i

TABLE OF CONTENT

1. FUNDAMENTAL OF THE SYSTEM....................................................................................1

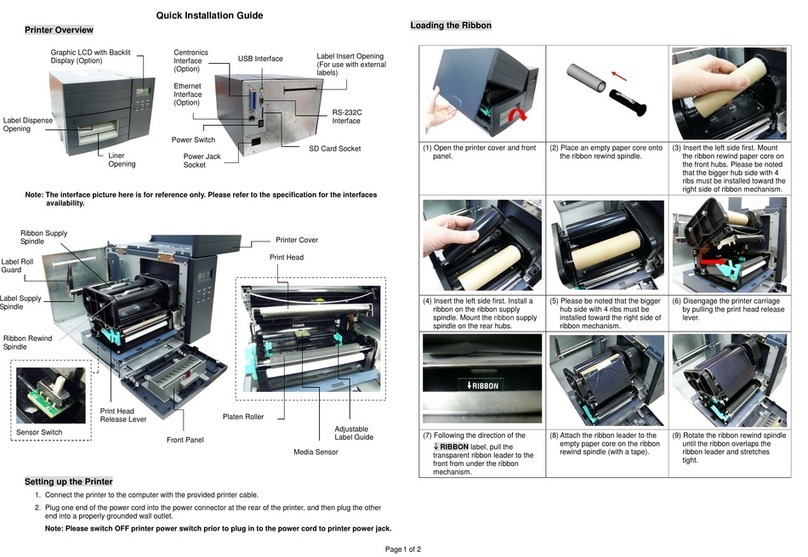

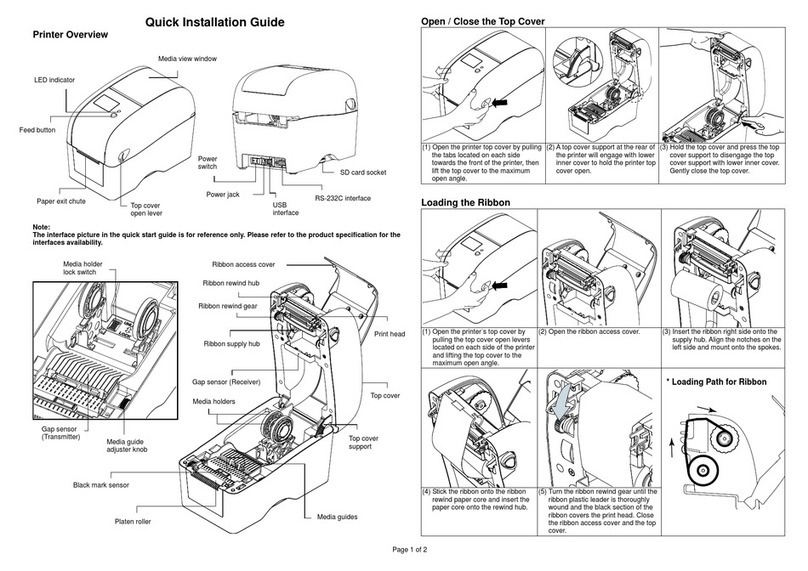

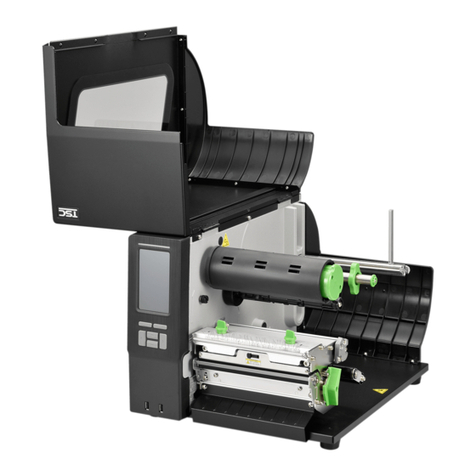

1.1. Overview.............................................................................................................................. 1

2. ELECTRONICS.......................................................................................................................5

2.1 Summary of Board Connectors...................................................................................... 5

2.2 Pin Configuration .............................................................................................................10

3. MECHANISM.........................................................................................................................12

3.1 Remove Covers ................................................................................................................12

3.2 Replacing the LCD Panel Module ................................................................................14

3.3 Replacing the Power Supply Unit................................................................................16

3.4 Replacing Multi-interface Board ..................................................................................17

3.5 Replacing the Main Board..............................................................................................18

3.6 Replacing the Platen Roller Assembly.......................................................................19

3.7 Replacing the Stepping Motor ......................................................................................20

3.8 Replacing the Printhead ASS'Y....................................................................................21

3.9 Replacing the Gap and Black-mark Sensor Module...............................................23

3.10 Replacing the DC Motor...............................................................................................24

3.11 Installing the Cutter Module........................................................................................25

3.12 Replacing the Cutter Driver IC Board.......................................................................27

4. TROUBLESHOOTING.........................................................................................................29

4.1 Common Problems..........................................................................................................29

5. MAINTENANCE....................................................................................................................33

UPDATE HISTORY...................................................................................................................35