Tru-Test EziWeigh5i User manual

Issue 2, 7/20171

EziWeigh5i, EziWeigh6i, EziWeigh7i,

WOW2 and

Dairy Automation Systems (DAS)

WOW2

Scale Indicator

LEVEL 1 SERVICE MANUAL

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 2

Contents

Service centre requirements................................................................................................................3

Product feedback...........................................................................................................................3

Technical bulletins..........................................................................................................................3

Returning a product........................................................................................................................3

Fault report card.............................................................................................................................4

Service equipment .........................................................................................................................5

Parts diagrams....................................................................................................................................6

Parts list............................................................................................................................................10

Troubleshooting................................................................................................................................12

Error messages ................................................................................................................................16

Testing the indicator..........................................................................................................................18

Checking for stable weights..........................................................................................................18

Checking the calibration...............................................................................................................18

Checking the load cell codes........................................................................................................18

Checking the power connection....................................................................................................19

Checking the USB connection (EziWeigh6i, EziWeigh7i, WOW2 and DAS WOW2 only)...............19

Checking the RS232 serial connection (EziWeigh6i, EziWeigh7i, WOW2 and DAS WOW2 only)..19

Checking the Bluetooth®wireless connection (EziWeigh7i, WOW2 and DAS WOW2 only) ...........19

Checking the LCDs......................................................................................................................19

Testing the keypad.......................................................................................................................19

Checking the battery....................................................................................................................21

Repair procedures ............................................................................................................................22

LCD handling and storage precautions.........................................................................................22

Using flexible printed circuits (FPCs)............................................................................................22

Protecting the case front ..............................................................................................................23

Removing and refitting the case back...........................................................................................24

Replacing the case seal ...............................................................................................................26

Replacing the case front...............................................................................................................27

Replacing the bezel, keypad and overlay......................................................................................28

Replacing the battery...................................................................................................................29

Replacing the load bar and power/communication connectors......................................................29

Replacing the piezo speaker ........................................................................................................30

Removing and refitting thePCA...................................................................................................31

Replacing the LCD.......................................................................................................................33

Updating the firmware..................................................................................................................33

Accessing the hidden menus.............................................................................................................34

EziWeigh5i ESC+MENU hidden menu .........................................................................................34

EziWeigh6i, EziWeigh7i, WOW2 and DAS WOW2 ESC+MENU hidden menu..............................36

Factory Calibration screen............................................................................................................37

Bluetooth®settings (EziWeigh7i, WOW2 and DAS WOW2 only)........................................................38

MAC Address...............................................................................................................................38

Bluetooth PIN...............................................................................................................................38

Bluetooth factory reset .................................................................................................................38

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 3

Service centre requirements

Product feedback

Receiving feedback from Service Centres about the type of field problems encountered is an important

part of product development. To assist us with improving the product, we ask that a Service Report be

returned to us each month. With this information, we can accurately identify trends in the field and

offer appropriate technical support.

We also encourage you to provide us with your comments about the product. We value your feedback.

Only qualified Service Centres are authorised to carry out service work on the scales products.

Warning! Static discharge can damage some components on the indicator. Such damage may

degrade an electronic component and may result in faults developing within that component over

time. When working on an indicator, ensure that correct anti-static procedures are used.

1. Use a wrist band and earth strap.

2. Work only on a grounded bench top.

3. Use a suitable lead-free anti-static soldering iron and solder sucker.

4. Store PCAs and LCDs in anti-static bags.

Technical bulletins

Technical bulletins are prepared as needed. They should be read in conjunction with the service

manual. Technical bulletins are available on the Tru-Test service agent portal

www.service.tru-test.com.

The current Technical Bulletins cover;

•Span calibration

•Updating the firmware

•Cell codes

Returning aproduct

Before a product or assembly is returned to Tru-Test for service or analysis, please advise us

beforehand so that a Return Authorisation (RA) number can be allocated. The RA number will ensure

that we are ready for the product when it is received and assist us in providing efficient and prompt

service. Please mark all packaging with the RA number.

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 4

Fault report card

Email to:

Service Department

Tru-Test Ltd

service@trutest.co.nz

From:

(Distributor)

(Tru-Test Ltd representative)

Date

Return authority (RA) number

Warranty

Yes

No

Product returned:

Indicator

Model:

Serial number

Configuration

kg

lb

Load bar/Load cells

Serial number(s) of the

load bars

Serial number(s) of the load

cells

Load bars/Load cells

model Load cell code

Distributor

Date installed

Zero offset

Insulation test

Bridge resistances

red/black

green/white

red/white

red/green

black/white

black/green

Fault description

(include visual impression and display messages)

Fault report (Service centre)

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 5

Service equipment

To service Tru-Test indicators, you will require the following equipment:

Item

Description

Multi-meter Good quality digital type with 300 mA and 300 mV range.

Screwdrivers Pozi-drive, size 1 (for connectors, PCA and LCDs – torque setting

0.5 Nm (4 lb-in.)).

Pozi-drive, size 2 (for case back screws – torque setting 0.9 Nm

(8 lb-in)).

A driver with adjustable torque setting is strongly recommended.

DO NOT use a variable speed electric drill!

Pliers

Long-nose, side cutting.

Rubber mat

Suitable for placing the indicator on while servicing.

Soft cloth

For cleaning the LCDs.

Indicator 0 mV/V calibration

plug

Part no. WIA70020. For field service technicians.

Indicator 2 mV/V calibration

plug Part no. WIA70022. For field service technicians.

Computer Windows XP or later with Data Link installed.

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 6

Parts diagrams

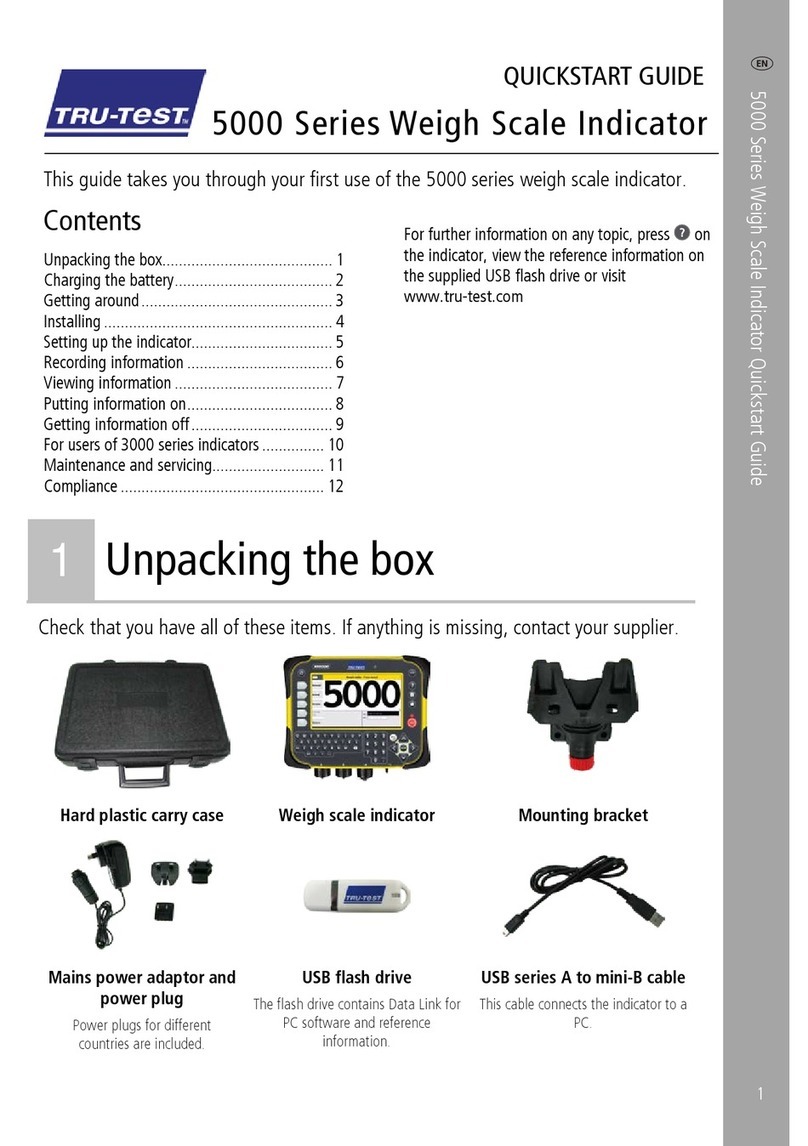

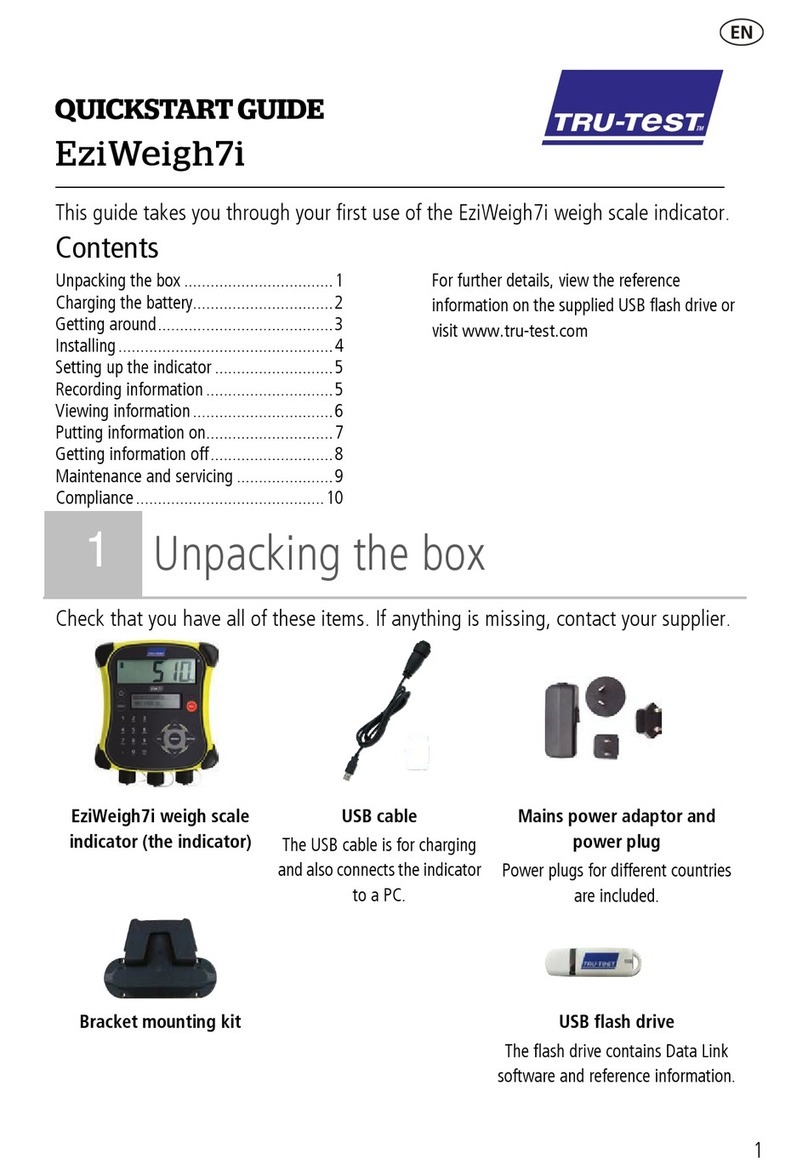

Figure 1a: EziWeigh5i Parts

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 7

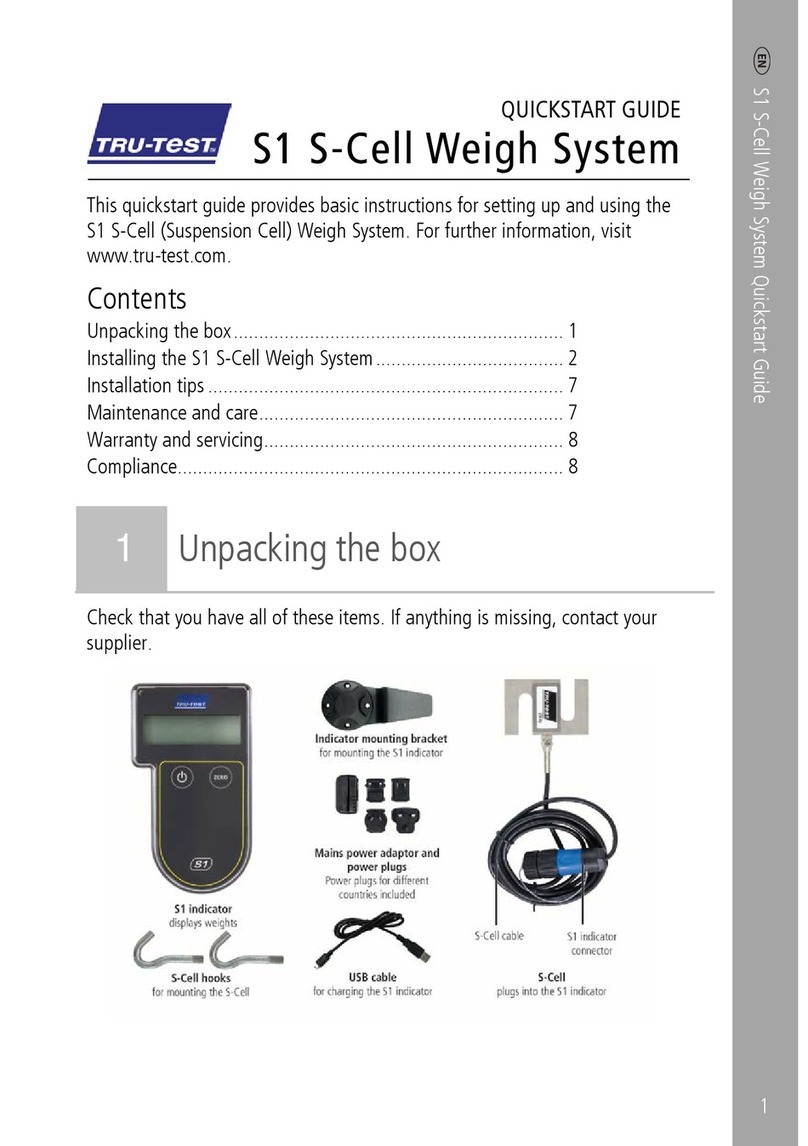

Figure 1b: EziWeigh6i Parts

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 8

816752P

828690P

816753P

828686P

816749P

816748P

815787P

830037P

828688P

830459P

830036P

EKZ31070P

816604P

SSS20416P

828687P

816747P

816753P

829036P

816597P

819797P

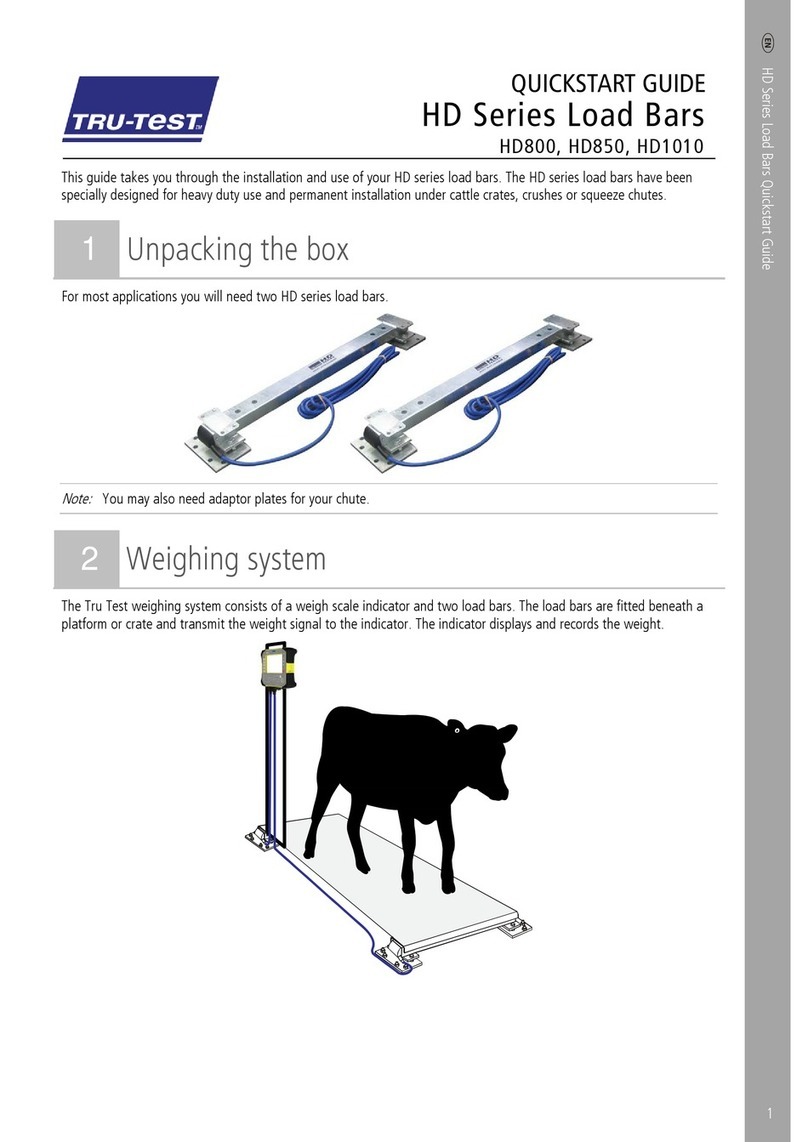

Figure 1c: EziWeigh7i Parts

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 9

816752P

828690P

816753P

829037P

or 830504P

816749P

815787P

830037P

828688P

830459P

830036P

EKZ31070P

816604P

SSS20416P

828687P

816747P

816753P

829038P

816597P

816748P

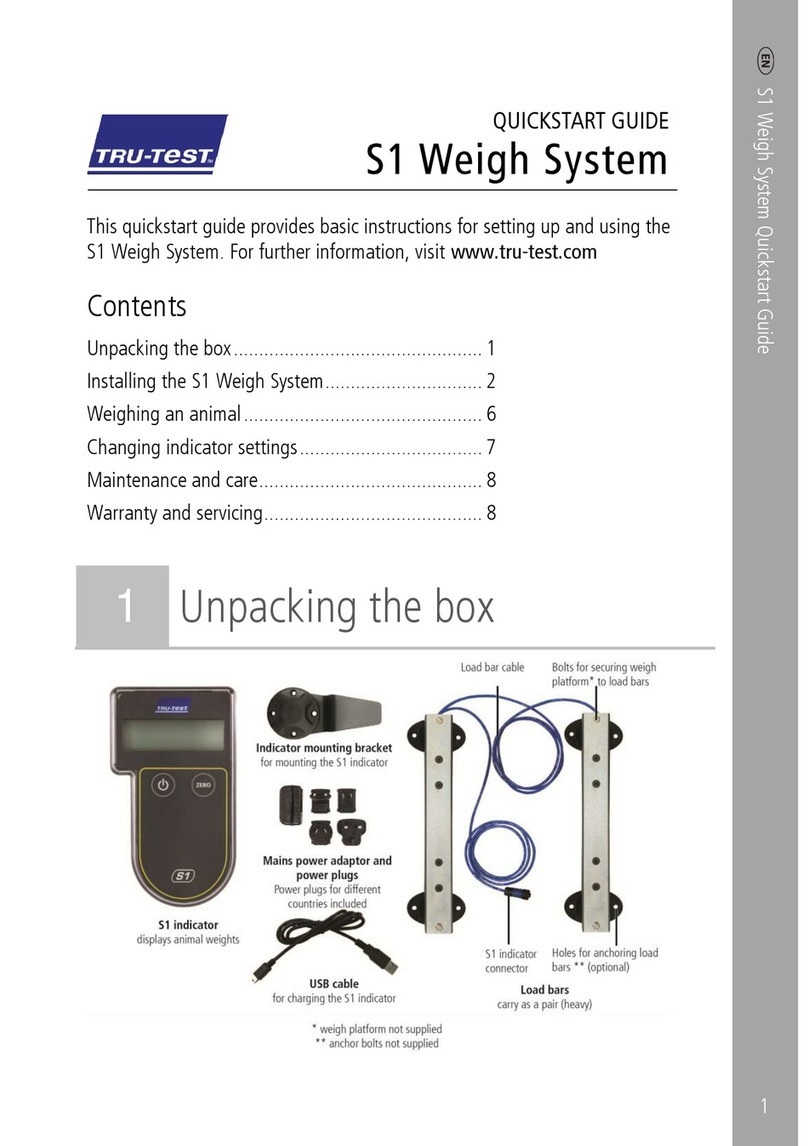

Figure 1d: WOW2 and DAS WOW2 Parts

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 10

Parts list

Description

Contents

Quantity

per indicator

Part number

LCD 7 segment All models 1 828687P

LCD dot matrix EziWeigh6i, EziWeigh7i, WOW2 and DAS

WOW2 1 815787P

Load bar connector and

FPC

Male connector. All models

2

830037P

Power/communication

connector and FPC Female. All models 1 830036P

Battery All models 1 828688P

PCA (printed circuit

assembly)

EziWeigh5i

EziWeigh6i

EziWeigh7i

WOW2

DAS WOW2

1

1

1

1

1

828684P

828685P

828686P

829037P

830504P

Case front (clear) All models 1 816748P

Case bezel (yellow)

All models

1

816747P

Case rear (yellow)

All models.

1

828690P

O-ring All models 1 816749P

Sound hole label kit

EziWeigh5i

Kit of 10 x 20 mm round labels used to cover the

sound hole in the case front.

1

828692P

Foam block kit EziWeigh5i

5 x foam blocks 80x30x14 for packing between

the case front and the PCA.

1 829778P

Piezo speaker

EziWeigh6i, EziWeigh7i, WOW2 and DAS

WOW2

Includes the round, double-sided label used to

affix the speaker to the case front.

1

830459P

Screw kit case All models

Kit of 50 screws used for securing the case

components

11 816752P

Screw kit C16 All models

Kit of 50 screws used for securing

power/communication and load bar connectors

6 SSS20416P

Screw kit LCD/PCA All models

Kit of 50 screws used for securing the LCD and

PCA.

8 (EziWeigh5i)

or

10 (EziWeigh6i,

EziWeigh7i,

WOW2 and DAS

WOW2)

816753P

Overlay

EziWeigh5i

EziWeigh6i

EziWeigh7i

WOW2 and DAS WOW2

1

1

1

1

829034P

829035P

829036P

829038P

Keypad All models 1 816597P

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 11

Description Contents

Quantity

per indicator Part number

Rubber bumper kit

(protective corners)

EziWeigh6i and EziWeigh7i

Kit of 4 rubber bumpers

4

819797P

Load bar connector

dust cap All models 2 EKZ31070P

Power/communication

connector dust cap All models 1 816604P

Power adaptor with

USB cable EziWeigh5i, Eziweigh6i, EziWeigh7i 1 818348P

Power adaptor WOW2 1 826639

Serial adaptors (2) and

power cable

WOW2 and DAS WOW2

1

826638

USB-DB9 adaptor WOW2 1 824429P

Serial cable WOW2 1 813610

Power/Communication

cable DAS WOW2 1 829970P

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 12

Troubleshooting

Symptom

Possible Fault

Action

Indicator does not

switch on. Battery fault. Check battery voltage – if < 2.7 V, try recharging for at least

ten hours. If the battery voltage has not risen above 3.3 V

then replace battery.

Faulty power

adaptor. Check using a known good power adaptor. Replace if faulty.

Faulty

power/communic

ation connector

and FPC

Check that the power/communication FPC is correctly

inserted into the PCA.

Plug a known good power/communication connector and

FPC into the PCA and check if the indicator switches on.

Poor keypad

connections. Check if keypad FPCs are inserted correctly and locked into

place.

Keypad fault.

Unplug existing keypad FPCs and try plugging in a known

good keypad to verify any fault. Replace keypad if faulty.

See page 28.

Faulty PCA.

Replace PCA. See page 31.

Indicator switches

on but does not

stay on.

Firmware fault.

If possible, update the firmware. Refer to the Technical

Bulletin Updating the firmware.

Low battery. Check battery voltage – if < 2.7 V, try recharging for at least

ten hours. If the battery voltage has not risen above 3.3 V

then replace battery.

Battery not

charging.

Battery fault.

Check battery voltage – if < 2.7 V, try recharging for at least

ten hours. If the battery voltage has not risen above 3.3 V

then replace battery.

Faulty

power/communic

ation connector

and FPC

Check that the power/communication FPC is correctly

inserted into the PCA.

Plug a known good power/communication connector and

FPC into the PCA and check if the indicator charges.

Faulty power

adaptor. Check using a known good power adaptor. Replace if faulty.

Faulty PCA.

Replace PCA. See page 31.

Short battery run

time. Battery not fully

charged. Try recharging for at least ten hours. Check that the

charging indicator on the 7 segment LCD is cycling.

Faulty battery.

Measure open circuit voltage on battery. Replace if < 2.5 V.

Faulty PCA.

Replace PCA. See page 31.

Sections or all of

LCD not working

OR

Very dark or very

light LCD screen.

LCD FPCs not

connected

properly.

Try reconnecting the two LCD FPCs. See page 22.

Faulty LCD Replace LCD. See page 33.

Faulty PCA. Replace PCA. See page 31.

Black / Blue / Grey

area on LCD. Cracked or

damaged LCD. Replace LCD. See page 33.

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 13

Symptom

Possible Fault

Action

Back light very

dim or not

working.

LCD FPC or

backlight loom

not connected

properly.

Try reconnecting the LCD FPCs. See page 22. Reconnect

the LCD backlight loom. See page ?

Faulty LCD

Replace LCD. See page 33.

Faulty PCA.

Replace PCA. See page 31.

Displayed weights

unstable and / or

will not zero,

“UNDERLOAD” or

“OVERLOAD”

displayed, or

indicator displays

incorrect weight.

Span calibrated

on cell code 99

(no code).

This behavior is normal when no load bars are connected.

Caution! Scan calibration settings can be important to the

customer so check before changing.

If the customer no longer requires this span calibration,

clear the settings. See the technical bulletin Span

Calibration Guide.

Load cell

settings may

have been

modified.

If the customer no longer requires these settings, reinstate

the default settings. See the technical bulletin Span

Calibration Guide.

Caution! These settings can be important to the customer so

check before changing!

Load bars are

faulty.

Test the load bars to see if they are functioning correctly.

See load bars service manual.

Faulty load bar

connector and

FPC.

Check that the load bar connector FPC is correctly inserted

into the PCA.

Plug a know good load bar connector and FPC into the PCA

and check if weights are stable.

PCA is faulty. Replace PCA. See page 31.

bAd.c, ER 05 or

Bad code

displayed

Note:See

diagnostics menu

and compare cell

code with the

technical bulletin

Cell Codes.

Non Tru-Test

load cell

Probably needs span calibration. See the technical bulletin

Span Calibration Guide.

Cell code in load

bar connector

incorrect

Check load bar cell code with a known good indicator.

Repair the cell code resistors in the load bar connector. If

necessary, replace the load bar connector. Instructions for

these repairs are in the service manual for the load bars.

Firmware does

not support load

bars

Update firmware. See page 33.

See diagnostics menu and compare cell code and firmware

version with technical bulletin Cell Codes.

Faulty load bar

connector and

FPC

Check that the load bar FPC is correctly inserted into the

PCA.

Plug a known good load bar connector and FPC into the

PCA and check if correct cell code is displayed. See

diagnostics menu to check measured cell code. See

Accessing the hidden menus on page 34.

PCA is faulty. Replace PCA. See page 31.

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 14

Symptom

Possible Fault

Action

Stable LED not

working. Weight never

stabilizes. Check indicator settings for Damp System and Resolution:

Damp System - set to SuperDamp III (Cattle) or SuperDamp

III (Sheep)

Resolution may be set to too small. Set to a coarser

resolution. See the technical bulletin Span Calibration

Guide.

Load bars faulty. Test the load bars to see if they are functioning correctly.

Test the indicator using calibration plugs.

Faulty load bar

connector and

FPC

Check that the load bar FPC is correctly inserted into the

PCA.

Plug a known good load bar connector and FPC into the

PCA and check if weights are stable.

LED damaged.

Replace PCA. See page 31.

Stable LED on,

but nothing works. Firmware error. If possible, update the firmware. See the technical bulletin

Updating the firmware.

PCA is faulty. Replace PCA. See page 31.

Some or all keys

not working. Poor keypad

connections. Check if keypad FPCs are correctly inserted into the PCA.

See page 22.

Keypad fault.

Unplug existing keypad FPCs and try plugging in anew

known good keypad. Replace keypad if faulty. See page

28.

User data lost.

EziWeigh6i,

EziWeigh7i,

WOW2 and DAS

WOW2 only

PCA is faulty.

Replace PCA. See page 31.

No accessory

power output from

power/communica

tion connector.

EziWeigh6i,

EziWeigh7i,

WOW2 and DAS

WOW2 only

Power/communit

cation connector

and FPC faulty

Replace power/communication connector and FPC. See

page 29.

PCA is faulty.

Replace PCA. See page 31.

RS232 (serial)

connection not

working.

EziWeigh6i,

EziWeigh7,

WOW2 and DAS

WOW2 only

Faulty cable

between

indicator and

serial connector.

Check/replace faulty cable.

Power/communi

cation connector

and FPC faulty

Replace power/communication connector and FPC. See

page 29.

Wrong bit rates The handshaking settings for the EziWeigh6i, EziWeigh7i,

WOW2 and DAS WOW2 are: 8 data bits, 1 stop bit, no

parity, with 9600 bps.

Ensure the other device has matching settings.

PC fault

Try another PC.

PCA is faulty. Replace PCA. See page 31.

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 15

Symptom

Possible Fault

Action

Bluetooth

®

wireless

connection not

working.

EziWeigh7i,

WOW2 and DAS

WOW2 only

Bluetooth

wireless

connection not

established.

Check that the indicator is on.

Check Bluetooth wireless connection (see page 19).

Problem with

master device.

When connected to another

Bluetooth

enabled device, the

indicator is always the slave and the other device is always

the master.

When troubleshooting the master device, refer to the

documentation supplied with that device. During

troubleshooting, you may need some information about the

indicator, see Bluetooth® settings (EziWeigh7i, WOW2 and

DAS WOW2 only) on page 38.

On the master device, ensure that the Bluetooth setting is

enabled.

Check that the master device is connected to the indicator

and not to another device.

The Bluetooth functionality on the master device may be

faulty.

Power/communi

cation connector

and FPC is faulty

Replace power/communication connector and FPC. See

page 29.

PCA is faulty.

Replace PCA. See page 31.

USB not working Faulty cable

between

indicator and

USB connector.

Check/replace faulty cable.

USB Drivers did

not install

properly on the

PC.

Re-install the Data Link software.

Power/communi

cation connector

and FPC is faulty

Replace power/communication connector and FPC. See

page 29.

PC fault Try another PC.

Firmware fault

Update the firmware. See the technical bulletin

Updating the

firmware.

PCA is faulty. Replace PCA. See page 31.

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 16

Error messages

EziWeigh5i

Error code

EziWeigh6i, EziWeigh7i,

WOW2,

DASWOW2

Error message

Meaning

Solution

Er 01

Factory calibration

lost

Calibration data lost.

Perform factory calibration procedure.

See page 37.

Er 02

Model number lost

Model number lost.

Replace PCA. See page 31.

Er 03

Flash checksum error

Program memory corruption.

Update the firmware. See page 33.

Er 04

About info lost

ABOUT data lost

Replace PCA. See page 31.

bAd.c or

Er 05

bAd.c or Er 05 (on 7

segment display)

Bad cell code.

Check the cell code in the

Diagnostics menu with known

good loadbar connected to one

indicator connector and then

the other.

Check the cell code in the Diagnostics

menu for each load bar on its own and

with both. See Accessing the hidden

menus on page 34. Compare with valid

cell codes for standard Tru-Test and

competitor load bars and cell codes

that need span calibration. Refer to

the technical bulletin Cell Codes.

See Troubleshooting on page 13.

Er 06

Test Weight >

Capacity!

The test weight is larger than

the capacity.

Was the entered Capacity incorrect?

Otherwise, use a smaller test weight.

Er 07

Test Weight < 1/3

Capacity!

The test weight is less than 1/3

of the Capacity. For maximum

accuracy, use a larger test

weight.

This is only a warning message. If a

larger test weight cannot be used, the

span calibration can still be completed,

but with reduced accuracy.

Er 08

Test Weight too small.

The test weight is too small for

an accurate calibration.

A larger test weight must to be used.

We recommend using a test weight

that weighs approximately the same as

a typical animal being weighed.

Er 09

Can't get good

reading.

Can't get good reading.

Use a static weight.

Er 10

The Test Weight is

overloading the scale.

The load bar output signal is

overloading the input of the

scale indicator.

Use a much smaller test weight.

Er 11

The load cell output

signal is

reversed.

The load cell wiring may be

reversed or the load cell may

be mounted upside-down.

Correct any load cell mounting or

wiring issue. If this doesn’t work, return

the indicator to Tru-Test Limited.

Er 12

No test load placed

on the platform.

No test load placed on the

platform.

Check mV/V response to loads in the

Diagnostic menu. See Accessing the

hidden menus on page 34. Correct any

shorted wiring.

Er 13

The load cell has a

large no load negative

offset.

The load cell has a large no

load negative offset.

Replace load bars.

Er 14

Reset caused by

watchdog.

The processor crashed due to

electrical supply trauma or

brown-out or software fault.

If problem persists, return to Tru-Test

Limited for analysis.

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 17

EziWeigh5i

Error code

EziWeigh6i, EziWeigh7i,

WOW2,

DASWOW2

Error message

Meaning

Solution

Er 15

Possible capacity

ove

rload!

A load equal to the capacity

would cause an output signal

from the load bars that would

be greater than the input signal

range of the indicator

(assuming the scale is zeroed

at the maximum platform

allowance i.e. with a heavy

crate or crush).

Check the entered test weight was

correct. Reduce the capacity.

Er 16

Capacity overload!

A load equal to the capacity

would cause an output signal

from the load bars that would

be greater than the input signal

range of the indicator

(assuming the scale is zeroed

at the no load point used

during the span calibration).

Check the entered test weight was

correct. Reduce the capacity.

Er 18

Number of d > 65535!

The number of divisions

cannot exceed 65535.

Use a larger resolution during span

calibration.

Er 19

Resolution out of

range!

Resolution out of range!

Perform span calibration again.

Er 20

Can’t record Wts >

32767 d!

Caution! Weights of more than

32767 divisions cannot be

recorded.

Turn "Fine Resol valid" off during Span

Cal. Use a larger resolution during

span calibration.

Er 21

Can’t record Wts >

8192 d!

Caution! Weights of more than

8192 divisions cannot be

recorded.

Use a larger resolution during span

calibration.

Er 22

Greater than 5000 d!

Caution! The number of

divisions is greater than 5000.

Use a larger resolution during span

calibration.

Er 27

Requires zero weight

The 'no load' measurement

needs to be done before the

Test Weight measurement.

Do the previous menu item: "Ensure

no load on platform. Press ENTER"

first.

Er 28

Possible load cell fault

(reading full scale

signal)

The signal from the load bars

is outside the indicator's ADC

input signal range.

Check for faulty load bars, wiring or

moisture.

Er 29

Possible load cell fault

(reading

negative

voltage)

Possible load cell fault

(reading zero voltage)

Check for faulty load bars, wiring or

moisture.

Er 30

Zero was unstable or

drifting

The load cell signal is

continuously moving so the

scale can't zero.

If the indicator is normally used with

load bars with cell code 99, this can be

normal when the load bars are

unplugged. Otherwise clear the span

cal or sensitivity cal from cell code 99.

If load bars are connected, check for

moisture. See load bars service

manual.

Er 99

Er 99

[

Note: Filename & line

number

appears on

the

other LCD

display]

.

Software internal error.

Record the details of the internal error.

If possible, clone the indicator for

analysis or send a {PE} command via

a terminal emulator and capture the

response. Contact Tru-Test Limited for

assistance with performing these

procedures.

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 18

Testing the indicator

Checking for stable weights

A stable weight is defined as a reading that does not move more than one division (resolution step) in

either direction. Testing the indicator for stable weights requires the use of a calibrator or a set of

calibration plugs. Known good load bars can be used.

Auto zero track may hide any small movements. Disable auto zero before testing for stable weights.

To disable auto zero on an EziWeigh5i indicator, press until ‘Off’ displays on the screen.

To disable auto zero on an EziWeigh6i, EziWeigh7i, WOW2 or DAS WOW2 indicator:

1 Press .

2 Press repeatedly to display Setups.

3 Press .

4 Press repeatedly to display Auto Zero.

5 Press to disable Auto Zero.

To test for stable weights

1 Connect the 0 mV/V calibration plug to a load bar connector on the indicator.

2 Press to turn on the indicator.

3 Press to zero the indicator.

Checking the calibration

1 Test that the weights are stable, as described in Checking for stable weights above.

2 Connect the 2 mV/V calibration plug to the other load bar connector and remove the 0 mV/V

calibration plug.

The weight displayed should be2000 kg (4410 lb) within ±1 kg (2 lb).

Checking the load cellcodes

Load bars have a unique cell code. Plug in known good load bars. The LCD should display the

expected weight when a test weight is put on the load bars.

If not:

•Check that the indicator is not span calibrated. Go to the Diagnostics screen within the hidden

menus (see Accessing the hidden menus on page 34).

Caution! These settings can be important to the customer so check before changing.

The easiest way around a span calibrated cell code is to check the weighing performance

using load bars of another type (e.g. single load bar instead of both load bars plugged in).

•Check both load bar connectors and FPCs. Check the PCA. See Troubleshooting on page

12.

•To view cell code number of the connected load bars, go to the Diagnostics screen within the

hidden menus (see Accessing the hidden menus on page 34).

•The latest firmware may include some new load cell codes for new models of load bars.If in

doubt, update firmware to the latest version from the Tru-Test website. See technical bulletin

Upgrading firmware.

For more information about load cells, refer to the technical bulletin Cell Codes.

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 19

Checking the power connection

Connect the power adaptor and check that the battery-charging symbol on the LCD is cycling during

charging. When the battery is fully charged, the battery-charging symbol will stop cycling, but may

restart periodically to apply a top-up charge.

Checking the USB connection (EziWeigh6i, EziWeigh7i, WOW2 and DAS WOW2 only)

Run Data Link (supplied with the indicator, or available for downloading from the Tru-Test Livestock

website www.livestock.tru-test.com).

Communication with Data Link indicates that the USB interface is functioning correctly.

Checking the RS232 serial connection (EziWeigh6i,EziWeigh7i, WOW2 and DAS WOW2 only)

Check that the indicator receives EIDs from a known good EID reader with serial connection.

Checking the Bluetooth®wireless connection (EziWeigh7i, WOW2 and DAS WOW2 only)

1 Establish a Bluetooth wireless connection between the indicator and a known good EID Reader

with Bluetooth wireless connectivity (see the EziWeigh7i or WOW2 Quickstart Guide for details).

2 Check that the Bluetooth wireless connection status indicator is displayed on the Weight screen.

When the indicator is connected to a device via Bluetooth wireless connection, a small triangle is

displayed on the top right-hand corner of the indicator’s LCD (►):

3 Check that the indicator receives EIDs from the EID Reader.

Checking the LCDs

Try various functions to check that the LCDs are operating correctly. Watch for missing or faded

segments, rows or columns of dots.

To test the backlight operation (EziWeigh5i):

Press repeatedly to scroll through the backlight levels.

To test the backlight operation (EziWeigh6i, EziWeigh7i, WOW2 or DAS WOW2):

1 Press .

2 Press repeatedly to display Setups.

3 Press .

4 Press repeatedly to display Backlight.

5 Press repeatedly to scroll through the backlight levels.

Testing thekeypad

Test the keypad in the order specified below. Every key on the keypad should produce a display

response (EziWeigh6i, EziWeigh7i, WOW2 and DAS WOW2 also produce an audible beep).

EziWeigh5i, EziWeigh6i, EziWeigh7i, WOW2, DAS WOW2

Issue 2, 7/2017 20

EziWeigh5i

Power

Zero

Backlight

Auto zero

Resolution

EziWeigh6i, EziWeigh7i, WOW2 and DAS WOW2

Power

Zero

Record

Keypad (all

numbers)

Escape

Menu

Enter

Up arrow

Down arrow

The keypad may fail due to an internal short circuit.

To test the keypad for short circuits

1 Disconnect the keypad FPCs from the PCA.

2 Test the resistance between the keypad FPCs for all contacts. All contacts can be tested at the

same time.

Figure

2

:Measuring keypad

contact resistance.

Other manuals for EziWeigh5i

1

This manual suits for next models

4

Table of contents

Other Tru-Test Accessories manuals

Tru-Test

Tru-Test 5000 Series User manual

Tru-Test

Tru-Test EziWeigh5i User manual

Tru-Test

Tru-Test S1 User manual

Tru-Test

Tru-Test HD Series User manual

Tru-Test

Tru-Test MP600 User manual

Tru-Test

Tru-Test Series 2000 User manual

Tru-Test

Tru-Test S1 User manual

Tru-Test

Tru-Test ID5000 User manual

Tru-Test

Tru-Test S2 User manual

Tru-Test

Tru-Test EziWeigh7i User manual