Trunsun Solar TSMxxx-72 series User manual

1

Installation Manual

General Installation Manual for TRUNSUN SOLAR PV Solar Module

Please read this manual carefully before installing the modules.

Module components and cross-section

1 WARNING

Please read this manual completely before

installing TRUNSUN SOLAR module. This

module produces electricity when exposed to

light. Follow all applicable electrical safety

precautions. Only qualified personnel should

install or perform maintenance work on this

module. Do not handle modules when they are

wet. Do not use mirrors or other magnification

device or artificially concentrate sunlight onto

the modules.

2 INTRODUCTIONS

TRUNSUN SOLAR modules come in various

sizes to satisfy a full range of applications.

Each module is made of crystalline-silicon cells.

To protect the cells from the most severe

-environmental conditions, modules are made

of high transmission rate and low iron tempered

glass, anti-aging encapsulation material, and

high climate resistant and insulation backsheet

by hot lamination, with anodized Aluminum

alloy frame and permanently attached junction

box.

3 APPLICATIONS

Modules are reliable,designed to operate

efficiently in sunlight. By modules, the solar

radiant energy is transformed into electrical

energy for using. Modules, usually are used as

one fitting of PV solar system. A set of basic PV

2

solar system is consisted of PV solar modules,

controller, inverter, and storage battery.

Modules can be used in roof PV solar systems,

PV stations, building, and other electric

generation application etc widely.

4 CODES and REGULATIONS

The mechanical and electrical installation of PV

systems should be performed in accordance

with all applicable codes; including electrical

codes, building codes, and electric utility

interconnect requirements.

Requirements may also vary with system

voltage, and for DC or AC application. Contact

local authorities for governing regulations.

Whatever district, local standards should also

be followed in such installations.

Use only stranded or solid copper single

–conductor type PV wire or USE-2 cable, rated

sunlight resistant, for modules and interconnect

wiring that is exposed to weather.

5 MECHANICAL INSTALLATIONS

5.1 Mounting Site

Modules can be used on land except for

corrosive salt area and sulfurous area.

Excluded applications include, but are not

limited to, installations where modules are likely

to come in contact with any salt water or where

likely to become partially or wholly submerged

in fresh or salt water, examples of which include

use on boats, docks and buoys. Don’t install

modules in a location where it would be

immersed in water or continually exposed to

water from a sprinkler or fountain etc.

Actual maximum allowable wind speed may be

influenced by module type, mounting

configuration, location, and other factors. In no

case should modules be exposed to pressures

greater than 112.9pounds per square foot

(551Kg/m2) of uniformly distributed wind, snow,

or other loading.

The modules have been tested by TUV for a

maximum front loading of 5400Pa,backside

loading of 2400Pa.

Don’t install modules near naked flame or

flammable materials.

When choosing a site, avoid trees, buildings or

obstructions. Modules should be mounted to

maximize direct exposure to sunlight and to

eliminate or minimize shadowing. Even partial

shadowing can substantially reduce module

and system output. Furthermore, partial

shadowing can elevate the shaded portion’s

internal temperature, which may lower the

output and shorten module life.

5.2 Orientation of installations

Modules may be mounted at any angle from a

vertical orientation to a horizontal one. The

appropriate fixed tilt angle and azimuth

orientation should be used in order to maximize

the exposure to sunlight.

Incorrect orientation of modules installation will

result in loss of power output. Modules

connected in series should be installed at same

orientation and angle. Different orientation or

angle may cause loss of power output due to

difference of amount of sunlight exposed to the

modules.

In the Northern Hemisphere, modules should

face south, and in the Southern Hemisphere,

modules should face north.

5.3 Module tilt angle

Modules produce the most power when they

are pointed directly at the sun. For installations

where modules are mounted to a permanent

structure, modules should be tilted for optimum

winter performance. As a rule, if the PV system

power production is adequate in the winter, it

will be satisfactory during the rest of the year.

The module tilt angle is measured between the

modules and the ground.

5.4 Mounting

3

Use fasteners to fasten the modules to the

mounting support structure. Modules should be

bolted to support structures through mounting

holes located in the frame’s back flanges only.

Do not drill additional holes in the frame. Doing

so will invalidate the warranty. Modules should

not be mounted by supports at the ends.

Mounting support structure should withstand

forces from wind and snowfall pressure etc.

Mounting support structure should use proper

materials and corrosive treatment. Installation

the modules should have proper ventilation.

Clearance behind the modules is required to

permit air circulation and cooler module

operation. Elevated temperatures lower

operating voltage and power, and shorten

module lifetime. Clearance of 1/4 inch (6.35mm)

or more between modules is required to allow

for thermal expansion of the frames.

The recommended standoff height is 4.5 inch

(about 115 mm). If other mounting means are

employed it would cause unpredictable effect.

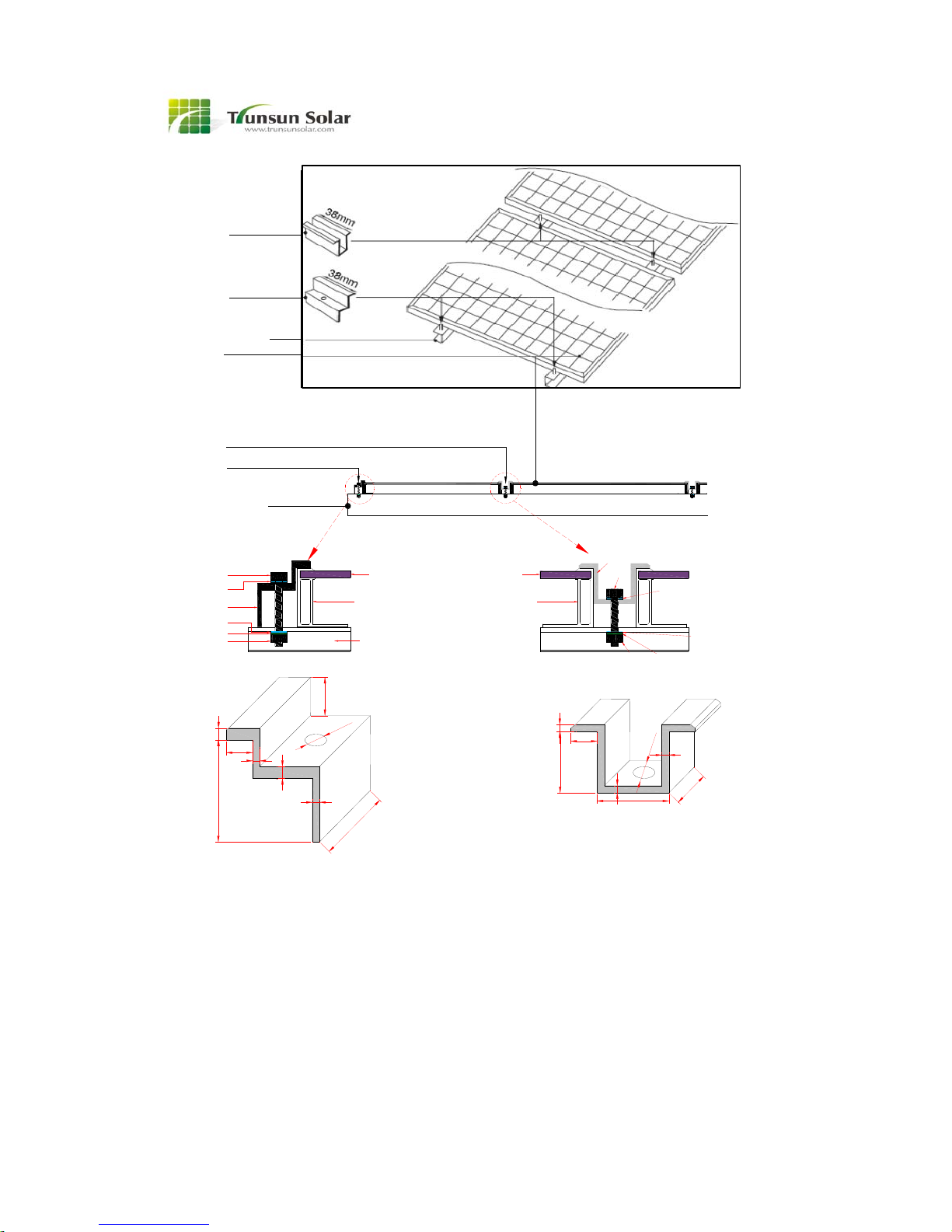

Figure 1:

Mounting holes for normal installation

Module must be securely attached to the

mounting structure using 8 holes for normal

installation as indicated in figure 1. Load

calculations shall be done by the system

designer or installer.

Each hole shall be installed in the order as in

the following figure.

Figure 2:

For your reference,please use the components

specified in below:

1.Bolt(inside hexagonal)

Material:Stainless Steel

Size and Length: M8*16mm

(M6*16 for TSP-54&TS*-60)

2.Washer

Material:Stainless Steel

Size:M8 (M6*16 for TSP-54&TS*-60)

3.Spring Washer

Material: Stainless Steel

Size:M8 (M6*16 for TSP-54&TS*-60)

4.Nut

Material: Stainless Steel

Size:M8 (M6*16 for TSP-54&TS*-60)

Remark: TS*-60 means TSM-60 & TSP-60

Recommended torque is between 14N.m to

20N.m.

Modules should be mounted using specialized

clamps as shown in Figure 3.

1.Modules should be attached on a supporting

structure rail by metal clamps. It is recommended

to use the clamps under the following condition or

approved by the system installation. At the edge

installation, using the similar clamp which can be

matched to the clamp in figure 3.

2.Recommended bolt (M8) torque rang:18N.m to

24N.m.

3.The Modules clamps must not contact the front

glass or deform the frame in any way. Avoid

shading effects from the Module clamps.

Drainage holes on the Modules frame must not

be closed or obscured by the clamps.

4

Figure 3: Clamp Details (Units: mm)

5.4.1 Roof mount

1. When installing a module on a roof or

building, ensure that it is securely and

cannot fall as a result of wind or snow

loads.

2. Provide adequate ventilation under a

module for cooling (5cm minimum air

space between module and mounting

surface).

3. The module is in a minimum fire resistance

rating of Class C, and the fire rating of this

module is valid only when mounted in the

manner specified in the mechanical

mounting instructions.

4. When installing module on a roof, ensure

that the roof construction is suitable. In

addition, any roof penetration required to

mount the module must be properly sealed

to prevent leaks.

5. In some cases, a special support frame

may be necessary.

6. The roof installation of solar modules may

affect the fireproofing of the house

construction. This module has a Class C

Fire Rating and must be installed over a

roof which is with appropriate fire

resistance.

Bolt

Washer

Clamp A

Washer

Spring Washer

Nut

PV laminate

Alumlnum

Frame

Substructure

rails

PV

laminate

Alumlnum

Frame

Substructure

rails

Nut Spring Washer

Washer

Washer

Bolt

Clamp B

Metal clamp B

(min.2 places)

Metal clamp A

(min.2 places)

Mountiing Structure Rail

Solar module

Metal clamp B

Metal clamp A

Mountiing Structure Rail

3

9-11

25,5

30

3

3

≥38

(recommendation)

(recommendation)

Clamp B

5

X

9-11

3

5

3

16

≥38

C

lamp A(X=height of Modules frame)

φ8-9

φ8-9

5

5.4.2 System mount

1. Solar modules produce electrical energy

when light shines on their front surface.

The DC voltage may exceed 30V. If

modules are connected in series, the total

voltage is equal to the sum of the individual

module voltage. If modules are connected

in parallel, The total current is equal to the

sum of the individual module current. Do

not disconnect during load connection for a

removable connector.

2. Keep children away from the system while

transporting and installing mechanical and

electrical components.

3. Completely cover the module with an

opaque material during installation to keep

electricity from being generated.

4. Do not wear metallic rings,

watchbands,ear,nose,lip rings or other

metallic devices while installing or

troubleshooting photovoltaic systems.

Only use approved insulate tools for

electrical installation work.

5. Abide with safety regulations for all other

components used in system, including

wiring and cables,connectors,charging

regulators,inverters,storage batteries and

rechargeable batteries,etc.

6. Use only equipment,connectors,wiring and

support frames suitable for use in a solar

electric system. Always use the same type

of module within a particular photovoltaic

system.

6 ELECTRICAL INSTALLAIONS

6.1 Bypass diodes

Modules contain bypass diodes when shipped

from the factory.

If the service personnel need to replace the

damaged bypass diodes, at least one diode

should be installed in each string.

Only qualified personnel are permitted to install

the bypass diodes.

Open the cover of junction box and install

diodes in each two conductors. Only diode with

the same model type is permitted to be used.

6.2 Over current protection

Whenever necessary to comply with local

codes, use a fuse or circuit breaker, rated for

the maximum series fuse rating of the module

and the system voltage.

Always fuse the connections at the battery for

safety. Refer to the module rating label (on

module) for recommended fuse size. Also, refer

to the charge controller owner’s manual.

When the modules are connected in parallel,

each module or each string of module shall be

provided with a fuse with the maximum series

fuse rating as indicated in “Electrical

Specification”.

All electrical components should have ratings

equal or greater to the system rating. Do not

exceed the maximum allowable system voltage

as listed on the module label.

6

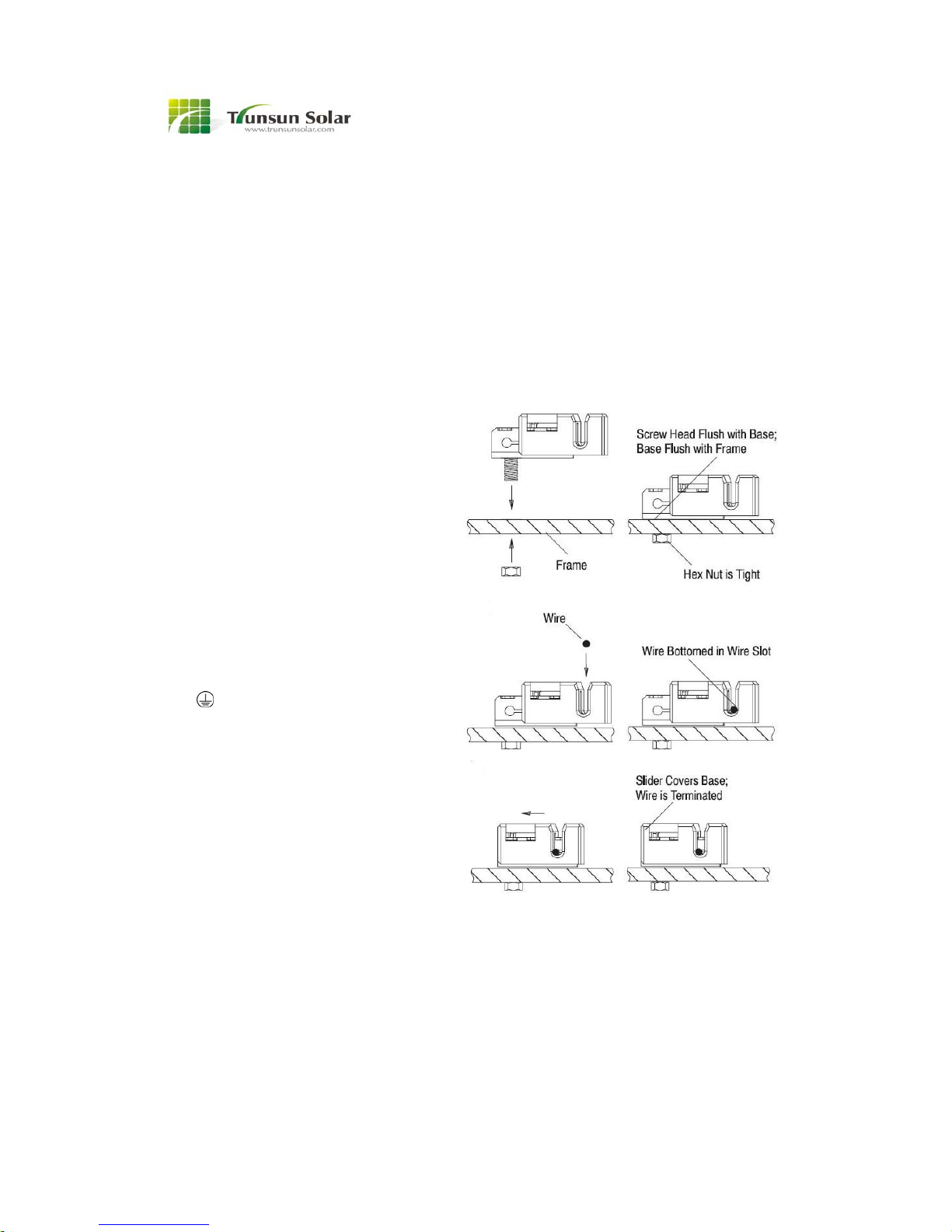

6.3 Grounding

Trunsun Solar modules use an anodic oxidized

aluminum frame to resist corrosion. So the

frame of modules must be connected to the

equipment grounding conductor to prevent

thunder and static injury. The grounding device

must be fully contact with the inside of the

aluminum alloy, and must penetrate the surface

of the frame oxidation film.

Please don’t drill any additional grounding hole

on the frame of the modules.

For optimal performance, Trunsun Solar

recommend the DC cathode of the modules

array is connected to ground. Failure to comply

whit this requirement may reduce the

performance of the system.

The grounding method must not result in direct

contact of dissimilar metals with the aluminum

frame of the modules that will result in galvanic

corrosion. An addendum to UL standard 1703

“Flat Plate Photovoltaic Modules and Panels”

recommends metal combinations not exceed

electrochemical potential difference of 0.6 volts.

The frame rails have pre-drilled holes marked

with is a grounding sing. These holes should

be used for grounding purpose and must not be

used for mounting the modules. The following

grounding methods are available.

There is a grounding hole 4.0mm diameter on

the edge side closer to the middle of the back

frame of module. All module frames should be

grounded for safety. The grounding

connections between modules must be

approved by a qualified electrician, the

grounding itself must be made by a qualified

electrician. The grounding clip accepts solid

uninsulated copper wire sizes 12 AWG. The

wire must not be nicked.

The module shall wire in accordance with the

standard, the grounding method of the frame of

arrays shall comply with IEC 61215. Of course,

in accordance with local laws and regulations to

carry out electrical installation is the best

choice.

Use the UL listed grounding clip manufactured

by Tyco Electronics Corp with type name

1954381-2. Place the grounding clip onto the

module frame so that the screw straddles the

grounding hole, then tighten the screw and nut

with a torque 2.3 to 2.8 Nm. The head of the

screw must be flush with the base and the base

must be flush with the frame. The copper wire

should not be compressed during the

installation.

Place a 12 AWG copper wire in the wire slot

then engage the slider. Detailed process is as

the following:

Figure 4

Trunsun solar modules can be grounded using

third party grounding devices so long as the are

certified for grounding modules and the devices

are installed according to the manufactures’s

specified instructions.

6.4 Wiring

Modules are equipped with factory installed

wires and quick connectors. Modules have

been designed to be easily interconnected in

series.

Bolt diameter is

4mm.

7

One module has a pair of male and female

waterproof cables and connectors for electrical

connection, that are pre-wired inside the

junction box. The cables have obvious marks of

the positive and the negative.

For a series electrical connection, connect

positive (+) connector of one module to the

negative (-) connector of the following module.

For a parallel electrical connection, connect

positive (+) connector of one module to the

positive (+) connector of the following module.

Figure 5

(1) serial -connection of modules

(2) parallel- connection of modules

For parallel connection, additional branch

connectors are needed. The module employs

connectors manufactured by Multi-Contact USA

with model type PV-KBT4/6II-UR (female) and

PV-KST4/6II-UR (male) or connectors

manufactured by other manufactories which

also can be matched to the connector of

Multi-Contact, check the connectors in the

module and choose branch connectors that

match the connectors of the modules.

Use 12 AWG or 14 AWG PV wire or USE-2 wire

for interconnection. The area of the cable

mated with the connector is recommended to

be 4mm², temperature range:-40℃to 90℃.

When connecting the modules to load or on

inverter, additional wires with pre-attached

connectors may be used. The wire shall be PV

wire or USE-2 wire, the connectors shall be

manufactured by Multi-Contact USA with model

type PV-KBT4/6II-UR (female) and

PV-KST4/6II-UR (male) or shall be

manufactured by other manufactories which

also can be matched to the connector of

Multi-Contact. Connect this wire to the module

by connectors, then the other end of the wire is

connecting to inverter or load by field wiring

method specified by inverter/ load

manufacturers.

7 MAINTENANCES

It is recommended to check the modules once

per year. Under most conditions, normal rainfall

is sufficient to keep the module glass clean. If

dirt build-up becomes excessive, clean the

glass with a soft cloth using mild detergent and

water. Modules that are mounted, flat (0°tilt

angle) should be cleaned more often, as they

will not self-clean as effectively as modules

mounted at a 15°tilt or greater.

It is recommended to perform periodic

inspection of the modules for damage to glass,

back skin, frame, and support structure. Check

electrical connections for loose connections

and corrosion. Check if mounting support

structure and modules are loose. Check

connections of cables, connectors, and

grounding.

All the modules have to pass comprehensive in

spection before delivery, which ensures that all

the modules can meet the requirements of the

8

Customers

The fault probability of the modules in the later

operation is extremely low.

You can use the below fault judgment methods:

apperance defects, such as break, cracked, su

rface stripping and so on, the electrical perform

ance of the whole string or of the whole module

failed.

For the fault modules, you cannot disassemble

them by yourself. Disassembling must be exec

uted by qualified experts. You should contact o

ur sales persons at once to apply for repaire or

replacement of the fault modules. (the modules

need to be replaced must be the same kind a

nd type ,if needed) .

Modules can operate effectively without ever

being washed, although removal of dirt from the

front glass can increase output. The glass can

be washed with a wet sponge or cloth. Wear

rubber gloves for electrical insulation.

8 SAFETY PRECAUTIONS

Module installation and operation should be

performed by qualified personnel only. Children

should not be allowed near the solar electric

installation. Modules of unpacking, transport,

installation process must be handled with care.

To avoid collision with the sharp and hard

objects so as not to cause damage and affect

the normal use.

Module must be installed in the absence of

shadowed areas, otherwise it will not work to

generate electricity. If the module long

shadowing state (dust and bird feces shadowed)

to work, it will Breakdown caused by

overheating

Avoid electrical hazards when installing, wiring,

operating and maintaining the module. Modules

produce DC electricity when exposed to light

and therefore can produce an electrical shock

or burn. Modules produce voltage even when

not connected to an electrical circuit or load.

Modules produce nearly full voltage when

exposed to as little as 5% of full sunlight and

both current and power increase with light

intensity. Do not touch live parts of cables and

connectors. As an additional precaution, use

insulated tools and rubber gloves when working

with modules in sunlight.

Fall of modules from high place will cause

death, injury or damage. Do not drop module or

allow objects to fall on module. Never leave a

module unsupported or unsecured. If a module

should fall, the glass can break. A module with

broken glass cannot be repaired and must not

be used.

When installing or working with module or

wiring, cover module face completely with

opaque material to halt production of electricity.

Modules have no on/off switch. Modules when

exposed to sunlight generate high voltage and

are dangerous. Modules can be rendered

inoperative only by removing them from

sunlight, or by fully covering the front surface

with opaque cloth, cardboard, or other

completely opaque material, or by working with

modules face down on a smooth, flat surface

when installing or maintaining.

Do not expose the artificially concentrated

sunlight to a module.

Trunsun modules are designed to fulfill the

criteria of Application class A requirements

according to IEC61730-1.Modules rated for use

in application class A may be used in systems

operating at greater than 50V DC or 240W,

where general contact access is anticipated.

Modules qualified for safety through

IEC61730-1 and IEC61730-2 within application

class A are considered to meet the

requirements for safety class Ⅱreferring to

IEC61140.

Modules can produce higher output than the

rated specifications. Industry standard ratings

are made at conditions of 1000 W/m2 and 25°C

cell temperature. Reflection from snow or water

can increase sunlight and therefore boost

current and power. In addition, colder

temperatures can substantially increase voltage

and power. Modules are intended for use in

terrestrial

9

applications only, thus excluding aerospace or

maritime conditions or use with sunlight

concentration.

It is recommended that the module remains

packed in the box until time of installation .Work

only under dry conditions, with a dry module

and tools.

Since sparks may be produced, do not install

module where flammable gases or vapors are

present.

Do not drill holes into module frame as it will

void warranty.

Modules are constructed with tempered glass,

but still must be handled with care. If the front

glass is broken or if the polymer back skin is

torn, contact with any module surface or the

frame can produce electrical shock, particularly

when the module is wet. Broken or damaged

modules must be disposed of properly. Do not

disassemble, bend, impact by sharp objects,

walk on, and throw or drop etc. Keep back

surface free from foreign objects. Avoid sharp

edges.

Use module for its intended function only.

Follow all module manufacturer’s instructions.

Do not disassemble the module, or remove any

part or label installed by the manufacturer. Do

not treat the back of the module with paint or

adhesives.

If not otherwise specified, it is recommended

that requirements of the latest local, national or

regional electrical codes be followed.

Retain this installation manual for future

reference.

9 NOTES

The installation shall be in accordance with

CSA C22.1, Safety Standard for Electrical

Installation, Canadian Electrical Code, Part 1.

Under normal conditions, a photovoltaic module

is likely to experience conditions that produce

more current and/or voltage than reported at

standard test conditions. Accordingly, the

values of Isc and Voc marked on this module

should be multiplied by a factor of 1.25 when

determining voltage ratings, conductor current

ratings, fuse sizes, and size of controls

connected to the module output. Refer to

Section 690-8 of the U.S. National Electrical

Code for an additional multiplying factor of 1.25,

which may be applicable.

For modules with a nominal open voltage or

maximum system voltage of 45V or more may

cause an electric shock.

The current output for the modules shown in

the Specifications is measured at Standard Test

Conditions. These conditions may not be

frequently observed in actual practice.

10

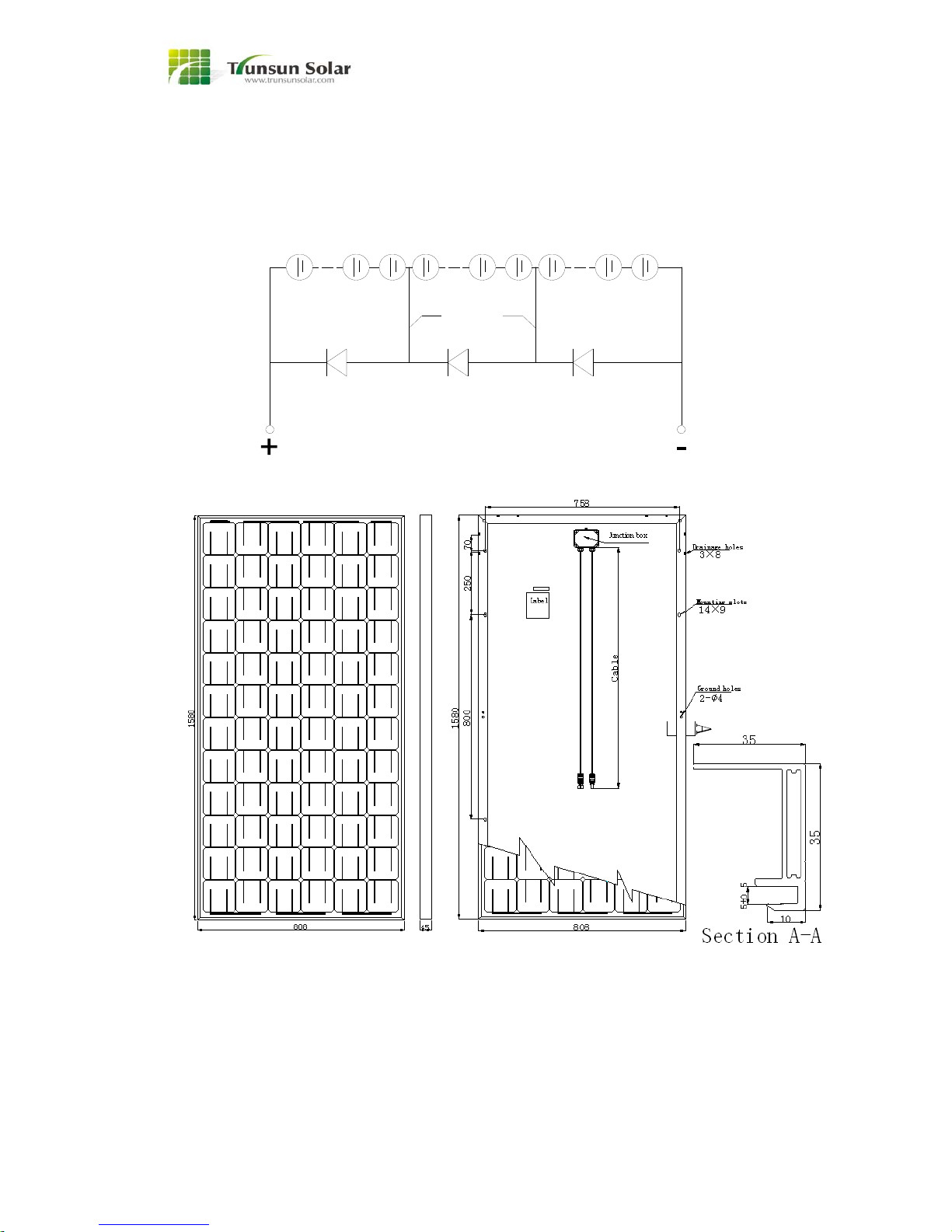

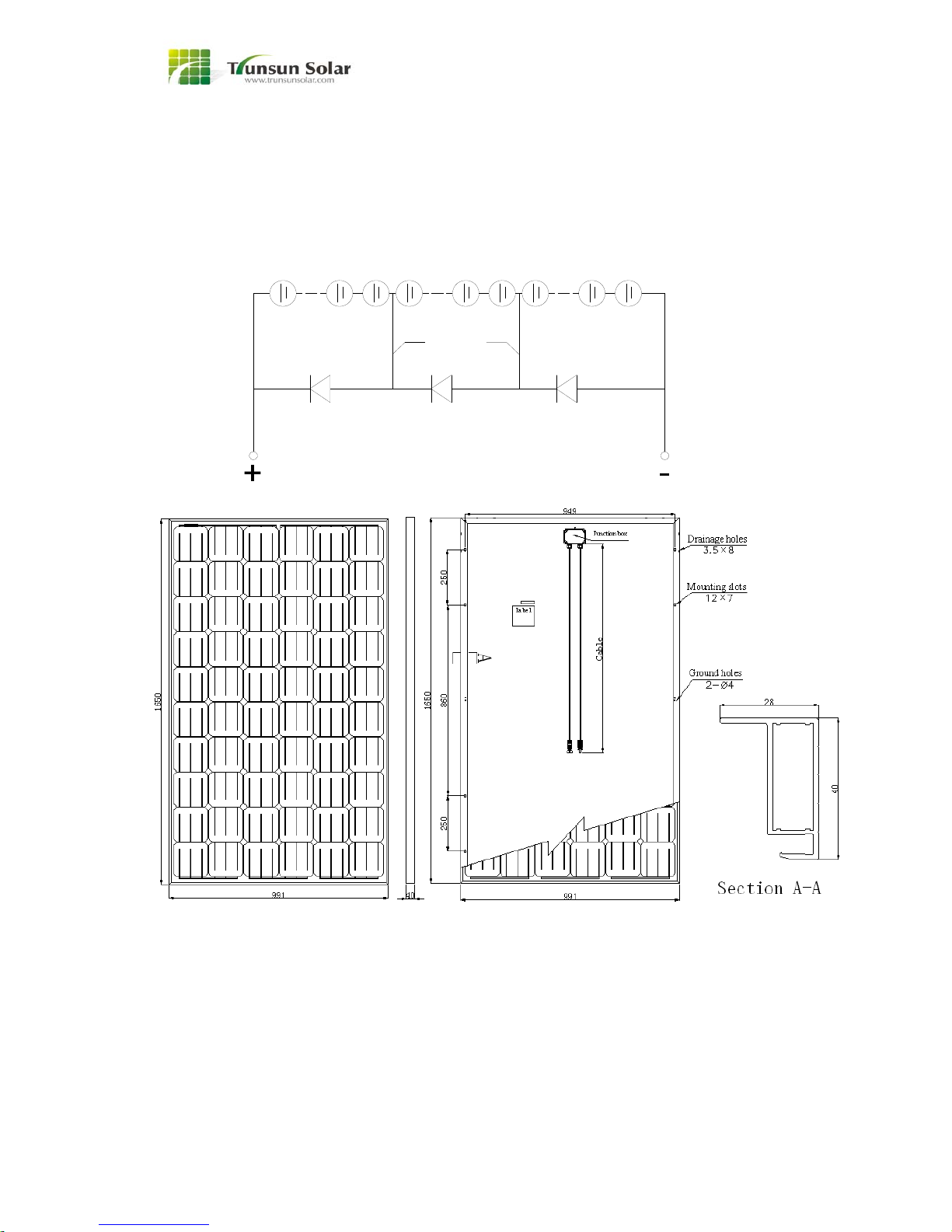

SPECIFICATIONS-1

Zhejiang Trunsun Solar single crystalline silicon PV module---TSMxxx-72

NOTE: TSM-72

Electrical Specification and Mechanical Specification can be found in the last page <Electrical

Specification and Mechanical Specification>

D

C

down-lead

24 cells 24 cells 24 cells

AB

output output

11

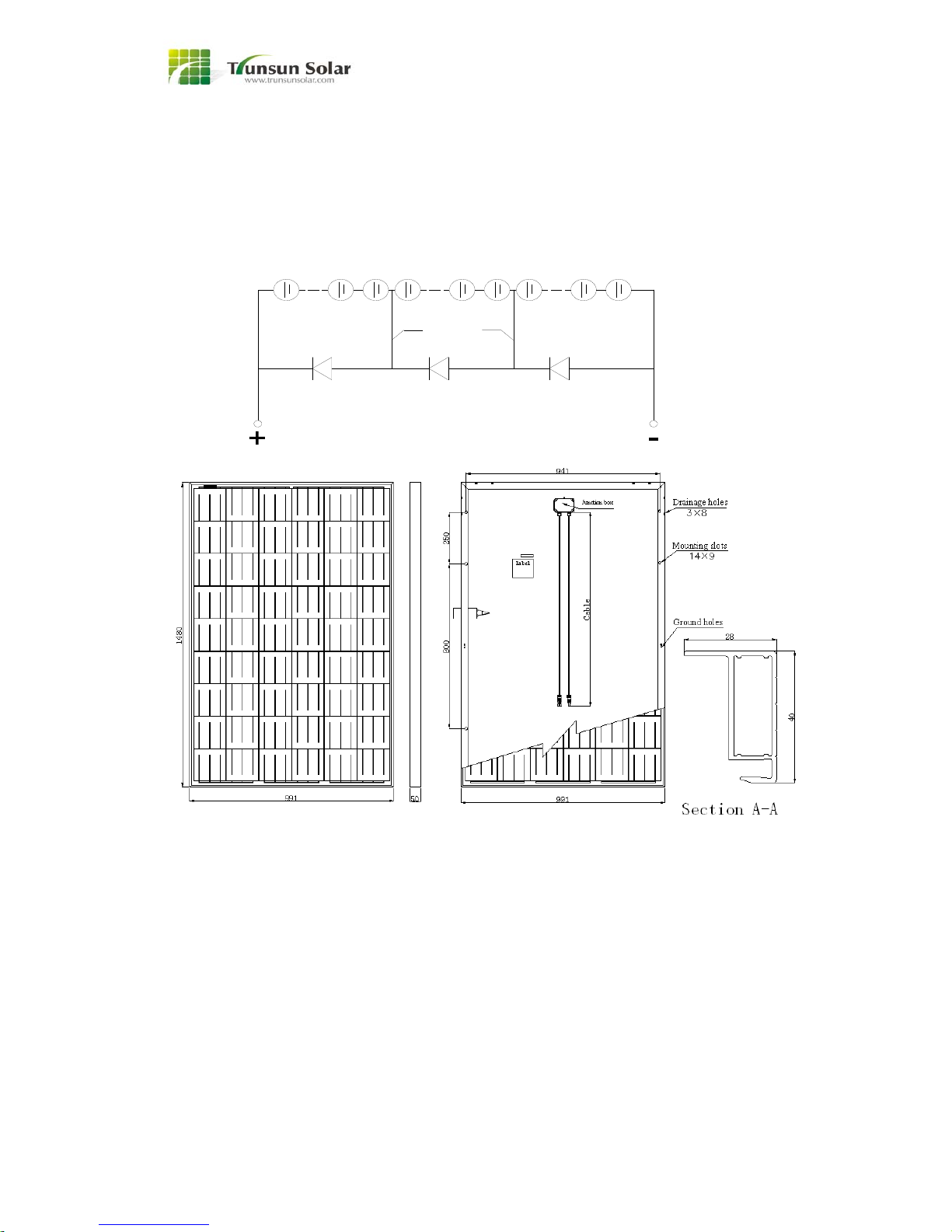

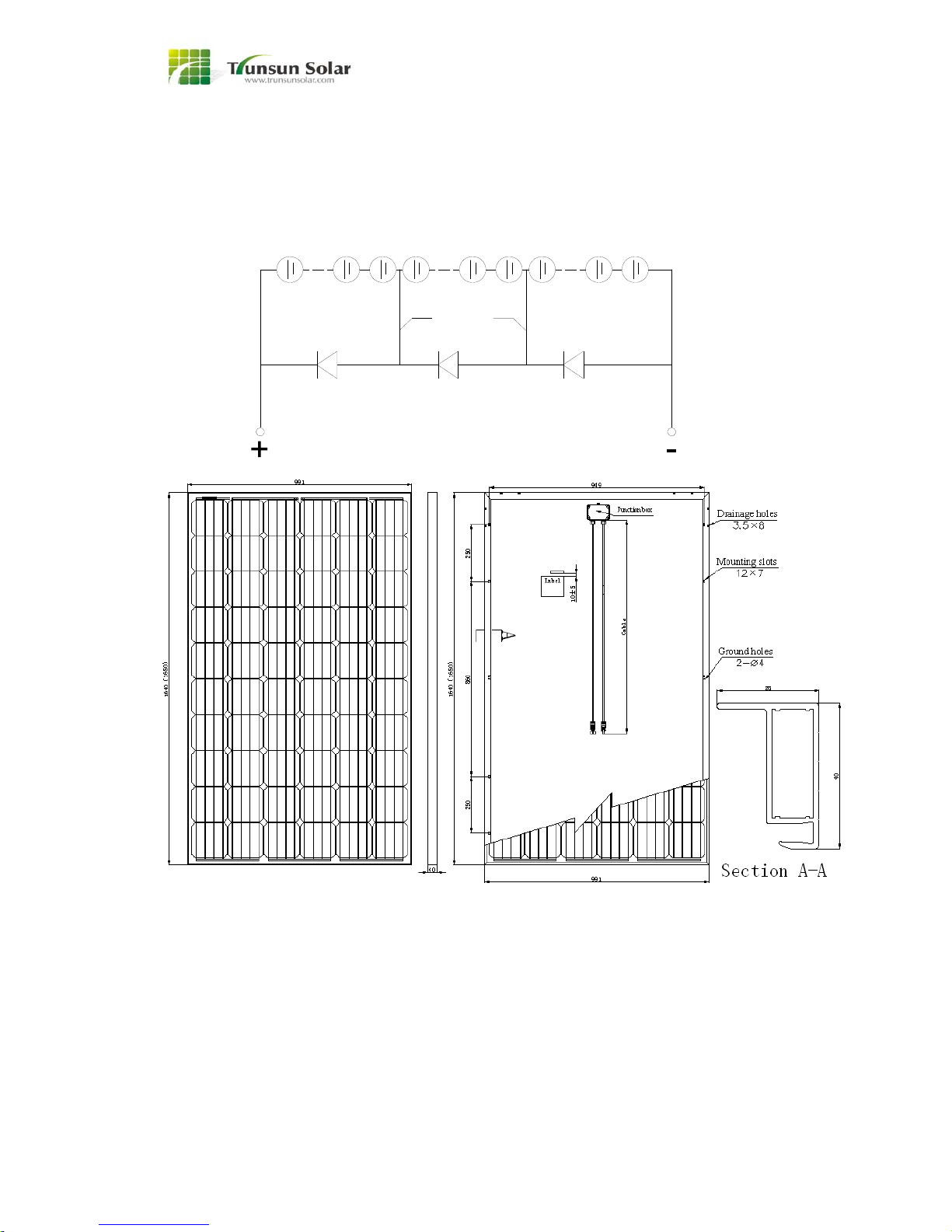

SPECIFICATIONS-2

Zhejiang Trunsun Solar single crystalline silicon PV module---TSPxxx-54

NOTE: TSP-54

Electrical Specification and Mechanical Specification can be found in the last page <Electrical

Specification and Mechanical Specification>

D

C

down-lead

18 cells 18 cells 18 cells

A B

output output

12

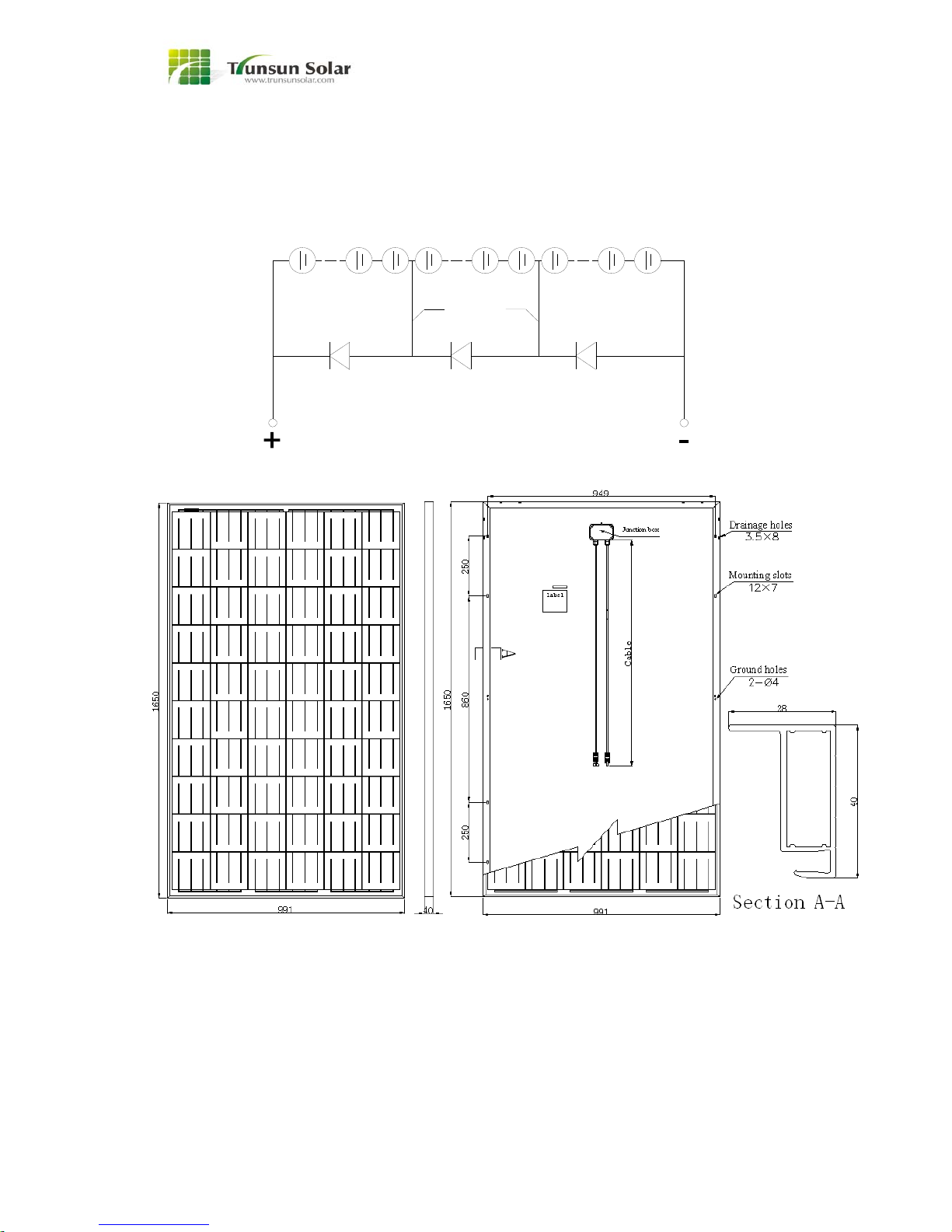

SPECIFICATIONS-3

Zhejiang Trunsun Solar single crystalline silicon PV module---TSMxxx-60

NOTE: TSM-60

Electrical Specification and Mechanical Specification can be found in the last page <Electrical

Specification and Mechanical Specification>

D

C

down-lead

20 cells 20 cells 20 cells

AB

output output

13

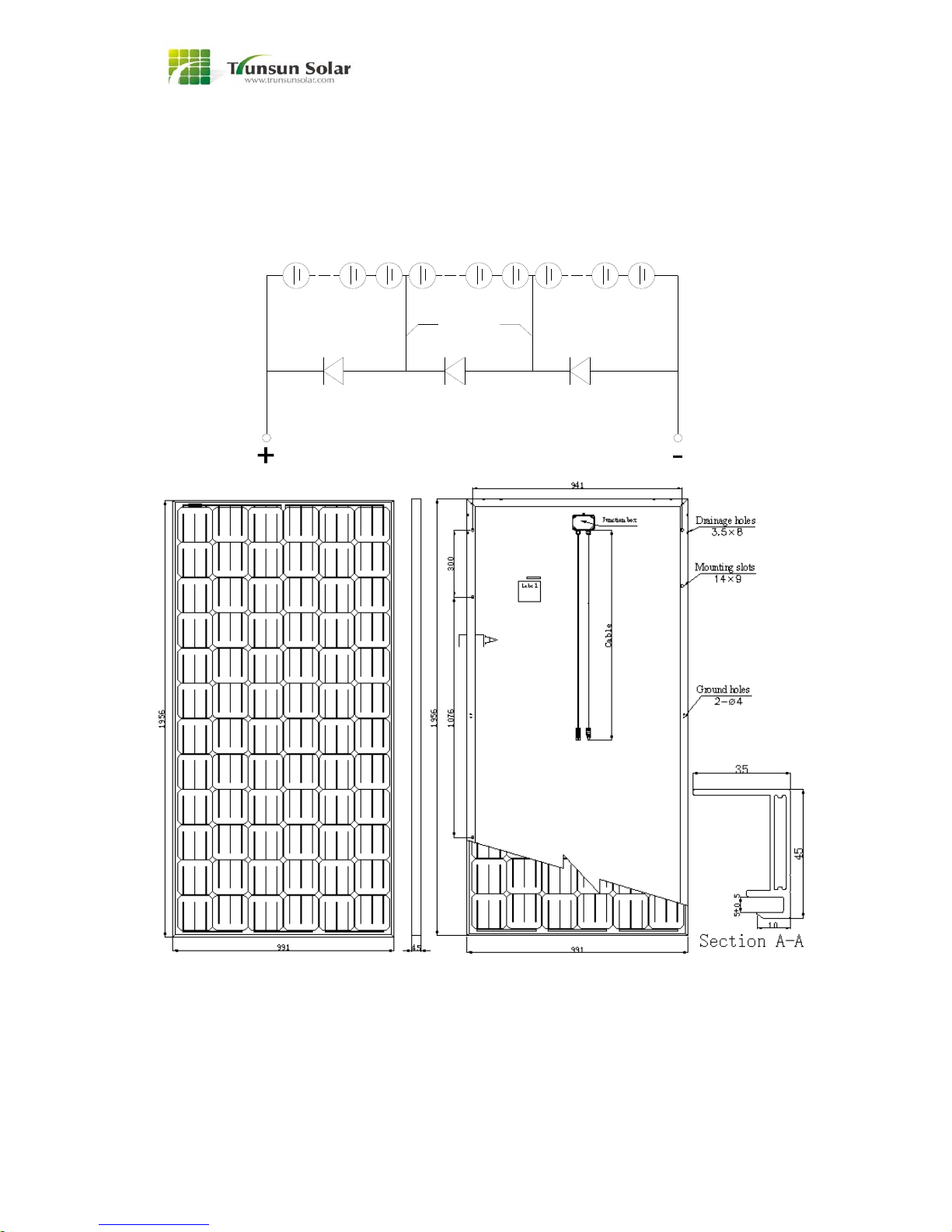

SPECIFICATIONS-4

Zhejiang Trunsun Solar single crystalline silicon PV module---TSMxxx-60

NOTE: TSM-60

Electrical Specification and Mechanical Specification can be found in the last page <Electrical

Specification and Mechanical Specification>

D

C

down-lead

20 cells 20 cells 20 cells

AB

output output

14

SPECIFICATIONS-5

Zhejiang Trunsun Solar single crystalline silicon PV module---TSPxxx-60

NOTE: TSP-60

Electrical Specification and Mechanical Specification can be found in the last page <Electrical

Specification and Mechanical Specification>

D

C

down-lead

20 cells 20 cells 20 cells

AB

output output

15

SPECIFICATIONS-6

Zhejiang Trunsun Solar single crystalline silicon PV module---TSPxxx-60

NOTE: TSP-60

Electrical Specification and Mechanical Specification can be found in the last page <Electrical

Specification and Mechanical Specification>

D

C

down-lead

20 cells 20 cells 20 cells

AB

output output

16

SPECIFICATIONS-7

Zhejiang Trunsun Solar single crystalline silicon PV module---TSMxxx-72

NOTE: TSM-72

Electrical Specification and Mechanical Specification can be found in the last page <Electrical

Specification and Mechanical Specification>

D

C

down-lead

24 cells 24 cells 24 cells

AB

output output

17

SPECIFICATIONS-8

Zhejiang Trunsun Solar single crystalline silicon PV module---TSMxxx-72

NOTE: TSM-72

Electrical Specification and Mechanical Specification can be found in the last page <Electrical

Specification and Mechanical Specification>

D

C

down-lead

24 cells 24 cells 24 cells

AB

output output

18

SPECIFICATIONS-9

Zhejiang Trunsun Solar single crystalline silicon PV module---TSPxxx-72

NOTE: TSP-72

Electrical Specification and Mechanical Specification can be found in the last page <Electrical

Specification and Mechanical Specification>

D

C

down-lead

24 cells 24 cells 24 cells

AB

output output

19

SPECIFICATIONS-10

Zhejiang Trunsun Solar single crystalline silicon PV module---TSPxxx-72

NOTE: TSP-72

Electrical Specification and Mechanical Specification can be found in the last page <Electrical

Specification and Mechanical Specification>

D

C

down-lead

24 cells 24 cells 24 cells

AB

output output

20

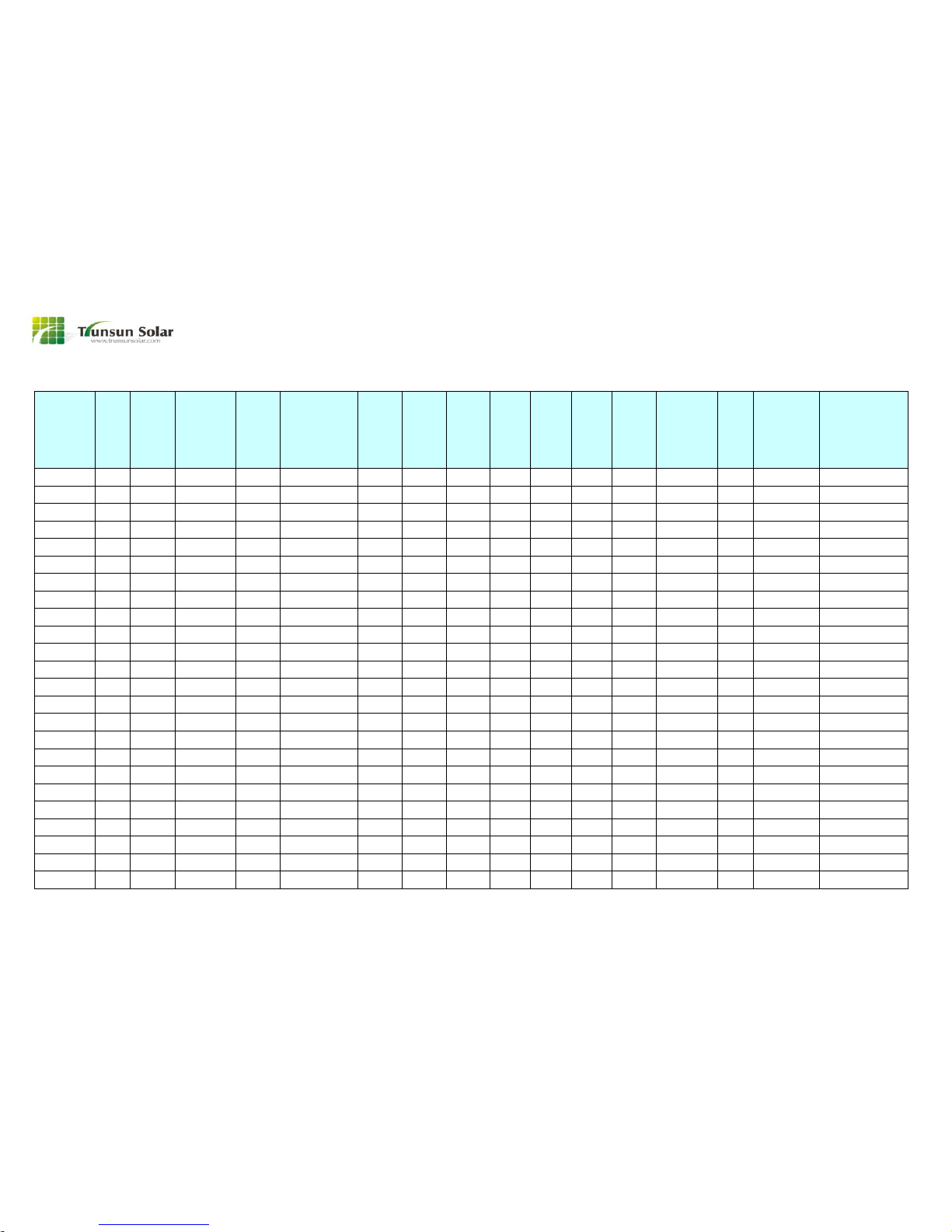

Electrical Specification and Mechanical Specification

Model Cell

Type Cell

number Cell

connection

Module

weight

(kg)

Module

size(mm) Max.

Power

Max.

system

voltage Voc (V) Isc (A) Vpm

(V) Ipm

(A) Eff(%) IEC

Application

Class

Fire

Class

Maximum

over-current

protection

rating (A)

Recommended

maximum

series/parallel

module

configurations

TSM175-72 Mono 72 6*12 16 1580*808*45*35 175 1000 42.60 5.52 35.50 4.93 13.7 A C 15 23/1

TSM180-72 Mono 72 6*12 16 1580*808*45*35 180 1000 42.60 5.68 35.50 5.07 14.1 A C 15 23/1

TSM185-72 Mono 72 6*12 16 1580*808*45*35 185 1000 43.20 5.76 36.00 5.14 14.5 A C 15 23/1

TSM190-72 Mono 72 6*12 16 1580*808*45*35 190 1000 43.20 5.91 36.00 5.28 14.9 A C 15 23/1

TSM195-72 Mono 72 6*12 16 1580*808*45*35 195 1000 43.20 6.07 36.00 5.42 15.3 A C 15 23/1

TSM200-72 Mono 72 6*12 16 1580*808*45*35 200 1000 43.20 6.22 36.00 5.56 15.7 A C 15 23/1

TSM205-72 Mono 72 6*12 16 1580*808*45*35 205 1000 43.80 6.29 36.50 5.62 16.1 A C 15 22/1

TSM210-72 Mono 72 6*12 16 1580*808*45*35 210 1000 43.80 6.44 36.50 5.75 16.4 A C 15 22/1

TSP190-54 Poly 54 6*9 17.5 1480*991*50*35 190 1000 30.80 8.28 25.70 7.39 13.0 A C 15 32/1

TSP195-54 Poly 54 6*9 17.5 1480*991*50*35 195 1000 30.80 8.50 25.70 7.59 13.3 A C 15 32/1

TSP200-54 Poly 54 6*9 17.5 1480*991*50*35 200 1000 31.30 8.58 26.10 7.66 13.6 A C 15 31/1

TSP205-54 Poly 54 6*9 17.5 1480*991*50*35 205 1000 31.30 8.80 26.10 7.85 14.0 A C 15 31/1

TSP210-54 Poly 54 6*9 17.5 1480*991*50*35 210 1000 31.80 8.88 26.50 7.92 14.3 A C 15 31/1

TSP215-54 Poly 54 6*9 17.5 1480*991*50*35 215 1000 31.80 9.09 26.50 8.11 14.7 A C 15 31/1

TSP220-54 Poly 54 6*9 17.5 1480*991*50*35 220 1000 32.30 9.16 26.90 8.18 15.0 A C 15 30/1

TSP225-54 Poly 54 6*9 17.5 1480*991*50*35 225 1000 32.30 9.37 26.90 8.36 15.3 A C 15 30/1

TSP230-54 Poly 54 6*9 17.5 1480*991*50*35 230 1000 32.80 9.44 27.30 8.42 15.7 A C 15 30/1

TSM245-60 Mono 60 6*10 18.5 1640*991*40*28 245 1000 38.32 8.52 30.94 7.92 15.1 A C 15 26/1

TSM250-60 Mono 60 6*10 18.5 1640*991*40*28 250 1000 38.55 8.64 31.21 8.01 15.4 A C 15 25/1

TSM255-60 Mono 60 6*10 18.5 1640*991*40*28 255 1000 38.76 8.72 31.37 8.13 15.7 A C 15 25/1

TSM260-60 Mono 60 6*10 18.5 1640*991*40*28 260 1000 38.92 8.81 31.67 8.21 16.0 A C 15 25/1

TSM265-60 Mono 60 6*10 18.5 1640*991*40*28 265 1000 39.12 8.89 31.97 8.29 16.3 A C 15 25/1

TSM270-60 Mono 60 6*10 18.5 1640*991*40*28 270 1000 39.25 8.98 32.30 8.36 16.6 A C 15 25/1

TSM275-60 Mono 60 6*10 18.5 1640*991*40*28 275 1000 39.36 9.09 32.55 8.45 16.9 A C 15 25/1

This manual suits for next models

69

Table of contents

Popular Solar Panel manuals by other brands

Baxi

Baxi Solargen PHOTOVOLTAIC manual

Schumacher Electric

Schumacher Electric SP-5400 owner's manual

Viessmann

Viessmann Vitovolt 300 operating instructions

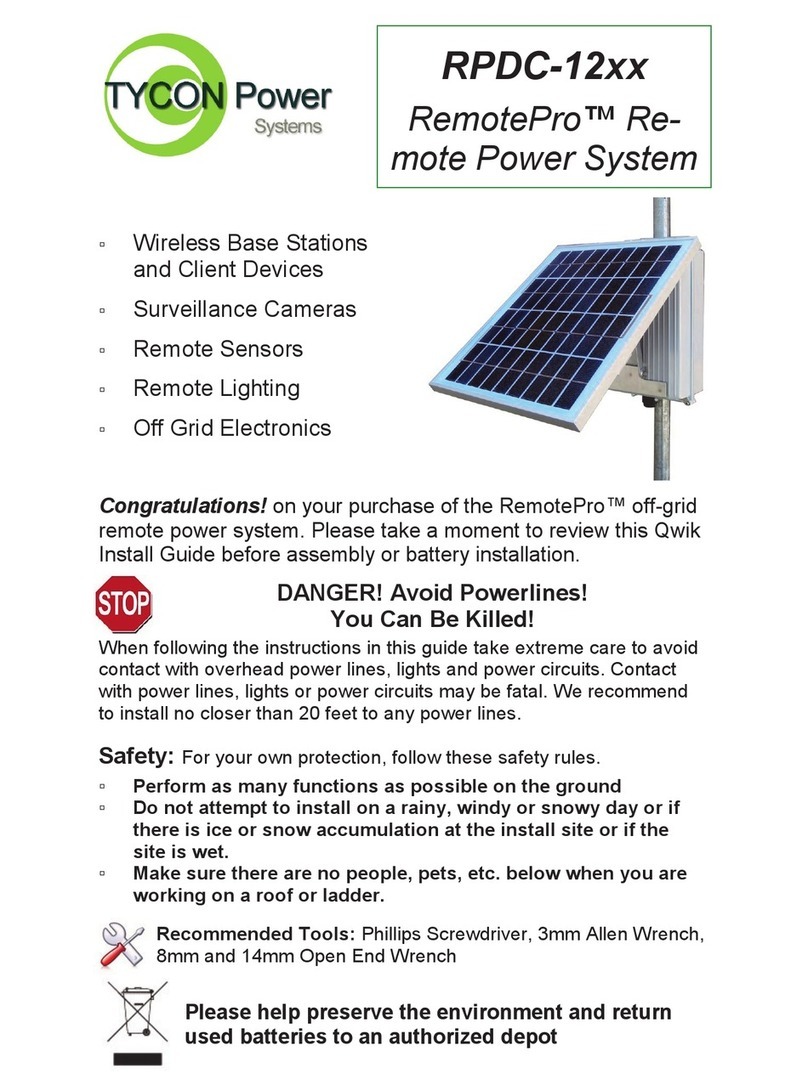

Tycon Power Systems

Tycon Power Systems RPDC-12 Series quick start guide

Viessmann

Viessmann VITOSOL-F Service instructions

Lippert

Lippert Furrion FSFP37MW2-BL user manual