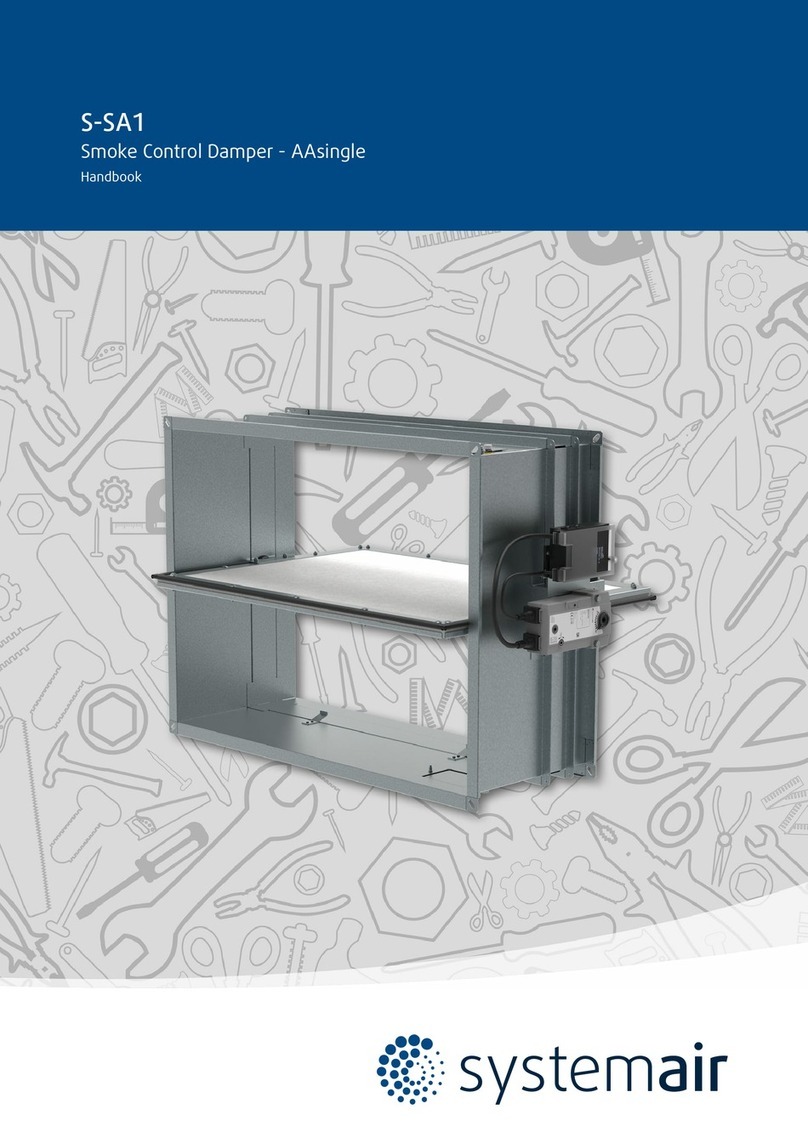

System air PK-I-R-EI60S User manual

Other System air Fire And Smoke Damper manuals

System air

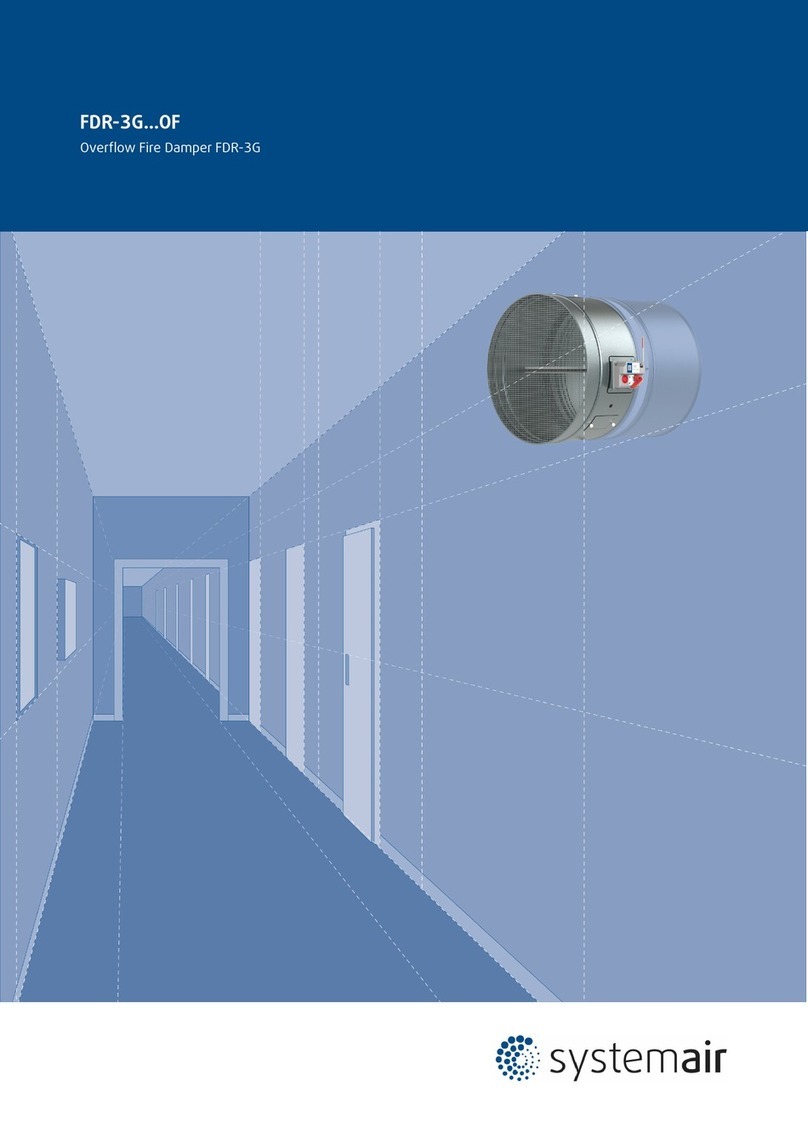

System air A-FDR-3G-OF User manual

System air

System air F-B90 User manual

System air

System air F-B90 User manual

System air

System air FDR-3G KS Series User manual

System air

System air FDR-3G User manual

System air

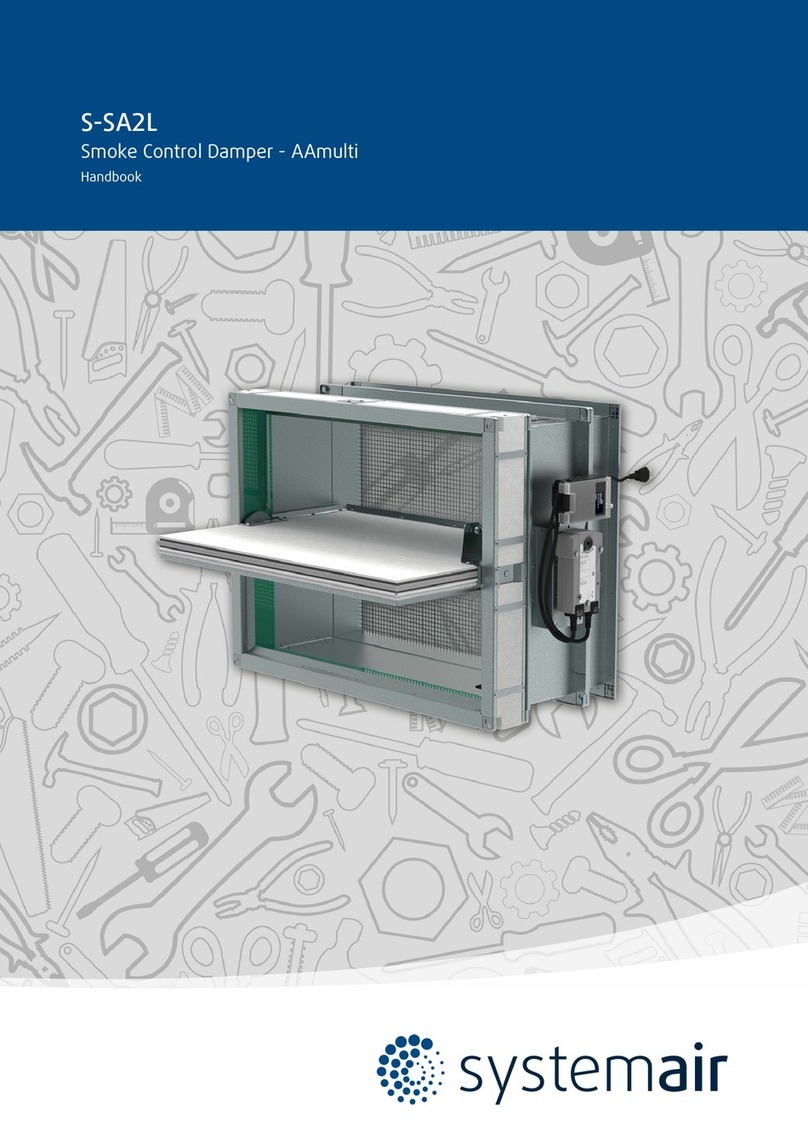

System air S-SA2L User manual

System air

System air fantech Pro 150 Manual

System air

System air FDR-3G KR Series User manual

System air

System air S-RA1 Series User manual

System air

System air fantech bathfan Select SC50-80-110 User manual

System air

System air FDS-3G OF Series User manual

System air

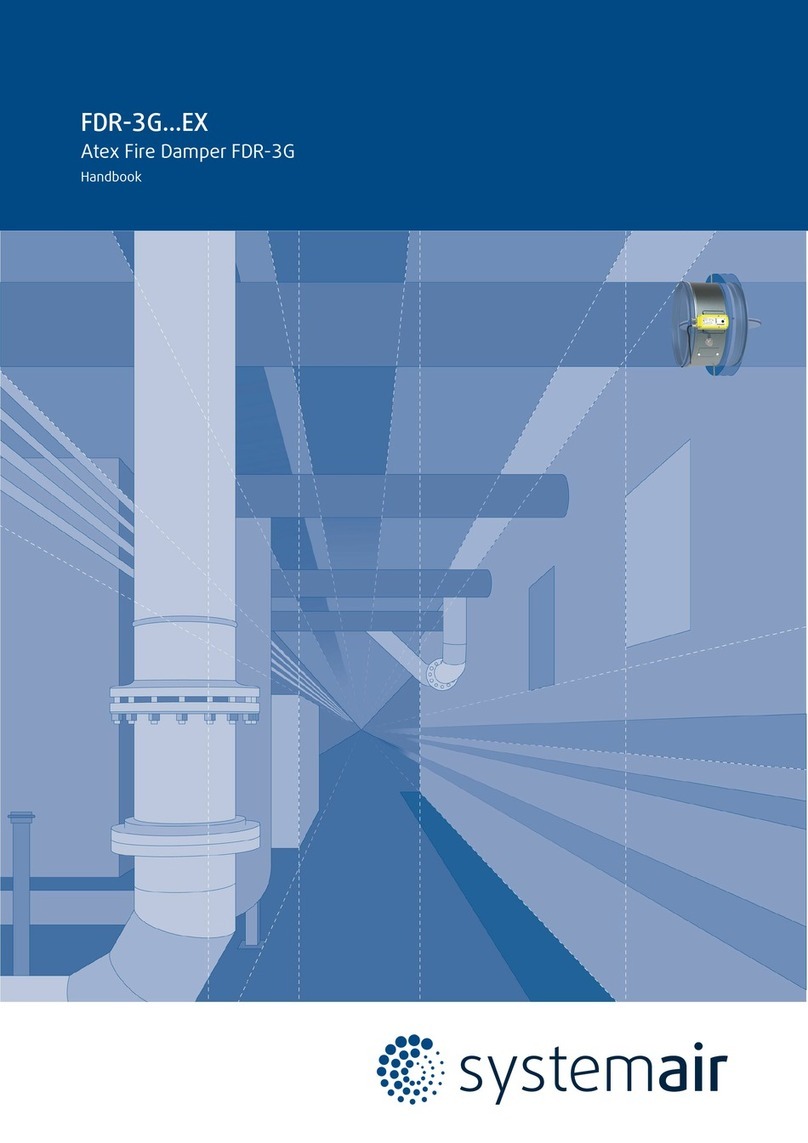

System air FDS-3G EX Series User manual

System air

System air MA multi User manual

System air

System air DKIR1 Owner's manual

System air

System air SAVE VTC 700 Guide

System air

System air F-R60 User manual

System air

System air IMOS-RK Use and care manual

System air

System air S-BA2 User manual

System air

System air PKIR-E60S Manual

System air

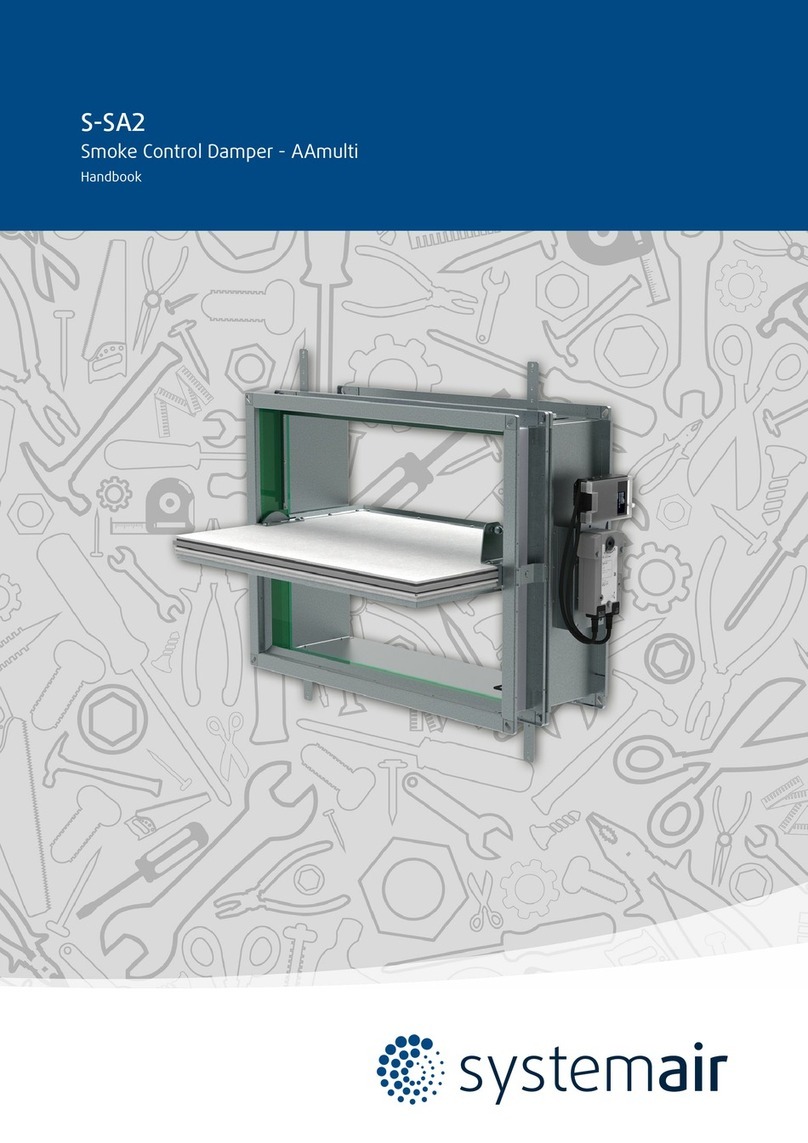

System air S-SA2 User manual

Popular Fire And Smoke Damper manuals by other brands

HVC

HVC NCA 700 Series Operation and maintenance manual

Wildeboer

Wildeboer FR90 user manual

FläktGroup

FläktGroup ETCE Instructions for installation, operation and maintenance

Tamco

Tamco 1000 SM Series manual

Greenheck

Greenheck Vektor-MD Installation, operation and maintenance manual

Lindab

Lindab FBC2 Installation booklet

EKOVENT

EKOVENT EKO-SRB1 Installation, operating and maintenance instructions

Greenheck

Greenheck HBS Series Installation, operation and maintenance instructions

Advanced Air

Advanced Air 0160 Series Installation, operation and maintenance manual

Greenheck

Greenheck CRD-1WT Installation, operation and maintenance manual

Swegon

Swegon Actionair CSS Series installation guide

TAKACHIHO

TAKACHIHO FYN-M 1 Series manual