4AMP1 INTEGRATED POWER AND ENERGY INSTALLATION INSTRUCTIONS

For

troubles

hooting

or

serv

ice

relat

ed

questions,

conta

ct

AB

B

at

800

-782-80

61

or

a

t

epis.componen

[email protected]AMP1

Safety

FCC PART 15 INFORMATION NOTE: This equipment has been

tested by the manufacturer and found to comply with the

limits for a class B digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment

is operated in a residential environment. This equipment

generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. This device complies with part 15 of the FCC

Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesired operation.

Modifications to this product without the express

authorization of the manufacturer nullify this statement.

A qualified person is one who has skills and knowledge related

to the construction and operation of this electrical equipment

and the installation, and has received safety training to

recognize and avoid the hazards involved.

NEC2011 Article 100: No responsibility is assumed by

manufacturer for any consequences arising out of the use of

this material.Control system design must consider the

potential failure modes of control paths and, for certain

critical control functions, provide a means to achieve a safe

state during and after a path failure. Examples of critical

control functions are emergency stop and over-travel stop.

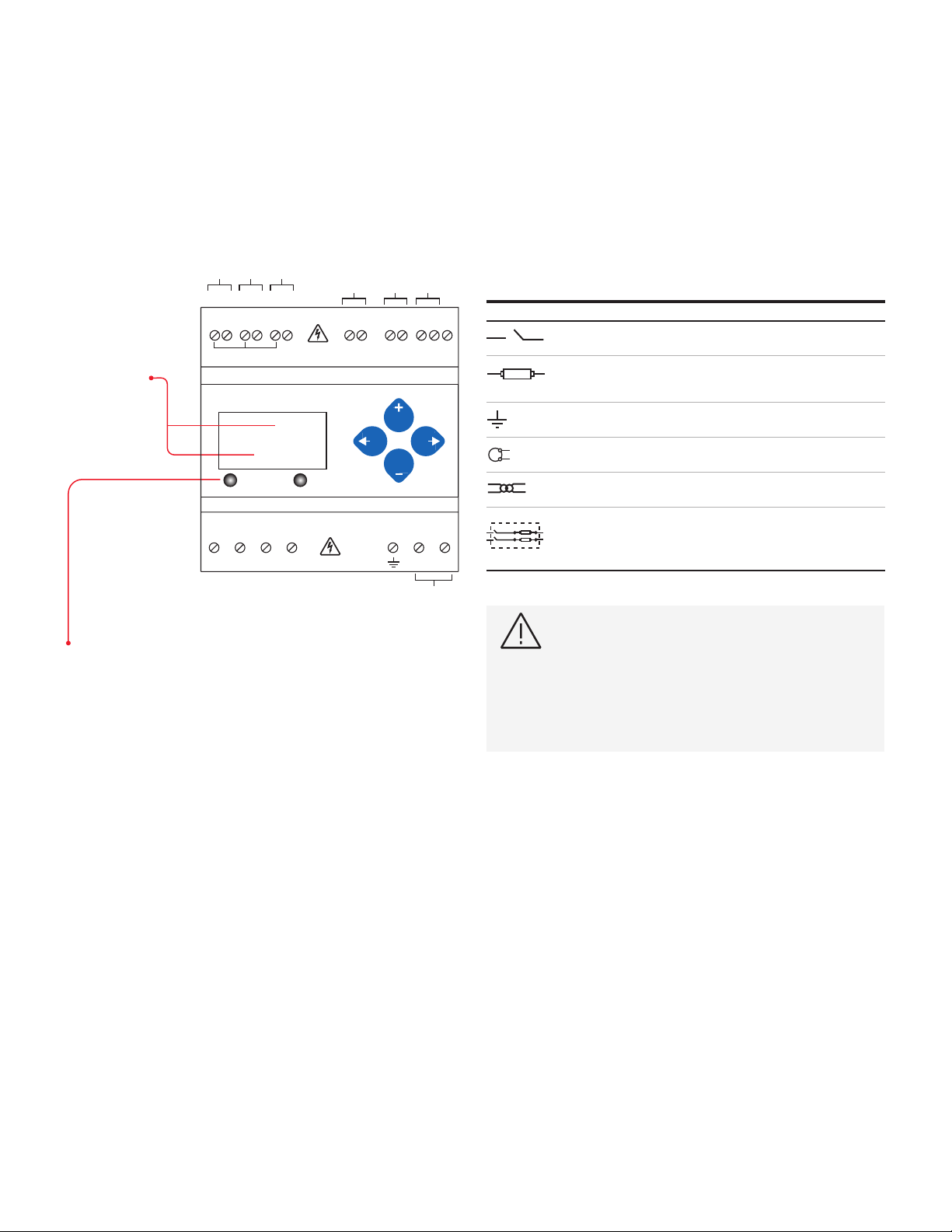

This symbol indicates an electrical shock

hazard exists.

Documentation must be consulted where this

symbol is used on the product.

DANGER: Hazard of Electric Shock, Explosion or Arc

Flash Failure to follow these instructions will result in

death or serious injury.

• Follow safe electrical work practices. See NFPA 70E in

the USA, or applicable local codes.

• This equipment must only be installed and serviced by

qualified electrical personnel.

• Read, understand and follow the instructions before

installing this product.

• Turn off all power supplying equipment before working

on or inside the equipment.

• Use a properly rated voltage sensing device to confirm

power is off. DO NOT DEPEND ON THIS PRODUCT FOR

VOLTAGE INDICATION

• Only install this product on insulated conductors

WARNING: Loss of Control

• Failure to follow these instructions may cause injury,

death or equipment damage.

• Assure that the system will reach a safe state during and

after a control path failure.

• Separate or redundant control paths must be provided

for critical control functions.

• Test the effect of transmission delays or failures of

communication links.

• Each implementation of equipment using

communication links must be individually and

thoroughly tested for proper operation before placing it

in service.a

NOTICE:

• This product is not intended for life or safety

applications.

• Do not install this product in hazardous or classified

locations.

• The installer is responsible for conformance to all

applicable codes

• Mount this product inside a suitable fire and electrical

enclosure.