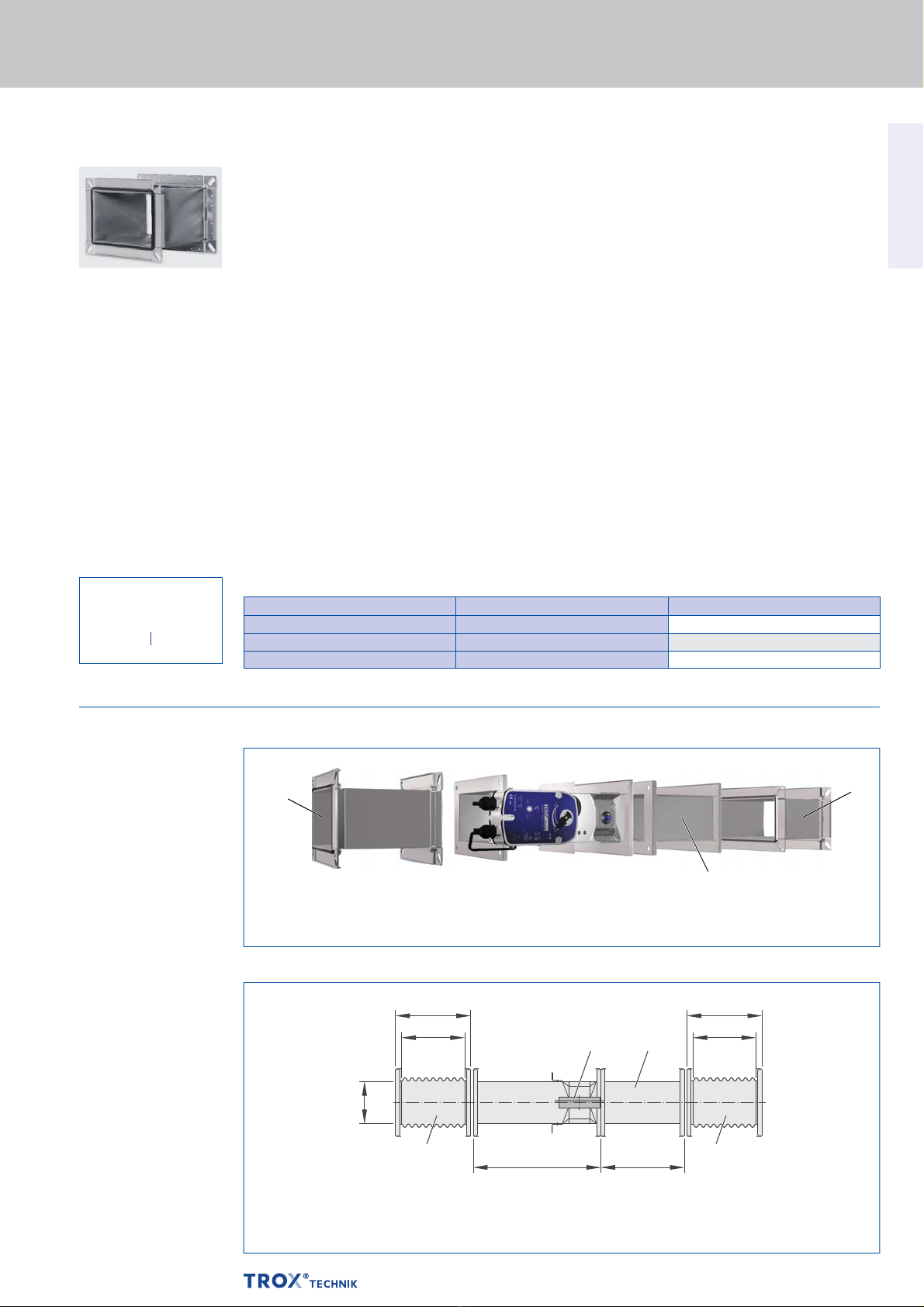

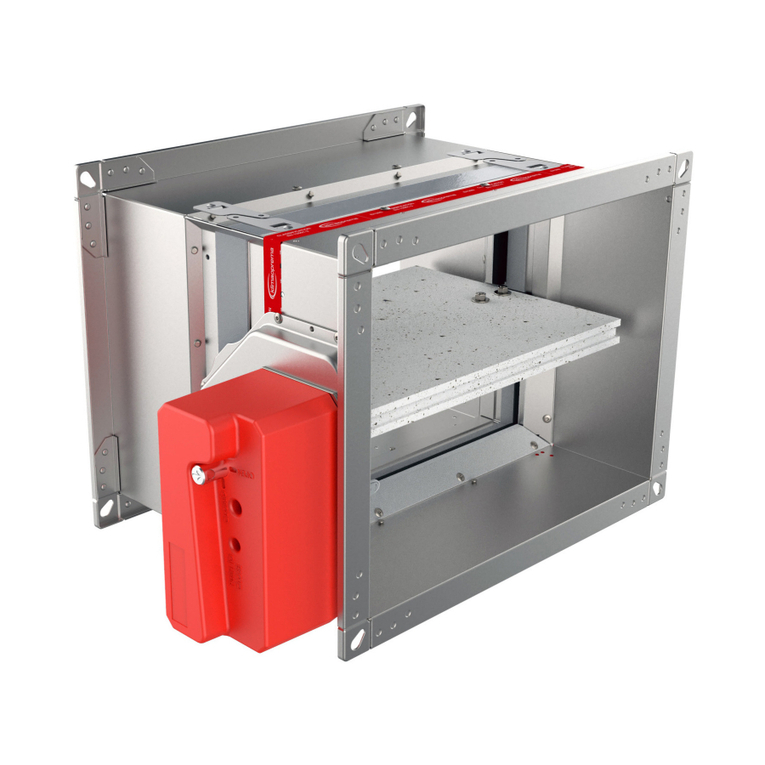

Fire dampers

General information FKS-EU

1

Application

– Fire dampers of Type FKS-EU,

with CE marking and declaration

of performance, for the isolation of duct

penetrations between fire compartments

in the event of a fire

– To prevent the propagation of fire

and smoke through ductwork to adjacent

designated fire compartments

Classification

– Class of performance to EN 13501-3,

up to EI 120 (ve, ho, i ↔o) S

Variants

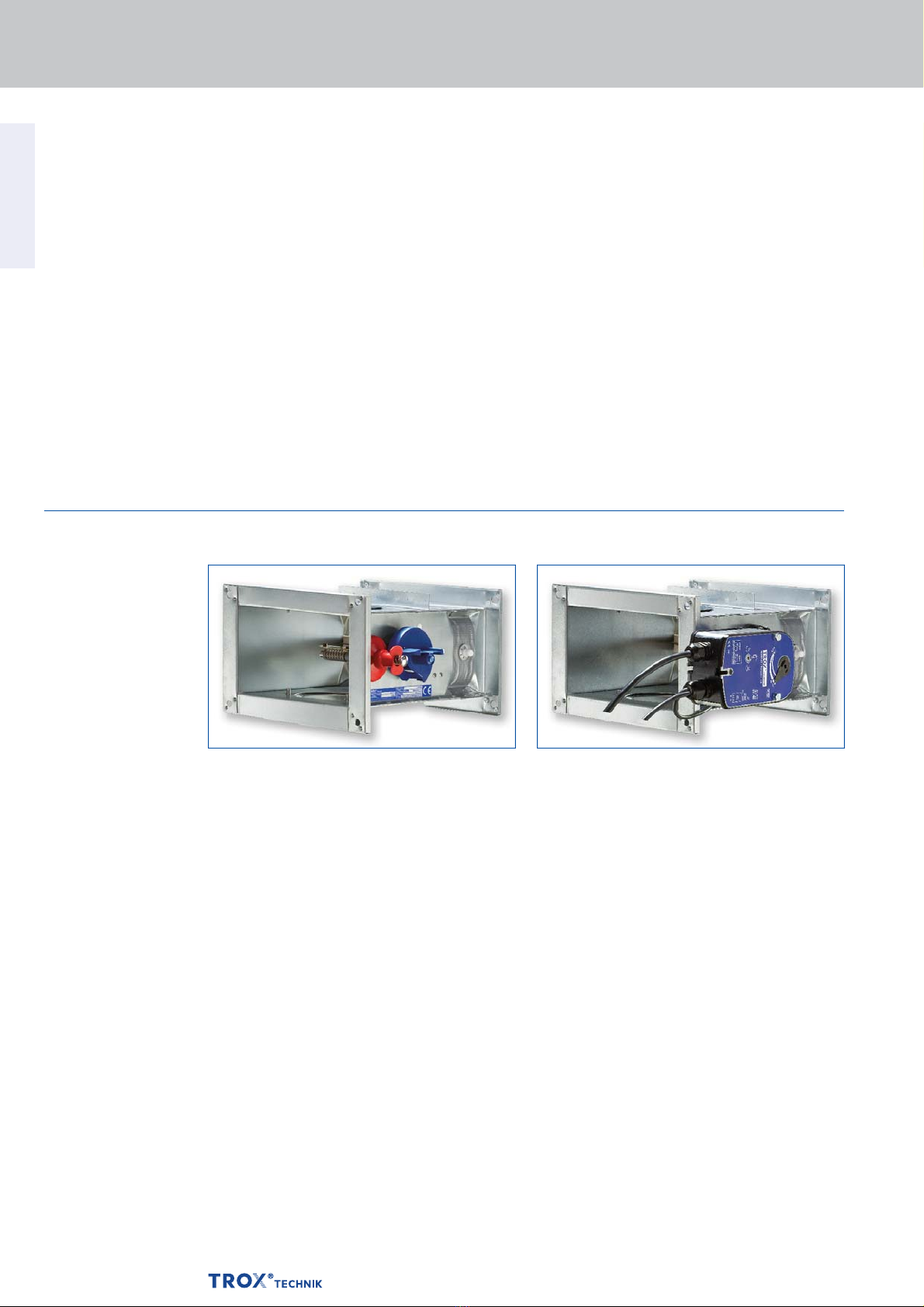

– With fusible link

– With spring return actuator

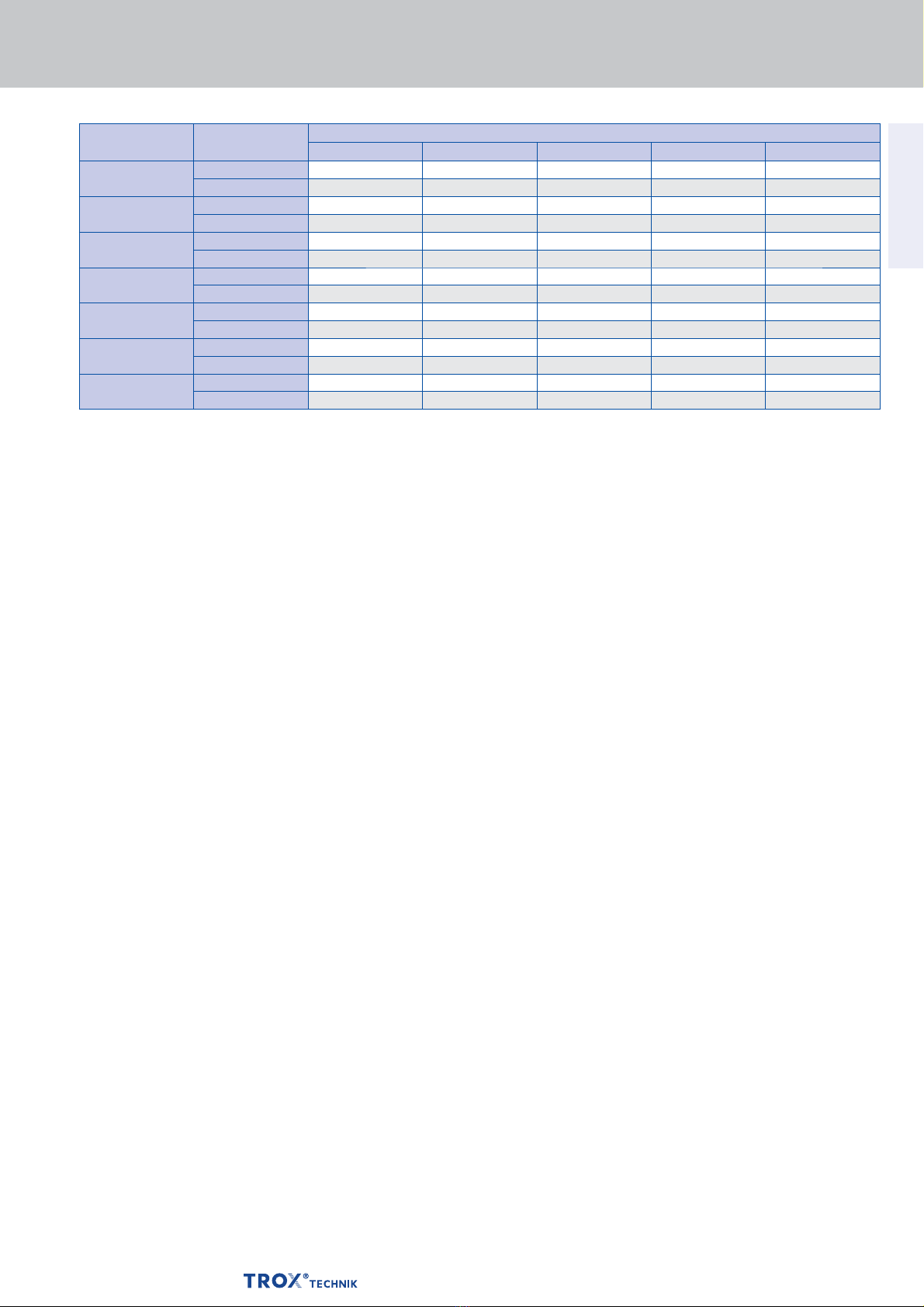

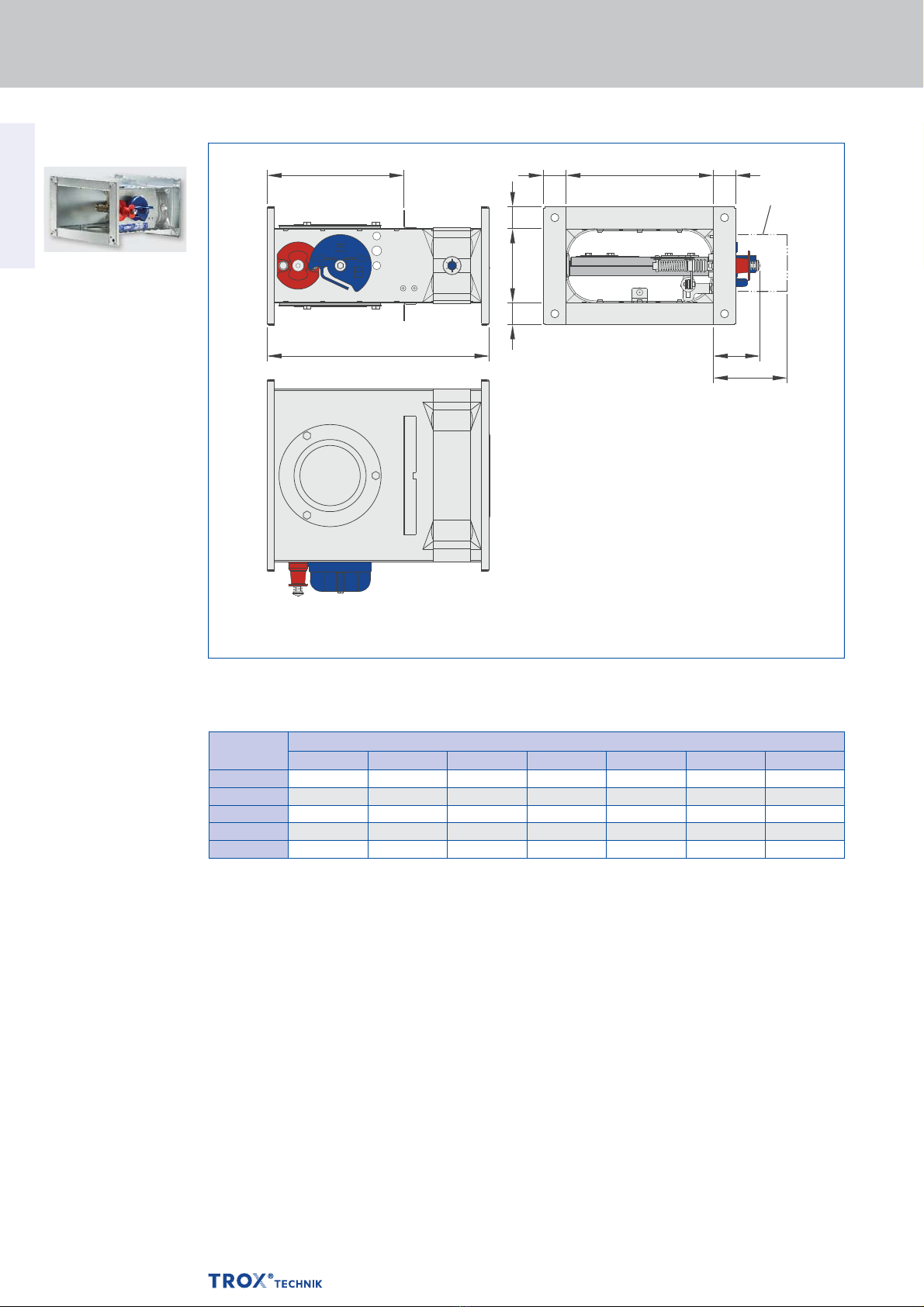

Nominal sizes

– B × H: 200 × 100 – 800 × 200 mm

(width in increments of 50 mm)

– L: 300 mm

Attachments

– Limit switch for damper blade

position indication

– Spring return actuator for 24 V AC/DC

or 230 V AC supply voltage

– Network module for the integration

with AS-i or LON networks

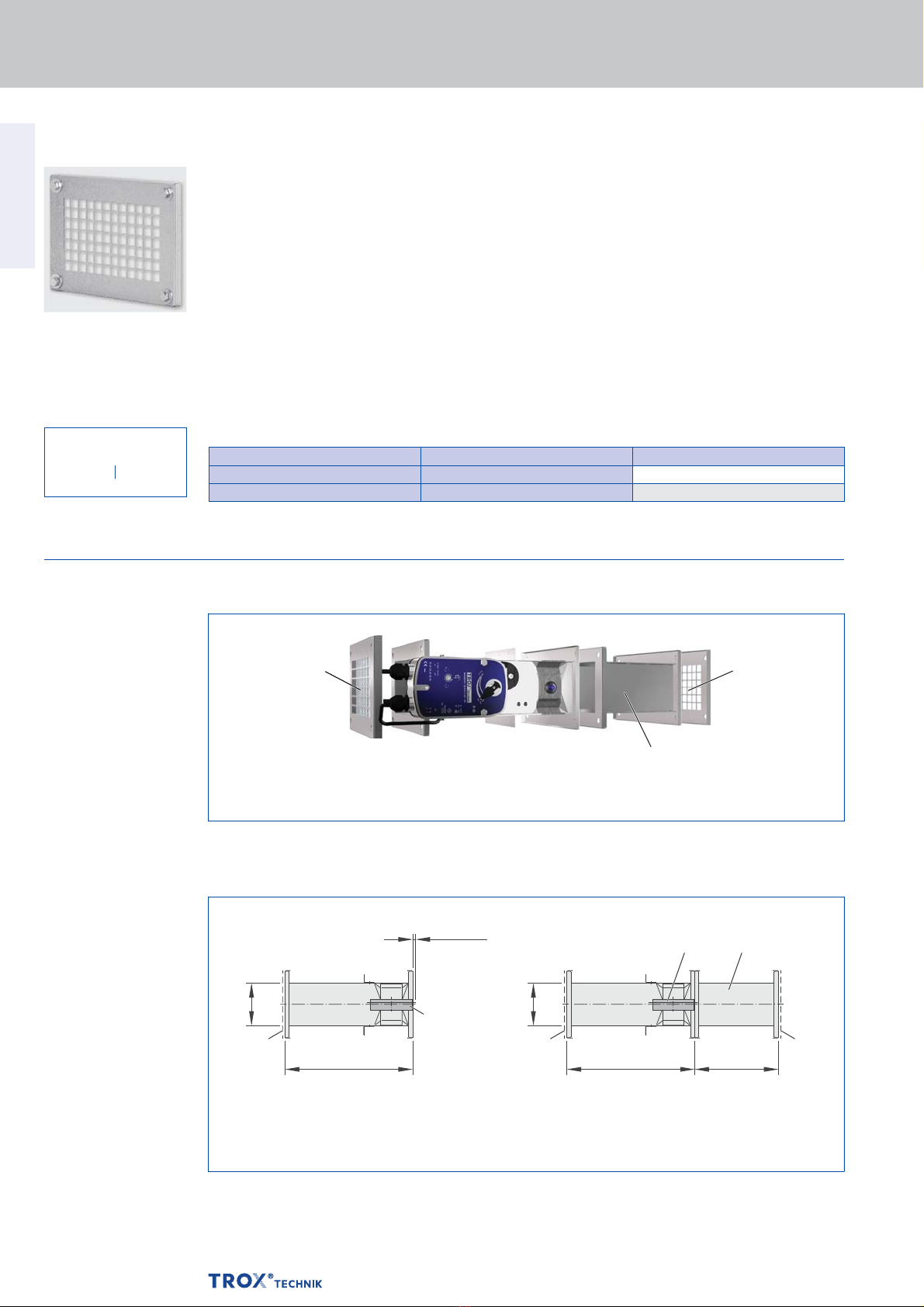

Accessories

– Cover plate (to keep the fire damper stable

and hence facilitate mortaring)

– Cover grille

– Flexible

connectors

– Extension piece

Useful additions

– Duct smoke detector RM-O-3-D

– Duct smoke detector

with airflow monitor RM-O-VS-D

Special characteristics

– Declaration of performance according

to Construction Products Regulation

– Classification to EN 13501-3,

up to EI 120 (ve, ho, i ↔o) S

– Building inspectorate licence Z-56.4212-991,

non-combustible and non-hazardous to health

– Complies with the requirements of EN 15650

– Tested to EN 1366-2

for fire resistance properties

– Hygiene complies with VDI 6022 part 1

(07/2011), VDI 3803 (10/2002), DIN 1946

part 4 (12/2008), and EN 13779 (09/2007)

– Corrosion protection according to EN 15650

in connection with EN 60068-2-52

– Closed blade air leakage to EN 1751, class 2

– Casing air leakage to EN 1751, class C

– Low differential pressure

and sound power level

– Any airflow direction

– Integration into the central BMS

with TROXNETCOM

Parts and characteristics

– Easy dry mortarless installation into solid walls

and ceiling slabs, lightweight partition walls,

fire walls and shaft walls using

an installation block

– Release temperature 72 °C or 95 °C

(for use in warm air ventilation systems)

Construction features

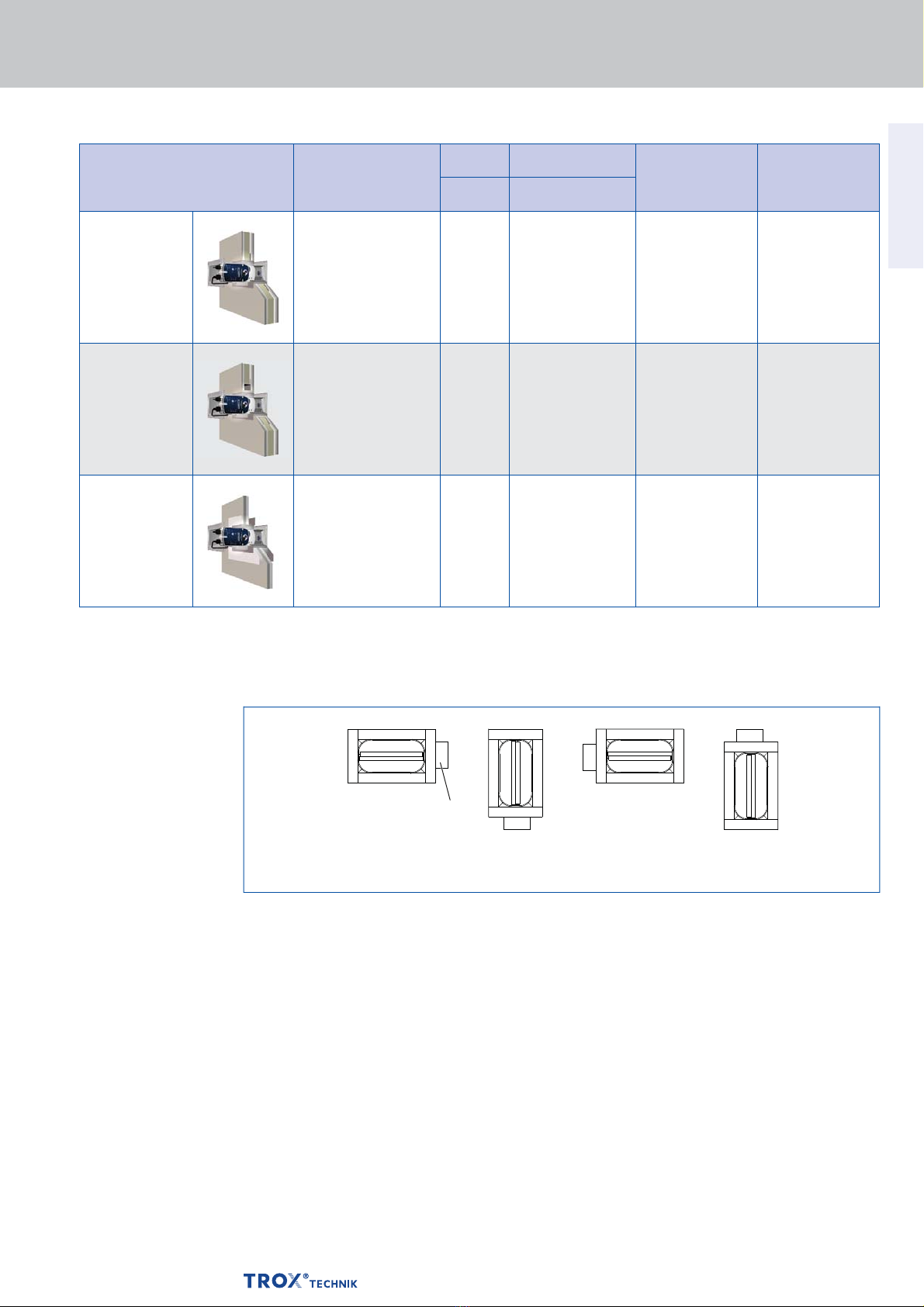

– Rectangular or square construction,

rigid casing, both flanges with fixing holes

(System 30)

– Suitable for the connection of ducts,

flexible connectors or a cover grille

– The release mechanism is accessible

and can be tested from the outside

– Two inspection access panels

– Intermediate dimensions in 50 mm

increments for width

– Remote control with spring return actuator

Materials and surfaces

Casing:

– Galvanised sheet steel

– Galvanised sheet steel,

powder-coated RAL 7001

– Stainless steel 1.4301

Damper blade:

– Special insulation material

– Special insulation material with coating

Other components:

– Damper blade shaft made of galvanised steel

or stainless steel

– Plastic bearings

– Seals of elastomer

The construction variants with stainless steel

or powder-coated casing meet even more critical

requirements for corrosion protection.

Detailed listing on request.

Installation and commissioning

Installion is to be carried out according

to the operating and installation manual

Mortar-based installation:

– In solid walls and ceiling slabs

– In lightweight partition walls and fire walls

with metal support structure

and cladding on both sides

– In shaft walls with metal support structure

and cladding on one side

Dry mortarless installation:

– In solid walls and ceiling slabs

with installation block E

– In lightweight partition walls with metal support

structure and cladding on both sides:

with

installation block E

– In shaft walls with metal support structure

and cladding on one side with installation

block E

K4 – 1.1 – 51

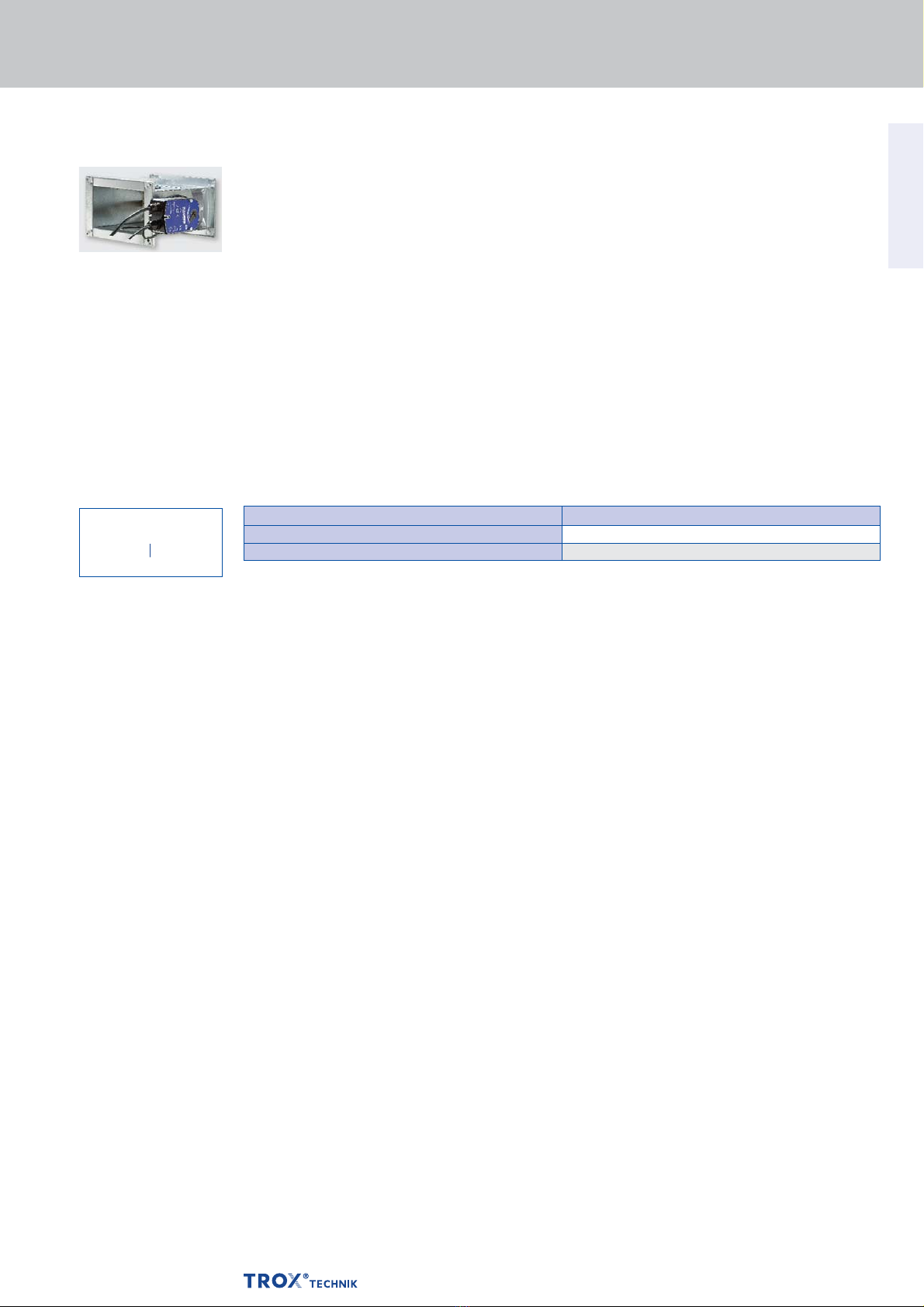

Description

Fire damper Type FKS-EU

For detailed information

on attachments

see Chapter K4 – 1.2.

06/2015 – DE/en