

Class of per-

formance EI TT

(ve–ho, i ↔ o) S

Installa-

tion type

Installa-

tion infor-

mation

Solid walls

Gross density

≥ 500 kg/m³

In solid walls 100 EI 120 S N

Ä

16

W1

Ä

18

EI 90 S E

Ä

17

W1

Ä

18

On the face of solid walls 100 EI 90 S E

Ä

20

Solid ceiling slabs

Gross density

≥ 600 kg/m³

In solid ceiling slabs 150 EI 120 S N

Ä

21

EI 90 S E

Ä

23

W

Ä

24

In concrete bases N

Ä

25

Lightweight partition

walls

In lightweight partition walls with

metal support structure and clad-

ding on both sides

100 EI 120 S N1

Ä

29

E

Ä

32

W1

Ä

34

EI 90 S N

Ä

29

E

Ä

32

W1

Ä

34

In lightweight partition walls with

metal support structure and clad-

ding on both sides, and with flex-

ible ceiling joint

100 EI 90 S E

Ä

36

Fire walls In fire walls with metal support

structure and cladding on both

sides

115 EI 90 S N

Ä

40

E

Ä

41

Shaft walls In lightweight partition walls with

metal support structure and clad-

ding on one side

90 EI 90 S N

Ä

44

EQ

Ä

45

1) The class of performance depends on the installation details. N = Mortar-based installation

E = Installation block or kit (ER, TQ, WA, GL)

EQ = Installation block EQ

W = Fire batt

Installation

Installation situations

Fire damper Type FKRS-EU 13

5.2 Safety notes on installation

Sharp edges, sharp corners and thin sheet metal

parts

CAUTION!

Danger of injury at sharp edges, sharp corners

and thin sheet metal parts!

Sharp edges, sharp corners and thin sheet metal

parts may cause cuts or grazes.

– Be careful when carrying out any work.

– Wear protective gloves, safety shoes and a hard

hat.

5.3 General installation information

NOTICE!

Damage to the fire damper

– Protect the fire damper from contamination and

damage.

– Cover openings and release mechanism (e.g.

with plastic foil) to protect them from mortar and

dripping water.

– Do not remove the transport and installation pro-

tection (if any) until installation is complete.

Please note:

Operating components, electric actuator, and

inspection access must remain accessible for

inspection and maintenance work.

Loads imposed on the casing may impair the func-

tion of the fire damper. The fire damper must hence

be installed without exercising any tension.

Mortar-based installation: The perimeter gap »s

« must be large enough such that mortar can be

filled in even in case of thicker walls.

Before installation: Perform a functional test, then

close the fire damper.

Ä

52

Installation position

The fire damper can be installed with the damper blade

shaft in any position (0 to 360°)(Fig. 6). The position of

the release mechanism is not critical but the mechanism

must remain accessible for maintenance.

a

a

Fig. 6: Installation positions and distances

a Distance between two fire dampers. The distance

depends on the installation situation and is given in

the installation details.

Acceptable mortars for mortar-based installation

In case of mortar-based installation, the open spaces

between the fire damper casing and the wall or ceiling

slab must be closed off with mortar. Entrapped air is to

be avoided. The mortar bed depth should be equal to

the thickness of the wall but must be at least 100 mm.

The following mortars are acceptable:

DIN 1053: Groups II, IIa, III, IIIa; fire protection

mortar of groups II, III

EN 998-2: Classes M 2.5 to M 10 or fire protection

mortar of classes M 2.5 to M 10

Equivalent mortars that meet the requirements of

the above standards, gypsum mortar or concrete

Acceptable fire batt systems

The following fire batt systems may be used:

Hilti fire batt system

Firestop board CFS-CT B 1S 140/50

Fire protection coating CFS-CT

Fire protection sealant CFS-S ACR

HENSEL fire batt system

Mineral wool slab ROCKWOOL Hardrock 40

Fire protection coating

HENSOMASTIK 5 KS Farbe (coating)

Fire protection sealant

HENSOMASTIK 5 KS Spachtel (sealant)

5.3.1 After installation

Clean the fire damper.

Remove transport and installation protection, if any.

In case of mortar-based installation this protection

must not be removed until the mortar has hardened.

Test the function of the fire damper.

Installation

General installation information > After installation

Fire damper Type FKRS-EU14

Connect the ductwork.

Make electrical connections.

Installation

General installation information > After installation

Fire damper Type FKRS-EU 15

5.4 Solid walls

5.4.1 Mortar-based installation

W

W

s 40

s 40

W

s 40

a 40

a 40

220

220

220

①

①

①

࿇࿆࿇࿆࿇࿆

Fig. 7: Installation into a solid wall

①Mortar

ⒶInstallation side

ⒷOperating side

Personnel:

Specialist personnel

Materials:

Mortar

Ä

‘Acceptable mortars for mortar-based installation’ on page 14

Requirements

Performance class EI 120 S

Solid walls or fire walls made of, for example, concrete, aerated concrete, masonry, or solid gypsum wallboards

according to EN 12859 (without open spaces), gross density ≥ 500 kg/m³ and W ≥ 100 mm

≥ 40 mm distance to load-bearing structural elements

40 mm minimum distance between two fire dampers

1. Create an appropriate opening or cut hole: ØDN + at least 80 mm

2. Push the fire damper into the installation opening and secure it. Make sure that the distance from the con-

necting spigot on the operating side to the wall is 220 mm.

If the wall thickness is >115 mm , extend the fire damper on the installation side with an extension piece or a

spiral duct.

3. Close off the perimeter gap »s« with mortar. The mortar bed depth must be at least 100 mm.

If the fire damper is installed as the wall is being erected, the perimeter gap »s« is not required. The open

spaces between the fire damper and the wall must be closed off with mortar. Entrapped air is to be avoided. The

mortar bed depth should be equal to the thickness of the wall.

Installation

Solid walls > Mortar-based installation

Fire damper Type FKRS-EU16

5.4.2 Dry mortarless installation with circular installation block ER

ØD1

DN

□B

࿇࿆④

③

②

①

:

ุ

Fig. 8: Intallation with circular installation block

①Circular installation block

②Screw fixing

③Cover plate

④Extension piece

∅D1 Installation opening

Ä

Table on page 17

ⒶInstallation side

ⒷOperating side

Personnel:

Specialist personnel

Requirements

Performance class EI 90 S

Solid walls or fire walls made of, for example, concrete, aerated concrete, masonry, or solid gypsum wallboards

according to EN 12859 (without open spaces), gross density ≥ 500 kg/m³ and W ≥ 100 mm

≥ 75 mm distance between installation block and load-bearing structural elements

200 mm minimum distance between two installation blocks

1. Create an appropriate opening with ØD1

Ä

Table on page 17

2. Push the fire damper assembly up to the cover plate into the opening.

If the wall thickness is >115 mm, extend the fire damper on the installation side with an extension piece or a

spiral duct.

3. Fix the cover plate with at least four M6 screws. For solid walls and solid ceiling slabs, suitable steel anchors

with building inspectorate approval must be used.

Dimensions of installation opening/cover plate [mm]

Nominal size 100 125 150 160 180 200 224 250 280 315

ØD1 200 250 250 250 300 300 350 350 400 400

☐B 250 300 300 300 350 350 400 400 450 450

Installation opening tolerance + 2 mm

Installation

Solid walls > Dry mortarless installation with circular inst...

Fire damper Type FKRS-EU 17

5.4.3 Dry mortarless installation with fire batt

A

A

A

50

24

40...400

40...400

40...400

W

220

100

100

W

220

a

2 x ∅DN + a + 80...800

a = 40...400

100 24

50 x 60

100 24

W

220

a

2 x ∅DN + a + 80...800

∅DN + 80...800

∅DN + 80...800

∅DN + 80...800

∅DN + 80...800

③

④

②

①

࿆⑤࿆③

④

②

②

࿇࿆࿇࿇࿇③

②

②

࿆④

⑤

⑤

Fig. 9: Installation with fire batt

①Extension piece (if required)

②Fire protection coating

③Coated mineral wool slabs, ≥ 140 kg/m³

④Fire protection coating

⑤Mineral wool strips ≥ 80 kg/m³ (only when distance

a≤ 50 mm)

ⒶInstallation side

ⒷOperating side

Note: Each fire damper must be suspended separately

Ä

46.

Installation

Solid walls > Dry mortarless installation with fire batt

Fire damper Type FKRS-EU18

Performance class and installation details

Perform-

ance class

Fire batt Casing construction /

∅DN [mm]

Distance to

load-

bearing

structural

elements

[mm]

Distance between two fire dampers

[mm]

Galvanised

steel

Stainless

steel

Two installation

openings

One installation

opening (flange to

flange)

EI 120 S HENSEL 100...200 – ≥75 ≥200 –

EI 120 S Hilti 100...200 – ≥75

EI 90 S Hilti 100...315 100...200 ≥40 ≥200 a = 40...400

EI 90 S HENSEL 100...315 – ≥40

Personnel:

Specialist personnel

Materials:

Fire batt systems

Ä

‘Acceptable fire batt systems’ on page 14

Requirements

Performance class EI 120 S or EI 90 S

Ä

‘Performance class and installation details ’ Table on page 19

Solid walls or fire walls made of, for example, concrete, aerated concrete, masonry, or solid gypsum wallboards

according to EN 12859 (without open spaces), gross density ≥ 500 kg/m³ and W ≥ 100 mm

Duct connection with flexible connector (recommended)

1. An opening is required, see Fig. 9. 400 mm maximum distance between fire damper and wall opening

2. Push the fire damper into the installation opening and fix it with threaded rods.

Ä

46

3. Extend the fire damper on the installation side with an extension piece (either attachment or supplied by

others).

Note

The fire damper must have a fire protection coating (50 mm) on the installation side. The spigot of the fire

damper must not be coated. This is why the fire damper requires an extension piece on the installation

side; alternatively, the fire damper can be connected to the ductwork before the coating is applied.

4. Completely close off the perimeter gap between the fire damper and the wall or ceiling slab with two layers of

coated mineral wool slabs, ≥ 140 kg/m³. Apply fire protection sealant to the cut faces of the mineral wool slabs

and fit them tightly into the opening. Seal any gaps between the mineral wool slabs and the trim panels, gaps

between the cut faces of cut-to-size pieces, and gaps between slabs and the fire damper by applying fire pro-

tection sealant.

5. Apply fire protection coating to joints, transitions, and any imperfections on the pre-coated mineral wool slabs.

6. Apply fire protection coating, at least 2.5 mm thick, to the fire damper casing perimeter on both sides of the

wall or ceiling slab. The actuator and release unit must not be coated.

Installation

Solid walls > Dry mortarless installation with fire batt

Fire damper Type FKRS-EU 19

5.4.4 Dry mortarless installation with wall face frame WA

ØD2

B2

W

≈100

220

∅DN

࿇࿆③

②

①

Fig. 10: Installation with wall face frame

①Wall face frame

②Screw fixing

③Extension piece

∅D2 Installation opening

Ä

Table on page 20

ⒶInstallation side

ⒷOperating side

Personnel:

Specialist personnel

Requirements

Performance class EI 90 S

Solid walls or fire walls made of, for example, concrete, aerated concrete, masonry, or solid gypsum wallboards

according to EN 12859 (without open spaces), gross density ≥ 500 kg/m³ and W ≥ 100 mm

≥ 75 mm distance to load-bearing structural elements

200 mm minimum distance between two fire dampers

1. Create an appropriate opening with ØD2

Ä

Table on page 20

2. Extend the fire damper with an extension piece or a spiral duct on the installation side.

3. Position the fire damper with the wall face frame in the centre of the installation opening.

4. Fix the wall face frame with four threaded rods M8 (push through installation) or with anchors. For solid walls,

suitable steel anchors with building inspectorate approval must be used.

Dimensions of installation opening/wall face frame [mm]

Nominal size 100 125 150 160 180 200 224 250 280 315

ØD2 130 155 180 190 210 230 254 280 310 345

☐B2 200 225 250 260 280 300 324 350 380 415

Installation opening tolerance -20 mm / 2 mm

Installation

Solid walls > Dry mortarless installation with wall face fra...

Fire damper Type FKRS-EU20

Other manuals for FKRS-EU

1

Table of contents

Other Trox Fire And Smoke Damper manuals

Popular Fire And Smoke Damper manuals by other brands

actionair

actionair FG Series manual

System air

System air PK-I-R-EI60S manual

Komfovent

Komfovent UVA60 M installation manual

pottorff

pottorff BD-50-SS installation instructions

mercor

mercor mcr FID WING Technical documentation operation manual

BSB

BSB FD-C Installation, operating, & maintenance instructions