5

2.3.

Communication and control devices

2.3.1.

BKS 24-1B communication and control device is used for control and checks of fire flap valves

with the BLF 24-T-ST actuating mechanism in conjunction with the BKN 230-24 supply and

communication device. BKS 24-1B receives information about the situation of the fire damper

through the BKN 230-24 supply and communication device and issues controlling commands.

The device is intended for building in into the distribution board. Light diodes on the front side of

the device signalise the operating situations of the damper and breakdowns of the whole system.

Nonpotential auxiliary contacts enable connection to the master control system (signalisation of

the damper position, failure reports, release of the ventilators etc.).

While a flashing green LED pilot light signalises flap blade motion towards the given position, the

same pilot light reports reaching the required position when shining constantly. If the damper, with

respect to the given time, does not reach the required position, then a red LED pilot light starts to

flash and at the same time, the failure contact is active. Once the damper blade reaches the given

position, this contact is deactivated. The LED pilot light keeps flashing unless the failure is

unblocked by means of the RESET button.

2.3.2.

BKS 24-9A communication and control device is used for group control and checks of 1 to 9 fire

dampers with the actuating mechanism BLF 24-T-ST in connection with the supply and

communication device BKN 230-24. Signalisation of the damper position is individual; the

dampers can be controlled and tested only as a group. BKS 24-9A is intended for use in the

distribution board and displays the operation situations and failure reports of the connected fire

dampers. It is possible to signalise functions such as the damper position and failure reports or to

transmit them further to the system by means of integrated auxiliary switches. BKS 24-9A

receives signals from BKN 230-24 through the two-conductor wiring and issues control

commands. Proper damper operation is indicated by two light LED diodes:

Control ON = position OPERATION

Control OFF = position FAILURE

If the fire dampers do not reach the given position in time tolerable for displacing, the appropriate

light diode FAILURE starts to flash and K1 contact is opened (current failure). In case that the

faulty damper finally reaches its given position, K1 is closed and the failure report light shines (the

failure is saved in memory).

K2-theauxiliarycontact-isusedforsignalisationoftheflappositiontothemasterdevice.Function

of this auxiliary contact can be programmed through the terminal 14 according to the Tab. 2.2.1.

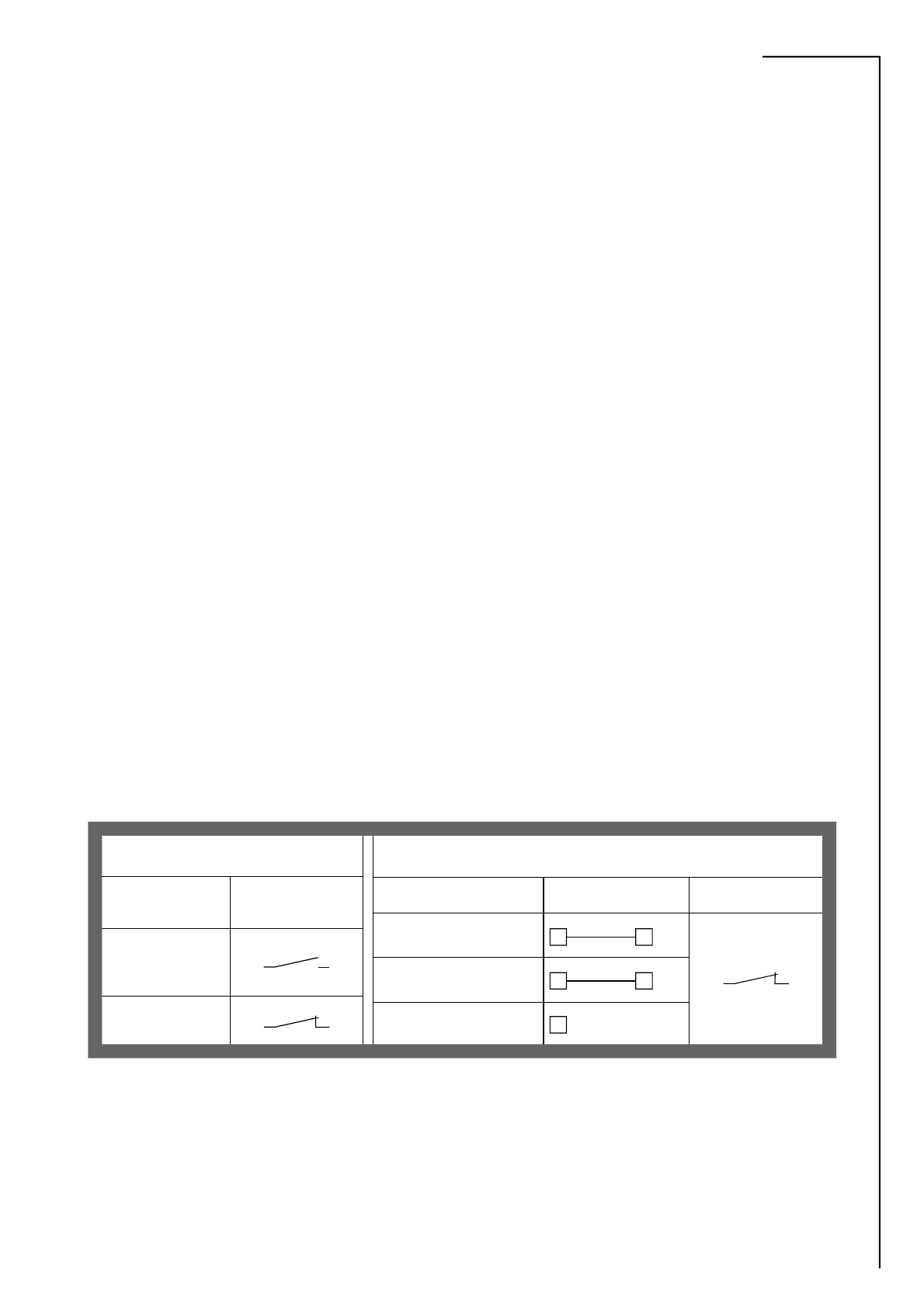

Tab. 2.3.1. BKS 24 -9A contacts K1 and K2

K1 Function Contact

Situation State

Current Failure

15 16

No Failure

15 16

Programming K2 Auxiliary Contact

Function Interconnection State

K2 contact is on if all the

damperss are open 14 11

17 18

K2 contact is on if the damper

No. 1 is open 14 12

K2 contact is on if all the

dampers are closed 14 open

Function check can be done in the position OPERATION by means of pushing the TEST

button. While the button is pushed, the flap blade is turning into the position FAILURE. Fault

function is indicated by a report "FAILURE".

2.4.

Design of the FDMD in terms of design. It shall be marked with the first and second additional digit

after the dot in the ordering key.