True blue power TA202 Series Technical Document

Revision J • June 30, 2020

1 Manual Number 9017899 • Revision J, June 30, 2020

FOREWORD

This manual provides information intended for use by persons who, in accordance with current

regulatory requirements, are qualified to install this equipment. If further information is required,

please contact:

True Blue Power

c/o Mid-Continent Instrument Co., Inc.

Attn: Customer Service Dept.

9400 E. 34th St. N.

Wichita, KS 67226 USA

Phone 316-630-0101

Fax 316-630-0723

www.truebluepowerusa.com

www.mcico.com

We welcome your comments concerning this manual. Although every effort has been made to

keep it free of errors, some may occur. When reporting a specific problem, please describe it

briefly and include the manual part number, the paragraph/figure/table number and the page

number. Send your comments to:

True Blue Power

c/o Mid-Continent Instrument Co., Inc.

Attn: Technical Publications

9400 E. 34

th

St. N.

Wichita, KS 67226 USA

Phone 316-630-0101

Fax 316-630-0723

© Copyright 2018

Mid-Continent Instrument Co., Inc.

Download the current

version of this

installation manual

using your smartphone

or tablet.

2 Manual Number 9017899 • Revision J, June 30, 2020

TABLE OF CONTENTS

SECTION 1GENERAL DESCRIPTION 4

1.1PURPOSE OF EQUIPMENT 4

1.2TECHNICAL SPECIFICATIONS 5

SECTION 2PRE-INSTALLATION CONSIDERATIONS 6

2.1COOLING 6

2.2EQUIPMENT LOCATION 6

2.3ROUTING OF CABLES 6

2.4LIMITATIONS 6

2.5MODIFICATIONS 7

SECTION 3INSTALLATION 8

3.1GENERAL INFORMATION 8

3.2UNPACKING AND INSPECTING EQUIPMENT 8

3.3CABLE HARNESS 8

3.4MOUNTING 9

3.5INSTALLATION COMPLETION 10

SECTION 4OPERATION 14

4.1ELECTRICAL PERFORMANCE 14

4.2PROTECTIVE FEATURES 14

SECTION 5CONFORMANCE 15

5.1INSTRUCTIONAS FOR CONTINUED AIRWORTHINESS 15

5.2ENVIRONMENTAL QUALIFICATON STATEMENT 15

3 Manual Number 9017899 • Revision J, June 30, 2020

REVISION HISTORY

Rev Date Detail Approved

A 03/14/2016 Initial release. BAW

B 04/25/2016 Updated formatting, added AEH statement to table 1.3 CAS

C 05/10/2016 Added single port unit mounting options, removed

configurations table. BAW

D 06/23/2016 Added two screws (1/4”) to include connector kit. ScH

E 01/04/2017 Updated to include new mounting option. Added 1.2.4. BAW

F 05/07/2019 Added single rear mount with cover plate option. VAA

G 06/06/2019 Updated figure 3.9 and added rear mount with circular

cover plate options. VAA

H 05/14/2020

Updated style and brand to meet Marketing and

Engineering guidelines. Update Section 3.2, Optional

Equipment names.

DLR

J 06/30/2020 Updated DO-160 qualifications in Section 5 based on

additional testing. Updated wire length in Section 3.3.1. DLR

4 Manual Number 9017899 • Revision J, June 30, 2020

SECTION 1 GENERAL DESCRIPTION

1.1 PURPOSE OF EQUIPMENT

The TA202 Series High Power USB Charging Port is a certified accessory that converts 10 to 32

volts of DC electrical input from the aircraft to standard 5 volt power for any electronic product that

charges using a USB connector. The TA202 provides one or two Universal Serial Bus-A or C

(USB-A or USB-C) ports and can be rear mounted or front mounted in a variety of locations

throughout the aircraft. The new “Type-C” USB port design is a smaller port that accommodates

the latest consumer electronic devices on the market. Among other features, the Type-C connector

accepts reversible cable plugging with no ‘up’ or ‘down’ requirement for cable orientation. The unit

is certified to FAA TSO C71 and qualified to multiple RTCA DO-160 requirements, providing

confidence and allowing installation in the cockpit or cabin.

This High Power USB Charging Port is designed as a DCP (Dedicated Charging Port) to industry-

standard protocol per the USB Battery Charging 1.2 Compliance Plan. It also complies with the

higher power requirements of USB Power Delivery 2.0. Newer electronics, such as the Apple

iPad®, other tablets and larger devices can accept or may require 2.1 amps or more to charge and

operate. As a high power DCP, the TA202 can provide up to 3.0 amps of power to charge USB

devices, including the higher demand products. Most dual USB chargers typically provide 1.0 amp

on one port and 2.1 amps on the second port, but the TA202 can provide 3.0 amps to both ports

simultaneously (for dual port units). The unit has built-in protections for short circuit, over-current,

and low voltage conditions. It is designed to protect against reverse polarity installation and has

temperature monitoring and shutdown capability, allowing the unit to handle unforeseen conditions

safely.

Small, compact and powerful, with plenty of installation flexibility, the TA202 is an ideal choice as a

highly useful and effective addition to any aircraft.

5 Manual Number 9017899 • Revision J, June 30, 2020

1.2 TECHNICAL SPECIFICATIONS

Electrical Attributes

Input Voltage 10-32 VDC

Input Power 35 watts max; 2.5 amps @ 14 VDC / 1.25 amps @

28 VDC

Output Voltage 5 VDC ±0.25 per port

Output Power 3.0 amps max per port

Efficiency ~90% nominal

Table 1.1

Physical Attributes

Weight 1.3 oz. (38 g) (dual port), 0.8 oz. (23 g) (single port)

Dimensions (Dual Port Units)

(not including connector)

1.50 inches wide X 1.03 inches high X 1.25 inches deep

Dimensions (Single Port Units)

(not including connector)

1.50 inches wide X 0.52 inches high X 1.25 inches deep

Charging Ports Type USB Standard-A or USB Standard-C

Connector Kit MCIA P/N 9017960

Mounting Panel mount; rear or front

Table 1.2

Qualifications

Certification FAA TSO-C71

EASA ETSO-C71

Environmental Qualification RTCA DO-160G Environmental Category

See Section 5.2

Airborne Electronic Hardware RTCA DO-254, Design Assurance Level E

Table 1.3

Configurations

Non Lighted Lighted Power Input

Location USB Connector

Part Numbers

6430202-1 6430202-11 Rear Dual: Type A+Type C

6430202-2 6430202-12 Bottom

6430202-3 6430202-13 Rear Dual: Type C+Type C

6430202-4 6430202-14 Bottom

6430202-5 6430202-15 Rear Dual: Type A+Type A

6430202-6 6430202-16 Bottom

6430202-7 6430202-17 Rear Single: Type C

6430202-8 6430202-18 Bottom

6430202-9 6430202-19 Rear Single: Type A

6430202-10 6430202-20 Bottom

Table 1.4

6 Manual Number 9017899 • Revision J, June 30, 2020

SECTION 2 PRE-INSTALLATION CONSIDERATIONS

2.1 COOLING

No external cooling is required. The unit will become warm when in use. This is normal and within

operational parameters. No special mounting considerations are required; however, mounting to a

metal surface can help dissipate any heat generated and extend the life of the product.

2.2 EQUIPMENT LOCATION

The TA202 High Power USB Charging Port is designed for mounting flexibility, allowing for

installation in the cockpit or in the cabin. It is designed for panel mounting and can be installed in a

rectangular configuration or, with an available installation kit, can be front mounted with a cosmetic

cover plate. An instrument mounting adapter bracket is also available to easily mount the unit in a

standard 2-inch round instrument opening that may already exist in the cockpit panel. There are

two versions to choose from which allow the input connector to be located either on the rear of the

unit or from the bottom.

The unit can be mounted in any orientation. Clearance should be provided for the mating

connector which may require an additional inch beyond the rear of the unit.

2.3 ROUTING OF CABLES

Avoid sharp bends in cabling and routing near aircraft control cables. Avoid close proximity and

contact with aircraft structures, avionics equipment or other obstructions that could chafe wires

during flight and cause undesirable effects.

2.4 LIMITATIONS

Environmental qualifications were verified per RTCA DO-160, Revision G in lieu of those identified

within the minimum performance standards (MPS) of the TSO.

The conditions and tests for TSO approval of this article are minimum performance standards.

Those installing this article, on or in a specific type or class of aircraft, must determine that the

aircraft installation conditions are within the TSO standards, specification of the article and

deviations as listed above. TSO articles must have separate approval for installation in an aircraft.

The article may be installed only according to 14 CFR part 43 or the applicable airworthiness

requirements.

The USB Type-C interface is an exciting new connector for electronic devices. Beyond the physical

format of the Type-C connector, it also allows for a variety of interface options when

communicating with compatible devices. This device-to-charger communication is defined within

the USB 3.1 Specification and Power Delivery 2.0 standards. However, manufacturers of

consumer electronic devices and/or cables may choose to implement proprietary versions or

modifications of the USB standards to operate specifically with their own charging equipment. The

TA202 has been tested with and supports a wide variety of devices now emerging on the open

market. However, compatibility with all devices may not be guaranteed. True Blue Power continues

to be proactive in evaluating new devices and strives to continually improve the product as needed

to serve the vast majority of USB Type-C electronic products.

7 Manual Number 9017899 • Revision J, June 30, 2020

2.5 MODIFICATIONS

This product has a nameplate that identifies the manufacturer, part number, description,

certification(s) and technical specifications of the unit. It also includes the “MOD” or modification

number representing notable changes in the hardware design of the unit.

Modification (MOD) 0 is the initial release of the product and is identified on the nameplate by the

lack of marking on the MOD numbers 1 through 9 (i.e. 1-9 are visible). All subsequent

modifications are identified on the nameplate by the marking/blacking out of that particular MOD

number (i.e. for MOD 1, the number 1 is not visible and 2-9 are visible - see Figure 2.1 for

examples). MODs do not have to be sequentially inclusive and may be applied independent of

each other.

For additional details regarding specific changes associated with each MOD status refer to the

product published Service Bulletins at www.truebluepowerusa.com.

Figure 2.1

Nameplate and MOD Status Example

MOD 0

MOD 1

MOD 1

& MOD 2

8 Manual Number 9017899 • Revision J, June 30, 2020

SECTION 3 INSTALLATION

3.1 GENERAL INFORMATION

This section contains interconnect diagrams, mounting dimensions and other information

pertaining to the installation of the TA202 Single and Dual USB Charger. After installation of

cabling and before installation of the equipment, ensure that power and ground are applied to the

proper pins specified in Section 3.3.2, Pin Assignment Information.

3.2 UNPACKING AND INSPECTING EQUIPMENT

When unpacking this equipment, make a visual inspection for evidence of any damage that may

have occurred during shipment. The following parts should be included:

A. High Power USB Charging Port MCIA P/N 6430202-( )

B. Installation Manual MCIA P/N 9017899

C. Connector Kit MCIA P/N 9017960

i. Mating Connector, 2-pin

ii. Pins (4) (2 required, 2 spares)

iii. Screws, #4-40 x 1/4 flat-head (2)

iv. Screws, #4-40 x 5/16 flat-head (2)

Optional Equipment Available:

A. Dual Port Front Mount Faceplate Kit MCIA P/N 9017897

B. Dual Port Instrument Mount Adapter Kit MCIA P/N 9017947

C. Dual Port Rear Mount Faceplate Kit MCIA P/N 9017958

D. Single Port Rear Mount Faceplate Kit MCIA P/N 9019351-1

E. Dual Port Rear Mount Circular Faceplate MCIA P/N 9019384-4

F. Single Port Rear Mount Circular Faceplate MCIA P/N 9019384-3

Equipment Not Provided:

A. Cable Harness Wire See Section 3.3.1 for specifications

B. Circuit Breaker Recommendation 3 amp (2 amp may be sufficient for 28V aircraft)

3.3 CABLE HARNESS

Construct the cable harness following the instructions outlined below and per Figure 3.1.

Refer to Section 2: Pre-Installation Considerations, for routing precautions.

Wire Gauge Selection

Use of PTFE, ETFE, TFE, Teflon or Tefzel insulated wire is recommended for aircraft use.

The wire harness should utilize 20-24 AWG stranded wire. Refer to table 3.1 below. This

table is provided to aid in the consideration of voltage drop due to harness length. Any

other wiring standards that are applicable to the installation should also be considered.

Wire Gauge Wire Length

20 AWG stranded wire 24 ft

22 AWG stranded wire 14 ft

24 AWG stranded wire 9 ft

Table 3.1

Wire Gauge and Length

9 Manual Number 9017899 • Revision J, June 30, 2020

Pin Assignment Information

INPUT POWER:

Pin A (keyed) – Positive DC input +10 to 32 VDC power

Pin B – Negative DC input / ground

Note: Pins should be crimped using Molex Hand Crimp Tool

63819-0000 (Preferred), 63811-2800 (obsolete) or 11-01-0200

(obsolete). See the Molex Hand Crimp Tool User Manual for

crimp procedures.

Harness Verification

Note:

The TA202 has built-in reverse polarity protection for the power

connector. If Pins A and B are swapped, the unit will not be

damaged, but will also not function.

Once the cable harness is prepared, prior to connecting the

TA202, activate the aircraft power bus and use a multimeter to

verify that aircraft power and ground is supplied with

appropriate voltage on the proper pins within the mating

harness.

3.4 MOUNTING

The TA202 can be installed in one of five ways:

rear mount, rectangular

instrument mount

1 2 3

front mount, decorative faceplate

1 2 4

rear mount, decorative faceplate

1 4

rear mount, circular faceplate

1 3

1

Installation kit required. See Section 3.2, Optional Equipment Available for part

number reference

2

Dual port units only

3

Black anodized

4

Brushed aluminum, bare (appropriate for additional plating/finish)

Prepare the panel cutout as shown in Figures 3.4 thru 3.11 per the selected mounting option.

Countersinks shown in the panel cutouts for flat head screws are optional. However, flat head

screws are provided for flush appearance. For Rear Mount Cover Plate Installations,

countersinks in the panel are required.

For Rear Mount Installations:

Mounting screws length MUST be between (PT +0.150”) and (PT +0.210”). [PT = panel thickness]

Mounting screws provided with the unit are 0.24” and 0.31”. (Accommodates 0.030” to 0.160” PT)

For PT greater than 0.125, the USB connector will be below the surface of the panel (below flush).

For Front Mount Installations: Minimum panel thickness is 0.04”. Maximum panel thickness is 0.20”.

For Rear Mount Installation with Cover Plate: Panel thickness greater than 0.065 will cause the

USB connector to be below the surface of the Cover Plate (below flush).

Figure 3.1

Pin B

(Bottom input versions)

Pin

A

Pin A

(Rear input versions)

Pin B

10 Manual Number 9017899 • Revision J, June 30, 2020

3.5 INSTALLATION COMPLETION

Prior to operating the unit in the aircraft, it is recommended to verify the output and functionality of

the unit. In order to prevent accidental damage to other systems, it is not recommended to attach

the output to other equipment prior to verification. Verify the output of the unit at the terminating

end of the cable with a multimeter to ensure proper voltage and polarity. Once verified, installation

can be completed and functionality should be checked.

Figure 3.4

Dual Port Rear Mount Installation Kit

Figure 3.2

TA202 Outline Drawing

Figure 3.3

TA202 Outline Drawing

Panel Cutout Detail

11 Manual Number 9017899 • Revision J, June 30, 2020

Figure 3.5

Dual Port Instrument Mount Adapter Kit

Step 1: install

grommets

Step 2: place scre

w

through mounting plate

(x4) with front

recess set to panel thickness

(see Gap set detail view)

Step 3: loosely attach mounting plate to unit

usin

g

screws included with uni

t

Step 4: twist unit through

panel cutout.

Tighten screws (x2)

Step 6: Apply adhesive backing, align pins

on rear of cover plate into holes on

mounting plate and press firmly

Step 5: Insert top and bottom screws

Ga

p

Set Detail

Step 1: attach

ada

p

te

r

Step 2: attach adapte

r

p

late to

p

anel

Figure 3.6

Dual Port Front Mount Installation

12 Manual Number 9017899 • Revision J, June 30, 2020

Step 1: install

grommets

Step 2: place screw through

mounting plate (x4) with front

latches set flush to front of unit

(see detail view)

Latch and front of unit - flush

Flush Detail

Step 3: place unit in panel

cutout and secure

with screws (x2)

Provided with unit

Step 4: place adhesive on

panel (x2) in locations

shown and remove

backing

Step 5: align pins on

rear of cover plate into

holes on panel and

press firmly

Figure 3.8

Dual Port Rear Mount Circular Faceplate

Circular Cover Plate is

Ø1.50

Note: screws provided

with unit

Figure 3.7

Dual Port Rear Mount Faceplate Kit

13 Manual Number 9017899 • Revision J, June 30, 2020

Port

protrusion

toward top

Step 1: Insert grommets

Step 2: Place mounting

plate over port

protrusion

Step 3: place unit in panel

cutout and secure with

screws (x2) provided with

unit

Step 4: place adhesive on

panel (x2) in locations

shown and remove

backing

Step 5: align pins on rear of

cover plate into holes on

panel and press firmly

Figure 3.9

Single Port Rear Mount Installation

Figure 3.10

Single Port Rear Mount Faceplate Kit

Figure 3.11

Single Port Rear Mount Circular Faceplate

Note: screws

p

rovided with unit

Circular Cover Plate is

Ø1.35

14 Manual Number 9017899 • Revision J, June 30, 2020

SECTION 4 OPERATION

4.1 ELECTRICAL PERFORMANCE

The TA202 Series High Power USB Charging Port converts an aircraft (DC) input voltage within

the range specified to a 5V (DC) output. This output power is applied to a single or dual USB-A or

USB-C connector in accordance with the USB Implementers Forum.

The USB D+ and D- data lines communicate with the USB portable device to tell the device it is a

dedicated charging port (DCP), capable of a higher current than a standard USB port. This allows

the USB portable device to draw up to 3.0 Amps.

The unit is designed as a DC-to-DC converter with a series switch on each output to regulate

current applied to that output. Each series switch independently reduces the output current to a

safe level if the USB portable device draws excess current, is shorted or has a fault.

If the temperature of the TA202 becomes elevated due to a fault or excessive load, the device will

seamlessly communicate with the USB portable device to lower the charge current. This allows the

device to continue charging while the unit returns to a temperature within designed limits. When

the temperature returns to a safe level the TA202 will automatically reestablish the higher charge

current level with the device and continue charging.

4.2 PROTECTIVE FEATURES

Short Circuit Protection

The TA202 is capable of surviving a short circuit event without permanent damage. The

unit goes into an over-current condition so that the average current is significantly reduced

and the device is protected.

Over-Current Protection

The TA202 monitors the current draw individually on each port. During an over-current

condition the voltage is reduced. If the voltage falls below 3.8 VDC the output is turned off

for a period of 12 seconds. The output is then checked for continued over-current

conditions every 16 milliseconds. This condition is referred to as a hiccup mode. The

device stays in this mode until the over-current condition is removed, then returns to normal

operation.

Low Input voltage Shutdown

If the input voltage applied to the TA202 drops below 10 VDC the unit will shut down until

the applied voltage returns to a level within range.

Over-Temperature

When the internal temperature of the TA202 exceeds designed thresholds, the unit will shut

down and stop providing power. When the temperature returns to an acceptable level the

unit will automatically begin providing power as required, up to a full charge of 3.0 amps.

15 Manual Number 9017899 • Revision J, June 30, 2020

SECTION 5 CONFORMANCE

5.1 INSTRUCTIONS FOR CONTINUED AIRWORTHINESS

No periodic scheduled maintenance or calibration is necessary for continued airworthiness of the

TA202 series Single and Dual USB Charger. If the unit fails to perform to specifications, the unit

must be removed and serviced by Mid-Continent Instruments and Avionics or their authorized

designee.

5.2 ENVIRONMENTAL QUALIFICATON STATEMENT

MODEL NUMBER: TA202 Series PART NUMBER: 6430202-( )

DESCRIPTION: Single and Dual USB Charger CERTIFICATION: FAA TSO-C71

MANUFACTURER: True Blue Power, a division of Mid-Continent Instrument Co., Inc.

ADDRESS: 9400 E. 34th St. North, Wichita, KS 67226, USA.

SPECIFICATION: Test Specification (TS) 365 Test Data Sheet (TDS) 365

STANDARD: RTCA DO-160, Rev G, dated 12/08/10; MIL-STD-810E, dated 7/14/1989

CONDITIONS SECTION DESCRIPTION OF TEST

Temperature and Altitude 4 Category F1

Temperature Variation 5 Category S2

Humidity 6 Category B

Operational Shock and Crash Safety 7 Category B

Vibration 8 DO-160: Category R; Curves C, C1

MIL-STD810E: See Remarks

Explosion 9 Category E

Waterproofness 10 Category W

Fluids 11 Category X

Sand and Dust 12 Category S

Fungus 13 Category F

Salt Spray 14 Category S

Magnetic Effect 15 Category Z

Power Input 16 Category B(XX)

Voltage Spike 17 Category B

Audio Frequency Conducted Susceptibility 18 Category R

Induced Signal Susceptibility 19 Category X

Radio Frequency Susceptibility 20 Category X

Emission of Radio Frequency Energy 21 Category H

Lightning Induced Transient Susceptibility 22 Category X

Lightning Direct Effects 23 Category X

Icing 24 Category X

ESD 25 Category A

Fire, Flammability 26 Category C

REMARKS:

Section 4: Category F1 with excursions as declared by the manufacturer:

4.6.2: Decompression +8,000 to 50,000 feet

Section 7: Crash Safety Impulse: 11ms, 40g Shock Wave

Section 8: Vibration per MIL-STD-810E: Sine-On-Random, Method 514.4, Cat. 4, Procedure 1

Other manuals for TA202 Series

1

This manual suits for next models

19

Table of contents

Other True blue power Batteries Charger manuals

True blue power

True blue power TA360 Series Technical Document

True blue power

True blue power TA202 Series Technical Document

True blue power

True blue power TWC15 Series User manual

True blue power

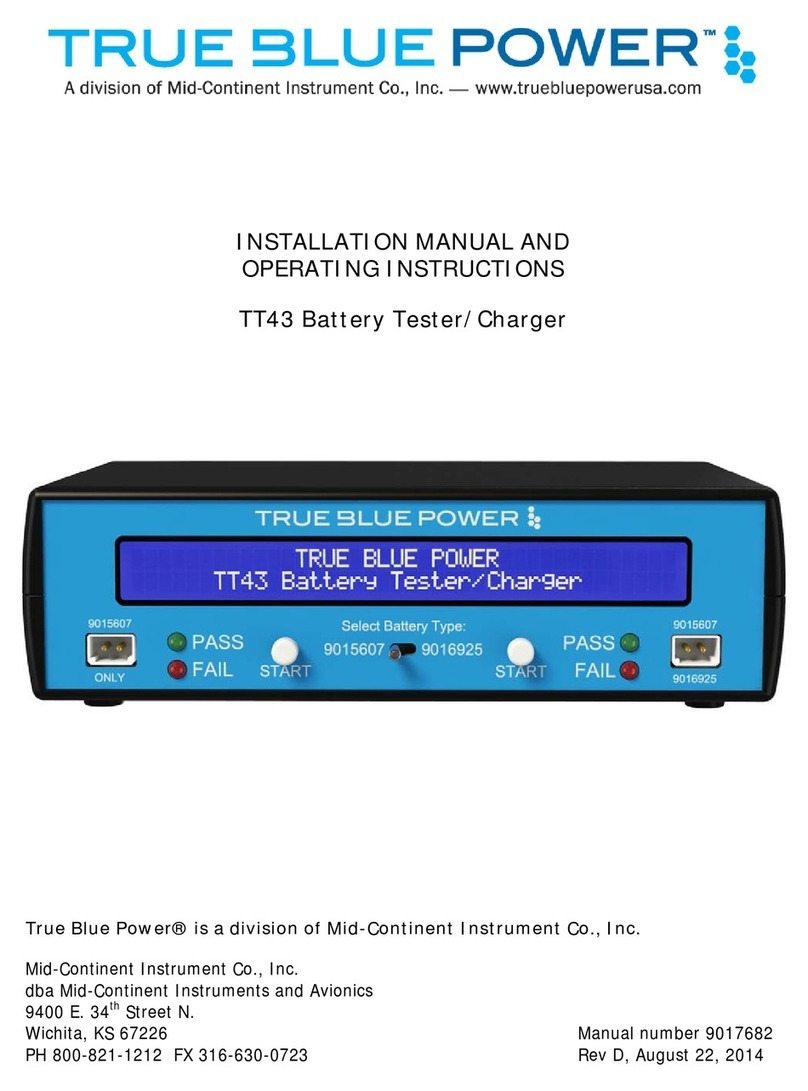

True blue power TT43 Technical Document

True blue power

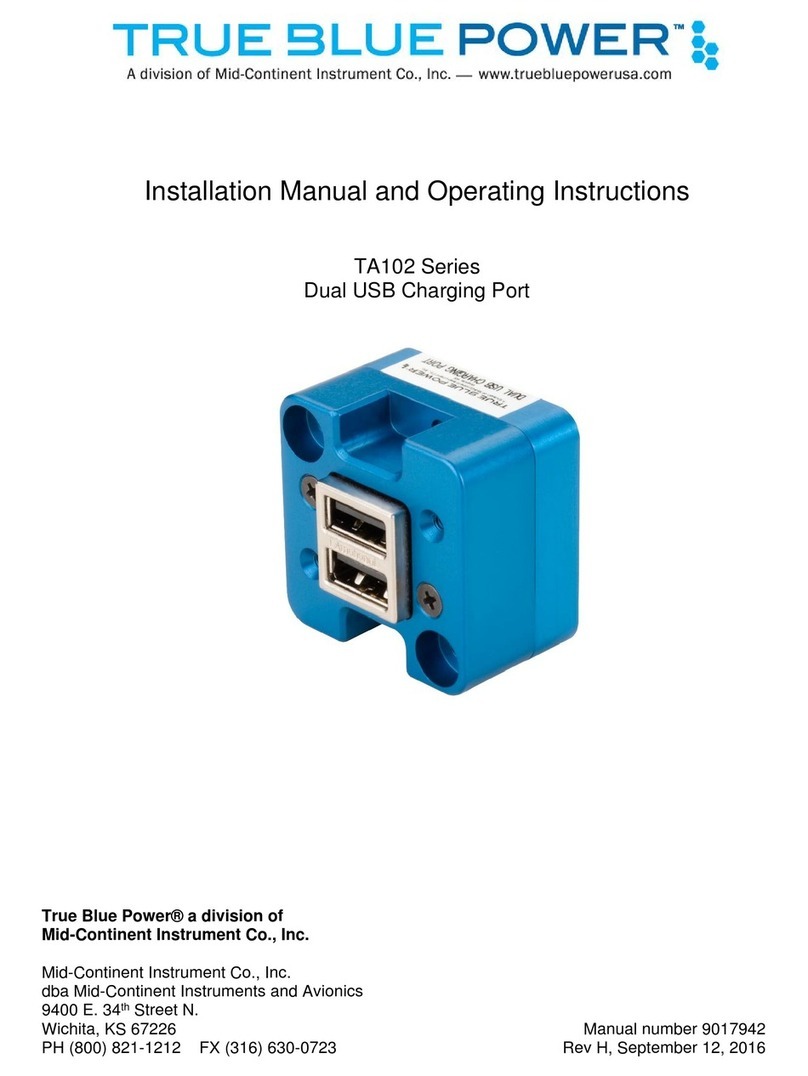

True blue power TA102 Technical Document

True blue power

True blue power TA102 Technical Document