Tsuruga 471B Installation guide

Panel meter with totalized function

Pulse input

471B

Quick Manual

Contents

Introduction ·····················································1

About this booklet ·········································································1

Precautions ··················································································1

Installation Precautions ··································································2

Nomenclature···················································3

Operation Panel ············································································3

Rear Panel····················································································5

Installation·······················································6

Installation Conditions····································································6

Accessories···················································································6

Mounting Method ··········································································7

Dismounting·················································································8

Wiring Method ············································································9

Terminal layout and explanation ···················································· 11

Usage of Function Code···································16

Function code list ········································································ 16

Setting method of code No. ·························································· 17

Function setting method······························································· 18

Specification···················································22

Optional output ··············································24

PhotoMOS compare output ··························································· 24

Analog output············································································· 26

BCD output (Digital output) ·························································· 28

Introduction

1

Introduction

About this booklet

Thank you for purchasing our digital panel meter 471B. Before use of the product, read this

quick manual carefully and thoroughly, and keep it available for routine reference.

The following symbol marks are used in this quick manual for the safety use of the product.

!Warning

This is the warning to avoid danger. Severe injure or fatal accident

may occur to the user in case the product is mishandled.

!Caution

This is the caution to avoid danger. Minor injury to the user or

physical obstacle may occur in case the product is mishandled.

Precautions

For the safe use of this product, users must follow the following warning and caution.

!Warning

There is no power on-off switch on the model 471B. It immediately starts

to operate after turning the power ON.

Never touch the terminals when power is ON. There may be risk of

electric shock.

!Caution

The rated data for warm up is specified for more than 15 minutes.

When the front panel or the case becomes dirty, wipe it with soft cloth. If

the dirt is difficult to remove, wipe it lightly with the soft moist cloth with

mild detergent diluted with water and finish by wiping with a dry cloth.

Do not use organic solvent like benzene or paint thinner as they may

deform or discolor the surface of the case.

Introduction(contd.)

2

Installation Precautions

For the safe use of this product, users must follow the following caution.

!Caution

If the product is installed inside the cabinet, provision for the proper heat

dissipation should be done to prevent the temperature to exceed more

than 50 ℃inside the cabinet.

Do not mount the product in quite near distance. The rise of temperature

may decrease the life of the product.

Do not use the products in the following places. It may be the cause of

damage or malfunction.

∗Wet place (rain, water drops), direct sunlight

∗Place having high temperature, humidity, dust and corrosive gases

∗Place having excessive noise, waves, static electricity

∗Place having lots of vibration and shock

Store the product in the specified temperature range between -20℃to

65℃

Nomenclature

3

Nomenclature

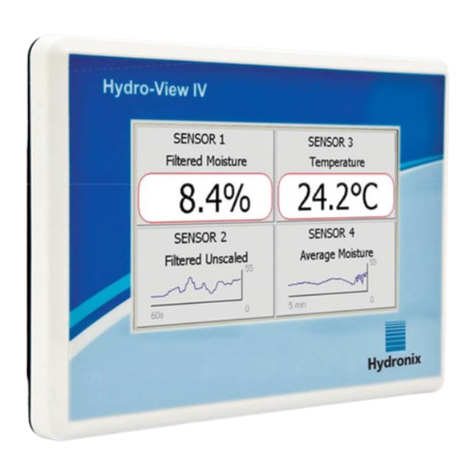

Operation Panel

No.

Name

Function

①

Display 1

Instantaneous or totalized value display

Red or green can be select for display color

②

Display 1 Over

Light on when instantaneous value display 1 exceeds 999999.

Light on when totalized value display 1 exceeds 999999.

③

TOTAL

Light on with red color during display 1 is totalized value

④

Display 2

Instantaneous or totalized value display in while color

⑤

INST

Light on with red color during display 1 is instantaneous value

⑥

Display1 Unit

Pasting position of instantaneous and totalization unit seal

⑦

Display2 Unit

Pasting position of instantaneous and totalization unit seal

⑧

Comparative

display

The comparison status of the comparison output is displayed.

⑨

SET Display

Light on during setting mode

OVER SETAL1 AL2 AL3 AL4

RESET

ENTER

MODE

INST

TOTAL

kW h

kW

①Display 1

②Display 1 Over

③TOTAL

④Display 2

⑤INST

⑧Comparative display

(AL1~AL4)

⑨SET Display

⑩Setting key

⑪Reset key

⑥Display1 Unit

⑦Display2 Unit

Nomenclature(contd.)

4

No.

Name

Function

⑩

Setting key

MODE

During measurement mode:Change to Setting

mode、Adjustment mode

During setting mode:Change to each code No.

▼

During measurement mode:Invalid

During setting mode:Digit selection of setting value

▲

During measurement mode:Invalid(Except when

switching to diagnostic mode)

During setting mode:Change of setting value

ENTER

During measurement mode:Invalid

During setting mode:Set value changed to saved

measurement mode

⑪

Reset key

RESET

During measurement mode:

Display shows “0”.(If the Reset totalizing

function is set, set the totalized to initial

value)

During setting mode:

Setting mode changes to measurement

mode without saving the set value.

LED Display

0

1

2

3

4

5

6

7

8

9

DP

マイナス

0

1

2

3

4

5

6

7

8

9

.

-

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

5

Rear Panel

No.

Name

Function

⑫

Terminal A1~A6

Sensor power supply, Input、P.O output terminal

⑬

BCD OUTPUT

CONNECTOR

Open collector NPN transistor output

Terminal RS-232C

B1~5:RS-232C communication, B6: Vacant terminal

Terminal RS-485

B1:+, B2:-, B4~5: Terminating resistance,

B3, B6:Vacant terminal

⑭

Terminal C1~C6

C1~3:Control input terminal, C4:Vacant terminal、

C5~6:Analog output terminal

⑮

Terminal D1~D6

D1~6:Compare output terminals of AL1 to AL4

⑯

Terminal E1~E6

E1,E3:Power supply terminal, E5:Ground terminal

E2,E4,E6:Vacant terminal

※The specification of ⑬, C5 to C6 of ⑭and ⑮are option.

1

2

3

4

5

6

A B C D E

12 13 14 15 16

Installation

6

Installation

Installation Conditions

Power supply

AC100 to 240V 50/60Hz、DC24V、DC110V

Voltage tolerance of

power supply

AC90 to 250V、DC24V±10%、DC100 to 170V

Power consumption

During AC100V: Approx. 11VA、During AC200V: Approx. 15VA

During DC24V: Approx. 250mA、During DC110V: Approx. 50mA

Operating ambient

temperature

0 to 50℃, 40 to 85%RH(No condensation)

Storage temperature

-20 to 65℃(No condensation)

Weight

Approx. 300g

Mounting method

Tighten from behind the panel with exclusive mounting bracket.

Insulation resistance

Measuring input terminals

–

External Case DC 500 V, More than 100 M

Ω

Power supply terminal

–

External Case DC 500 V, More than 100 M

Ω

Power supply terminal

–

Measuring input DC 500 V, More than 100 M

Ω

Measuring input terminals

–

BCD output DC 500 V, More than 50 M

Ω

Measuring input terminals

–

Analog output DC 500 V, More than 50 M

Ω

Withstanding voltage

Measuring input terminals

–

External Case AC 2000 V for one minute

Power supply terminal

–

External Case AC 2000 V for one minute

Power supply terminal

–

Measuring input AC1500 V for one minute

Measuring input terminals

–

BCD output AC 500 V for one minute

Measuring input terminals

–

Analog output AC 500 V for one minute

Protective structure

Front operation unit IP65, Case part except front side IP20,

Terminal block IP00

Accessories

Make sure that the following things beside the main body part are included.

471B main unit

Bracket 2 pcs.

Waterproof packing

Quick Manual (This booklet)

(For the model with RS-232C or RS-485, exclusive quick manual is included.)

Unit Sticker

Connector (2m with flat cable) (In case of BCD Output model)

7

Mounting Method

Mounting pitch

Panel cutout dimensions: 92 0

+0.8×45 0

+0.6mm

Panel thickness: 0.6 to 3.5mm (Degree of protection IP65)

3.6 to 10mm (Degree of protection IP20)

If the material of the panel is aluminum, it may

be deformed due to its weak strength. So, it is recommended to use the

thickness of aluminum panel sheet at least 1.5mm.

Mounting Method to Panel

1Insert the main unit fitted with the waterproof packings into the hole, from the panel

front, and insert the attached bracket to the ditch on both sides of the main unit.

Push the bracket as shown by arrow ①until the main unit is stably stays and fix the

bracket. The packings functions as stopper too, so do not remove it. Refer to the

side view of the bracket mounting.

2To fix the main unit more firm, press the back part (center part) of the bracket

indicated by arrow ②by screwdriver, which enhances the stopper strength.

!Caution

When pushing by screwdriver, apply it to the arrow ②

The pushing of other part may cause the damage of bracket.

More than 30mm

More than 130mm

More than 75mm

ECBA D

①

②

①

Push ②

Top view of bracket mounting

Side view of bracket mounting

Bracket

Panel to mount

Waterproof packings

Installation(contd.)

8

Dismounting

1By extending with fingers the lever outward by about 1mm, as shown in the bracket

lock releasing figure, the lever lock can be released.

2Keep extending the lever outward, slide the bracket backward of the main unit, and

remove it from the ditch.

!Caution

The extension of the lever for long time or the stress to it by metallic

piece like screwdriver may damage the lever.

ECBA D

Lever

About 1mm extension

releases the lock

Enlarged view of

bracket inside

Bracket lock releasing

9

Wiring Method

Remove the terminal base cover of the rear side terminal and conduct the wiring. Make sure

that the terminal base cover is attached after wiring. If both options of comparison output and

analog output are used, first complete the wiring of the comparison output and then start the

wiring of analog output.

Notes for wiring

!Warning

To avoid an electrical shock, turn the power off when wiring.

Do not conduct wiring at moistened place or by wetted hands. There may

be risk of electric shock.

Do not touch the terminals when turning the power on. There may be risk

of electric shock.

!Caution

Power supply and load should be within the suitable range as prescribed

in specification. Negligence may cause the damage of products.

Power supply should reach the rated power within a second.

After the power is OFF, pause more than 10 seconds before the power ON

again.

Do not use the product with wrong wiring. It may be the cause of product

damage.

◆Others caution during wiring

Always use input line and power line independently. If input line and power line are wired in

parallel, it may cause an in stability of the display.

When the auxiliary relay is operated by the relay output to run the electro- magnetic switch

or big size relay, take the noise preventive measures.

In case that the noise is frequently occurred, it will be effective to store the product in the

shielded housing or to insert the power source line filter or insulated transformer.

Installation(contd.)

10

About the crimp terminal

Direction of crimp terminal

Recommended crimp terminal:V1.25-FS3

(Made of Fuji Terminal Industry Co.,Ltd)

Ext. diameter of covered cable:Max.φ3.3

Terminal screw:M3

Crimp terminal: Refer figure at the right

!Caution

For the C column and D column terminal blocks, apply one crimp terminal

per one terminal block.

Do not do the parallel connection, using two crimp terminals (overlaying)

at the same terminal block. It stresses the internal PCB and so on and

may cause the failure or trouble. As for the A column and E column

terminal blocks, up to two crimp terminals per terminal block are

acceptable.

1

2

3

4

5

6

AB C D E

6

18.25

9.5

5.85

5.8

Unit: mm

11

Terminal layout and explanation

Rear side terminal

1

2

3

4

5

6

▲

AB C D E

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

4

2

8

1

4

2

8

1

4

2

8

1

4

2

8

1

4

2

8

1

4

2

8

1

10

10

10

SEL

0

2

4

OUTPUT ENABLE

E1

E2

E3

E4

E5

E6

N C

N C

+

-

RESET

P/L

N C

C1

C2

C3

C4

C5

C6

A.OUT+

A.OUT-

BCD_LATCH

OVER

SYNC

DC24V、DC110V

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

GND

DP1

DP2

DP3

DP4

DP5

D.COM

DATA COM

DATA COM

A B C D E

D1

D2

D3

D4

D5

D6

AL3

AL4

AL1

AL2

ALCOM1

ALCOM3

BCD output

Analog output

Power supply

Comparison output

Control input

At optional comparison outputAt optional BCD output

At optional analog output

NC:Vacant terminal

Sensor power supply

P.O output Measuring input

RS-485RS-232C

Term

NC

-

+

B6

B5

B4

B3

B2

B1

NCNC

SG

CS

RD

RS

SD

Term

At optional RS-232C output At optional RS-485 output

NC:Vacant terminal

NC:Vacant terminal

Do not use as relay

terminal etc.

NC:Vacant terminal

(B column is a terminal block) (B column is a terminal block)

10

10

10

1

3

5

A1

A2

A3

A4

A5

A6

P.O

COM

P.O COM

SIG1

SIG2

SENSOR

AC100 to 240V

!Caution

Replacement of the units by customers

themselves may cause the damage of the

equipment and Tsuruga Electric Corporation

may not be able to respond in this case.

Installation(contd.)

12

Power supply connection

Connect the power supply at Terminal No.E1-E3.

Power supply voltage is written on the Terminal

nameplate at the time of product shipment.

○AC power supply

AC100 to 240V 50/60Hz

permissible range AC 90 to 250V

○DC power supply

For DC 24V, Permissible range DC24V±10%

For DC110V, Permissible range DC100 to 170V

!Caution

Do not use the voltage out of permissible range. It may be the cause of

equipment damage.

Power on / off, power supply should reach up to rated voltage or shut

down within 1 second.

After the power is OFF, pause more than 10 seconds before the power ON

again.

GND (ground) terminal

In case of fear that the noise is frequently generated on the power source

line, it is effective to earth the ground terminal directly to the ground. If

the instrument is not affected by environmental noise, the grounding can

be omitted. In this case, take care for the ground terminal not to touch

other input terminals, as it is charged with neutral electric potential of

power source voltage.

1

2

3

4

5

6

AB C D E

+

-

1

2

3

4

5

6

AB C D E

GND for

power supply

GND for

power supply

AC power supply

DC power supply

13

Connection of input signal

Power supply for the sensor is connected from terminal No.A1-A2. If the power supply of sensor

is applied from external sources, the connection of terminal No. A1 will not be required. When

sensor power source is not used, A1 will be vacant and do not used it for other purpose.

○Connection example of

non voltage contact or

NPN open collector

○Connection example of

voltage pulse output

Caution

If sensor power supply terminal A1 is accidentally short-circuited with

COM terminal A2, it may cause malfunction of the sensor. At that time,

guarantee of the counter value can’t be given because of error in internal

memory writing.

Connection of P.O output

Terminal No. A5 and A6 give the output

the total sync pulse of NPN open collector.

Please connect the load with the contact

capacity within the specification range.

(Refer page 23『General specification』)

1

2

3

4

5

6

A B C D E

A1

A2

A3

A4

A5

A6

P.O

P.O COM

1

2

3

4

5

6

A B C D E

A1

A2

A3

A4

A5

A6

P.O

COM

P.O COM

SIG1

SIG2

SENSOR

A1

A2

A3

A4

A5

A6

P.O

COM

P.O COM

SIG1

SIG2

0V

OUT

0~2V

4.5~30V

SENSOR

Installation(contd.)

14

Connection of Control signal

Please input the control signal. The configuration is as

follows.

Connection of Analog output

The analog output is can be obtained

from the Terminal No.C5-C6.

Allowable load resistance should be

connected within the specified range.

(Refer page 22『Specification』)

Connection of comparison outputs(AL1, AL2, AL3, AL4)

Comparison output scan be obtained in terminal No.

○

D2 -○

D1 、○

D2 -○

D3 、○

D5 -○

D4 and ○

D5 -○

D6

Instantaneously

Instantaneous value <lower limit set value

:

AL1

○

D2 -○

D1

Instantaneous value> upper limit set value

:AL2 ○

D2 -○

D3

Totalization

6 digits under accumulation totalized value> upper limit set value

:

AL3 ○

D5 -○

D4

Lower 6 digits totalized value> upper upper limit set value

:AL4 ○

D5 -○

D6

Contact capacity:AC/DC250V 200mA

1

2

3

4

5

6

A B C D E

RESET

P / L

N C

C1

C2

C3

C4

C5

C6

D.COM

+5V

D.COM

Less than 10mA

Swich

RESET or P/L

Photocouplers

parts

471B internal

1

2

3

4

5

6

A B C D E

C1

C2

C3

C4

C5

C6

A.OUT+

A.OUT-

1

2

3

4

5

6

A B C D E

15

Connection of BCD output

Data output 6 digits Open collector (NPN) configuration is

as shown in the connector arrangement table of BCD

output shown in page 11.

Control input pin 16 BCD_LATCH, 17 SEL, 15 OUTPUT

ENABLE are as shown in the connector arrangement table

of BCD output, shown in page 11.

Accessory: Cable (5808-05) 2m

Connector (8822E-036-171-F, Kel Corp.)

Electrical schematic diagram

1

2

3

4

5

6

A B C D E

▲Mark

0V

24V

(0V)

OUT

OUT

OUT

0V

DC24V

DC24V

IN

IN

IN

IN

IN

ENABLE

13 OVER

16 BCD_LATCH

17 SEL

15 OUTPUT

19 1×10

20 2×10

21 4×10

22 8×100

0

0

0

18,36 DATA COM

Transistor output unit

Transistor output unit

Transistor output unit

Darington

Controller side

DC power supply

471B

▲Mark

Lower cable No.19~36

Upper cable No.1~18

Upper cable

No.1(Brown)

Upper cable

No.18(Gray)

Lower cable

Lower cable

No.19(White)

No.36(Blue)

Usage of Function Code

16

Usage of Functio n Code

Function code list

●Display functions

Code No.

Function

Display 1

Setting range

Default value

00

Key protection

KEY.

OFF, ON

OFF

01

Totalized pulse coefficient

TPLS

9999E-0 to 0001E-9

0001E-0

02

Converted value of

instant pulse

IPLS

1000E-0 to 0001E-6

0001E-0

03

Unit of instant time

UNIT

2(hour), 1(minute), 0(second)

0(second)

04

Filter of input frequency

FLT

2(HF), 1(MF), 0(LF)

2(HF)

05

Cut off time

CUT

0.1 to 199.9

199.9

06

Instantaneous display cycle

DISP

0 (100ms), 1(1s), 2(5s)

0(100ms)

07

Totalized decimal point

T DP

0, 0.0, 0.00, 0.000, 0.0000, 0.00000

0

08

Instant decimal point

I DP

0, 0.0, 0.00, 0.000, 0.0000, 0.00000

0

09

Initial totalizing value

I NT.

0 to 999999

0

10

Display 1 switching

I.T.

0(Instantaneous), 1(Totalization)

0(Inst.)

11

Display color

COLO.

R(Red), G(Green)

G(Green)

12

Reset totalizing function

I.RST

OFF, ON

OFF

13

Synchronized totalization

pulse division

P.O R

0(1/1), 1(1/10), 2(1/100)

0(1/1)

14

Synchronized totalization

pulse width

P.O W

0(100ms), 1(50ms), 2(10ms)

0(100ms)

15

Display switch-off function

TURN.

0(Invalid)/1(All display)/2(Display2),

0 to 99 minute

2(Display2),01

16

Invalid of reset key

RST

0 (Invalid), 1(Valid)

1(Valid)

17

Pause / Latch

P.L.

0 (Pause), 1 (Latch)

0(Pause)

18

Over display of display 1

OVER

OFF, ON

OFF

●Comparison outputs function

Code No.

Function

Display 1

Setting range

Default value

41

AL1 Comparative value

AL. 1

0 to 999999

0

42

AL2 Comparative value

AL. 2

0 to 999999

999999

43

AL3 Comparative value

AL. 3

0 to 999999

999999

44

AL4 Comparative value

AL. 4

0 to 999999

999999

45

Batch switching

B.SEL.

0(ALARM),1(BATCH)

0(ALARM)

46

AL3 Output width

WID.3

0.1s,0.2s,0.5s,1.0s,-(Continuous)

0.1s

47

AL4 Output width

WID.4

0.1s,0.2s,0.5s,1.0s,-(Continuous)

0.1s

48

AL4 Auto reset

A.RST

OFF,ON

OFF

●Analog output function

Code No.

Function

Display 1

Setting range

Default value

75

Analog output switching

A.SEL.

0(Instantaneous), 1(Totalization)

0(Inst.)

79

Full scale (Totalization)

A.FUL.

200 to 999999(Totalization)

200

17

Measurement

Operation

Mode Setting

(Set Code No.)

●RS-232C, RS-485 output function

Code No.

Function

Display 1

Setting range

Default value

80

Baud rate

BAUD.

4800,9600,19200bps

9600bps

81

Parity

PARIT

non(none), odd(odd no.), even(even no.)

non(none)

82

BCC switching

BCC

ON, OFF

OFF

83

Device number

RS.NO.

0 to 99

00

Setting method of code No.

This is the basic input method of function code.

Following the setting of the Code No., perform the function setting on the following pages.

Identification of the key color during

set up is as follows.

Black key: Valid key

White key: Invalid key

[

Common matters during the Setting mode

]

During setting mode, if the key is not

operated for about 5 minutes, the

operation returns into measurement

mode automatically. At this time, the

setting contents are not saved.

Again, if the reset key is pressed more

than 1 second, setting value which

was under changing process before

becomes invalid and returns to

measurement operation undergoing

mode.

MODE

▲

SET

SET

SET

MODE

Press 1 sec.

Confirm

Select the Code №

,▲

To function setting

Usage of Function Code(contd.)

18

Mode

Setting

(Set number)

Mode

Setting

(Item setting)

Function setting method

The following is an example of the input function setting. Please refer this page when changing

to the setting other than factory setting value. Please continue the operation of the function

setting after referring Code No. setting method only.

Code No.00『Key protection』

Code No.01『Totalized pulse coefficient』

When the key protection mode is made ON,

function other than the Key protection can be

forbidden to use.

Setting range:ON[Key protection is on.]

OFF[Key protection is off]

Totalized pulse coefficient can be set.

The totalized pulse coefficient can be set by

multiplying 4 digits of the mantissa and one

digit of the exponent per pulse

Setting range:1×10-9 to 9999×100

The exponent part is not indicated by ‘minus’.

Change from “OFF”to “ON”

Change from 0001E0 to 1666E3

▲

SET

MODE

MODE

SET

SET

▲

MODE

SET

MODE

MODE

,▲

To measurment

operation

To code No.setting

ENTER

1sec.

ENTER

1sec.

ENTER

1sec.

ENTER

1sec.

Displays of

current setting

Memory

Change of setting

Code №01

MODE

MODE

MODE

▲

▲

SET

SET

SET

SET

▲

MODE

MODE

Code №00

To measurment

operation

Memory

To code No.setting

Select ON or OFF

Displays of

current setting

ENTER

1sec.

ENTER

1sec.

ENTER

ENTER

1sec.

1sec.

Table of contents

Other Tsuruga Measuring Instrument manuals