21 South Field Drive, Elmira, Ontario, N3B 0A6 - Tel: (519) 669-5421 - Fax: (519) 669-8912

TROLLEY TO RAIL INSTALLATION STEPS

Warning

IMPORTANT COUGAR® MAX TROLLEY NOTES

Part Number #4.957.0037.001

Manufacturer’sinstructions must be followed regarding proper system use, maintenanceand installation. Alternationsor

misuse of product or failure to follow instructions may result in serious injury or death.

All safety rail systems and components are to be used under the safety standards in place in the jurisdictionin which you are

working. These instructionsare not meant to supersede any local or federal safety standards.

Any Safety Trolley, which has seen fall arresting incident should not be used afterwards. and should be replaced as well the whole

system: trolley, rail and all accessories will need to be inspected and replaced at once. Until a full replacement of the system is

implemented you should not ascend or descend on a system that has been subjected to a fall.

Step 1: Step 2:

Hold the trolley so that the UP arrow Ensure trolley slips onto rail channels

is pointing upwards and insert trolley

properly, with UP arrow pointing to the

onto bottom of rail. top of the safety rail

Step 3: Step 4:

Pull up on the karabiner to duplicate To ensure trolley is functioning properly,

a climbing up motion. By pulling up, pull down on karabiner to duplicate a

the cam will disengage and trolley will fall arresting situation. Trolley should grab

move up freely in the up direction. safety rail immediately.

Notes/Best Practice:

1. If UP arrow is in proper direction, the SafetyLock™ mechanism will be

oriented to ensure Trolley cannot be installed upside-down. Never disable or

otherwise modify the SafetyLock™feature as this may lead to the Trolley failing

to lock onto the rail in a fall, thereby resulting in serious injury or death.

2. Climbers should tie off to a structure by means of a lanyard while working or

resting.

3. Climbers should also tie off the trolley when they are detached from it and

working elsewhere on the structure. This is an extra precaution to avoid any

slippage of trolley down the rail during extreme vibrations.

Use

Trylon’s Safety Trolley & Rail system is intended to arrest personnel (not material) should they (the individual) slip or fall while

climbing.

Ensure the anchorage system can support a minimum load of 3600 pounds. Certification is applicable to the device only. Neither

the manufacturer nor CSA has investigated the anchorage system. The Cougar MAX Trolley is designed to work on Trylon’s

Safety Rail Systems only. To minimize the potential for accidental disengagement, a competent person must ensure system

compatibility.

Cougar MAX Trolley should only be used with Trylon Cougar rail product. The Cougar MAX trolley is not compatible with rail

manufactured by any other manufacturer.The Trylon Rail product is only designed to be compatible with the Cougar MAX

Trolley. The use of either the Rail or Trolley with another manufacturer’s product could result in serious injury or death.

Climbers should always tie off to a structure by means of a lanyard while working or resting. When detaching from the trolley to

work elsewhere on the structure, as a best practice, climbers should also tie off their trolley to avoid the unlikely event of the

trolley ‘slipping’ down the rail during extreme vibrations.

Trylon Fall Protection systems are not intended to be used as a life line or work position device while working.

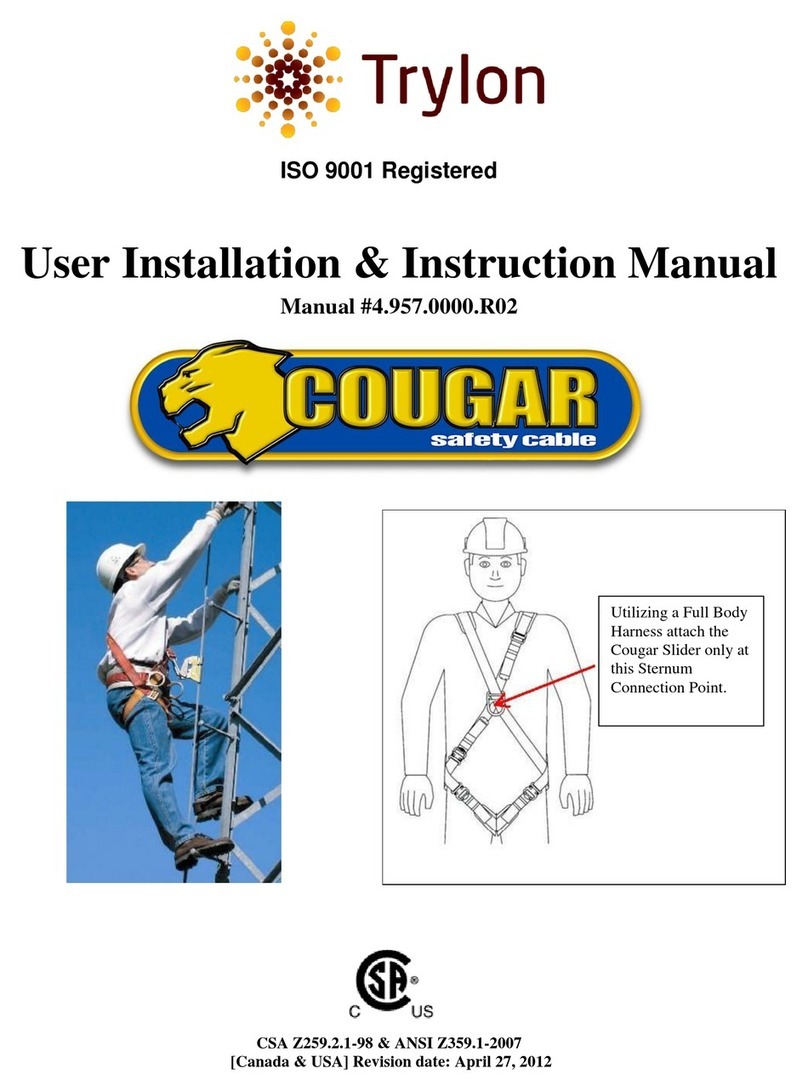

All climbers should ensure that the correct certified (CSA Z259.10-06, Class “AL”) body harness which includes a sternum

connection point is properly fitted according to the manufacturer’s instructions and ensures that it does not interfere with arresting

features of the fall protection system. All instructions and warnings provided with the body harness must be read and understood

before using the fall protection system. A proper harness fit also helps ensure that the climbing action of the Trolley on the rail is

smooth and reduces the potential to “snag”. Snagging is a nuisance to climbers, although not a safety hazard. A body belt is NOT

approved or recommended for use with the Cougar Rail System. Climber MUST use a harness with a sternum connection point.

The attachmentfrom the sternum D-ring to the Trolley must not exceed 0.15 m (6 inches) in length.

Care and Maintenance of Trolley

All trolleys should be stored in a clean, dry area with limited exposure to the following:

1) sunlight

2) excessive heat

3) harmful fumes

4) corrosive chemicals or conditions

The trolley can be cleaned by dipping it in a mild soap and water solution. Do not use harsh detergents or chemicals or pressure

washers. After cleaning, the unit should be rinsed in clear water and allowed to air dry naturally. After washing, hardware should

be inspected. No lubrication is necessary.