11 12

ОК

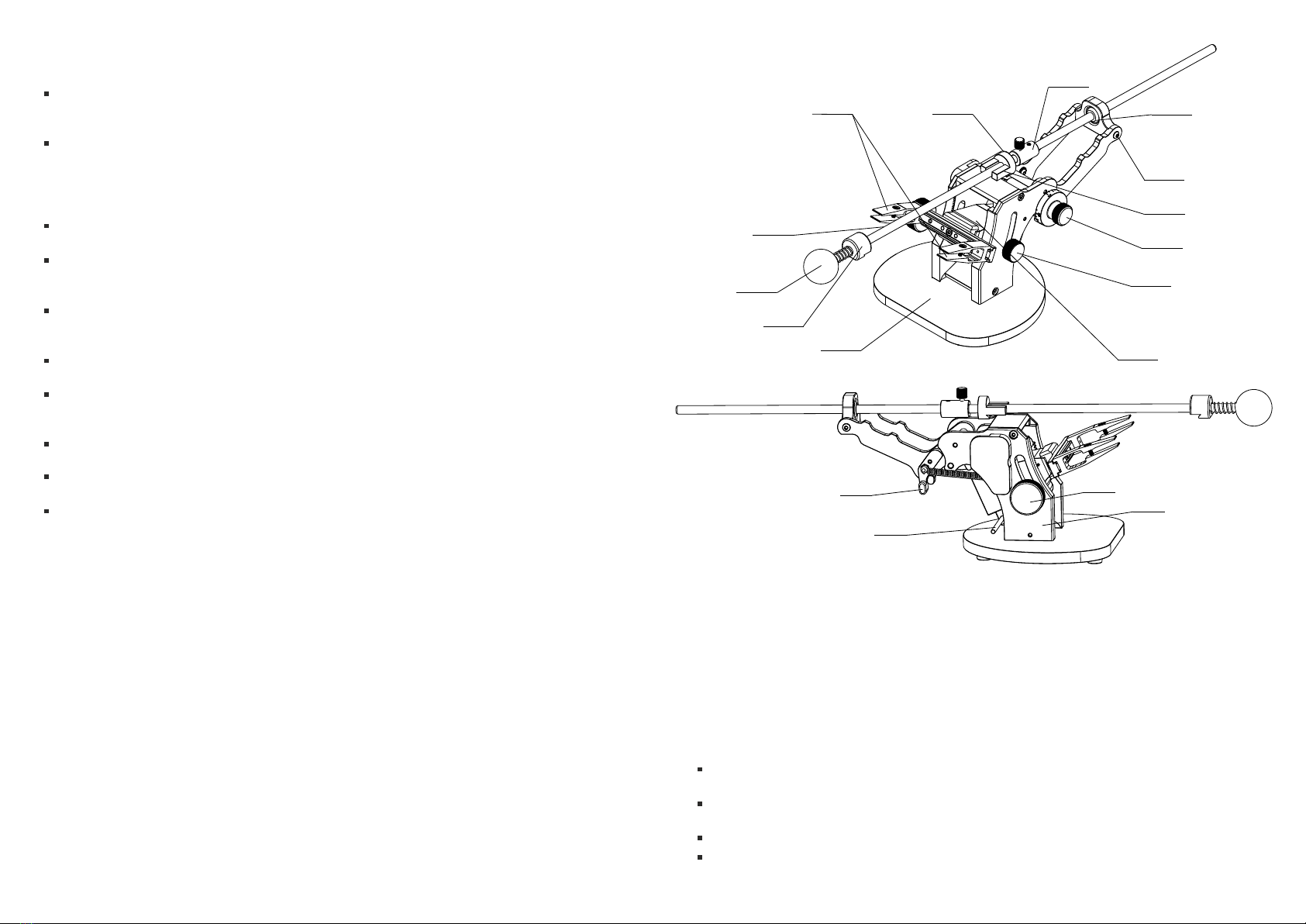

7.1 Select the clamp installation option that matches the shape and size of your knife. Place the

.7

OPERATING PROCEDURE

7.1

knife in the clamps so that the blade reaches the edge of the jaws as close as possible to 17 mm.

7.1

Tighten the clamps with a screwdriver for clamps of 2 mm from the package. The jaws of the

7.1 clamp should fit tightly without gaps to the knife, but excessive force should not be applied when

7.1

tightening, so as not to damage the jaws and screws of the clamps (Fig.14).

(Fig. 15)

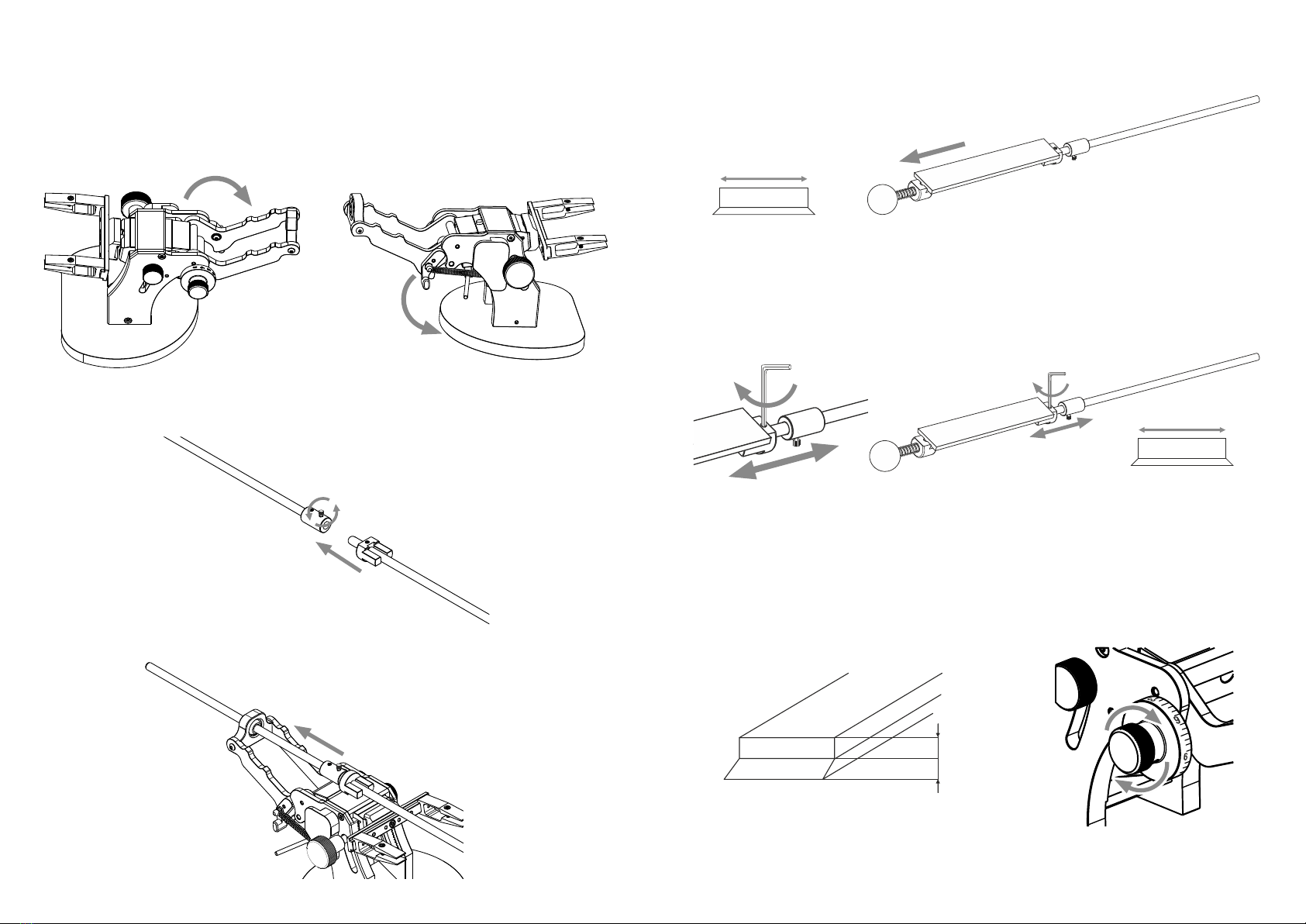

(Fig. 16)

reverse side (Fig. 16).

180 degrees (Fig. 16). Sharpen the second side of the knife also until the burr appears on the

pull the abrasive holder (4) to the side, pull the flip lever (16) and turn the frame with the knife

7.3 Sharpen the knife until there is a burr along the entire cutting edge on the reverse side,

15).

the track, adjust the sharpening angle so that in one movement the paint is sanded along the entire

on, apply a marker mark on the sharpening edge of the knife, run an abrasive along it and, focusing on

17 mm

(Fig. 14)

use a syringe (Fig. 17).

to add 2 drops of oil every 2-3 months to the oil tank, closed with a rubber stopper. For convenience,

with industrial oil. There is a certain amount of oil in the device when it is delivered. Later on you need

8.3 For proper operation of internal mechanisms it is necessary to periodically lubricate the device

8.2 Do

not

wash

the

device

with

abrasives, detergents, or

under

running

water.

8.1 Clean

the

device

from

abrasive

residues

and

metal

dust

with

a

soft

cloth

after

each

use.

(Fig. 17)

with

the

same

frequency

Lubricate

the

clamp

screws

width of the sharpening edge. Tighten the thumbscrew (12) and remove any remaining paint with a cloth

(Fig.

appropriate position (see p. 6.5). In order to get to the angle the knife was sharpened

8.

CLEANING AND MAINTENANCE

cloth.

increases

the

sharpening

angle

by

one

division

(0,13о).

After

sharpening,

wipe

the

knife

with

a

soft

abrasive.

In

the

process

of

sharpening,

you

can

form

secondary bevel

-

the

adjusting

knob

(11)

7.4

forget

to

set

the

adjusting

knob

(11)

in

the

position

corresponding

to

the

thickness

of

the

7.4

Change

the

abrasives

to

smaller

ones

and

repeat

the

operation

in

paragraph

7.3.

Do

not

7.2

Fix the abrasive of the desired gritness in the holder (see p. 6.4) and install the adjusting knob (11) in the

the

kit.

If

the

knife

blade

is

thinner

than

1.5

mm,

replace

the

screws

in

the

clamps

with

the

M2,5x6

screws

from