05/2004 TSCHAN

-TORMAX VSG - 2 -

Contents

Chapter Page

1Safety Instructions............................................................................................................2

2Function............................................................................................................................3

2.1 Designated use............................................................................................................3

3Storage.............................................................................................................................3

4

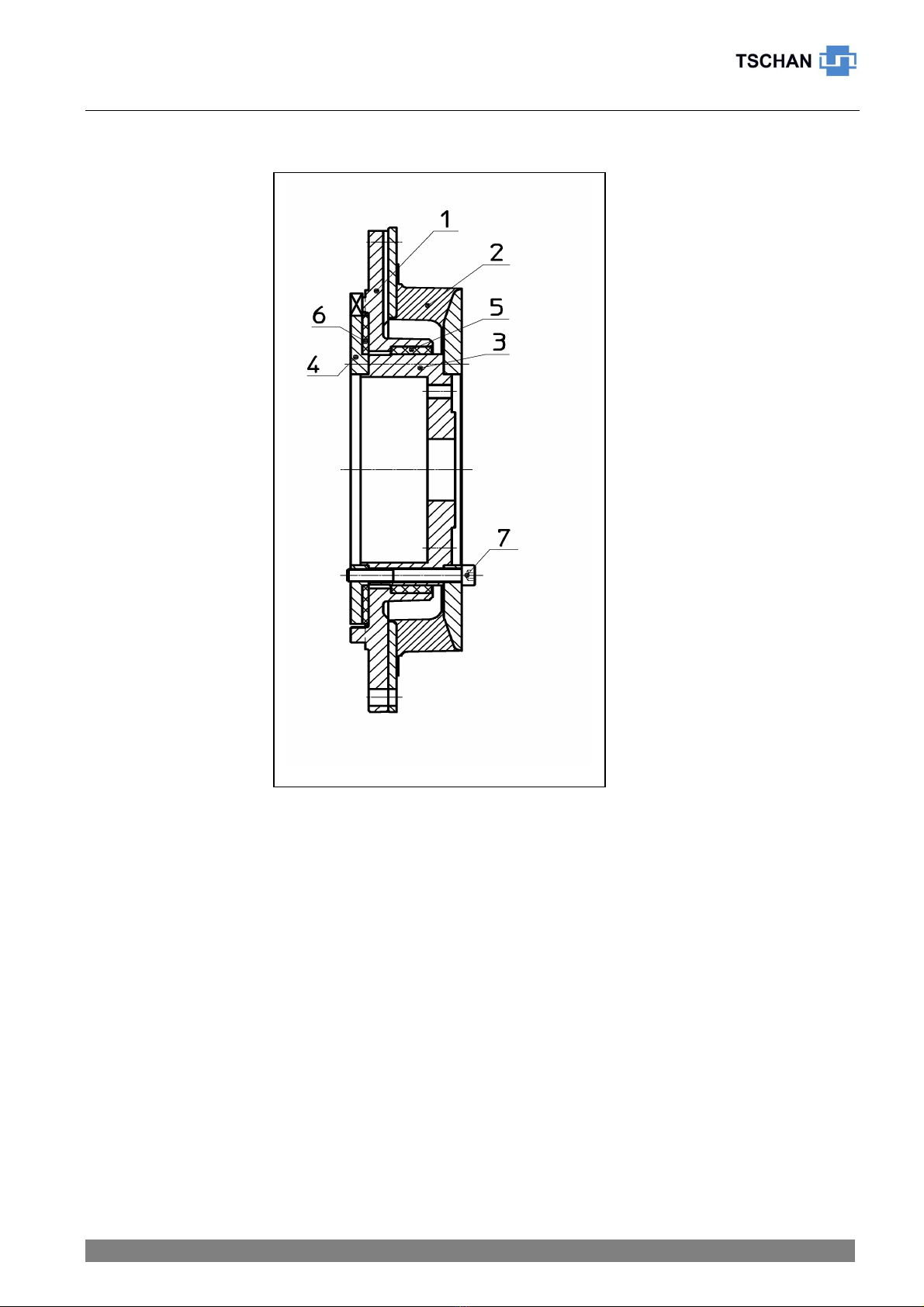

Construction .....................................................................................................................4

5Assembly..........................................................................................................................5

5.1 Before assembly..........................................................................................................5

6Operation..........................................................................................................................6

7Maintenance.....................................................................................................................8

7.1 Inspection and servicing intervals................................................................................8

7.2 Replacing the rubber element......................................................................................9

8Disposal............................................................................................................................9

1 Safety Instructions

These assembly and operating instructions form part of the coupling schedule. Always keep

these assembly and operating instructions easily accessible near the coupling.

Please ensure that all persons authorised to assemble, operate, maintain and repair the

product have read and understood the assembly and operating instructions and observe

them in all points in order to:

- Avoid hazards to life and limb of operating personnel or third-parties.

- Guarantee the operational safety of the coupling.

- Eradicate stand-still time and environmental hazards caused by improper handling.

During transport, assembly, dismantling and maintenance, the relevant health and safety

regulations and environmental protection regulations must be observed.

Ensure that suitable means of transport are available.

The coupling may only be operated, assembled, maintained and repaired by authorised,

trained personnel.

In the interests of progress, we reserve the right to carry out technical modifications.

TSCHAN GmbH accepts no responsibility of any kind for damage arising from the use of

non-original accessories and spare parts.