Bevent Rasch BSK6 User manual

13/09/2017

www.bevent-rasch.com

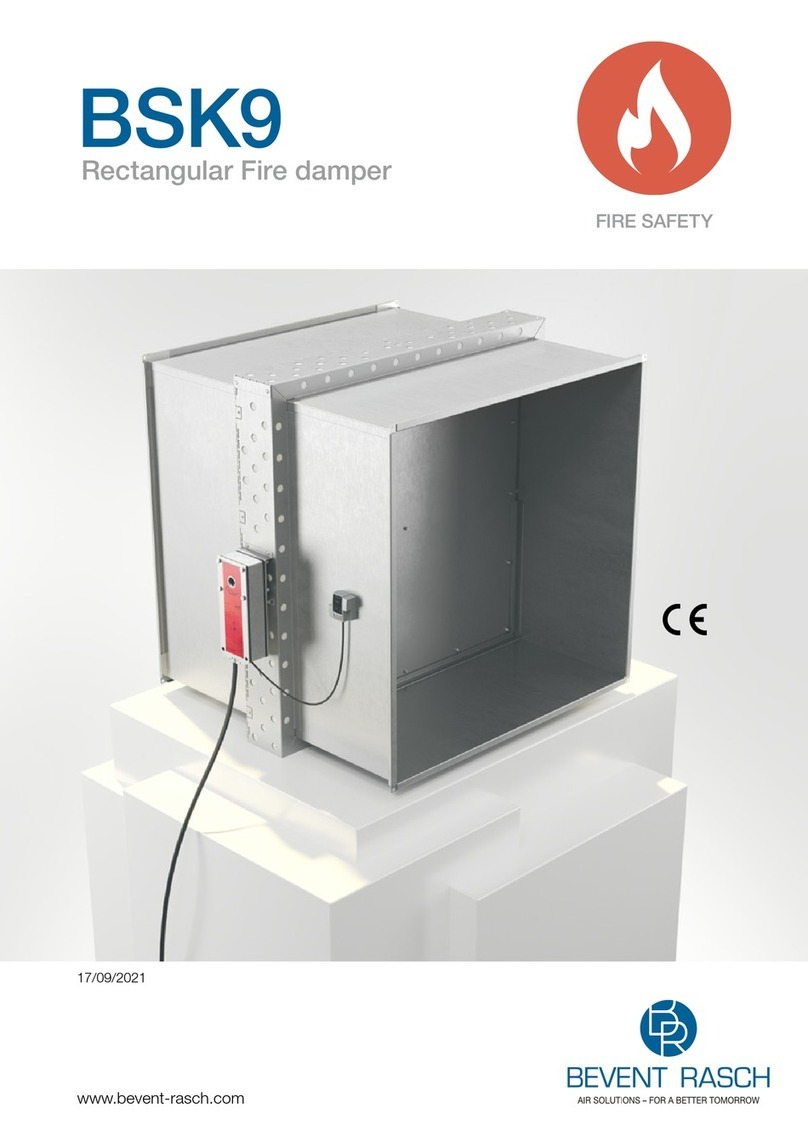

BSK6

Rectangular Fire damper

FIRE SAFETY

2BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

Fire damper BSK6 EI60

Installation

BSK6 is installed in duct work separating walls or joist sys-

tems, according to the adjoining installation instructions.

Should not be installed outdoors or in damp areas.

Actuator

BSK6 is always supplied with an electric safety actua-

tor with spring return complete with thermal sensor with

pushbutton for local manual operating test. The sensor

disconnects the power to the actuator if the temperature

exceeds 72°C inside or outside the damper. 24V actuators

are always used in connection with the MRB monitoring

system. Dampers can also be supplied with electric actu-

ator 230V.

Note that the BSK6 damper is always supplied with an

actuator.

Activation

According to Boverket’s Building Regulations smoke de-

tectors must be verified according to SS-EN 54-7 to acti-

vate dampers. The mandatory thermal sensor closes the

damper at 72°C according to ISO 10294-4.

Control and monitoring

When the damper is used to prevent the spread of fire and

combustion gases it must be closed via impulses from the

smoke detector. This must be fitted in the ventilation duct

in the proximity of the damper or in another suitable loca-

tion. Smoke detectors are monitored by means of Bevent

Rasch’s MRB system or the like. The MRB monitoring

system also performs automatic operating checks on the

damper every 48 hours and is designed so that faults are

indicated immediately and the damper closes.

See www.bevent-rasch.com for further details.

Quick facts

• Fire resistance class EI60 / EI60S

• Sizes from 200 x 200 mm to 800 x 800 mm

• Prefitted safety actuator 24V or 230V

• Low weight

• Easy installation

• CE-marked building product according to 15650:2010

• Available in MagiCAD

Use

Damper in combination with walls or joist systems for fire

separation of heating, ventilation and air conditioning in-

stallations in buildings. In accordance with the harmonised

European standard EN 15650:2010. In designs according

to associated documents, installation instructions and

when the damper is used in combination with smoke

detectors and monitoring system (MRB), or the like, the

spread of fire/combustion gases is prevented. No further

action against the spread of fire/combustion gases is re-

quired.

Performance

EC certificate according

to EN 15650:2010

0402-CPR-SC1299-13

Classification of fire resistance

according to EN 13501-3

EI60 (ve ho i <–> o) S

For complete classification,

see the Declaration of Performance.

3BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

EI60 Fire damper BSK6

Size

From 200 x 200 mm to 800 x 800 mm, in steps of 50 mm.

Design

BSK6 is supplied complete with factory mounted,

maintenance-free, 24V or 230V electric safety actuator

with thermal sensor featuring built-in signal contacts to

indicate the damper position. Flanged connections.

Material and surface finish

Casing and components of galvanized steel sheet

according to environmental class C3. Fabric seals.

Blade and casing of solid fire protection materials.

Accessories

BRAS Connection spigot for spiral duct

RBFS Extension spigot for wall/joist systems

thicker than 280 mm, and in combination

with BRAS or wire mesh grilles

RBMP Assembly plate, excl. refinishing material

(RBBM), for installation in plaster

structures EI 60 / EI 120

RCKB Connection box

RCDU MRB system, max 2 dampers

RCBK4 MRB system, max 4 dampers

RCMU8 MRB system, max 8 dampers

RCKD/-RD Smoke detectors

BRTR Wire mesh grille, rectangular

RCTU/RCTC MRB3 system, max 236 dampers

Specification

Example:

Fire damper BSK6 - 400 - 400 - 1 - 1

Size

Width x Height (W x H), mm

Material

Galvanized sheet steel = 1

Stainless AISI 3041 – EN 1.4301 = 2

Stainless AISI 316L – EN 1.4404 = 3

Actuator

Electric 24V with thermal sensor = 1

Electric 230V with thermal sensor = 3

Electric 24V incl. RCTU = 5

Note. Factory fitted actuator always included.

4

Brand-/Brandgasspjäll BSKC6 EI60

BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

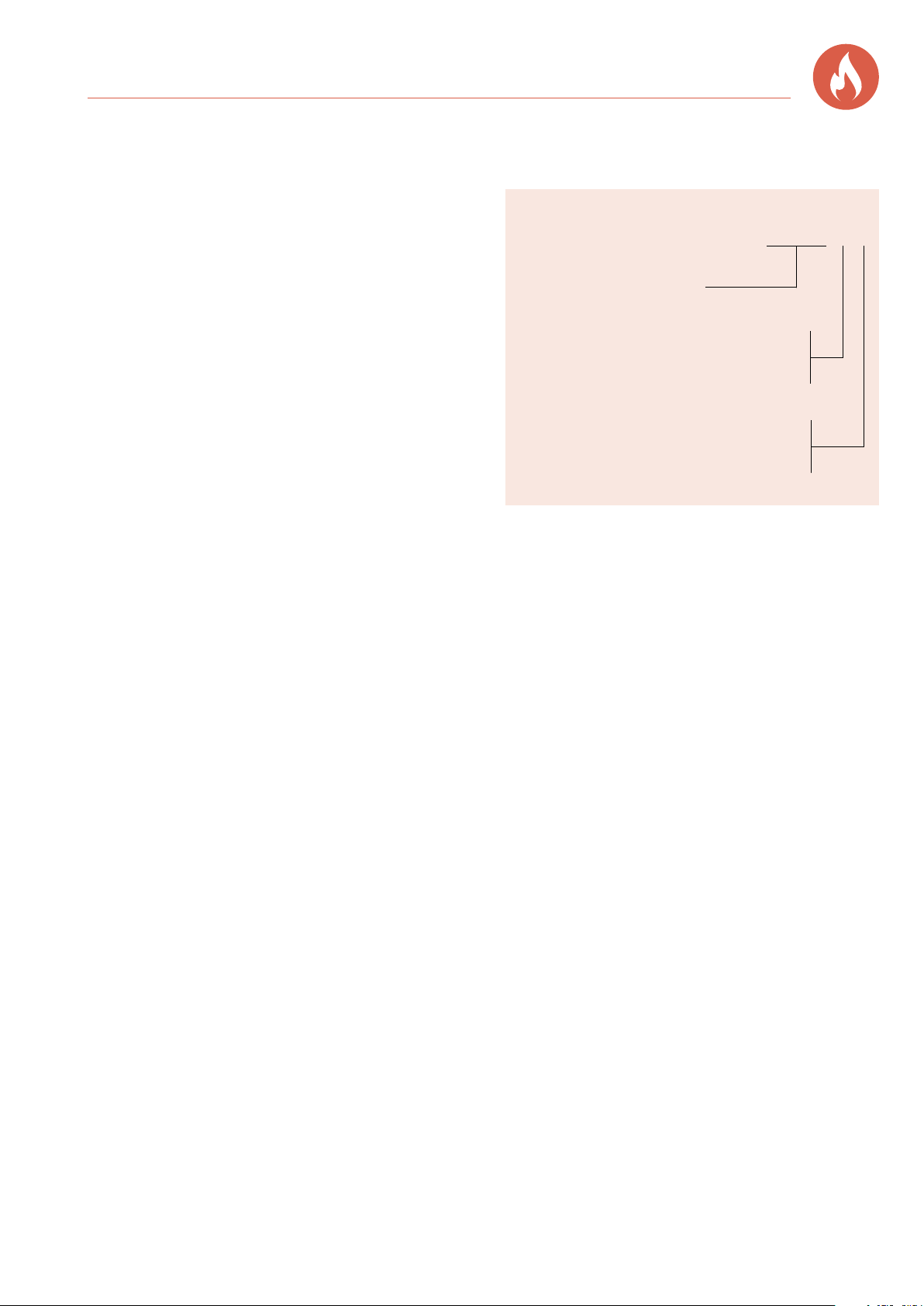

Fire damper BSK6 EI60

Dimensions and weight

Electrical data (values in brackets refer to 230V)

Actuator type BF...

Sizing, max ...................... 10 VA (12.5 VA)

Running time:

– motor opening, max ..... approx. 120 s

- spring return, max ......... approx. 20 s

Protection class ............... IP 54

Power supply .................. 24V~ ±20%, 50/60Hz

24V= ±10%

(220-240V~ , 50/60Hz)

Ambient temperature ....... -30° to +50°C

Safety temperature .......... -30° to +75°C

(24 hrs. guaranteed safety)

Tripping temperature

thermal sensor .................

72°C

End position contacts

- load ≤ 300 mW ..... min 1 mA/5V=, max 100 mA/250V~

After exceeding the above values it applies:

- load > 300 mW ..... min 100 mA, max 3 A/250~

Sound level when opening approx 45 dB(A)

Sound level when closing approx 62 dB(A)

Chart indicates in

the de-energized

state

Wiring

diagram

Tf1 Tf2

BAE72-S

Actuator

C

O

N

L1

M

1

2

1

2

3

4

5

6

5°

80°

Thermal

sensor

Actuator

43

48 D125 227

400

A

max*)

128 W

H

Flanged connection19

*) applies to standard design

HAD

200 0 0

250 25 0

300 50 0

350 75 0

400 100 0

450 125 0

500 150 0

550 175 0

600 200 20

650 225 45

700 250 70

750 275 95

800 300 120

Dimensions, mm Weight incl. 24V actuator, kg

H

W

200

250

300

350

400

450

500

550

600

650

700

750

800

200 12 13 15 16 17 18 20 21 22 24 25 27 28

250 13 15 16 17 18 20 21 22 24 25 27 28 30

300 15 16 17 18 20 21 22 24 25 27 28 30 32

350 16 17 18 20 21 22 24 25 27 28 30 32 33

400 17 18 20 21 22 24 25 27 28 30 32 33 35

450 18 20 21 22 24 25 26 28 30 32 33 35 36

500 20 21 22 24 25 26 28 30 32 33 35 36 38

550 21 22 24 25 26 28 29 32 33 35 36 38 39

600 22 24 25 26 27 29 30 33 35 36 38 39 41

650 24 25 26 27 29 30 31 35 36 38 39 41 42

700 25 26 27 29 30 31 33 36 38 39 41 42 44

750 26 27 29 30 31 33 34 38 39 41 42 44 45

800 27 29 30 31 33 34 35 39 41 42 44 45 47

5

EI60 Brand-/Brandgasspjäll BSKC6

BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

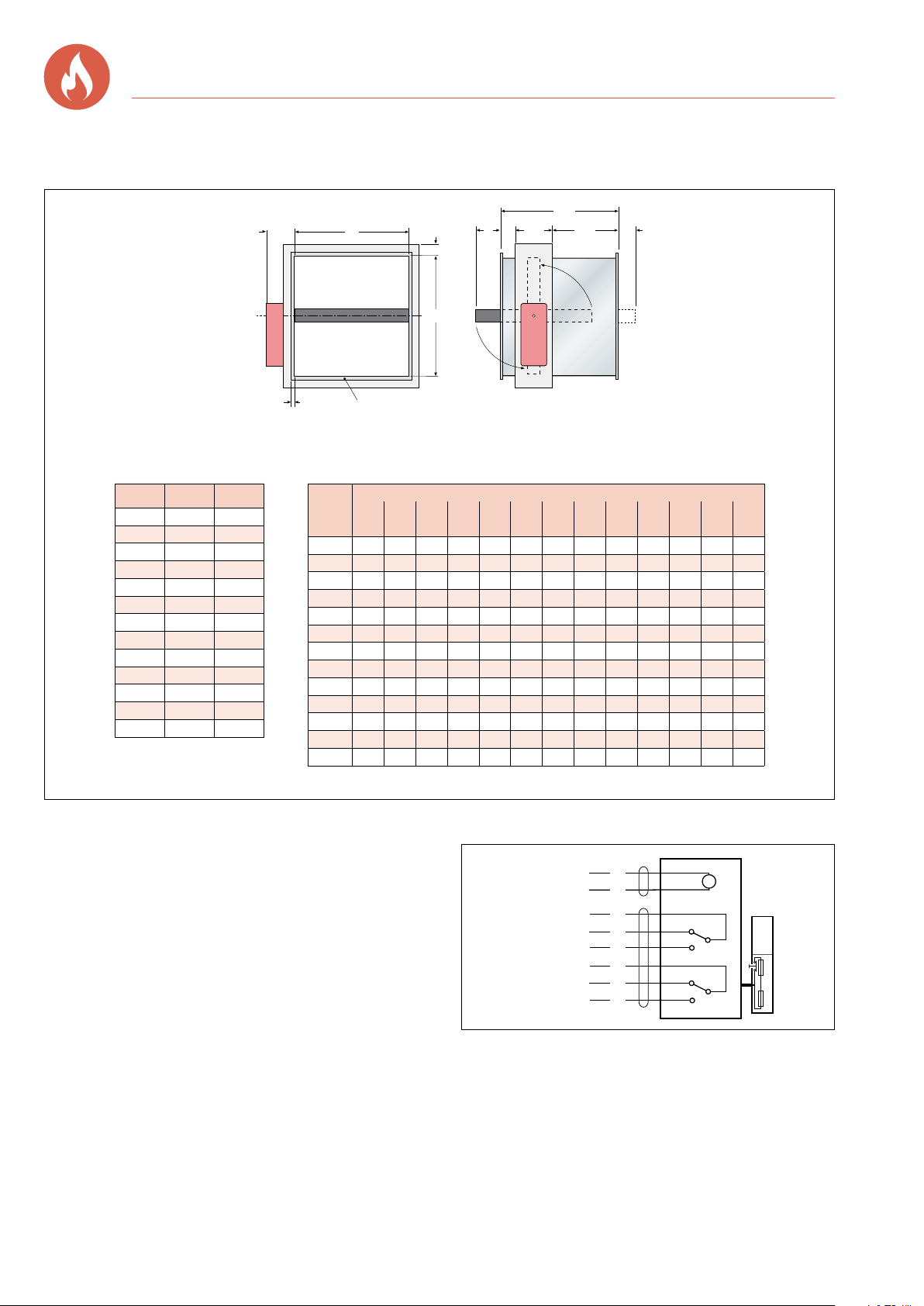

EI60 Fire damper BSK6

Assembly plate (incl. in delivery)

Supplied unassembled

Ød Ød

A 400 A

A 400 A

BRAS RBFS BRAS

BRAS RBFS BRAS

RBFS

L2

L1

L1

Ød

L

1

/L

2

A

Connection spigot

BRAS

Extension spigot

RBFS

Ød = 250 - 500 mm

1 x RBFS required Ød = 630 - 800 mm

2 x RBFS required

Installation

*) Length as per the table above

*)

*)

*)

Note. For circular dampers first use the BSKC6 damper.

BRAS

Ød

Min. damper

size A

RBFS

L1L2

100 200 x 200 50 – –

125 200 x 200 50 – –

160 200 x 200 50 – –

200 200 x 200 50 – –

250 250 x 250 50 155 –

315 350 x 350 65 155 –

400 400 x 400 80 155 –

500 500 x 500 80 330 –

630 650 x 650 80 330 155

800 800 x 800 80 330 155

Duct size W/H + 65 mm

60

60

6

Brand-/Brandgasspjäll BSKC6 EI60

BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

Fire damper BSK6 EI60

13-0272_ENG / Sept. 2017 teamfront.se

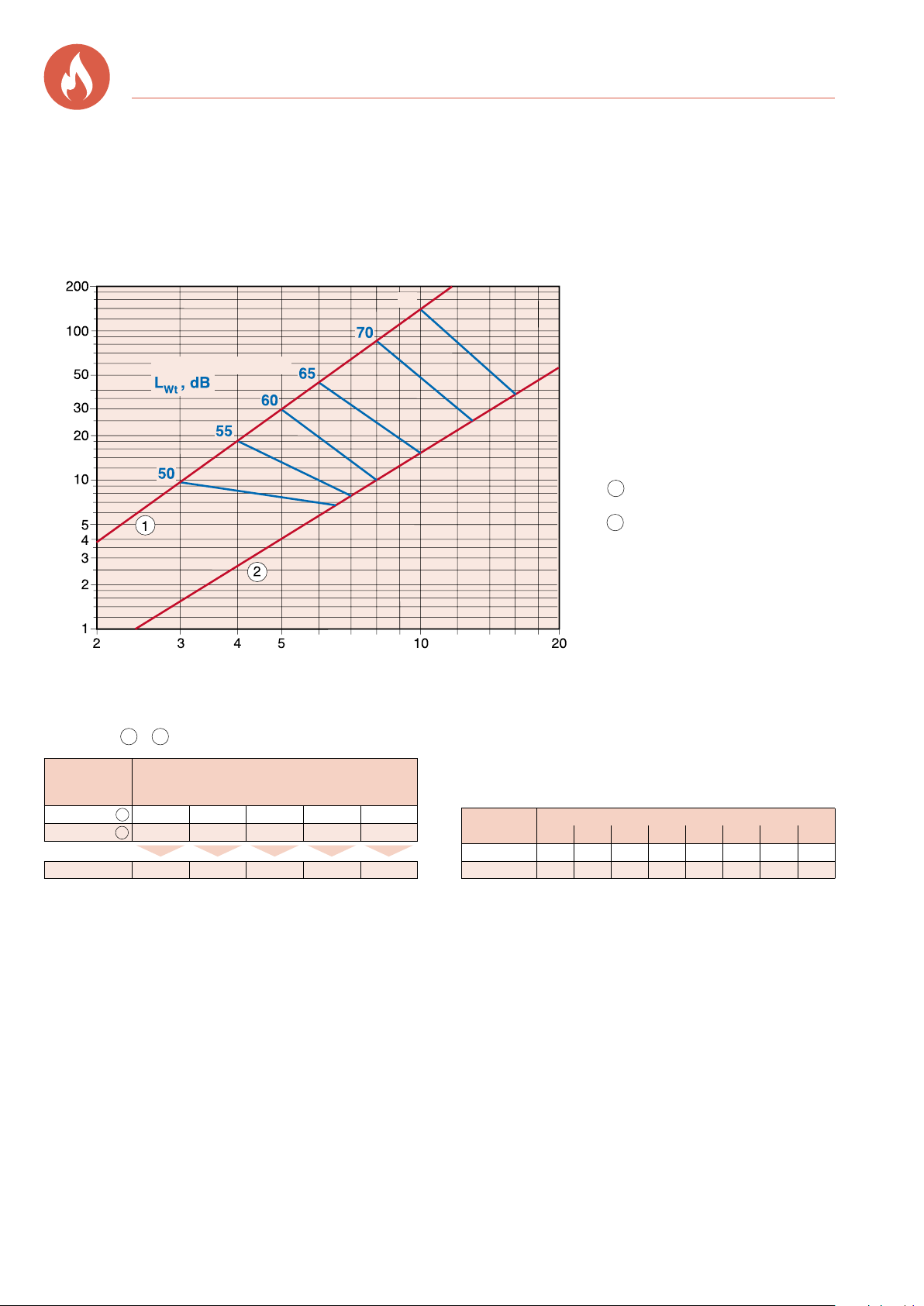

Sound data

The speed is calculated on the damper’s gross area, i.e. a

BSK6 - 400 x 400 has a gross area of 0.16 m2.

The specified pressure drop applies to the damper without accessories.

Technical data

75

Total pressure drop, Pa

Air speed, m/s

Sound power level

1 Damper Height < 400 mm

2 Damper Height ≥ 400 mm

Correction of sound power level, Lok, in octave band

LWok = LW+ Kok

Correction of sound power level, LW, for different sizes

use curves 1 - 2 according to: LW= LWt + K1

Damper

height

mm Damper area, m2

<200 as per 1 - 0,08 0,16 0,28 -

≥400 as per 2 0,08 0,16 0,32 0,64 1,28

K1-3 0 3 6 9

Correction, Kok

Opening

angle

Centre frequency Hz

63 125 250 500 1000 2000 4000 8000

90° -1 -11 -18 -23 -26 -28 -32 -38

Tol. ± dB 1 2 3 4 6 6 6 6

7

EI60 Brand-/Brandgasspjäll BSKC6

BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

EI60 Fire damper BSK6

13-0272_ENG / Sept. 2017 teamfront.se

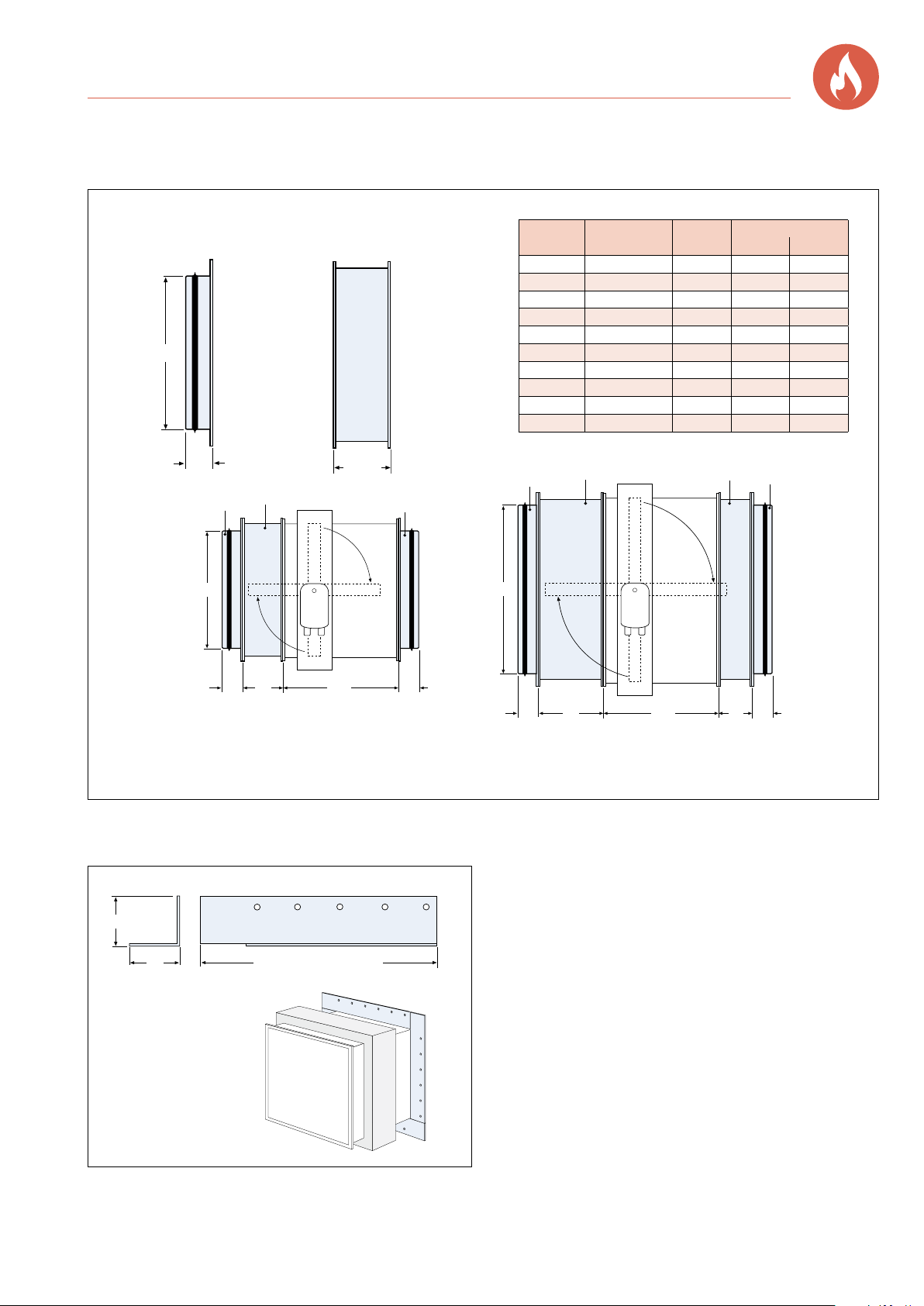

Options 1 and 2

1. Aperture equivalent to damper dimensions + 50 mm,

is produced in the building element.

When mounted in a drywall, horizontal metal joists

45x45 mm shall be applied as a frame in the wall

structure.

2. The damper is secured flat and tight using fire stopping

sealant (Intumex AN) against the wall/joist structure with

the fastening lugs, which are opened out.

When mounted in drywall, Spax screws shall be

screwed in to the joists.

3. Make sure the gap between damper and wall is 25 mm

all around. Sealing is carried out by caulking with miner-

al wool, min 40 kg/m3.

4. Fit the assembly plates RBMP on to the building ele-

ment, using appropriate fastening material.

When mounted in drywall, Spax screws shall be

screwed in to the joists. Attach the assembly plates on

to the damper, using stainless steel pop rivets through

the prepunched holes in the assembly plates.

Mount the pop rivets from the inside and out. Make

sure nothing is obstructing the movement of the

damper blade.

Building element (wall or joist structure)

in fire resistance class EI60.

Damper’s fire resistance class: EI60

(ve ho i <-> o) S.

EC certificate 0402-CPR-SC1299-13

Option 1 Option 2

5. If fire damper is not connected to the duct system, fit

non-combustible grilles designed for the damper on the

unconnected sides. Connection piece RBFS may be

needed from sizes 600 mm or larger.

The minimum distance between the damper blade in

the open position and the grille is 50 mm.

6. Install the thermal sensor with the sensor body in the air

stream without obstructing the movement of the

damper blade.

7. Install the duct system according to applicable require-

ments.

8. Install the duct system according to applicable require-

ments. Make sure that the connected duct system

does not impact on the damper in the event of a fire

load.

• Minimum distance between dampers must be 200 mm.

• Minimum distance to joist structure/wall must be 75 mm.

• Horizontal installation of the damper spindle.

W + 50 mm

H + 50 mm

Refinish

see section

3

(Protective grille,

see section 5)

Concrete screw

8x5x65 or equivalent

approved fastening

material

Fastening

lugs

Assembly

plate RBMP

Pop rivet

mounted

fr

om inside

and out

Min. thickness

125 mm

Joist of concrete

or equivalent

fire resistance

class ≥EI60

Installation instruction

W + 50 mm

H + 50 mm

Refinish

see section 3

(Protective grille,

see section 5)

Screw (Spax 5x45

or equivalent approved

fastening material)

Fastening lugs

Assembly plate RBMP

Pop rivet mounted

from inside and out

Horizontal joist,

see section 1

Min. thickness 95 mm

Drywall insulated

with mineral wool

≥ 40kg/m3.

Or equivalent with

wall fire resistance

class ≥ EI60.

Table of contents

Other Bevent Rasch Fire And Smoke Damper manuals

Popular Fire And Smoke Damper manuals by other brands

BSB

BSB FSD-C Series quick start guide

CARNES

CARNES EFOA Installation, operation and maintenance instructions

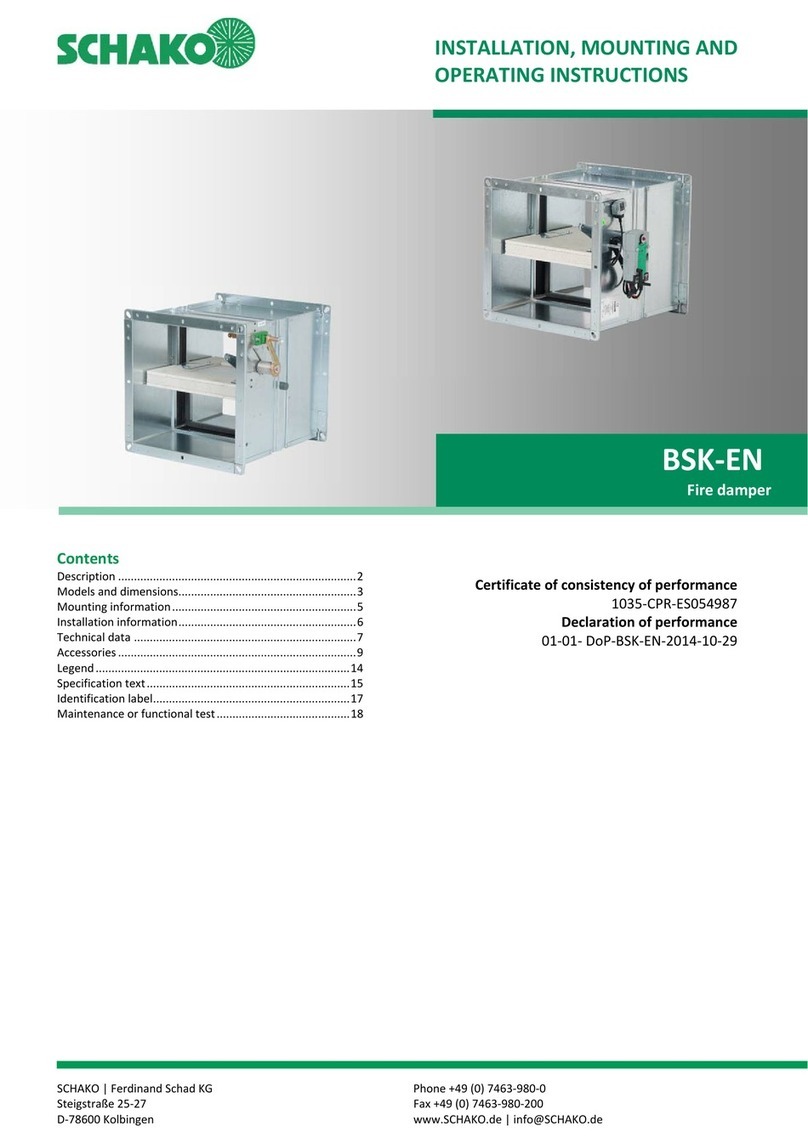

Schako

Schako BSK-EN Installation, mounting and operating instructions

Mandik

Mandik FDML manual

Mandik

Mandik MSD Technical documentation

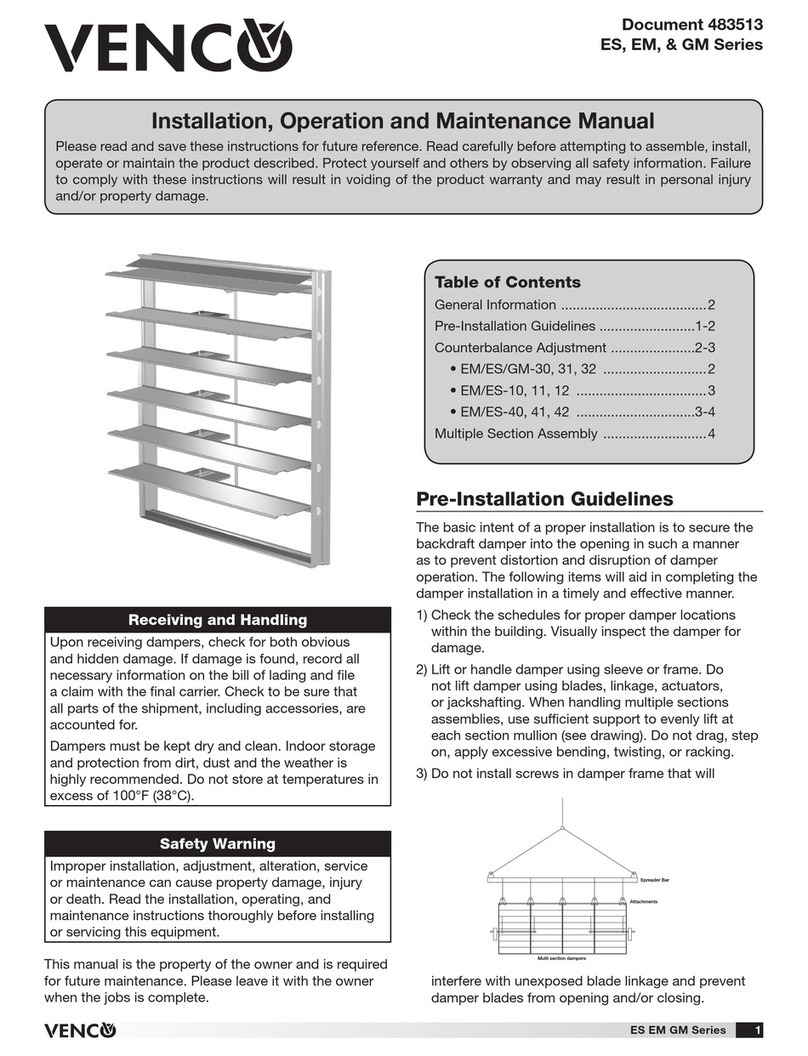

VENCO

VENCO ES Series Installation, operation and maintenance manual