tsw TEPACK TPS 400 User manual

TPS 400

REFERENCE DOCUMENTATION

VOLUME I

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 3

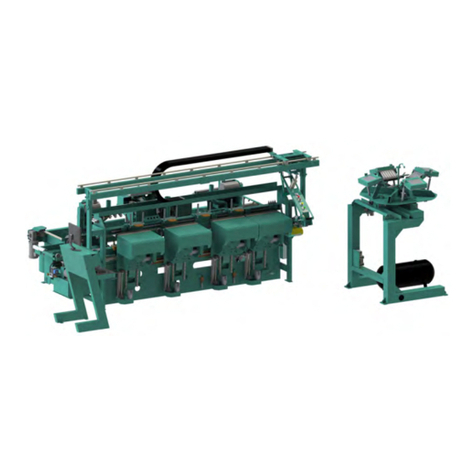

TPS 400

MULTILANE SACHET MACHINE

REFERENCE DOCUMENTATION

CUSTOMER: ORIENT BIO TECH

SERIAL Nº : 0318003

TEPACK reserves the right to change or modify the contents of this publica on

without prior no ce.

Manual drawn up in conformity with EEC direc ve 89/392/CE. and successive

amendments.

Created by the TEPACK. Documenta on Department (Edi ng/Graphic) in collabo-

ra on with the Technical Design Department.

Date of fi nal print: 03-2020

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 4

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 4

TABLE OF CONTENTS

1.- INTRODUCTION ...........................................................................................................5

1.1.- Presenta on of documenta on. ..........................................................................5

1.2.- General Informa on. ...........................................................................................6

1.3.- Limita ons of Use of the Plant. ..........................................................................6

1.4.- Documenta on (Purpose, Storage, Updates). .....................................................6

1.5.- Main Defi ni ons. .................................................................................................7

1.6.- References to Standards. .....................................................................................7

1.7.-Hazards / Warnings / Safety. .................................................................................7

1.8.- Produc on Control (Op onal). ............................................................................8

1.9.-Specifi ca ons of the Founda ons and Prepara on of the Working Area. ............8

1.10.- Prepara on of the Plant. ...................................................................................8

1.11.- Iden fying the Degree of Prepara on of the Plant............................................9

2.- SAFETY AND ACCIDENT PREVENTION. .........................................................................9

2.1.- General Informa on. ...........................................................................................9

2.2.- Main Rules. ..........................................................................................................9

2.2.1.- Warnings. .....................................................................................................9

2.2.2.- Hazards. ......................................................................................................10

2.3.- Sound Level. .......................................................................................................11

2.4.- User Categories and Limita ons of Interven on. ..............................................11

2.5.- Opera ng Condi ons. ........................................................................................11

2.6.- Safety Clothing. ..................................................................................................11

2.7.- Accident Preven on Signs on the Plant. ............................................................12

.2.7.1.- Hazard Signs (Existence of Risk) ................................................................13

2.7.2.- Obligatory / Instruc ve Signs. ...................................................................13

2.7.3.- Prohibi on Signs. .......................................................................................13

2.8.- Safety Devices for the Plant. ..............................................................................14

3.- IDENTIFICATION AND TRANSPORT OF THE MACHINE ...............................................15

3.1.- Machine’s iden fi ca on. ....................................................................................15

3.2.- Installa on. .......................................................................................................16

3.2.1.- Li ing and Shipment. .................................................................................16

3.2.2.- Placement. .................................................................................................17

3.2.3.- Cleaning. ....................................................................................................17

3.2.4.- Electrical and Pneuma c Connec on. .......................................................17

4.- SUPPORTING FILES FOR THE USER. ...........................................................................18

- DEFECT OR FAULT REPPORT SHEET ..........................................................................18

- REQUEST FOR TECHNICAL ASSISTANCE SHEET ........................................................19

- REQUEST FOR SPARE PARTS SHEET ..........................................................................20

5.- DECLARATIONS, SHEETS AND DIAGRAMS. ................................................................21

5.1.- General Informa ons. ........................................................................................21

5.2.- Main Technical Data of the Plant. ......................................................................21

5.3.- Machine Lay-Out. ...............................................................................................26

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 5

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 5

1.- INTRODUCTION

1.1.- Presenta on of documenta on.

All the documenta on deals with topics in accordance with the user at which it is aimed.

Whatever the case, the contents of these topics are always combined with notes on safety

rela ng to the various opera ng stages of each procedure.

The documenta on comprises the combina on of these concepts with the various opera-

ng no ons provided, and it has been drawn up in accordance with the guidelines set out in

the specifi c EC 89/392 standards and the subsequent amendments 98/37 EC.

The documenta on includes considera ons rela ng to preven on, taking the upkeep and

quality of the plant into considera on.

We recommend that you carefully read the sec on on “Safety and Accident Preven on” in

the chapter “Reference Documenta on”, which deals with the following concerns:

- Safety in the workplace (Rules, Regula ons, Specifi ca ons, Noise Level).

- Opera ng categories of the end-users (Limita ons of interven on).

- Warning signs and safety devices.

The diff erent parts of the documenta on are divided into sec ons. Each sec on can be

divided into topics, and each topic can be divided into subtopics

A series of symbols may be used in the various descrip ons and alongside certain paragra-

phs. These are used to call a en on to concepts, no ons and opera ons that are of special

importance to users, such as:

HAZARD

This symbol is used to highlight the descrip ons of opera ons which entail imme-

diate risks or which can be hazardous. Therefore, special a en on must be paid to the

sequence of instruc ons provided and/or warnings given

GENERIC WARNING

This symbol is used to highlight warnings rela ng to opera ons of special impor-

tance or descrip ons of par cular interest.

CLEANING REQUIRED

This symbol is used to highlight cleaning procedures that are essen al in order to

maintain the produc on quality of the plant. Such procedures should be performed

with the aid of exhausters or damp cloths using non-aggressive detergent solu ons.

It is strongly advised that compressed air fl ows or chemical solvents, gasoline, etc.,

should NOT be used.

LUBRICATION REQUIRED

This symbol is used to highlight lubrica on procedures that are essen al in order

to maintain the produc on quality of the plant. Such procedures should be perfor-

med with the aid of brushes, grease guns, lubricators, etc.

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 6

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 6

RISK OF INVALIDATING THE EC CERTIFICATE OF CONFORMITY

This symbol is used to highlight notes, no ons or procedures which, if not fulfi lled

or followed, render the “EC Declara on of Conformity” issued by TEPACK null and

void. Therefore, the failure to comply with and abide by these descrip ons shall free

TEPACK of all liability, with the consequent obliga on on the part of the customer to

obtain new cer fi ca on for the plant.

IDENTIFICATION OF OPERATIN CATEGORY 1ST LEVEL

This symbol is used to highlight the descrip on of procedures that may be carried

out under “Normal Opera ng Condi ons”.

IDENTIFICACION DE CALIFICACION OPERATIVA 2º NIVEL

This symbol is used to highlight the descrip on of procedures that may be carried

out under “Special Opera ng Condi ons”.

1.2.- General Informa on.

TEPACK undertakes to provide, together with the machine supplied, “original” documen-

ta on which contains suffi cient informa on for the opera on and maintenance of the machi-

nery, while you are reminded that:

- The documenta on forms an integral part of the machine and helps to reduce the risk of

improper use.

- The documenta on is necessary for the correct procedures to be learnt. In the event of

disputes, the prevailing documenta on is always that which is wri en in the language of the

constructor of the plant.

1.3.- Limita ons of Use of the Plant.

The plant may only be used in accordance with the indica ons of the “EC Declara-

on of Conformity”, which also specifi es the type of produc on for which the machi-

ne was designed.

1.4.- Documenta on (Purpose, Storage, Updates).

The documenta on contains the necessary informa on for instruc ng and warning users

about all the procedures rela ng to their role in the produc on processes, and therefore:

- The ‘ORIGINAL” documenta on must be preserved by the person responsible for safety

and/or quality at the company where the plant is to be used. This documenta on must be

kept for the en re dura on (life) of the plant. It must remain in good condi on, be protected

from humidity and heat, and the original dra must not be altered in any way.

- All updates must be integrated into the “ORIGINAL” documenta on; the parts subs tuted

must be deleted and all exis ng copies must be updated.

- The ‘ORIGINAL” documenta on must be passed on to any subsequent owner of the plant;

if possible TEPACK should be informed of the new recipient of the plant.

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 7

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 7

1.5.- Main Defi ni ons.

The following table illustrates and describes the main elements involved in the produc on

process.

PRODUCTION PROCESS

Cycle of opera ons/ac ons which link a “plant for making one or more products” and a “set

of individuals”.

INSTALLATION

Machine, accessory, feed unit or combina ons of several units for producing one or more

products.

CUSTOMER

An individual or organiza on in possession of a plant (machine or others) or who has full

responsibility for it.

USER

Person in charge of the installa on, opera-

on, maintenance or repairs of the plant

(machine or other), who is not necessarily

the owner or purchaser of this plant.

OPERATOR

A user without specifi c technical experience

with rela on to the plant inques on (machi-

ne or other).

TECHNICIAN

A user with specifi c technical experience re-

la ng to the func on that he or she has been

assigned with respect to the plant (machine

or other).

1.6.- References to Standards.

The following TABLE lists the standards which have been considered for the prepara on

and standardiza on of a plant.

MACHINE DIRECTIVE 89/392/EC and subse-

quent amendments 98/37 EC of 22 June 1998

All the standards in this direc ve rela ng to

the type of produc on undertaken by TEPACK

been adopted and applied. Notwithstanding

this, said standards will con nue to be deve-

loped un l they have been fully adapted.

ISO 7000 and PREN 50099/1 and 2 The main symbols for signs (visual) have been

taken from these standards.

BSi 4884 Part 1, Part 2, Part 3, dated 1993

The concepts for the dra ing and elabora-

on of the documenta on (on paper) have

been taken from these direc ves.

1.7.-Hazards / Warnings / Safety.

Observe all the indica ons in the documenta on in order to avoid invalida on of the “EC

Declara on of Conformity”. Should the customer fail to observe these indica ons, TEPACK

shall be exonerated of all responsibility, and the customer shall be obliged to prepare new

cer fi ca on for the plant.

Pay par cular a en on to the sec on “Safety and Accident Preven on” which specifi es the

principal rules with respect to opera ng the machines.

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 8

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 8

produc on must be subjected are dictated by the customer to TEPACK, which

undertakes to include these controls in the produc on processes, integra ng all the

necessary safety devices and/or making the appropriate adjustments.

TEPACK shall complete the documenta on as necessary, inser ng the notes on procedures

and opera ons, for said controls to be carried out in condi ons of safety.

Should the customer require any modifi ca on in order to include new controls

or to modify exis ng controls, such modifi ca ons should be directly requested of

TEPACK, which will be responsible for upda ng the documenta on supplied with the

plant.

1.9.-Specifi ca ons of the Founda ons and Prepara on of the Working Area.

The customer must check that the founda ons of the working area in which the

plant is to be installed are of standard size and that they are able to support the

weight of the plant.

Moreover, during installa on, it is extremely important that the minimum dimensions

for the areas indicated in the diagrams supplied by TEPACK are respected.

Ensure that all the main switches are prepared in the area where the plant is to be

installed, namely:

• Electric current and corresponding switch (of suitable size).

• Compressed air and corresponding switch (of suitable size).

• The same switches must also be present for any other power lead that is necessary.

1.10.- Prepara on of the Plant.

There are three categories of plant prepara on:

- 1ST DEGREE PREPARATION.

This refers to a plant prepared on the premises of TEPACK which has been shipped

ready-assembled and therefore it only needs to be started up.

- 2ST DEGREE PREPARATION.

This refers to a plant prepared on the premises of TEPACK which has been shipped

without being assembled. It can be assembled by suitably trained technicians of the

customer.

- 3ST DEGREE PREPARATION.

This refers to a plant prepared on the premises of TEPACK which has been shipped

without being assembled. It can only be assembled by the technicians of TEPACK

1.8.- Produc on Control (Op onal).

The rules necessary for the execu on of the various types of quality control to which

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 9

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 9

1.11.- Iden fying the Degree of Prepara on of the Plant.

As a general rule, this condi on is established when the customer places the order

with TEPACK.

2.- SAFETY AND ACCIDENT PREVENTION.

2.1.- General Informa on.

Plant users must be familiar with the contents of all the documenta on supplied in all

aspects rela ng to their specifi c func ons.

It is necessary that they observe the “Accident Preven on” regula ons, without forge ng

that the safety measures established for the plant only provide a minimal guarantee that

accidents will not occur.

The following are the main rules to be observed when opera ng the plant.

Use the plant solely and exclusively for the produc on processes for which it has been

designed.

2.2.- Main Rules.

2.2.1.- Warnings.

Failure to observe the Accident Preven on regula ons may give rise to problems or

accidents in the workplace, for which TEPACK declines all responsibility.

- Use the plant solely and exclusively for the produc on processes for which it has been

designed.

- All plant users must be suitably authorized (through job training) to carry out their par cular

tasks and they must be appropriately qualifi ed for the type of interven on concerned.

- Never use the plant in an area with insuffi cient ven la on, especially when the plant is fi ed

with thermoforming or hot-melt gluing devices, which some mes give off dangerous fumes.

- All plant users must be suitably dressed. They must never wear es, chains/necklaces or

belts, since these could get caught up in moving parts or in other parts of the plant.

- Before connec ng machinery to the mains power supply, ensure that the data on the ra ng

plate coincide with those of the premises, observing the standards of the country in which

the machinery is installed.

- Never modify machine parts such as: connec ons, drillings or fi nishes in order to connect

other devices.

- Any modifi ca on made to the machinery will aff ect its opera on and safety. Therefore,

modifi ca ons must be made by TEPACK technicians only, or by suitably trained technicians

(Service technicians).

- The customer is fully responsible for any modifi ca on made to the plant which is not

communicated to TEPACK or does not comply with EEC Direc ves, thereby exonera ng

TEPACK of any responsibility.

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 10

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 10

- Only li , move and posi on machinery in accordance with the instruc ons provided in the

documenta on (refer to the diagrams a ached), and always observe the terms established at

the moment of ordering.

- Ensure that the oil level of the sprayers and the drive housings are correct.

- Constantly check that all warning signs (cards, symbols, etc.) on the machinery are legible

and are not obscured by extraneous materials.

- Waste materials (oil residues, broken parts replaced, etc.) must be disposed of in

accordance with the regula ons in force, so as to avoid pollu ng the environment.

- It is strictly forbidden to reproduce or circulate the so ware supplied with the machines

to third par es.

- It is strictly forbidden to copy or reproduce this publica on, which forms an integral part

of the plant supplied.

2.2.2.- Hazards.

- Warning: the machines do NOT have fl ame-proof electrical systems.

- Never work on the machine while it is in opera on, and never approach moving parts.

- It is forbidden to enter, jump or climb on to parts of the machine. Use must be made of

suitable means (ladders, gangways) or the corresponding passages.

- Never perform work on a plant with which you are unfamiliar. Every possible precau on

should be taken when eff ec ng any opera on.

- If any opera onal problem is observed, disconnect the plant from the mains power

supplies (electrical, pneuma c, etc.) and hang one or more warning signs on it.

- Whenever work is performed on the plant (for purposes of maintenance, cleaning, etc.),

switch off the mains power supply and press at least one of the emergency push-bu ons.

- In the case of any opera on which must be carried out with the plant powered up or

in mo on, the user must enlist the aid of a second person, who in case of emergency can

operate the main machine switch or the emergency push-bu ons.

- Warning: before star ng up the unit, ensure that it does not contain any extraneous

materials (keys, screwdrivers, etc.).

- Always carry out a general opera onal test at the end of any technical interven on.

- Never fi t spare parts which do not comply with the manufacturer’s specifi ca ons.

- Clean casings, panels and controls using so , dry cloths (or cloths slightly dampened with

a mild detergent solu on). Important: never use solvents, alcohol and/or gasoline.

- Never adjust or remove parts of the plant from their loca on if you are unfamiliar with

their opera on.

- During normal opera on (produc on), never remove or inhibit the guards or safety

devices installed on the machines or accessory units (unless expressly instructed to do so by

the manual).

- During normal opera on of the plant, constantly check the working phases from the

appropriate control zones.

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 11

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 11

2.3.- Sound Level.

The plants of TEPACK are designed to produce a sound level which is below the legal

minimum.

To maintain these values, observe the notes to be found in the documenta on, to be specifi c:

- Periodically adjust any possible play (in chain or belt tension, etc.).

- Check the condi on of the various mechanisms, replacing any worn parts.

- Do not remove internal and/or external plant guards or covers.

- Carry out six-monthly maintenance opera ons (greasing and lubrica on).

2.4.- User Categories and Limita ons of Interven on.

All opera ons that may be carried out on the plant are classed according to whether they

must be performed by operators or technicians, according to the opera ng condi ons:

LEVEL 1 CATEGORY “OPERATOR”

This level corresponds to users who are able to work under “Normal Opera ng

Condi ons”, that is to say, persons without special technical experience.

LEVEL 2 CATEGORY “TECHNICIAN”

This level corresponds to users who are able to work under “Special Opera ng

Condi ons”, that is to say, persons with technical experience that is appropriate to

the opera ons to be eff ected.

2.5.- Opera ng Condi ons.

Iden fi ca on and summary of the opera ons which may be carried out using the plant:

NORMAL OPERATING CONDITIONS

Cleaning / Normal produc on / Feeding of products and/or produc on materials.

Control of produc on phases / Diagnos cs for re-establishing normal produc on.

SPECIAL OPERATING CONDITIONS

Packaging / Unwrapping / Li ing / Transport / Posi oning. Ini al start-up / Change

to normal produc on. Change of format / Maintenance / Correct opera on checks.

2.6.- Safety Clothing.

It is advisable for users of the plant to be equipped with the following items, as a minimum:

- PROTECTIVE GLOVES.

- PROTECTIVE MASK.

- SAFETY GLASSES.

- PROTECTIVE FOOTWEAR.

These must be used whenever necessary, or where required by the documenta on.

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 12

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 12

2.7.- Accident Preven on Signs on the Plant.

This sec on introduces the symbols present on the plant produced by TEPACK whose purpose

is to provide indica ons for the user and/or to a ract his/her a en on.

There are basically three types of symbols:

- Hazard signs (existence of risk).

- Obligatory / instruc ve signs.

- Prohibi on signs.

The list and precise descrip on of these symbols appears on the following pages, in the

paragraphs of the same name.

Par cular care must be taken not to remove, damage or cover these types of signs.

It is advisable for the plant supervisor to make a copy of the following pages devoted

to the paragraphs “Hazard Signs (Existence of Risk)”, “Obligatory / instruc ve Signs”,

“Prohibi on Signs”, so that this may be le near the plant in a place that is easily

accessible to all users.

It is also recommended that the plant supervisor should explain these signs to all

the users at least once, especially to those users who are working with the plant for

the fi rst me.

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 13

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 13

.2.7.1.- Hazard Signs (Existence of Risk)

PICTOGRAM MEANING PICTOGRAM MEANING

HIGH TEMPERATURE

DANGER OF BURNS

HIGH VOLTAGE DAN-

GER OF ELECTRIC

DISCHARGE

LOW TEMPERATURE

DANGER OF ABRA-

SIONS

MOVING PARTS

DANGER OF BEING

CRUSHED

DANGER OF BEING

CUT

DANGER TRANSPA-

RENT SURFACE

ZONE CROSSED BY

LASER RAYS DANGER

OF BURNS

KEEP HANDS AND

OBJECTS CLEAR

2.7.2.- Obligatory / Instruc ve Signs.

PICTOGRAM MEANING PICTOGRAM MEANING

USE OF PROTECTIVE

GLOVES OBLIGATORY AIR-JET

MANUAL CLEANING

OBLIGATORY SUCTION DEVICE

LUBRICATION OBLI-

GATORY COOLING CIRCUIT

OBLIGATORY DIREC-

TION OF MOVEMENT

2.7.3.- Prohibi on Signs.

PICTOGRAM MEANING PICTOGRAM MEANING

MANUAL OPERA-

TIONS FORBIDDEN

KEEP OFF THE MA-

CHINE

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 14

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 14

When these devices are triggered, the plant is stopped out of phase with

“emergency” status through the mains power supplies (electricity and compressed

air) being cut off .

- Microswitches, sensors, photocells (electronic safety devices).

When these devices are triggered, the plant is either stopped out of phase with

“emergency” status (cut-off of the mains power supplies), or it is stopped in phase

(with indica ons provided for the operator or working cycles control)

We recommend that the plant supervisor should explain the meaning of the signs

to all users at least once, especially to those users who are working on the plant for

the fi rst me.

Par cular care must be taken to avoid removing, disabling or modifying the

adjustment of these devices.

The presence of these devices is obligatory, as established by TEPACK in the project

demands. It is strictly forbidden to remove them or disable their control and safety

func ons.

2.8.- Safety Devices for the Plant.

The plant produced by TEPACK may be fi ed with safety devices such as:

- Protec ve guards (mechanical safety devices).

- Clutches, limiters, thermal cut-outs (mechanical safety devices)

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 15

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 15

3.- IDENTIFICATION AND TRANSPORT OF THE MACHINE

3.1.- Machine’s iden fi ca on.

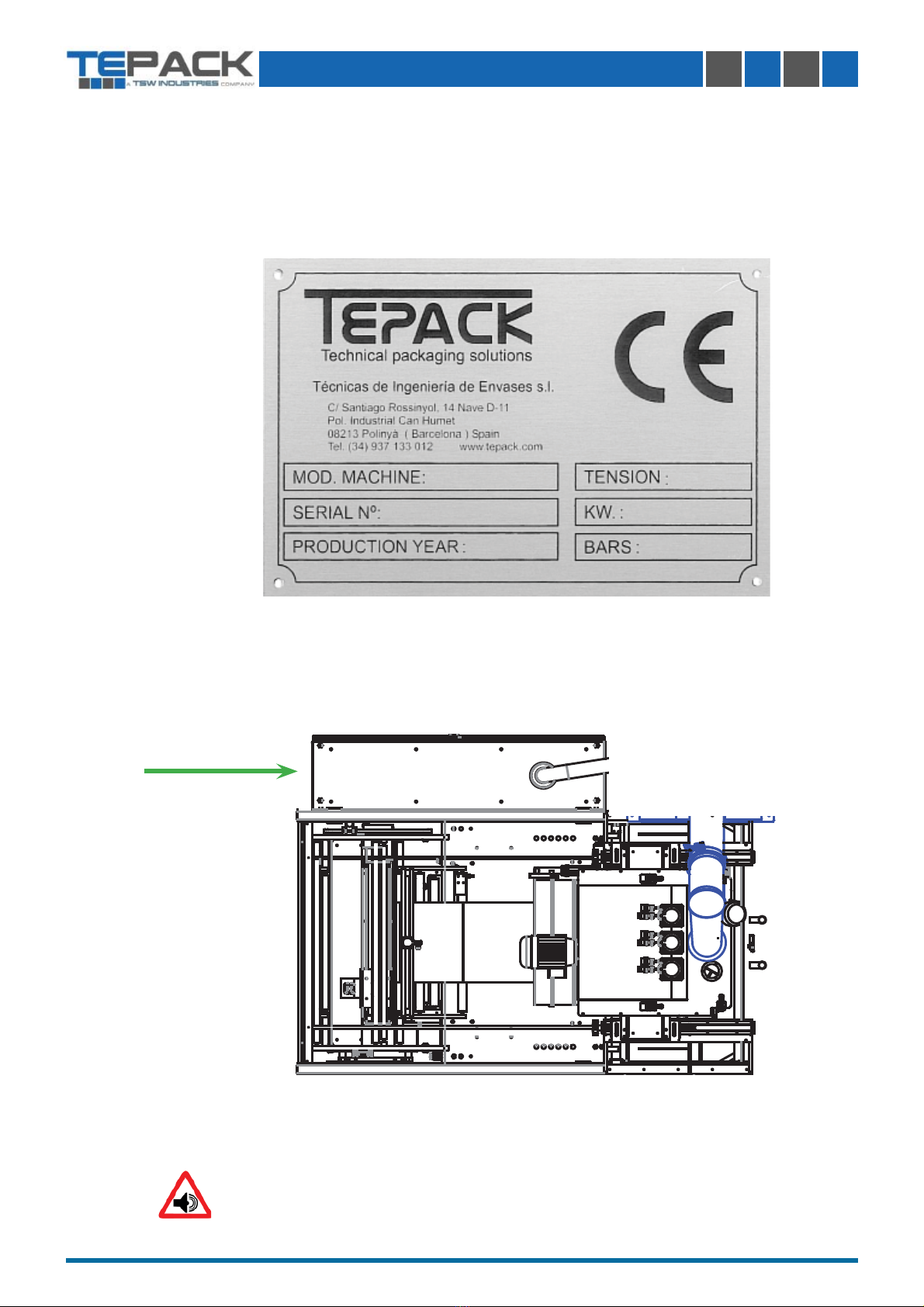

Each machine is iden fi ed by a card with its registra on number.

The registra on number of the machine must be given when ordering spare parts

or any other item related to the machine.

Fig. 25: Machine’s iden fi ca on.

0318003

TPS 400 400

10

6

2019

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 16

3.2.- Installa on.

Opera ons concerning the li ing and shipment of the machine must be carried

out by a specialized professional.

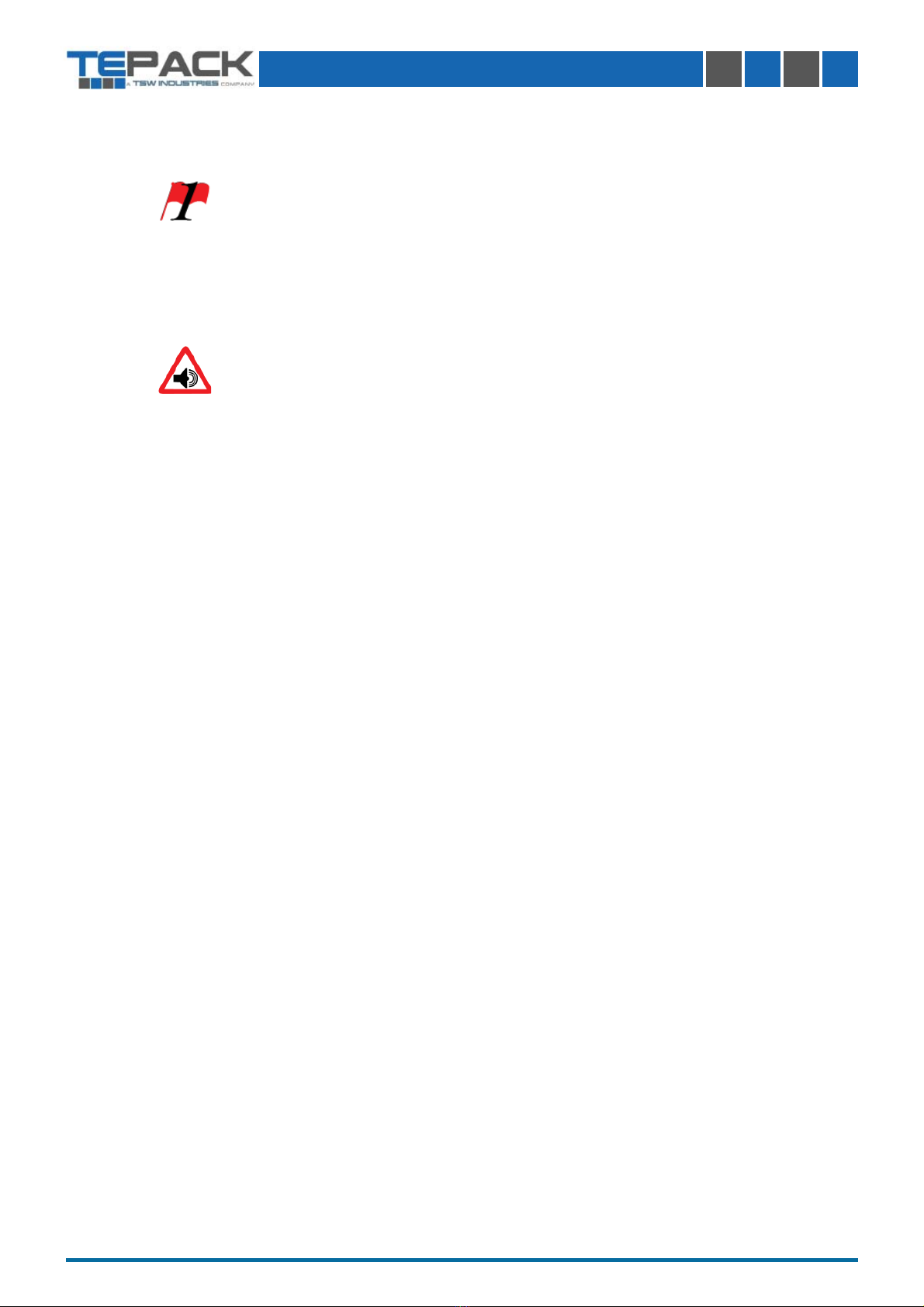

3.2.1.- Li ing and Shipment.

In case of li ing with a forkli truck, for safety, check that polycarbonate protec on

doors are closed; if not they can be broken.

Do the li ing by introducing the forkli truck shovels frontally (Fig. 23 (a)) because

this is the most heavy part.

In case of using a forkli truck to li the machine, it is possible to use a standard

one provided that it will have enough load capacity.

Fig. 26: Li ing by a forkli truck.

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 17

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 17

The li ing of the mul lane sachet machine can be done with a normal forkli bearing in mind

that it will have enough loading capacity. In this case there is not necessary to remove the

polycarbonate guards.

3.2.2.- Placement.

The mul lane ver cal pouch packing machine does not require a special suppor ng

base. However, it is recommended to check that it is evenly set on the ground in order

to avoid vibra ons that may aff ect its proper opera on. To avoid possible vibra ons,

level the machine with the levelling feet.

Fig. 27: Levelling feet

3.2.3.- Cleaning.

Wash with a degreasing product all those surfaces protected with a grease excess,

in par cular parts with ball bearings.

3.2.4.- Electrical and Pneuma c Connec on.

- A er the setup and the cleaning of the machine, proceed to its connec on to the

main power and pneuma c grid. Control that the current and the frequency specifi ed

on the card match those of the electrical grid a er connec ng the wires to the R/S/

T/N + T.T. located inside the electrical board.

- Control also that the pressure and the volume of air supplied is the one the

installa on requires.

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 18

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 18

DEFECT OR FAULT REPPORT SHEET

DEFECT OR FAULT REPPORT SHEET

Customer ORIENT BIO TECH Order Date

Machine Serial No. 0318003 Pe oner

Machine Model. TPS 400

Def./Fault. Rela ng to:

Machine

Feed unit

Other

Type:

Electronic

Mechanical

Hardware/So ware

Condi on of the machine with

rela on to the defect/fault:

Machine cannot be started

Machine can be started

Has it caused the breakage

or failure of any compo-

nent?

Yes No

Descrip on Códe

If the answer is

“Yes”

Which one(s)?

Descrip on of Defect / Fault

Descrip on of Defect / Fault

4.- SUPPORTING FILES FOR THE USER.

This sec on includes the main supports for the opera ons carried out by the users, namely:

- Defect or fault repport sheet.

- Request for technical assistance sheet.

- Request for spare parts sheet.

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 19

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 19

REQUEST FOR TECHNICAL ASSISTANCE SHEET

REQUEST FOR TECHNICAL ASSISTANCE SHEET

Customer ORIENT BIO TECH Order Date

Machine Serial No. 0318003 Pe oner

Machine Model. TPS 400

Request rela ng to:

Machine

Feed unit

Other

To receive:

More informa on

Explana ons

Sugges ons

Type

Electronic Notes

Mechanical Notes

So ware Notes

Reason for the request:

Reason for the request:

Descrip on of Defect / Fault:

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 20

VOLUME I

REFERENCE DOCUMENTATION

TÉCNICAS DE INGENIERIA DE ENVASES S.L. 20

REQUEST FOR SPARE PARTS SHEET

REQUEST FOR SPARE PARTS SHEET

Customer ORIENT BIO TECH Order Date

Machine Serial No. 0318003 Pe oner

Machine Model. TPS 400

Request rela ng to:

Machine

Feed unit

Other

To receive:

More informa on

Explana ons

Sugges ons

Type

Electronic Notes

Mechanical Notes

So ware Notes

Coder

Coder Descrip on QTY.

Comentary:

Other manuals for TEPACK TPS 400

1

Table of contents

Other tsw Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Kval

Kval 994-X Operation and service manual

Spirax Sarco

Spirax Sarco UTD30 Series Installation and maintenance instructions

Hyundai power products

Hyundai power products HYC5030 user manual

Siemens

Siemens 1MB115 Installation and maintenance manual

Chamberlain

Chamberlain Clopay HPH1 installation manual

ABB

ABB GE ReliaGear AMP1 installation instructions